Array flow velocity control valve structure suitable for incompressible fluid

A flow rate control and fluid compression technology, which is applied in the field of array flow rate control valve structure, can solve problems affecting the operation of on-site staff, bubble bursts, strong vibration of pipelines, etc., to facilitate online maintenance, reduce fluid kinetic energy, and reduce valve noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings.

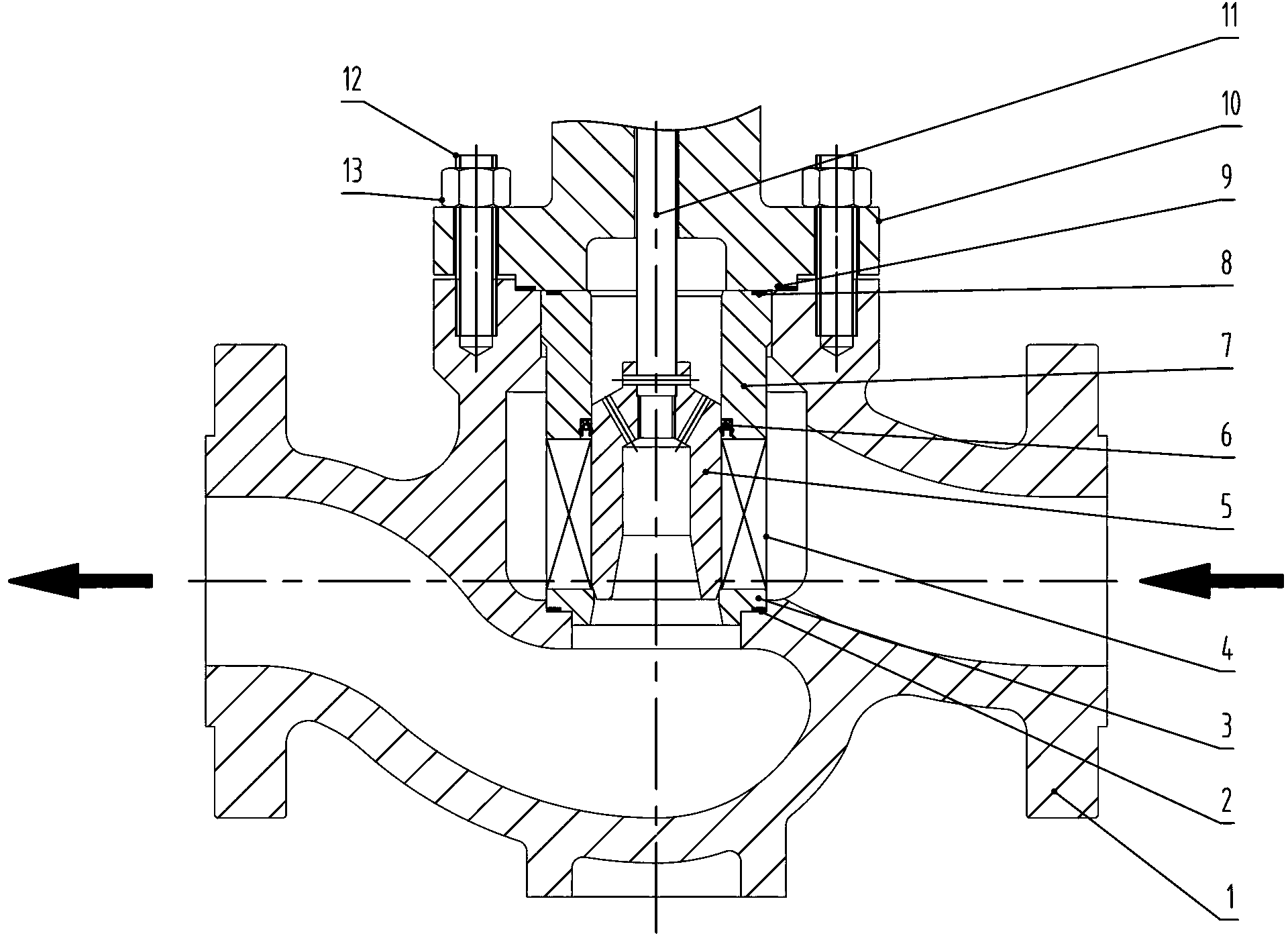

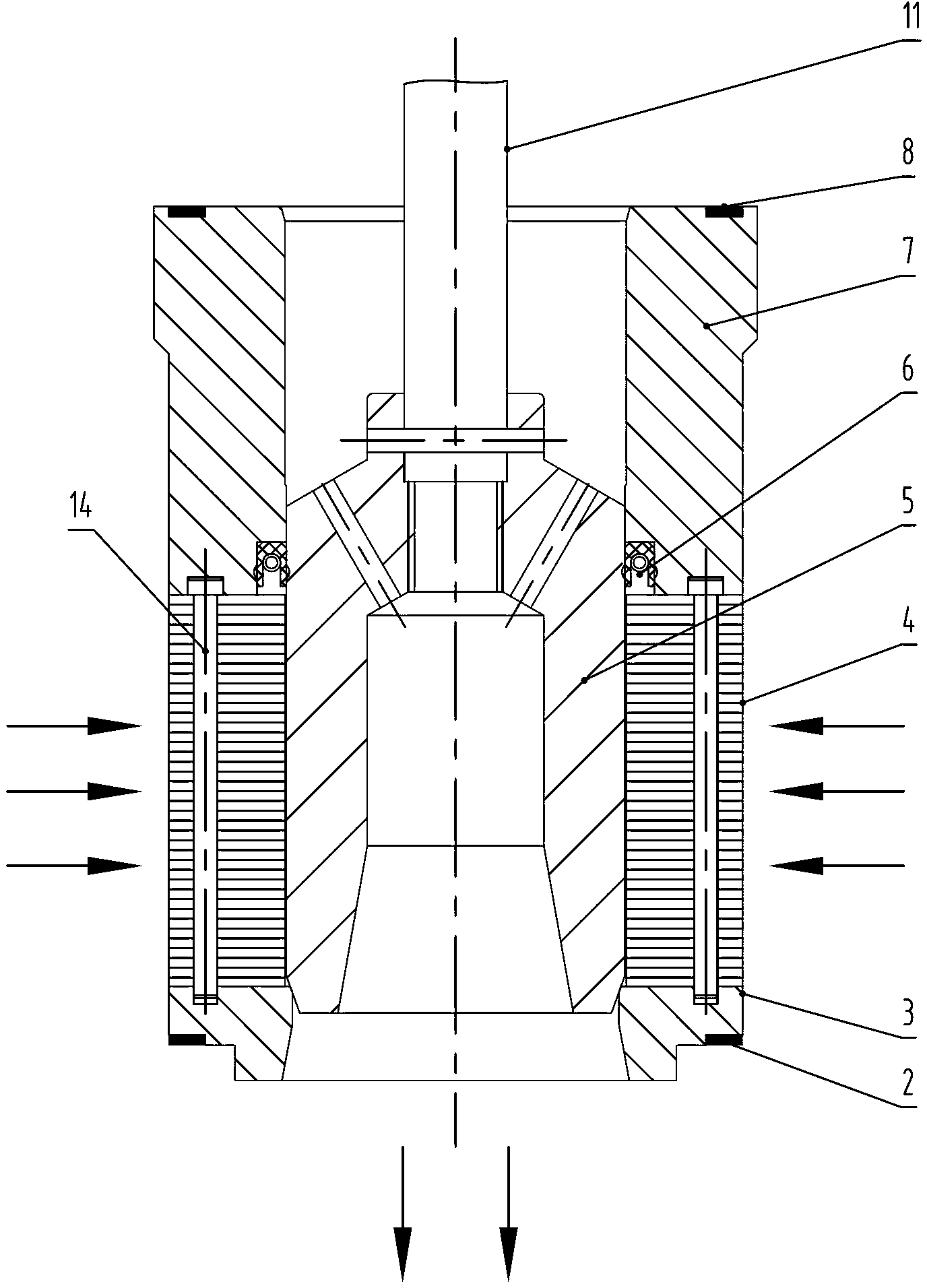

[0031] Such as Figure 1 ~ Figure 2 Shown: an array flow rate control valve structure suitable for compressible fluid, including valve body 1, sealing gasket 2, valve seat 3, throttle plate 4, valve core 5, balance sealing ring 6, guide seat 7, Gasket 8, gasket 9, upper cover 10, valve stem 11, stud 12, nut 13, positioning pin 14.

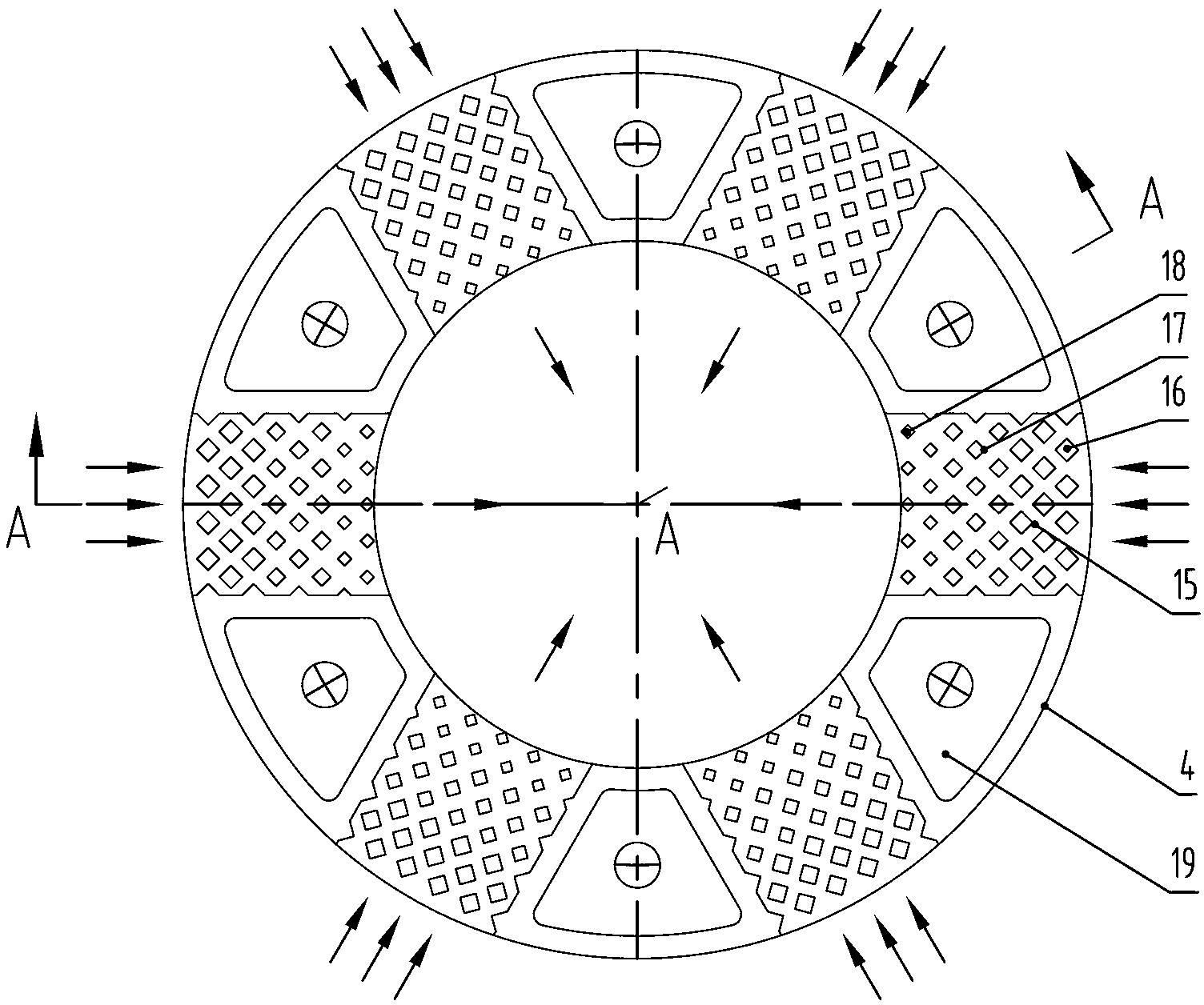

[0032] The present invention includes that a valve seat 3 is provided in the valve body 1 , and a sealing gasket 2 is used to seal between the valve seat 3 and the valve body 1 . Several throttle plates 4 are installed on the valve seat 3 , and the throttle plates 4 are positioned by positioning pins 14 . Each throttle plate 4 is composed of a parallel thin plate body 19 and a prism array structure 15, and the prism array structure 15 includes a large prism convex body 16, a prism convex body 17, and a small prism convex body 18. Wait for severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com