Patents

Literature

222 results about "Incompressible flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In fluid mechanics or more generally continuum mechanics, incompressible flow (isochoric flow) refers to a flow in which the material density is constant within a fluid parcel—an infinitesimal volume that moves with the flow velocity. An equivalent statement that implies incompressibility is that the divergence of the flow velocity is zero (see the derivation below, which illustrates why these conditions are equivalent).

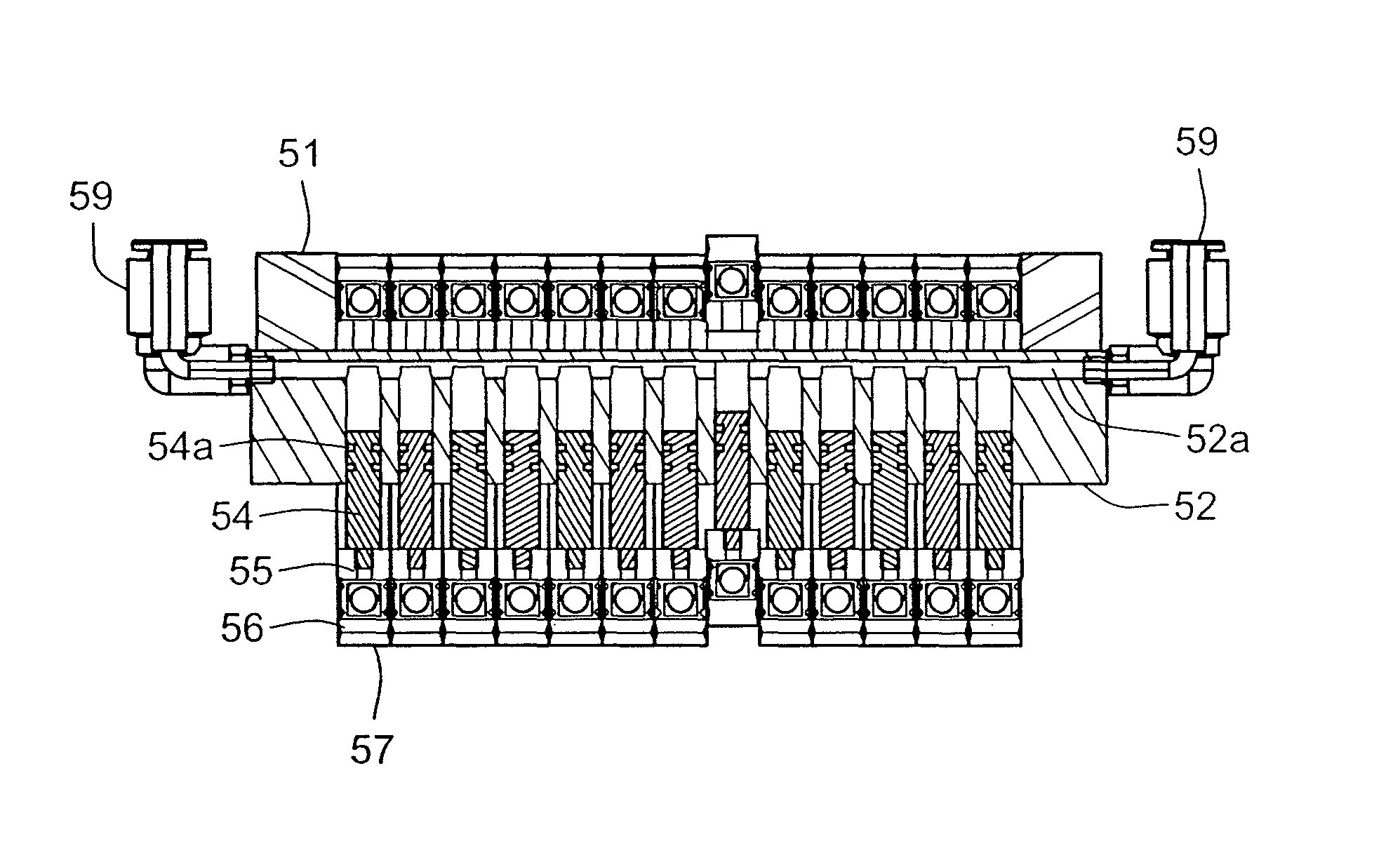

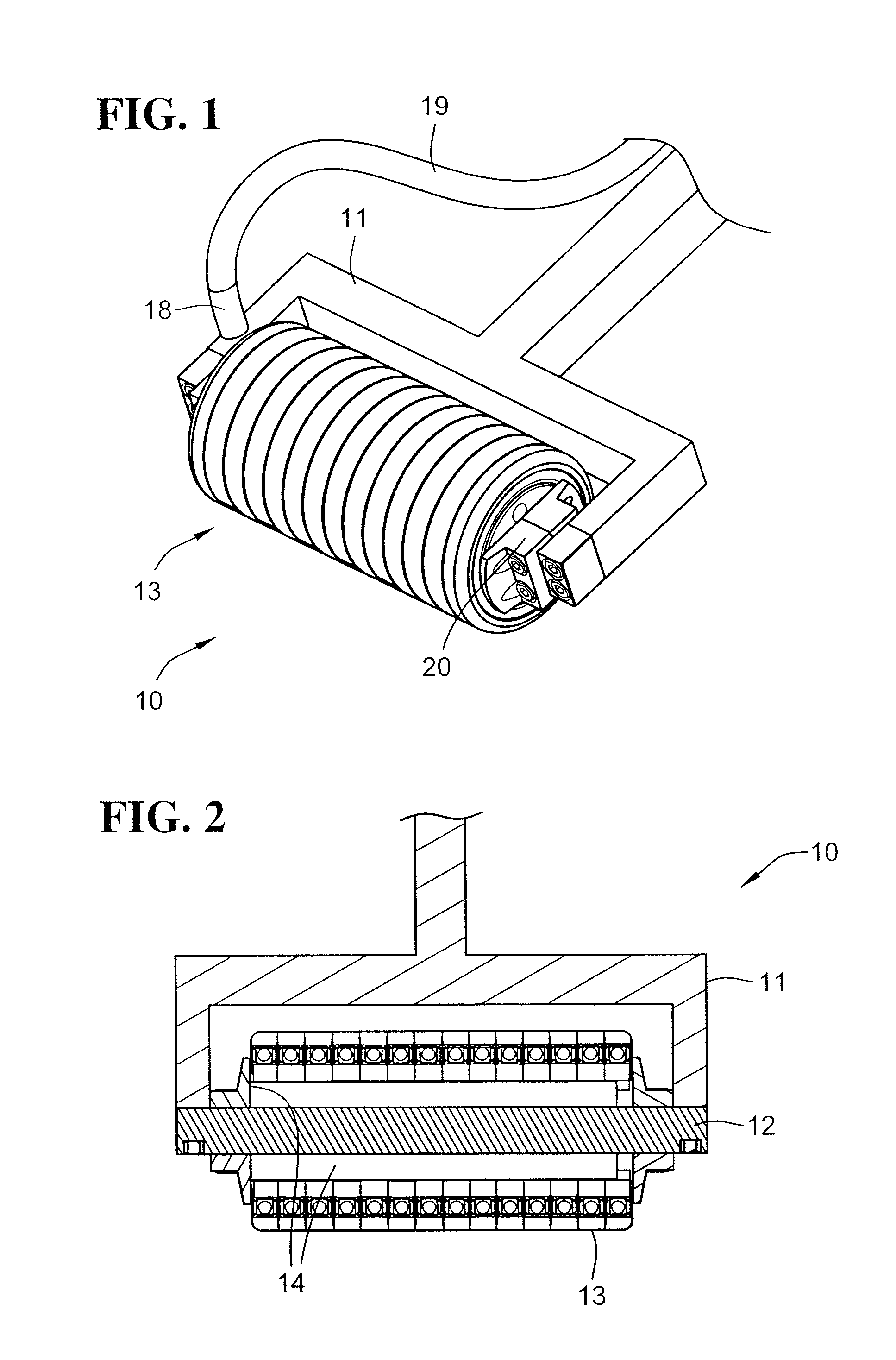

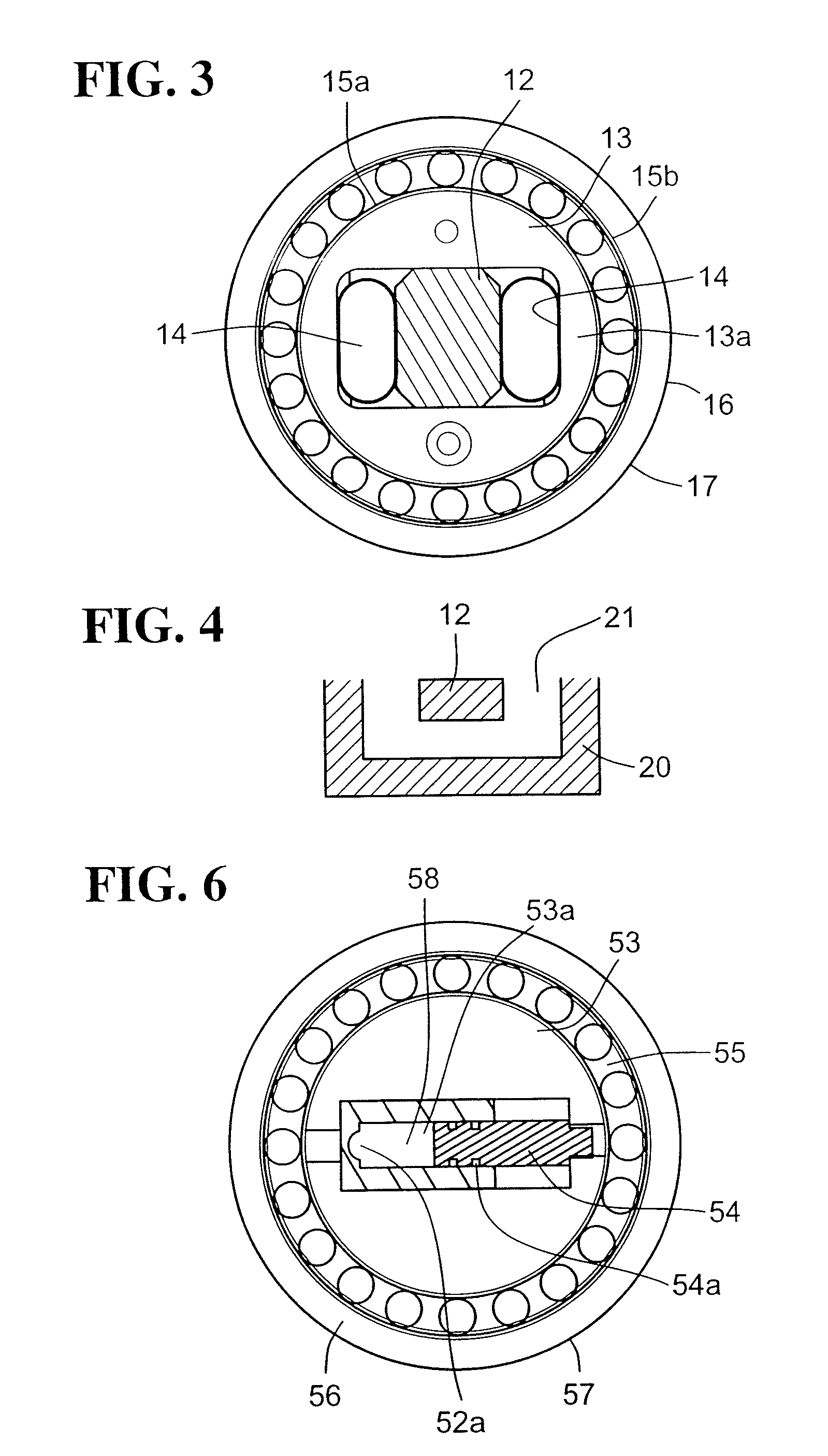

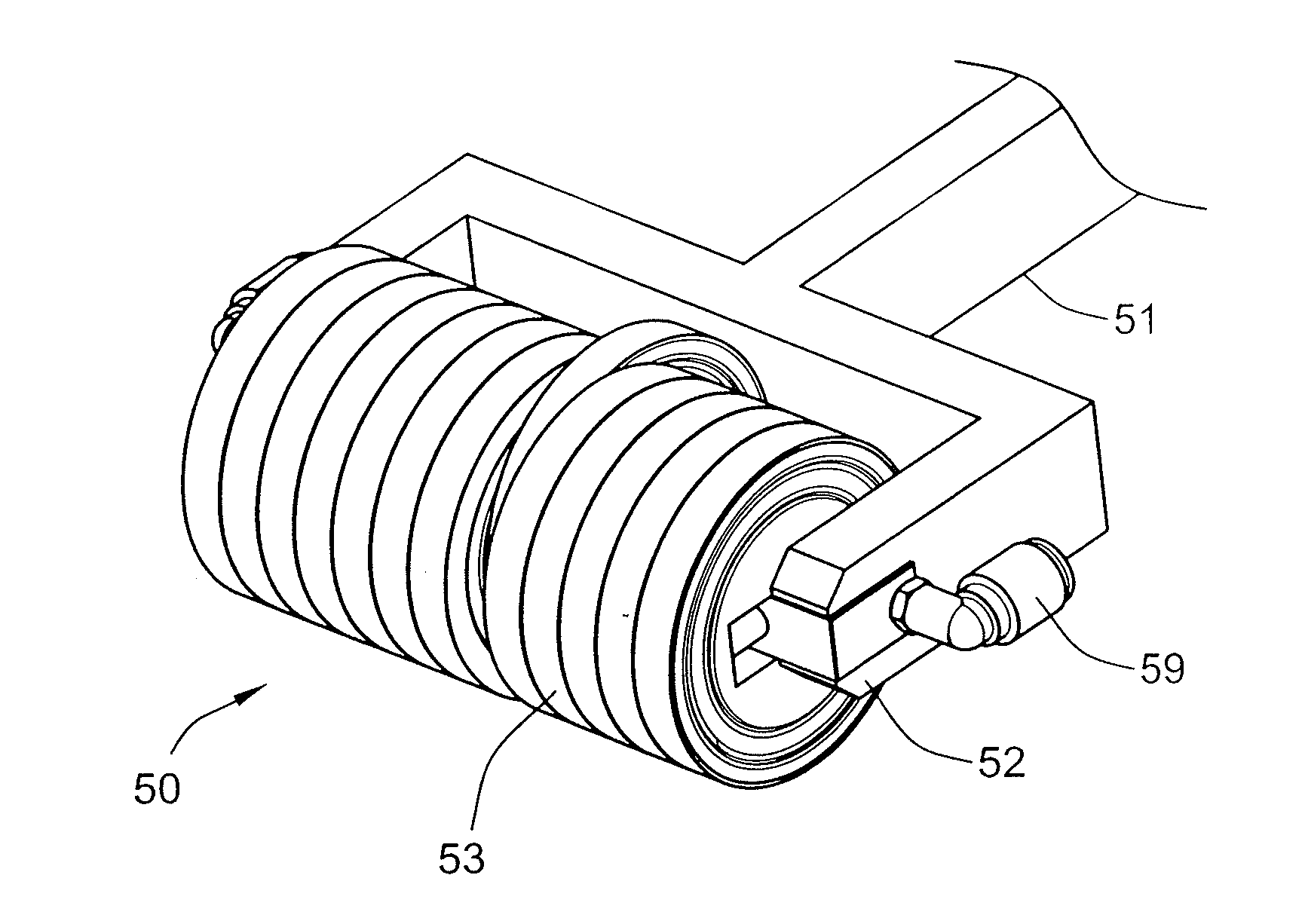

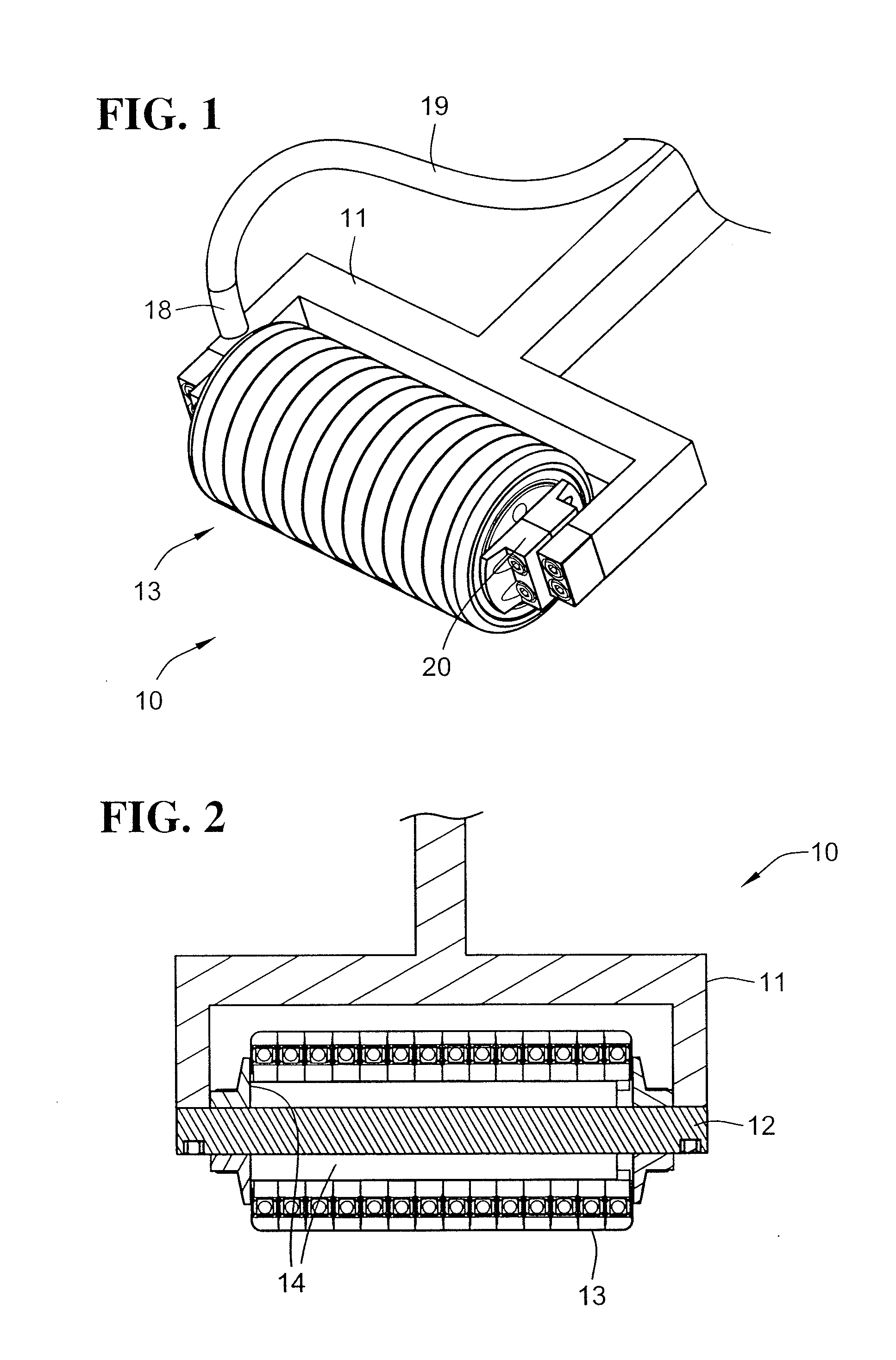

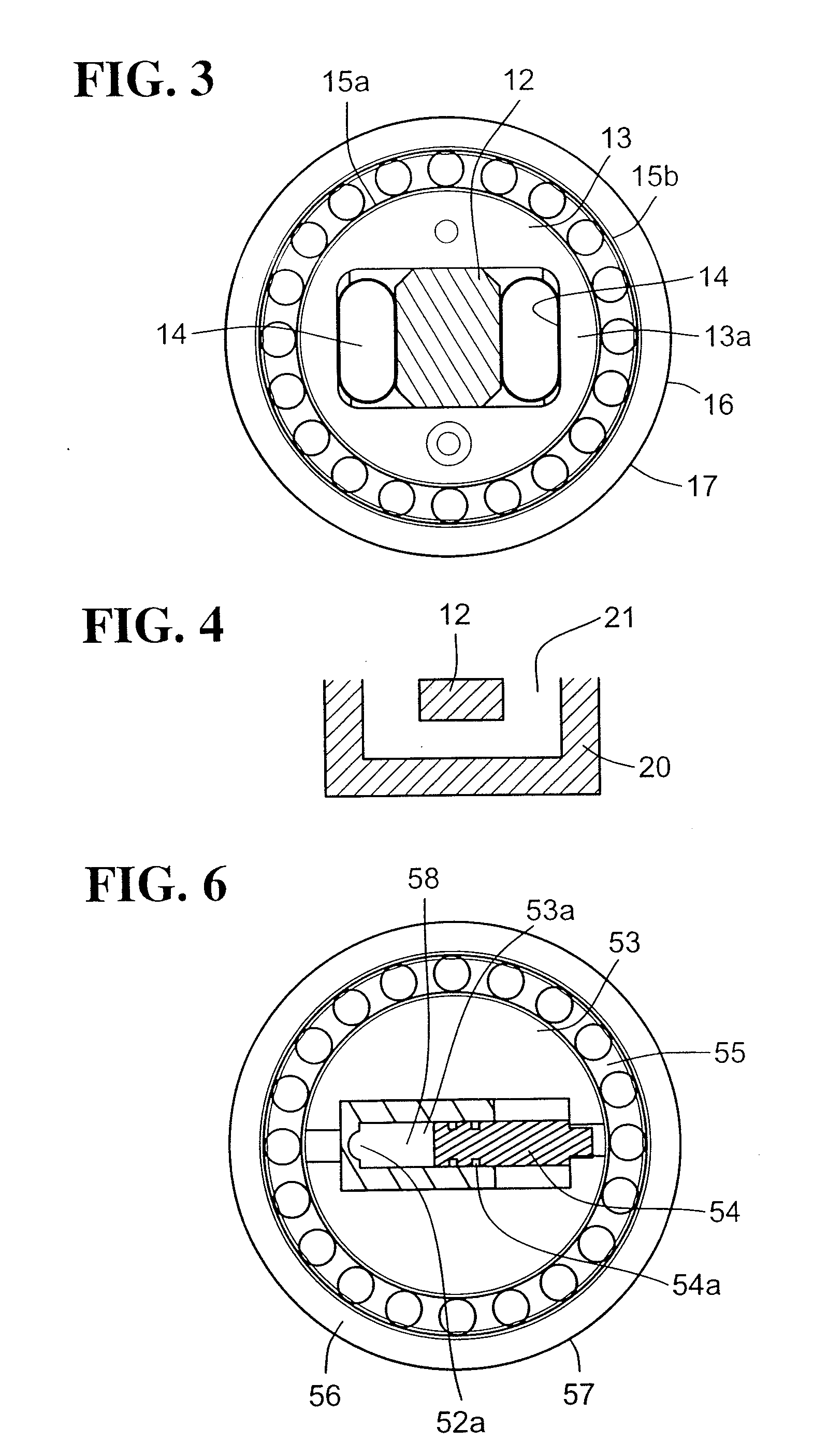

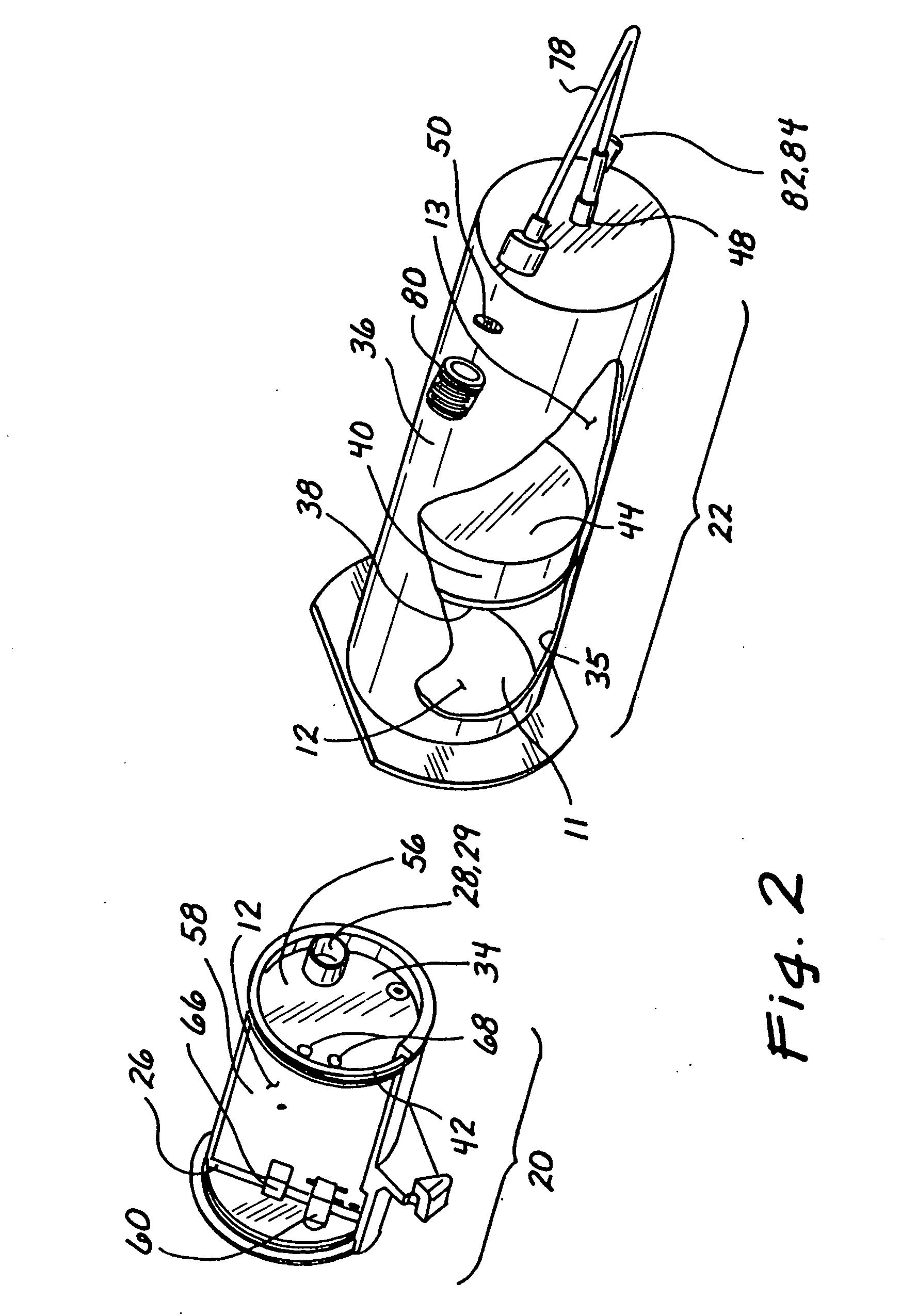

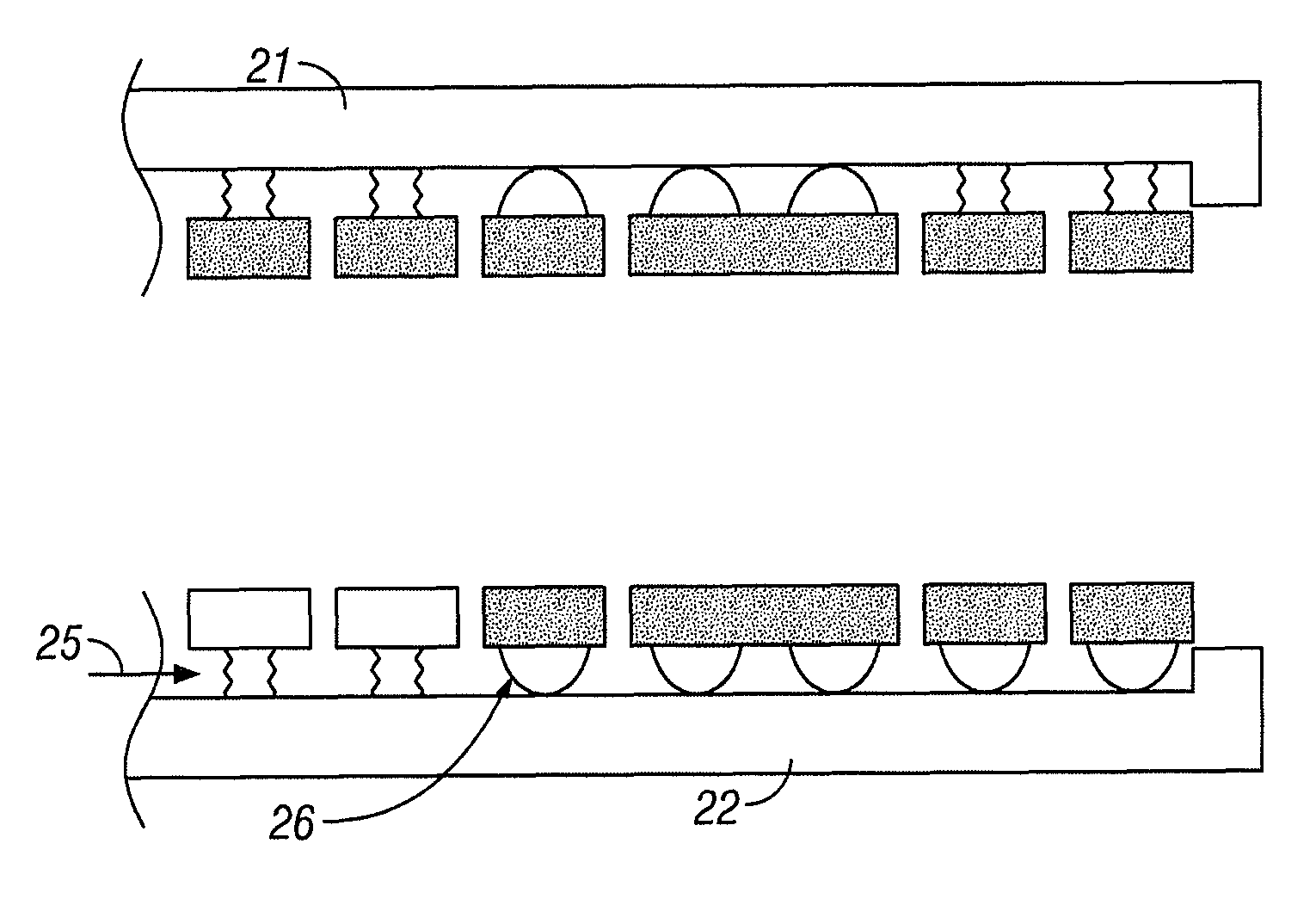

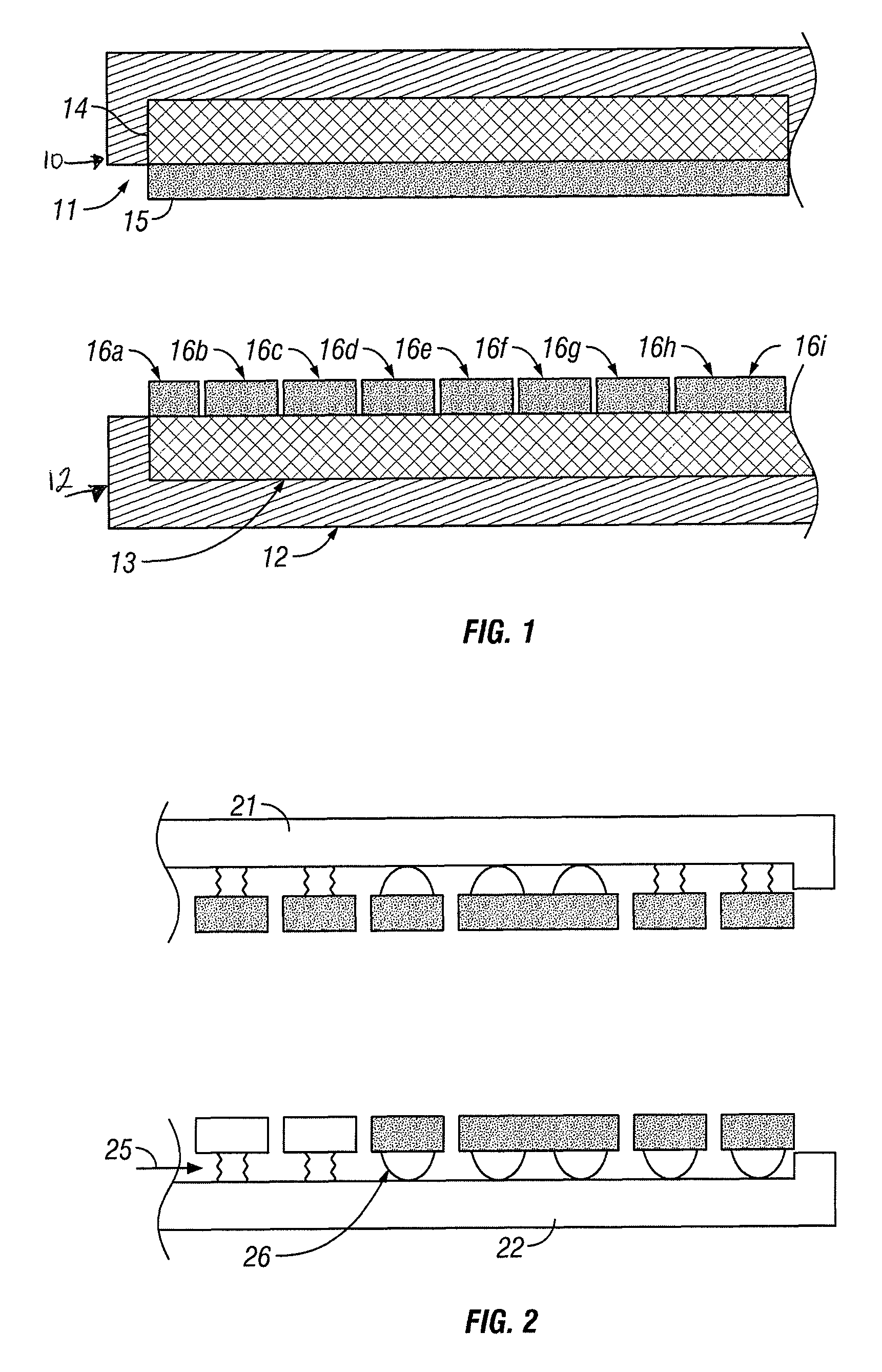

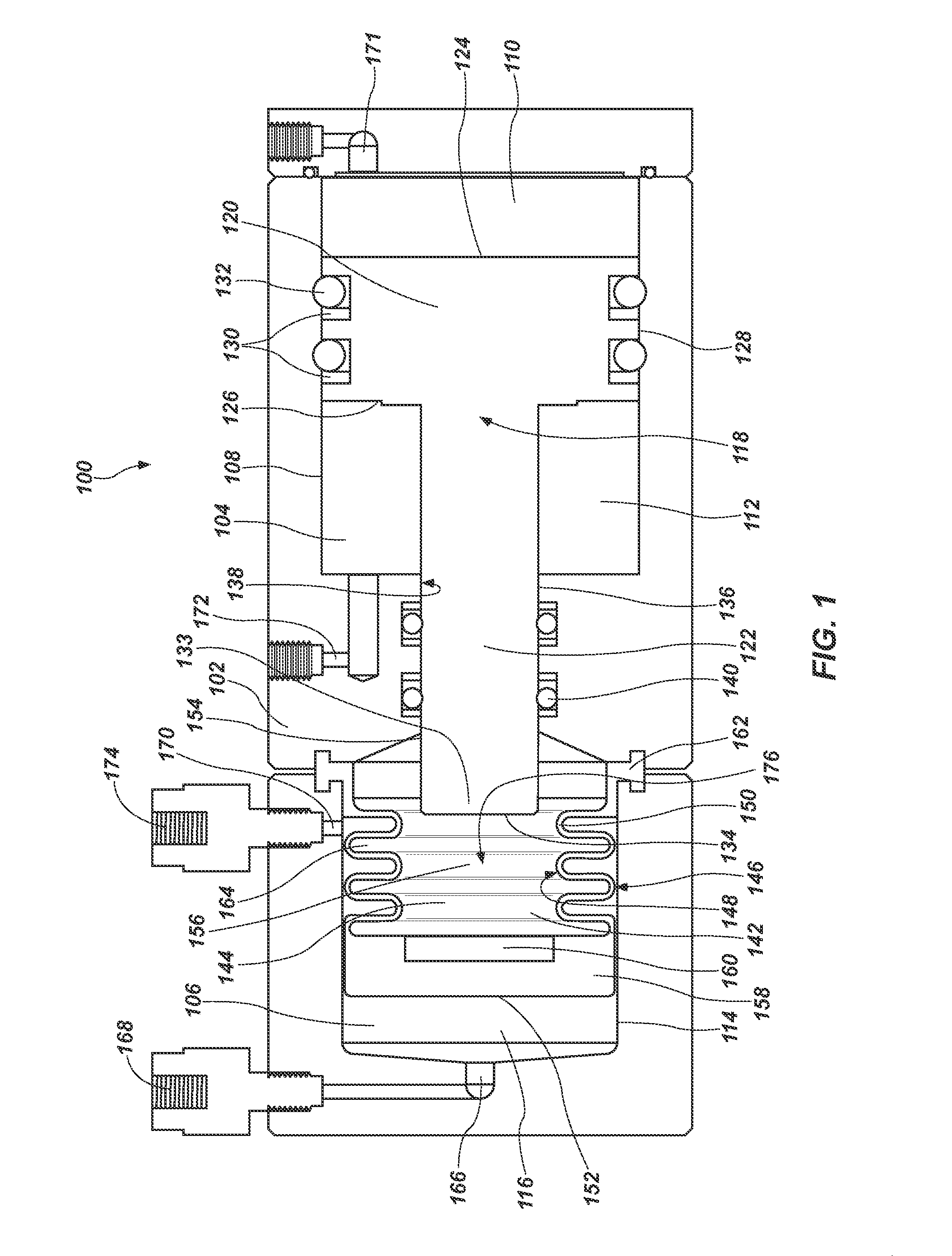

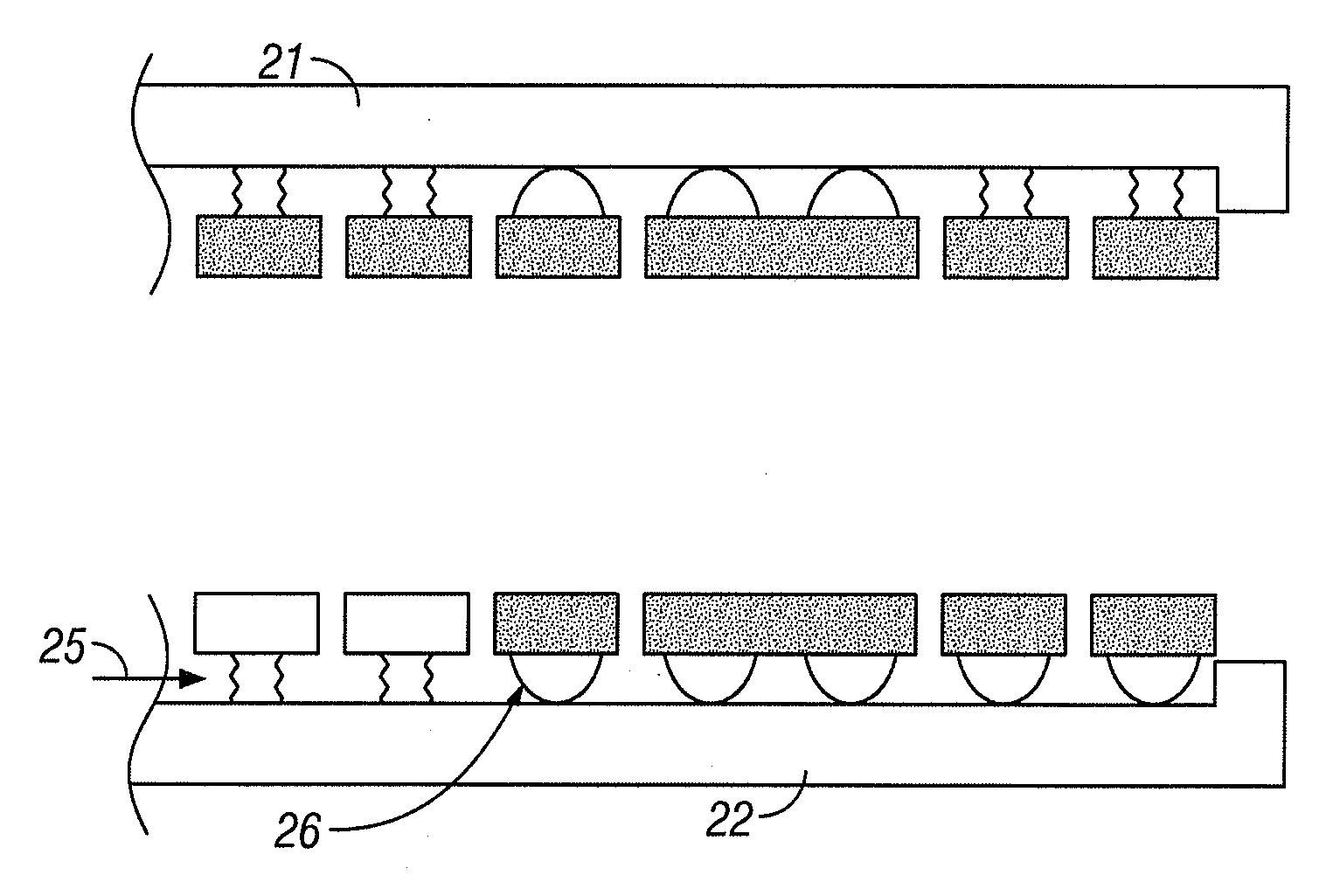

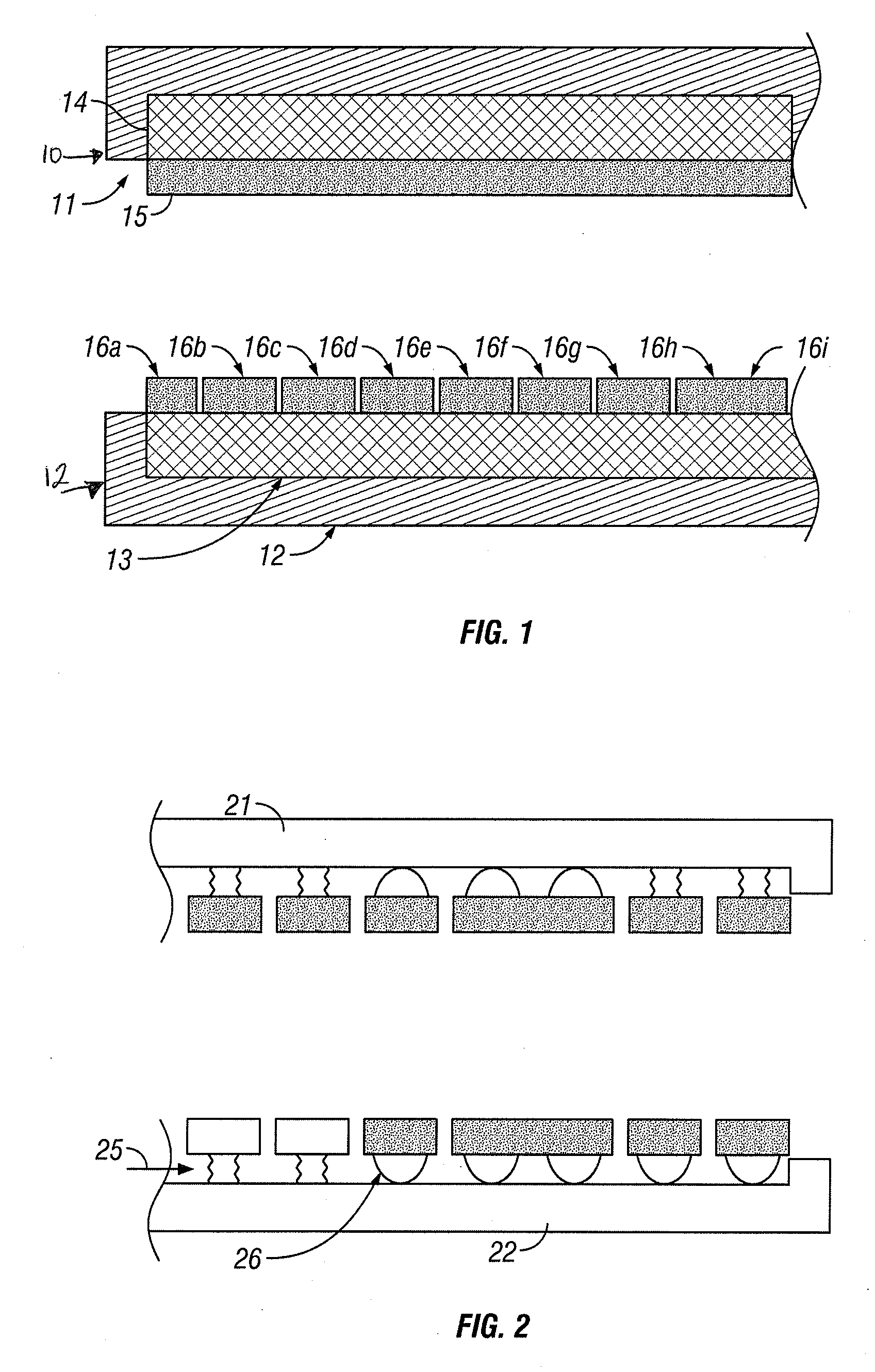

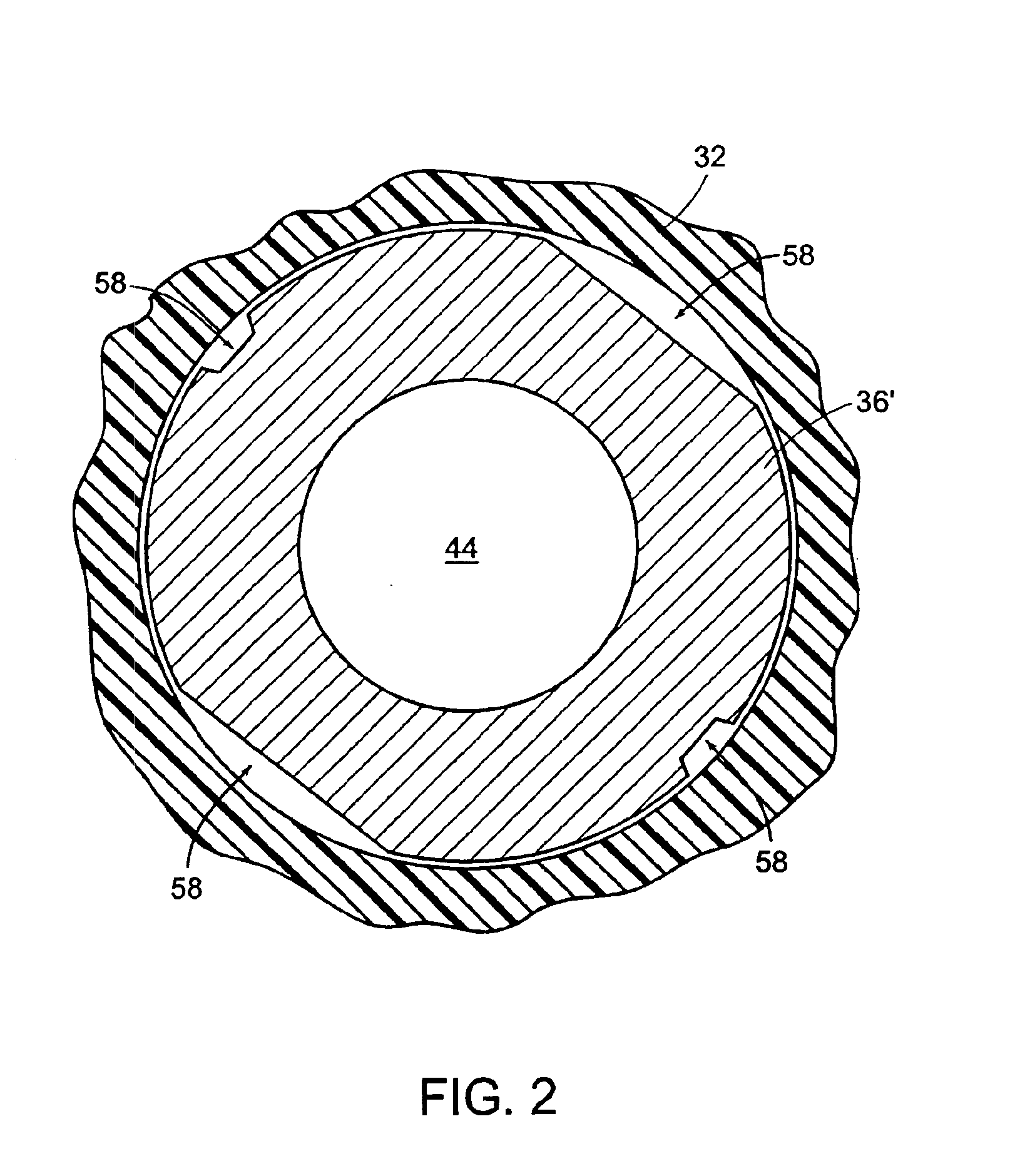

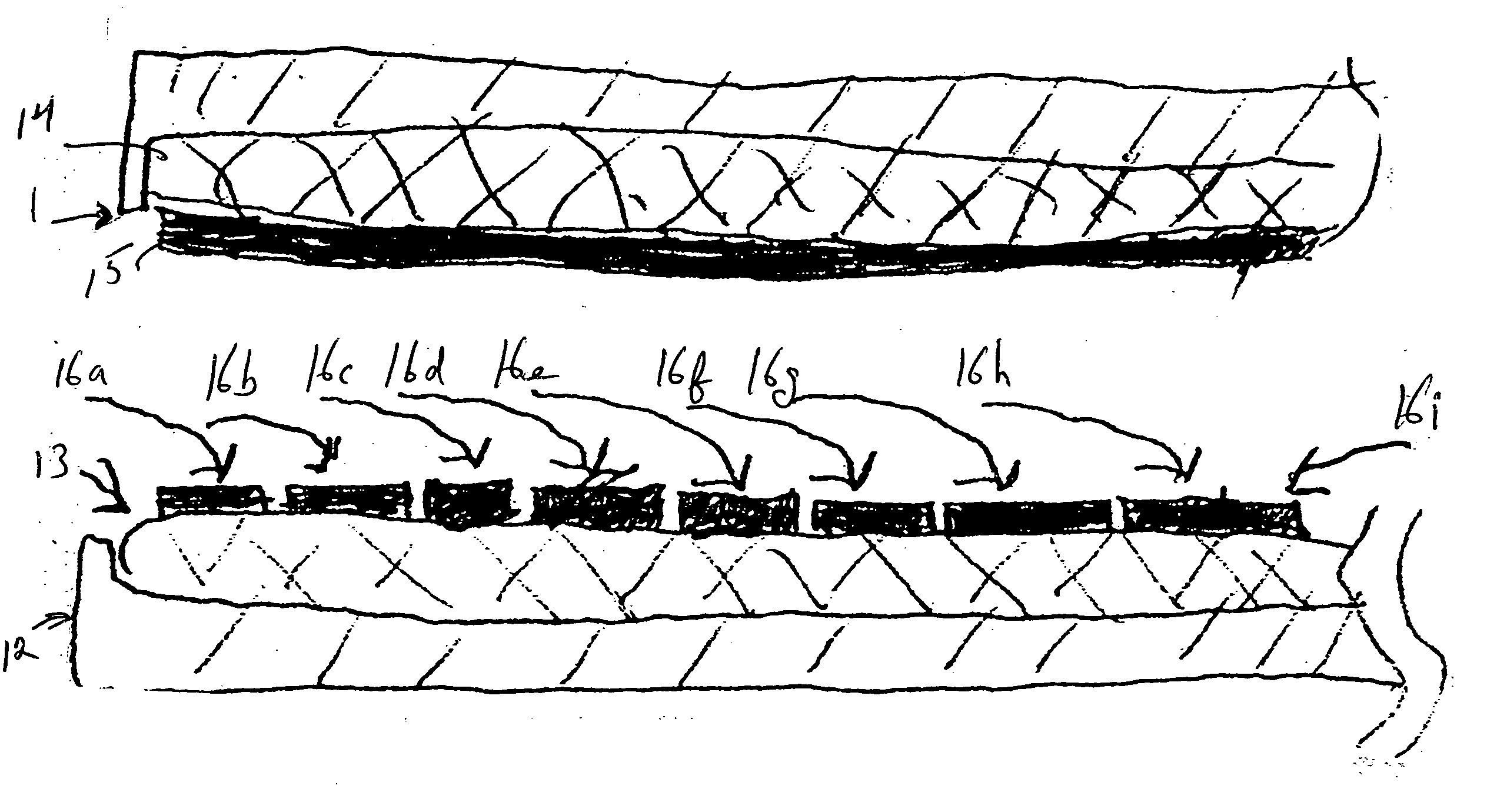

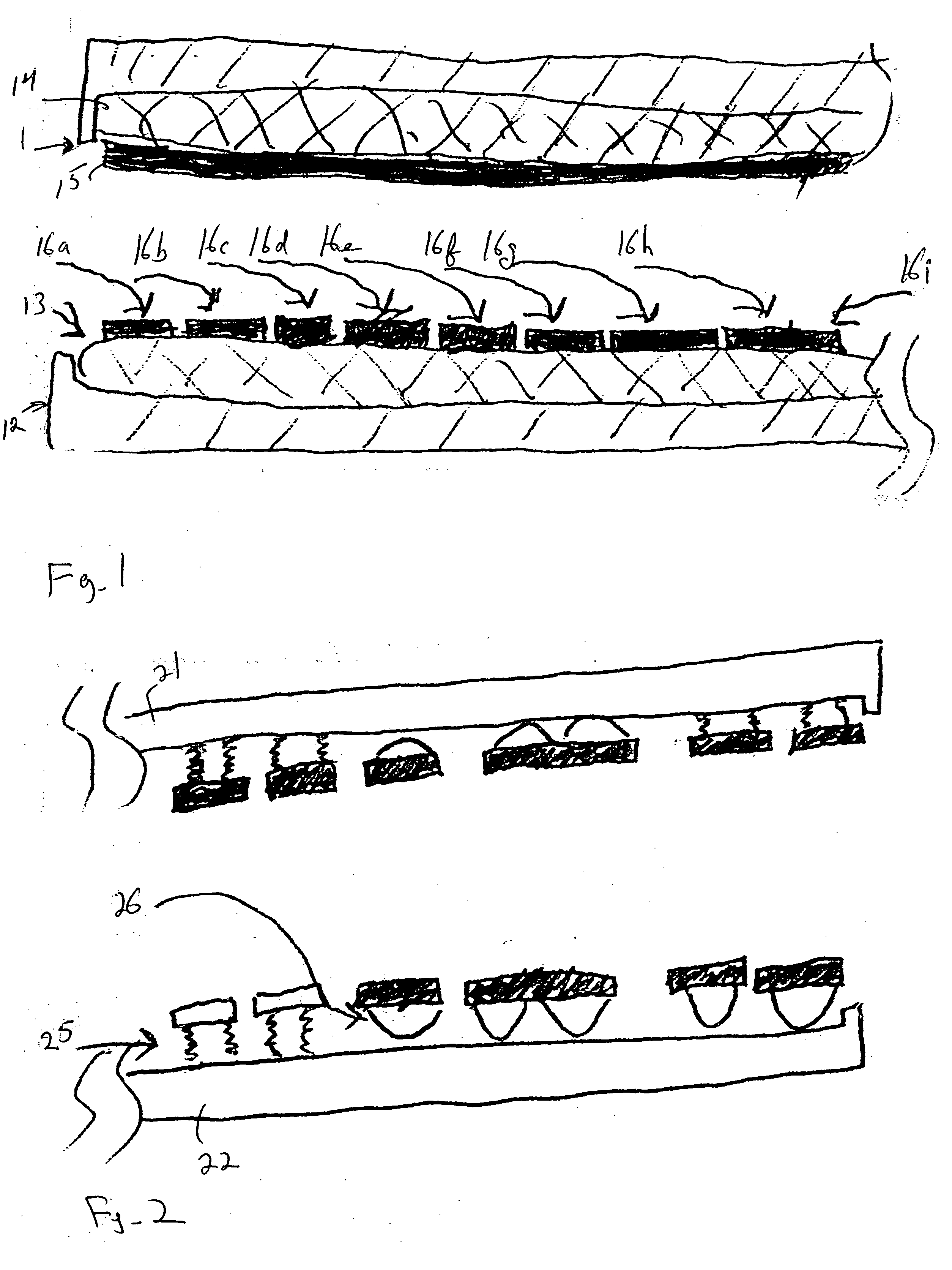

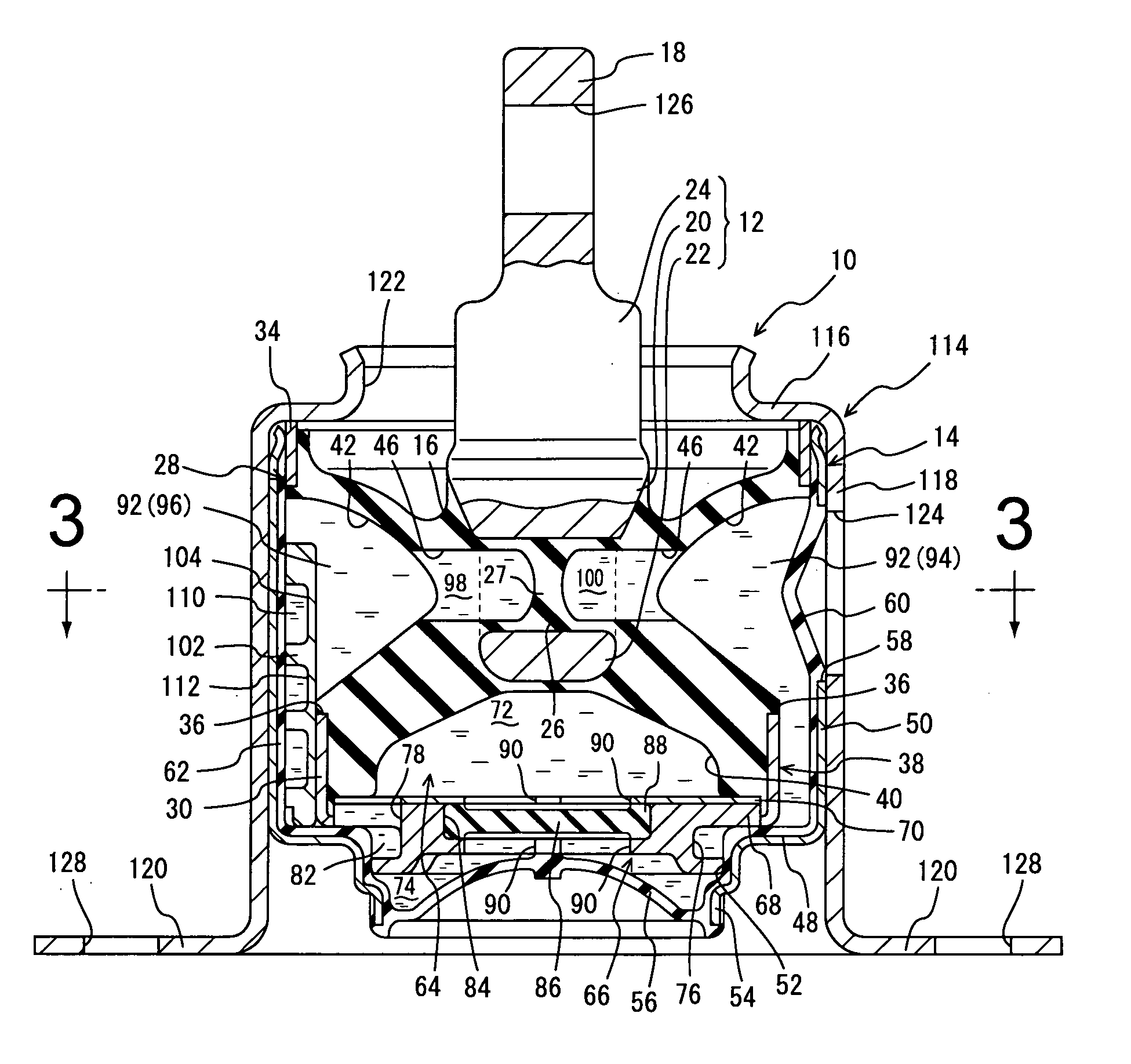

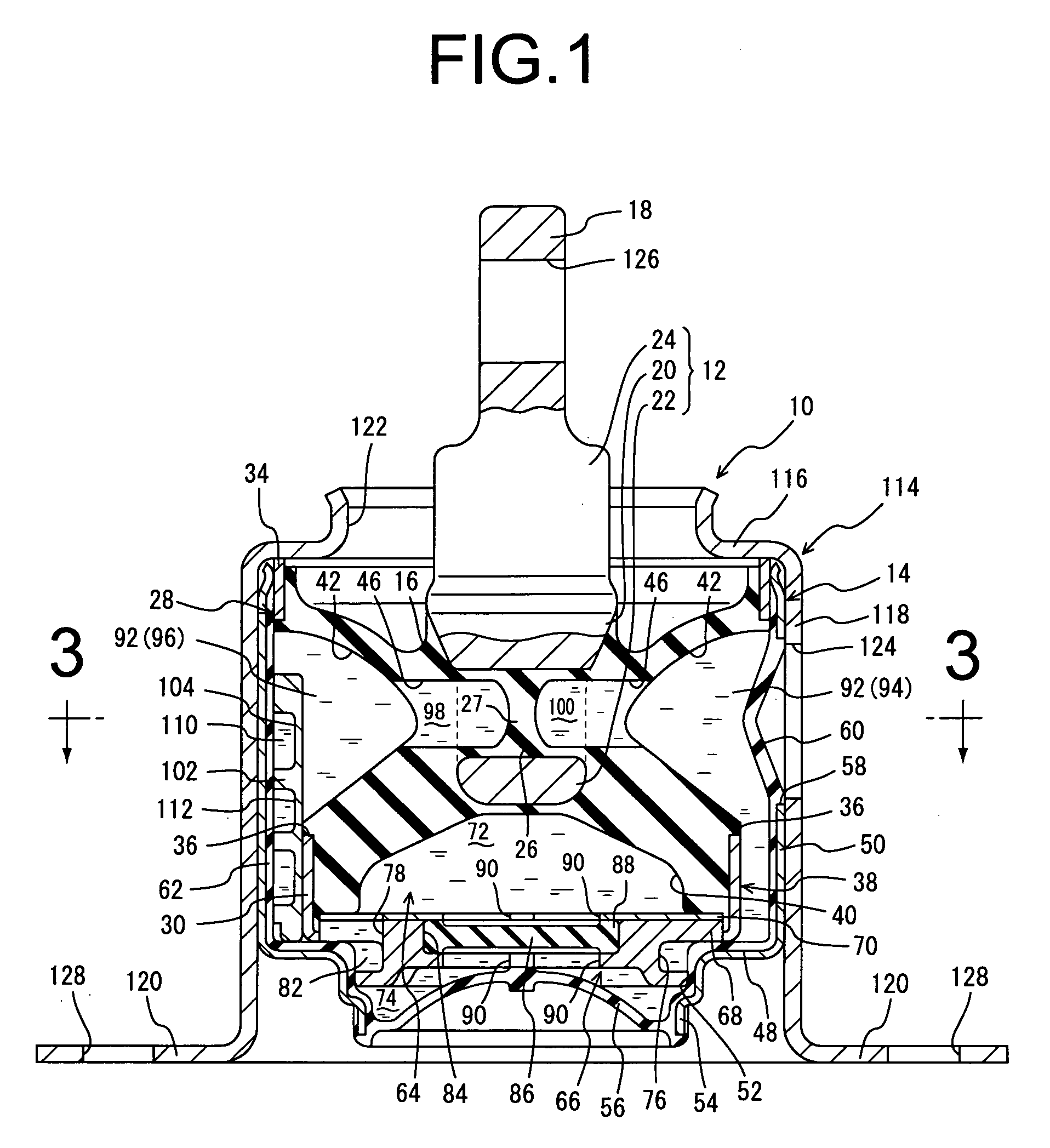

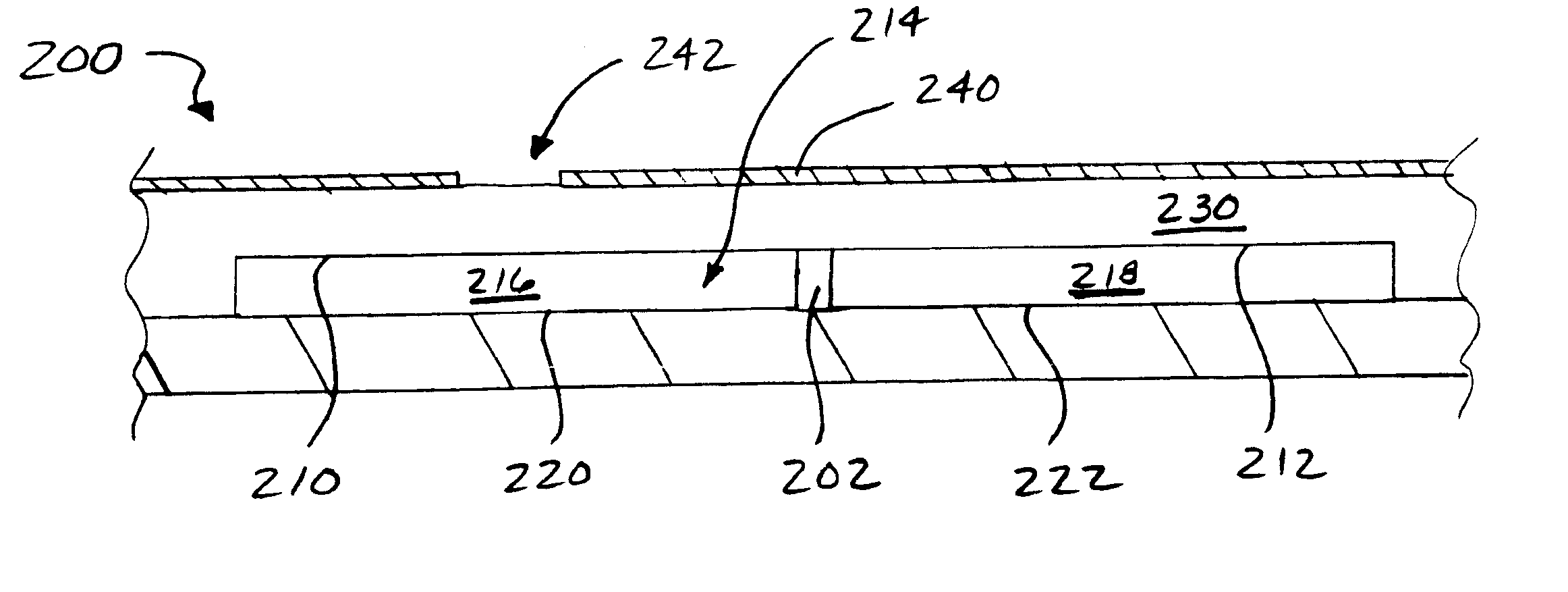

Compaction roller for a fiber placement machine

Tools for compacting composite parts are disclosed. These tools are used while layers of composite material, such as tows or laminae, are being deposited onto a fabricating surface, such as a mold or other forming tool. The compacting tool is typically divided into a series of narrow segments, each segment able to advance or retreat individually so as to conform to the surface of a composite part being formed. Pressurized fluid, such as air or hydraulic fluid, or non-pressurized internal bladders with incompressible fluid, are used to evenly apply pressure to the segments in order to compact the material with which the tool and the segments are in contact. The compacting tool thus helps eliminate voids and helps the material conform to the desired shape on the forming tool.

Owner:INGERSOLL MACHINE TOOLS

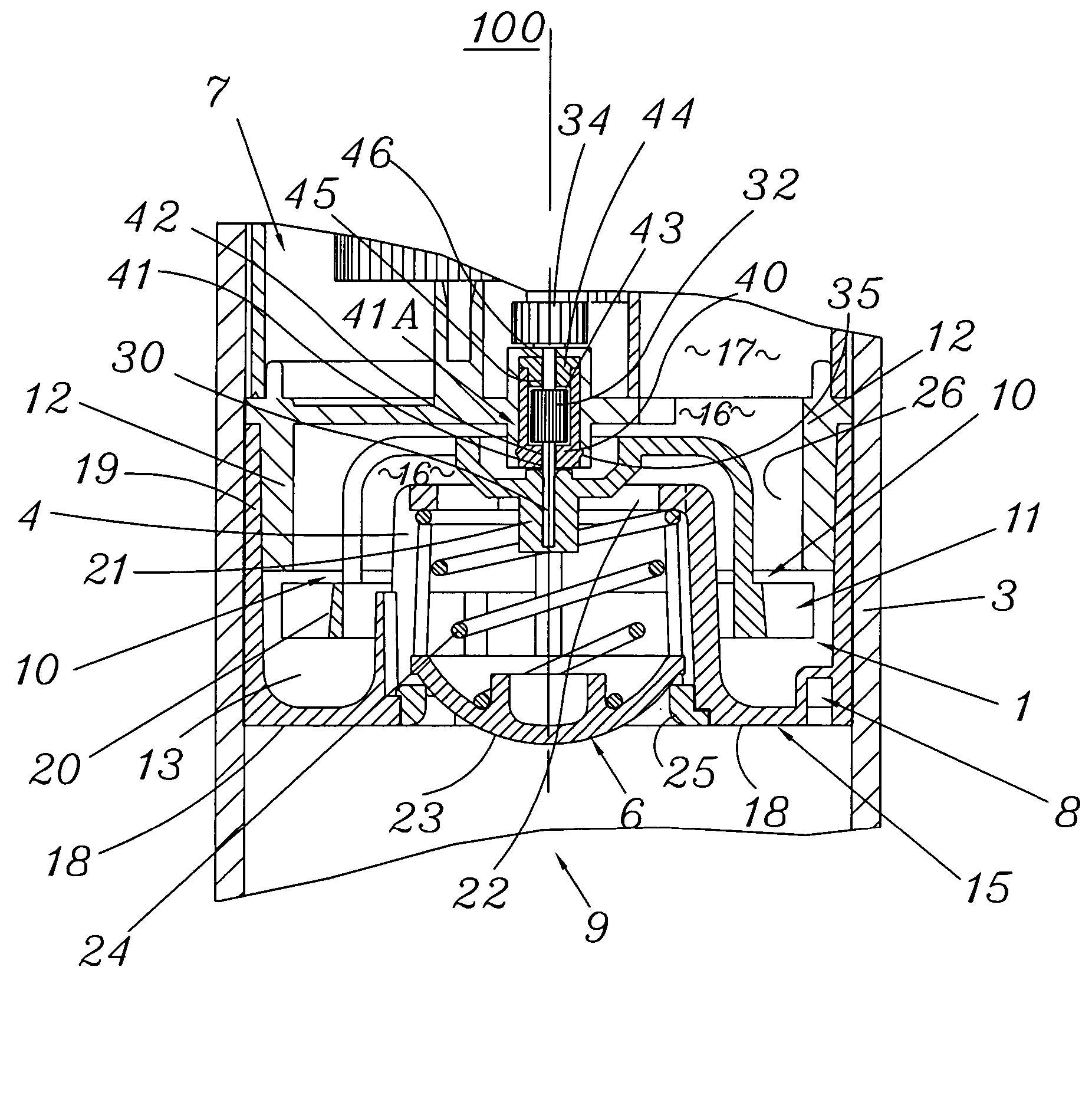

Compaction roller for a fiber placement machine

Tools for compacting composite parts are disclosed. These tools are used while layers of composite material, such as tows or laminae, are being deposited onto a fabricating surface, such as a mold or other forming tool. The compacting tool is typically divided into a series of narrow segments, each segment able to advance or retreat individually so as to conform to the surface of a composite part being formed. Pressurized fluid, such as air or hydraulic fluid, or non-pressurized internal bladders with incompressible fluid, are used to evenly apply pressure to the segments in order to compact the material with which the tool and the segments are in contact. The compacting tool thus helps eliminate voids and helps the material conform to the desired shape on the forming tool.

Owner:INGERSOLL MACHINE TOOLS

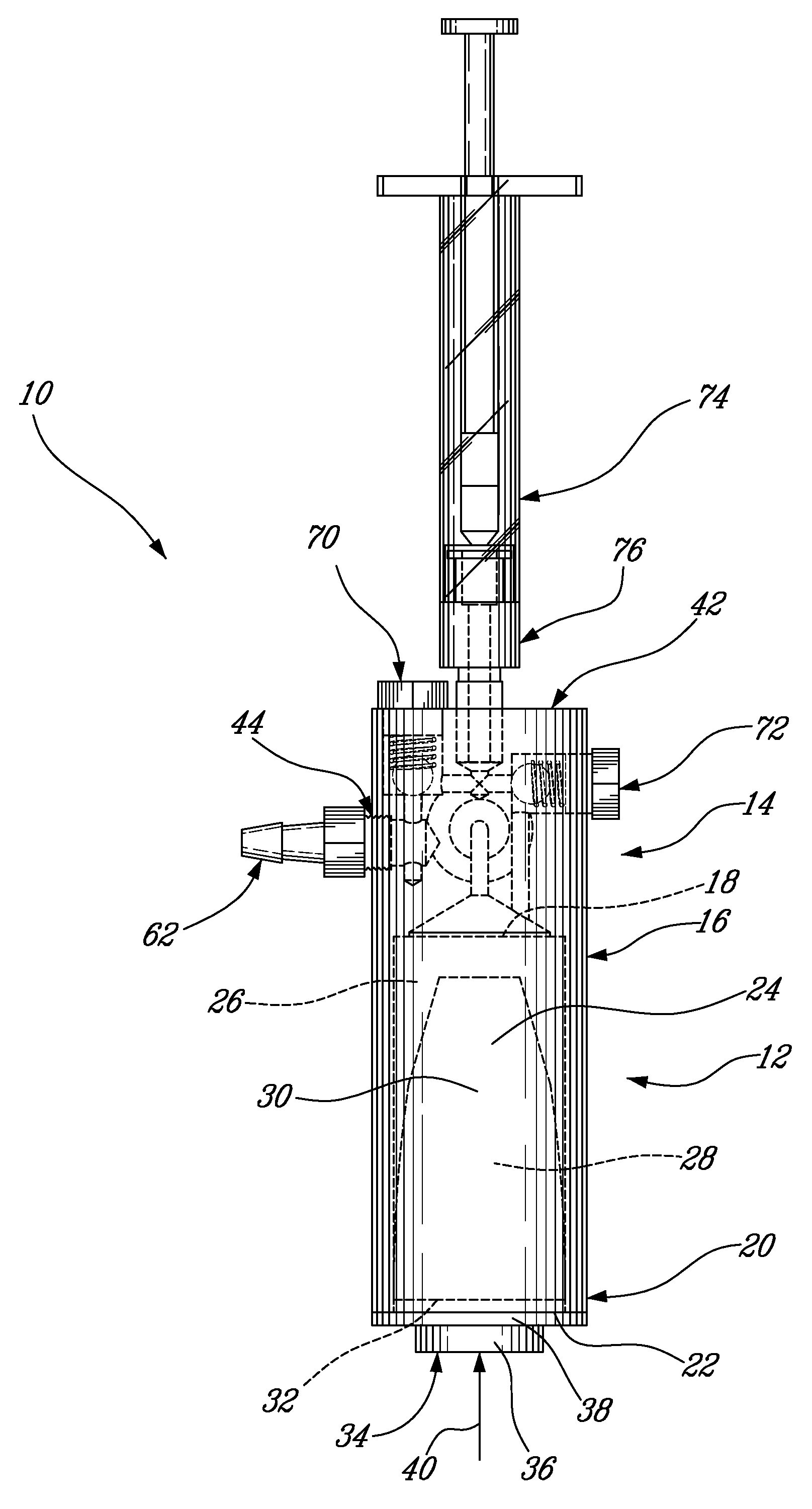

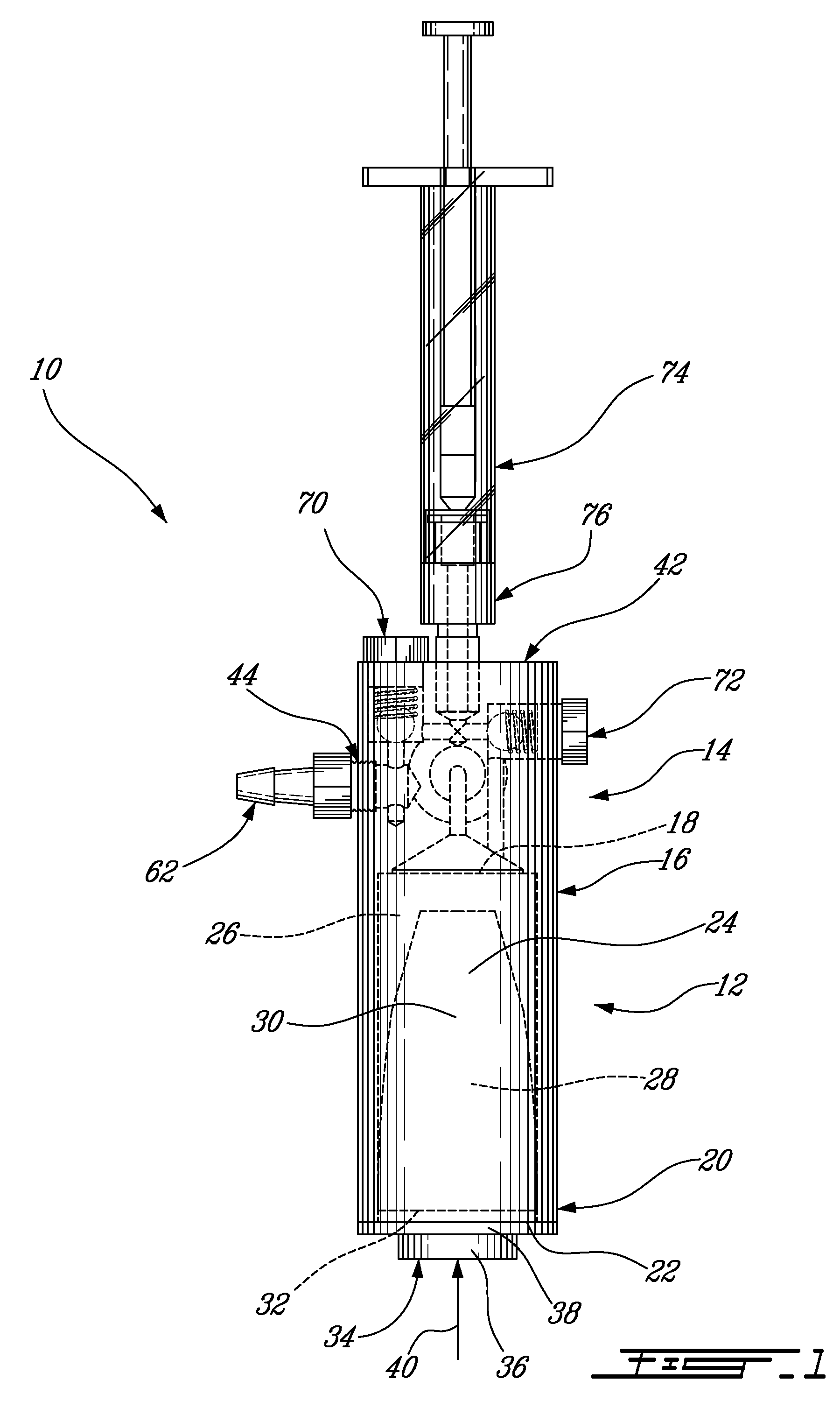

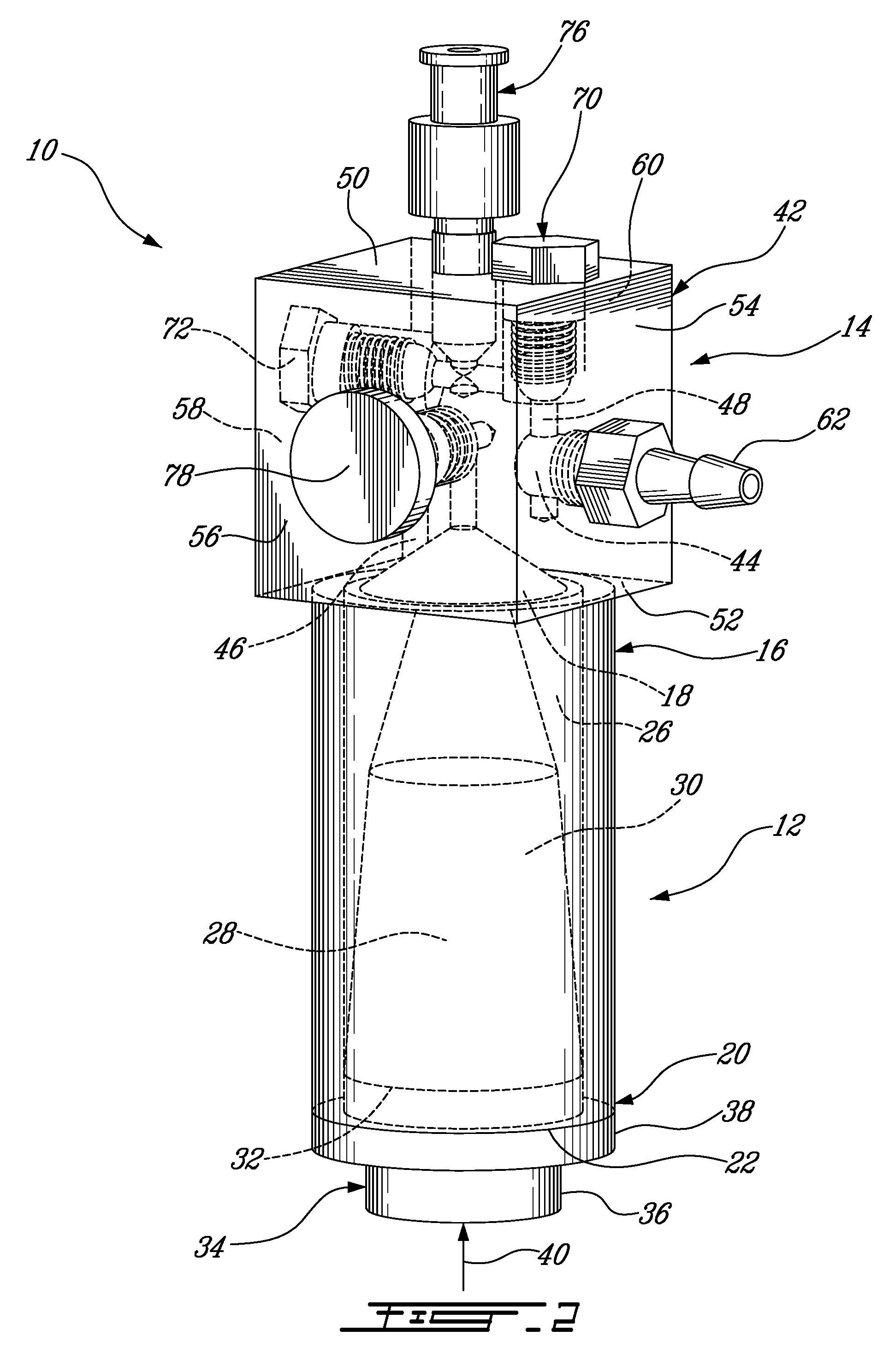

Infusion pump and method for use

InactiveUS20060150747A1Increased riskMeasurement is limitedContracting/expanding measuring chambersVolume variation compensation/correction apparatusSolenoid valveContact method

A fluid dispensing system provides a non-contact method of monitoring the change in the fluid volume over time. This approach avoids the use of probes or sensors that come into direct contact with the fluid to be dispensed. The system comprises an apparatus comprising three chambers. The first chamber has a fixed volume and contains a pressurized gas. A solenoid valve is used to control the flow of gas from the first chamber into the second. The second chamber is sealed so that the combined mass of air in the first and second chambers remains fixed. The third chamber is adjacent to the second and contains medication in the form of incompressible fluid that is to be administered to a human or animal subject via a suitable delivery port. A piston is disposed between the second and third chambers and is movable responsive to the flow of gas into the second chamber to dispense fluid from the third chamber as desired. By sensing the pressure in the first and second chambers at any point in time, a processor is programmed to calculate the flow rate or dispensed volume of the fluid being delivered using principles derived from the Ideal Gas Law.

Owner:TANDEM DIABETES CARE INC

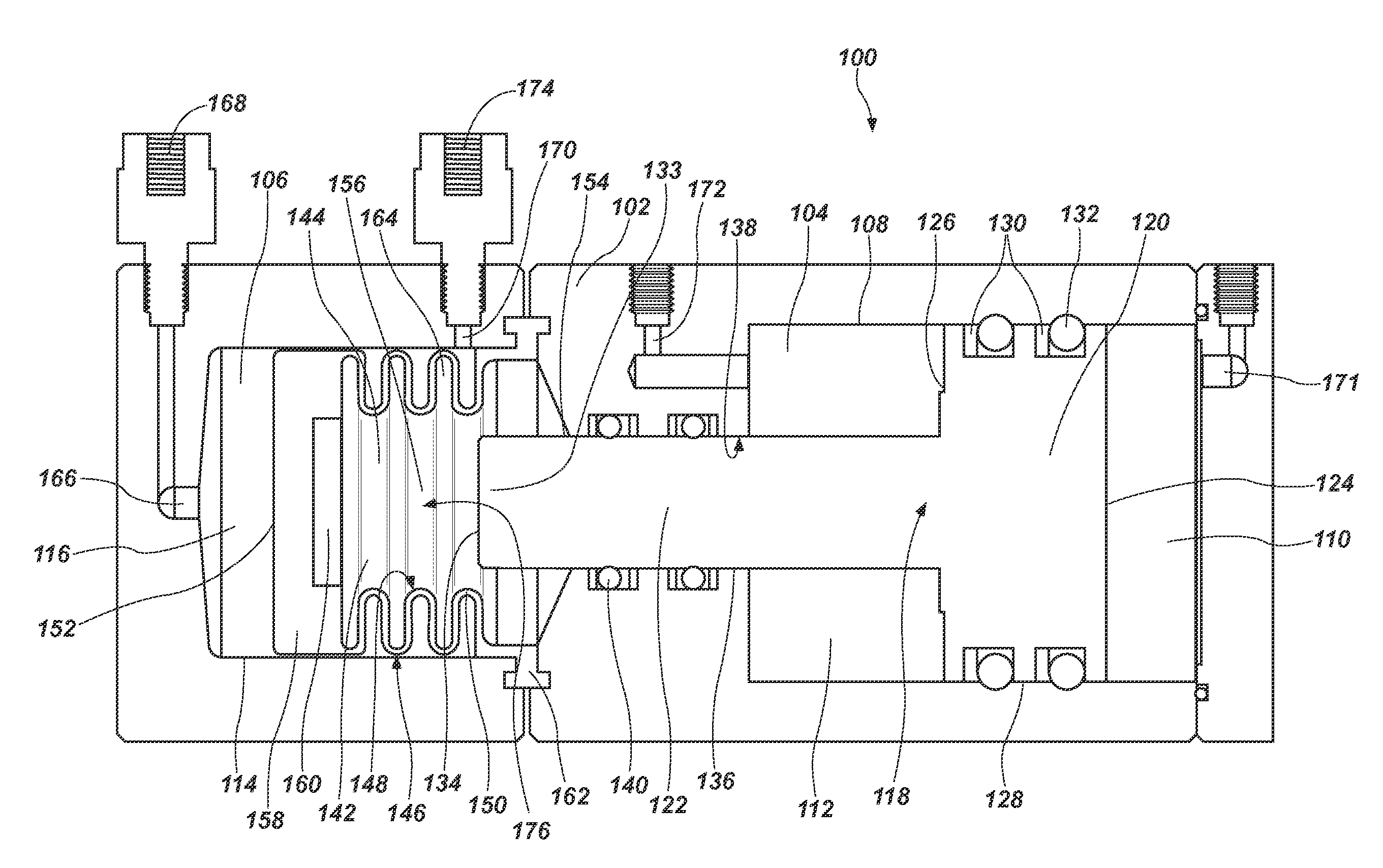

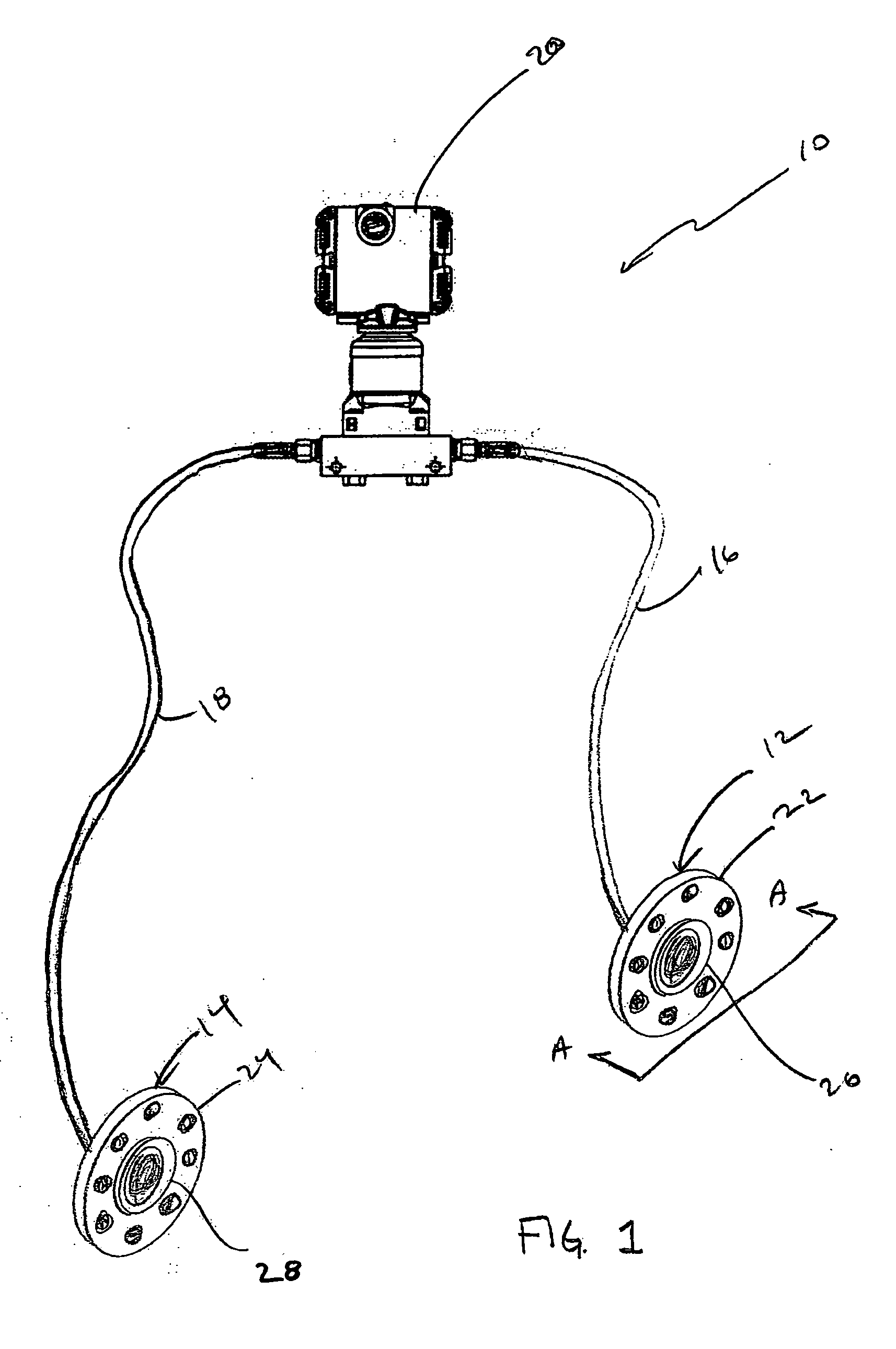

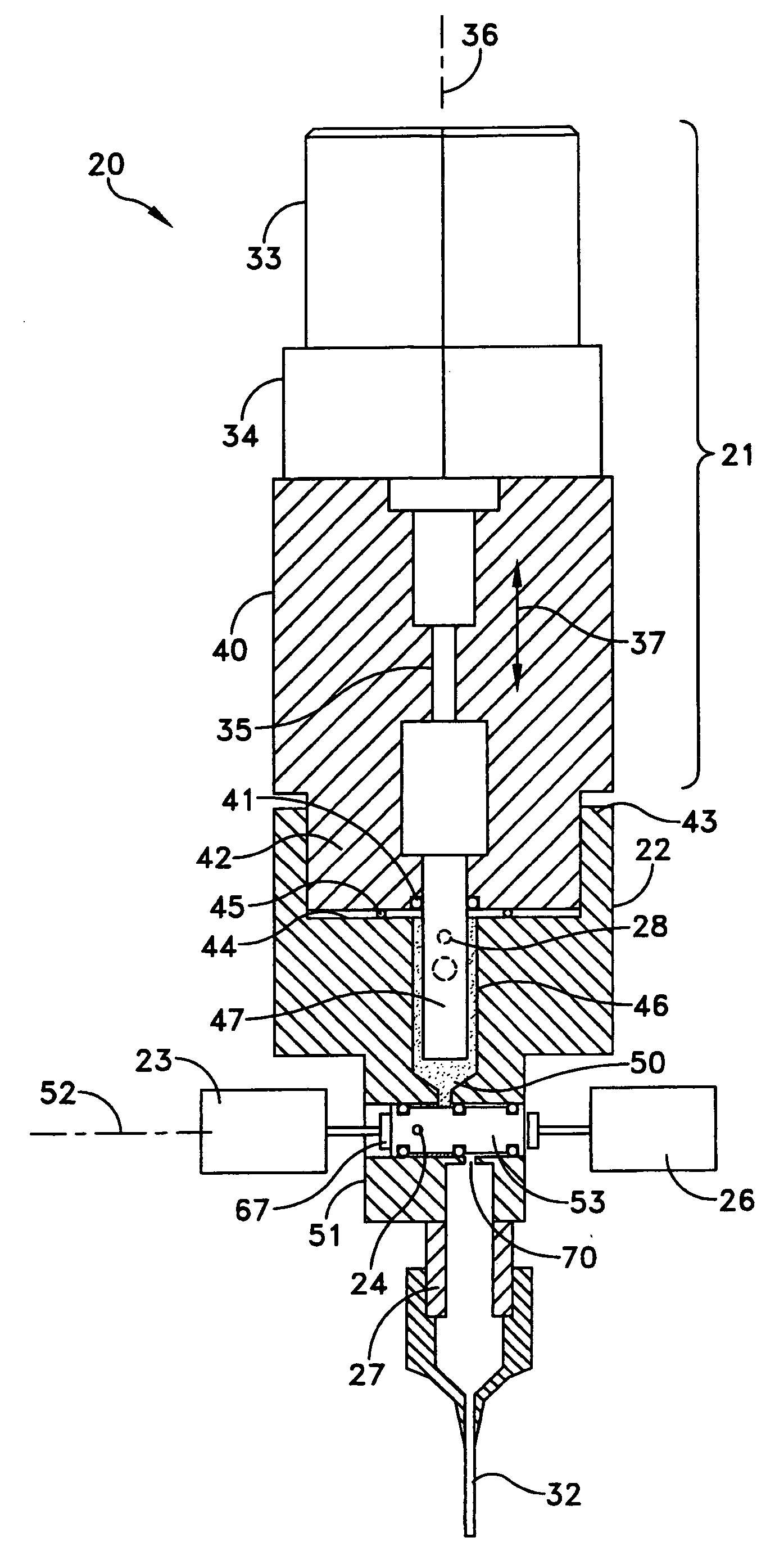

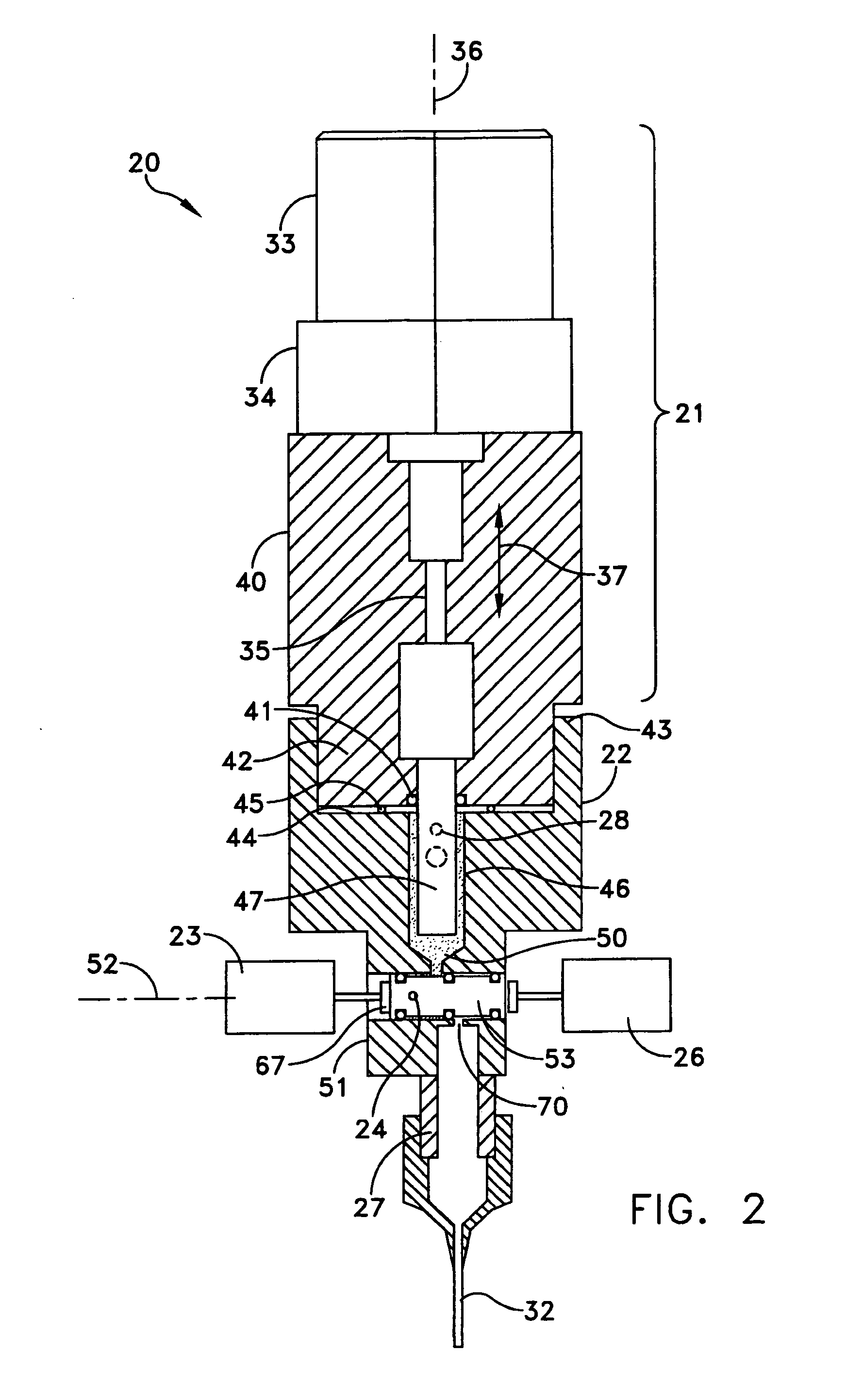

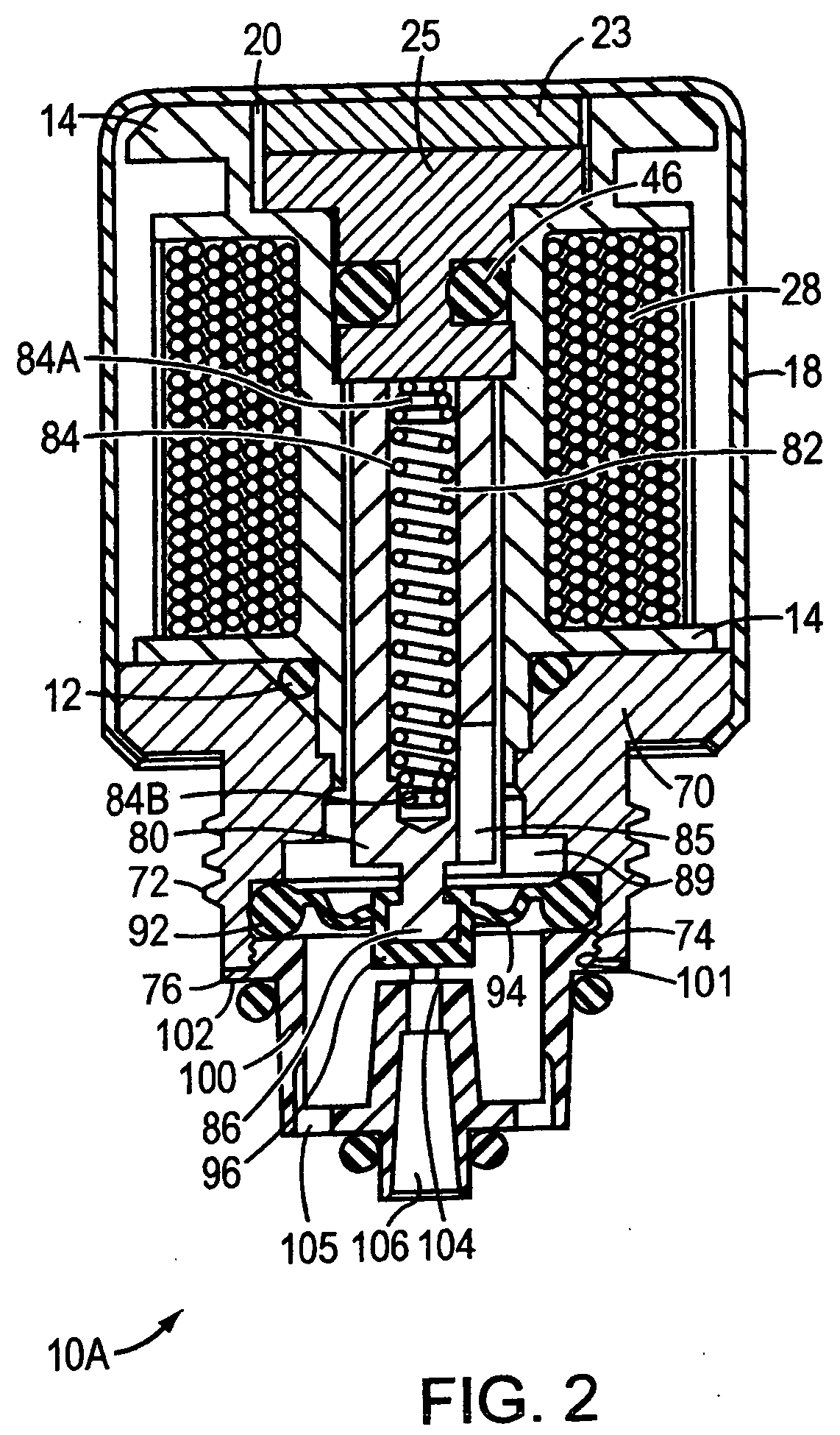

Electromagnetic apparatus and method for controlling fluid flow

InactiveUS20070241298A1Reduce energy wasteReduce energy consumptionSpindle sealingsDiaphragm valvesDriving currentBobbin

An actuator including actuator base, bobbin, and pole piece forming a pocket for a ferromagnetid armature located therein. The actuator including a radial magnet and a solenoid coil constructed and arranged to cause a linear displacement of the armature upon application of a coil drive current from a control circuit. The actuator may include a flexible membrane that partially encloses the armature to form an armature chamber filled with an incompressible fluid. In a valve design, a fluid flow is stopped by driving the membrane against a valve seat. Pressure from the controlled fluid in the conduit is transmitted through the membrane to the fluid within the armature chamber so that the armature does not need to counteract force applied to the membrane by the conduit fluid's pressure. A fluid flow is opened by driving the membrane away from the valve seat.

Owner:SLOAN VALVE COMPANY

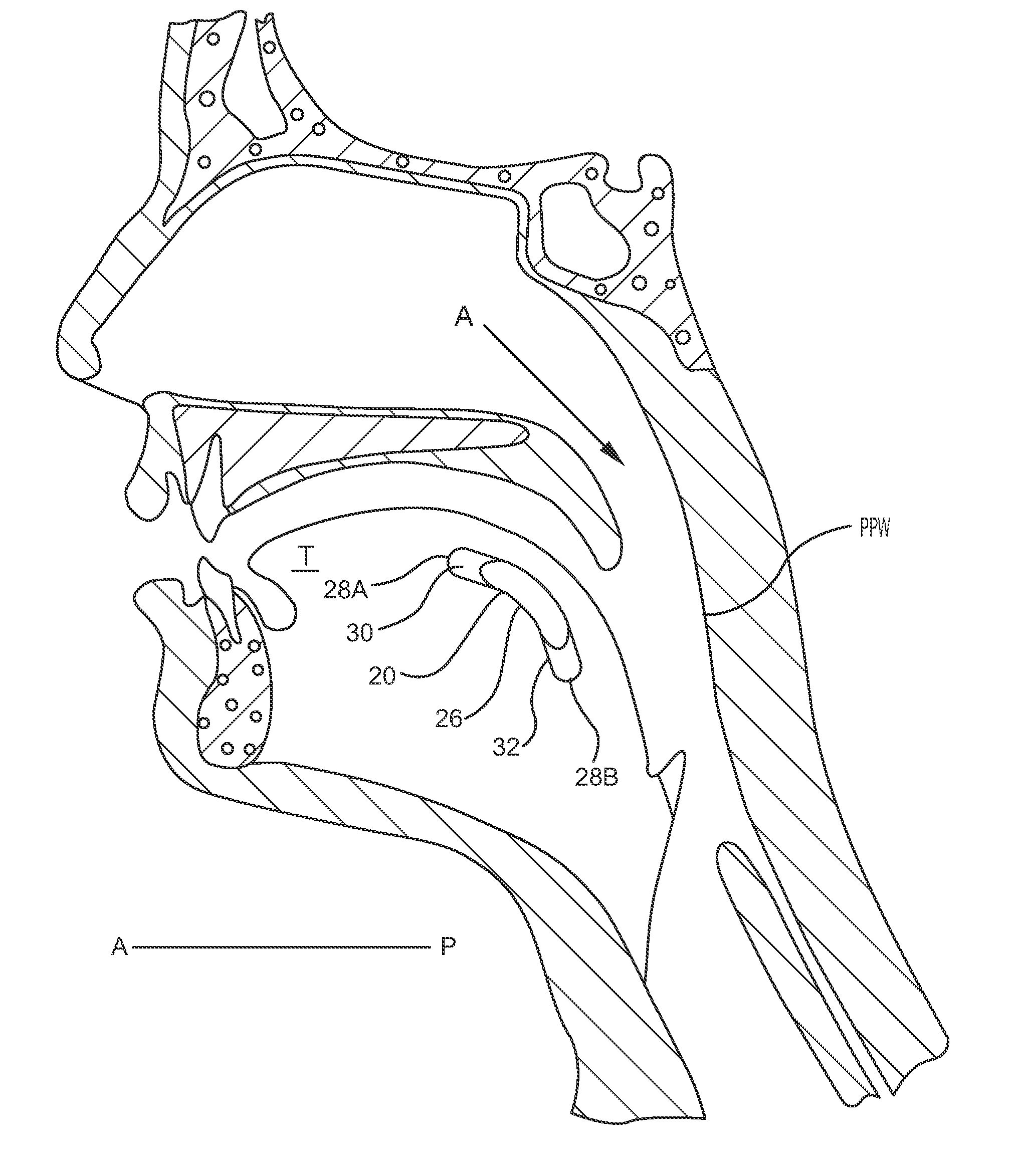

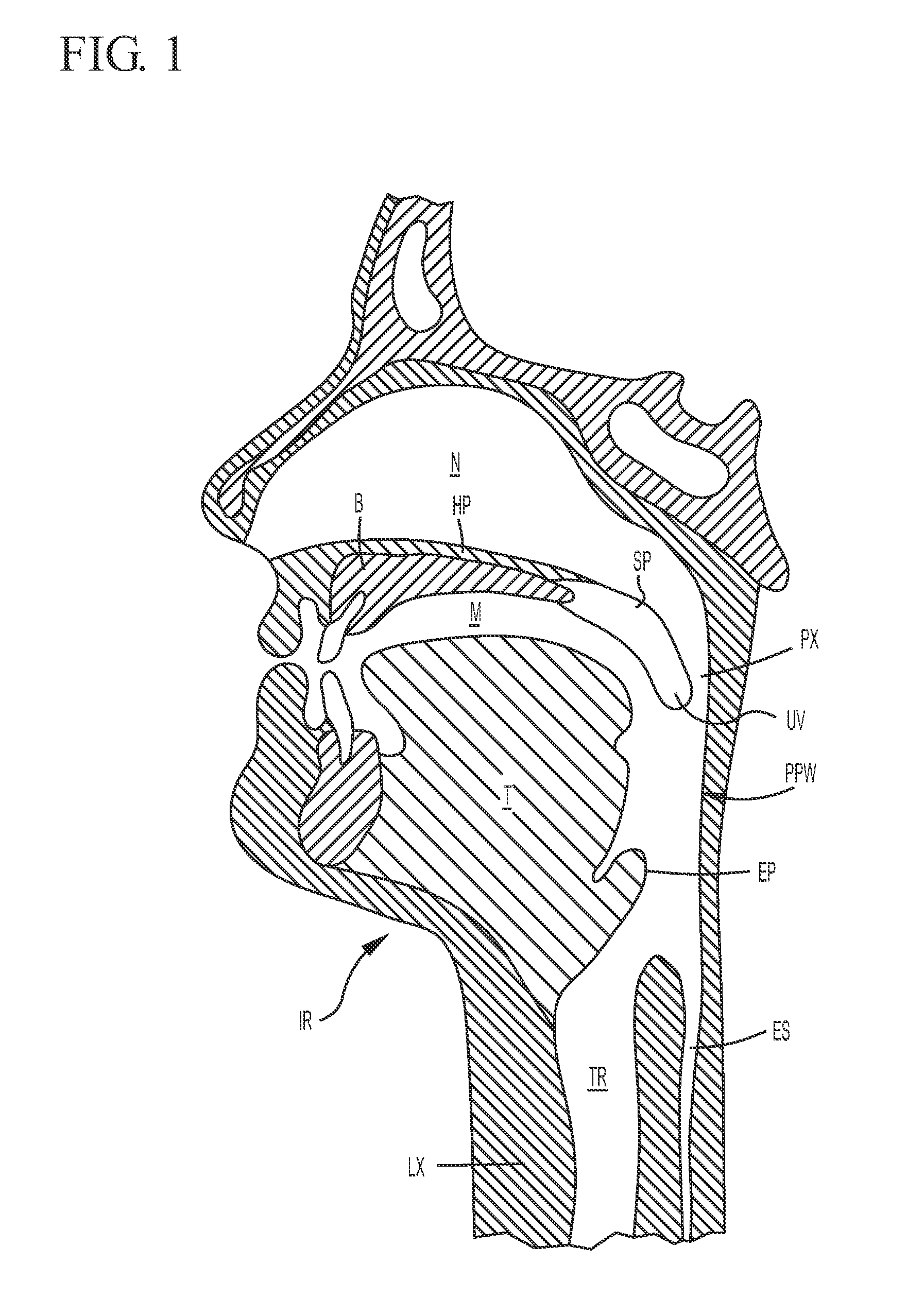

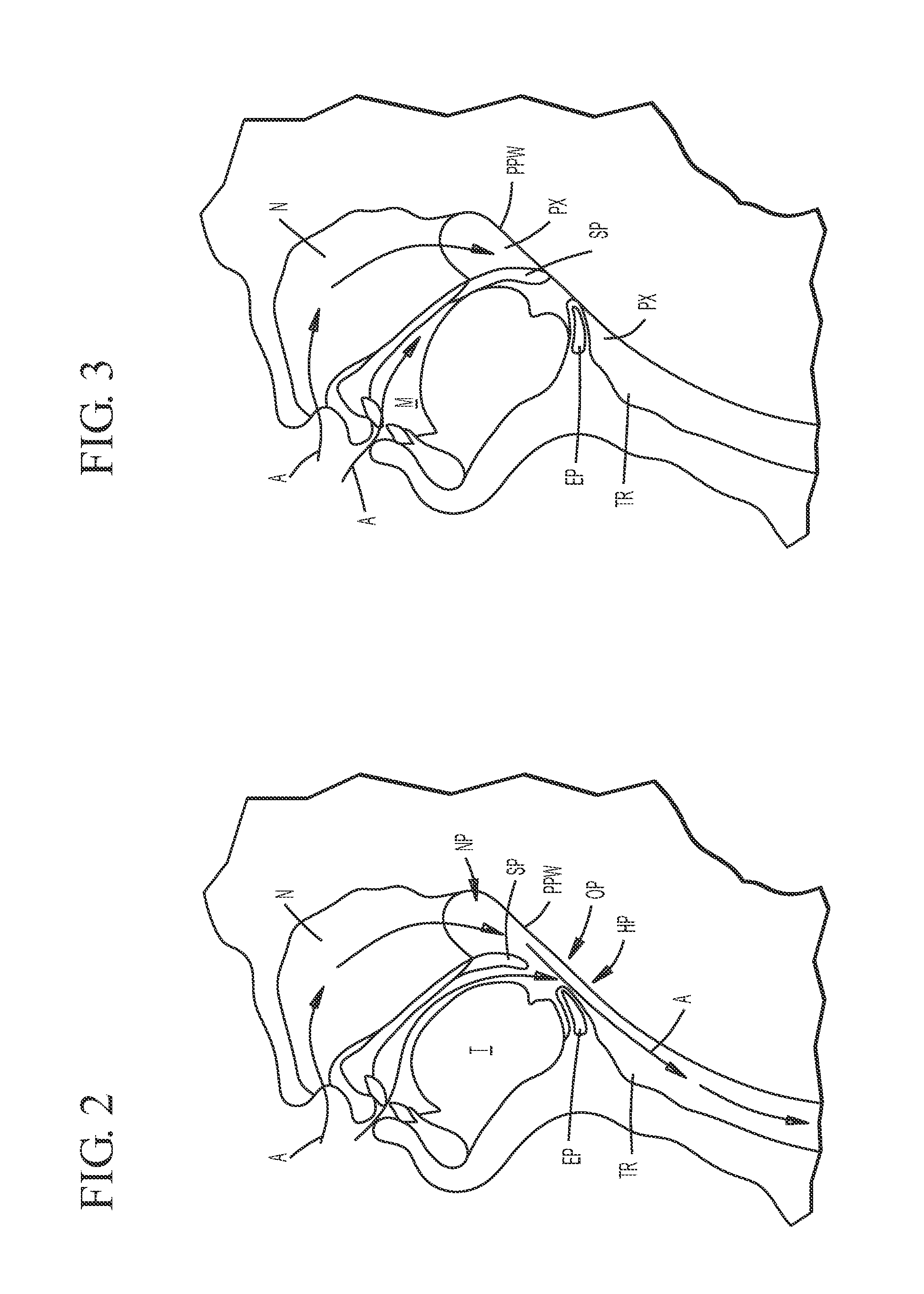

Flexible implants having internal volume shifting capabilities for treating obstructive sleep apnea

InactiveUS20110100378A1Lower the volumeLower resistanceSnoring preventionNon-surgical orthopedic devicesSleep apneaBiomedical engineering

An implant for treating obstructive sleep apnea includes a first chamber containing an incompressible fluid, a second chamber containing a compressible fluid, and a flexible diaphragm separating the first and second chambers. The incompressible fluid is in communication with the compressible fluid via the flexible diaphragm. The first chamber has a first volume that remains constant in response to an external force applied upon the implant and the second chamber has a second volume that is changeable when the external force is applied upon the implant. The flexible diaphragm is extendible into the second chamber for reducing the second volume of the second chamber and compressing the compressible fluid within the second chamber. The compressible fluid within the second chamber provides less resistance to flexing during initial flexing of the implant and more resistance to flexing during further flexing of the implant.

Owner:ETHICON INC

Method and apparatus for surgical electrocautery

The invention provides a surgical electrocautery method and apparatus that achieves sealing along the entire tissue length, and that also is able to deliver adequate force to produce an effective electrocautery seal. This problem is solved by using an incompressible fluid contained in a sac or sacs positioned to support the one or more electrodes used for electrocauterization. The profile of the electrodes thus conforms to the tissue surface and thickness variations, while exerting an optimized pressure along the entire length of the surface.

Owner:AESCULAP AG

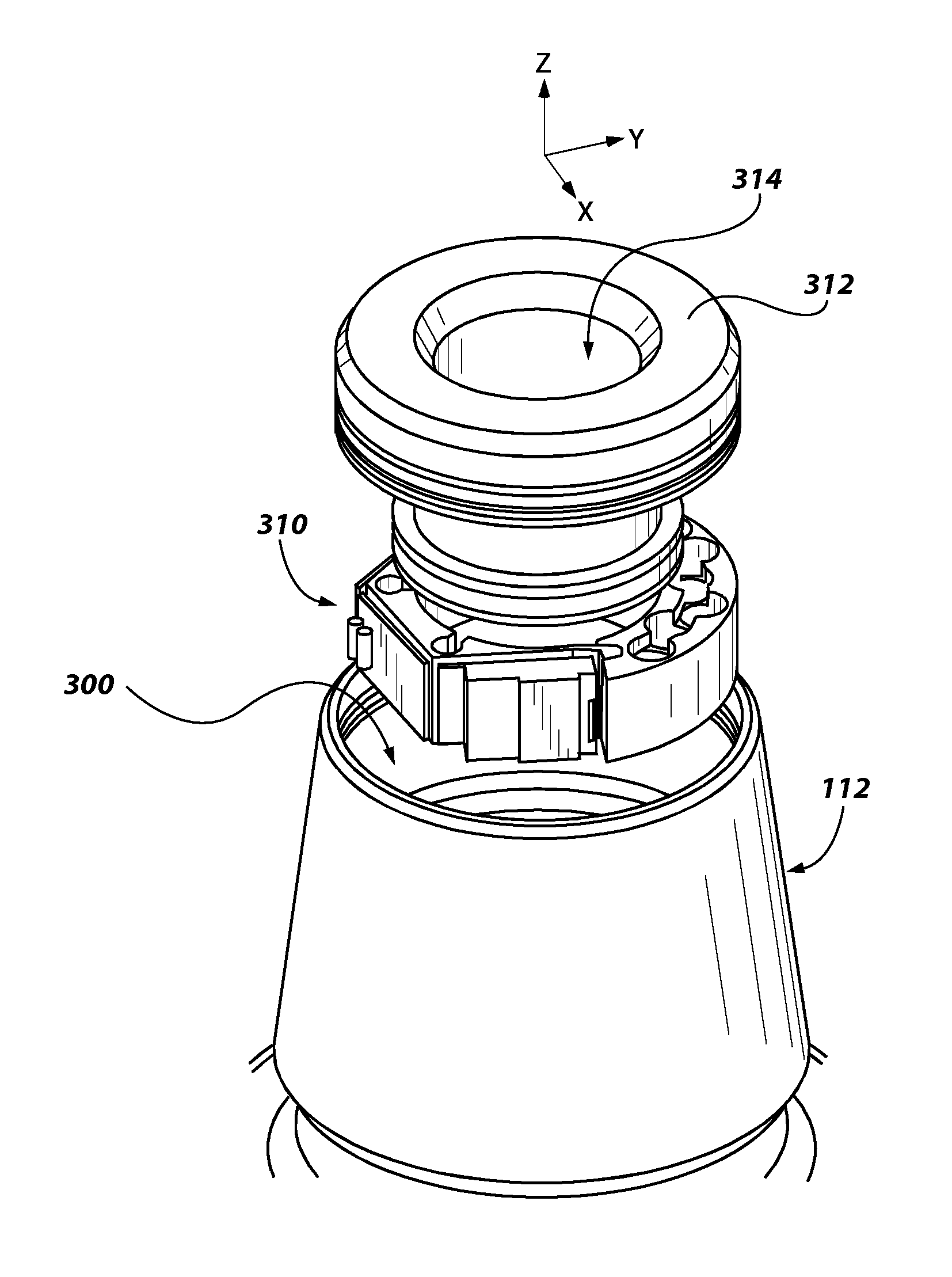

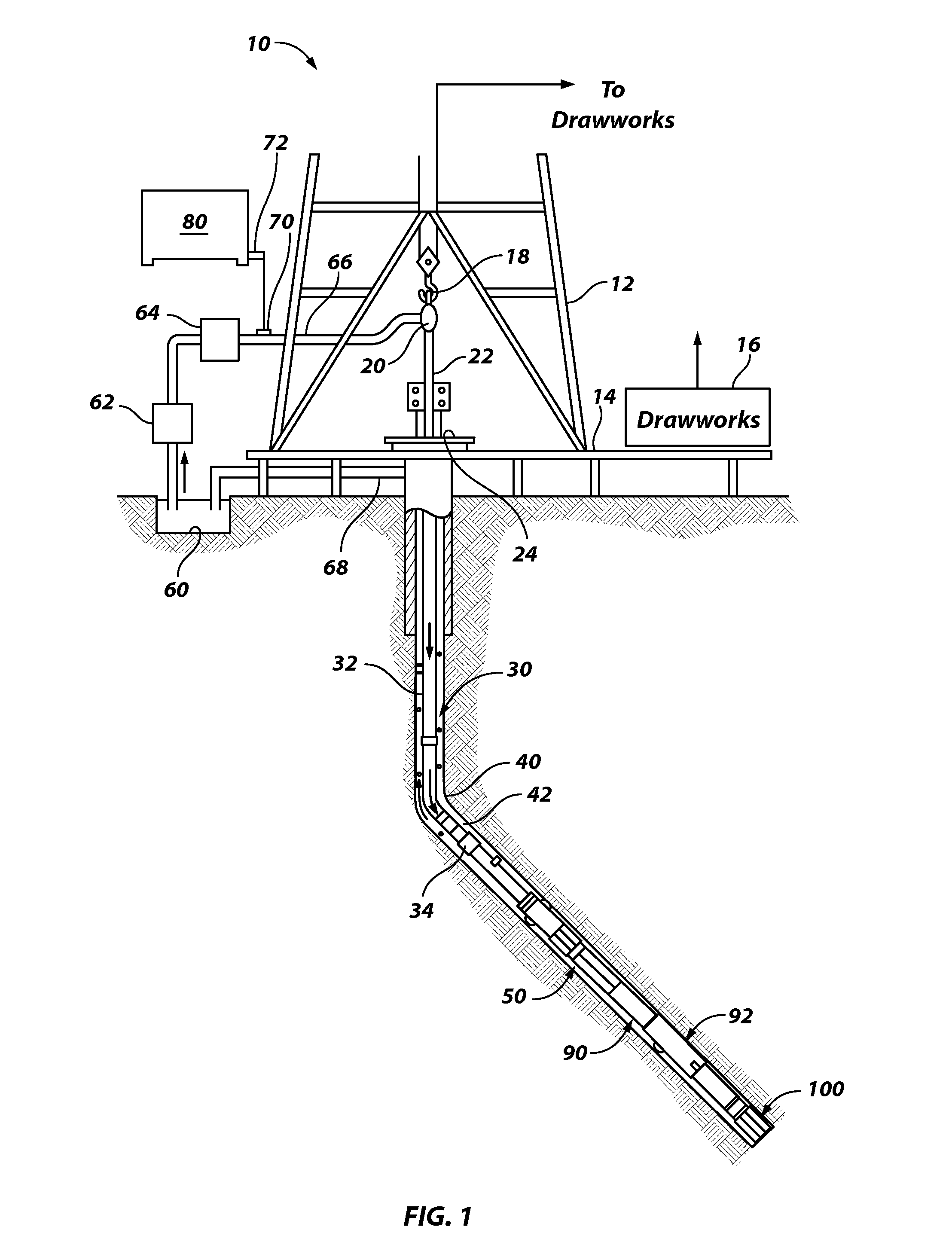

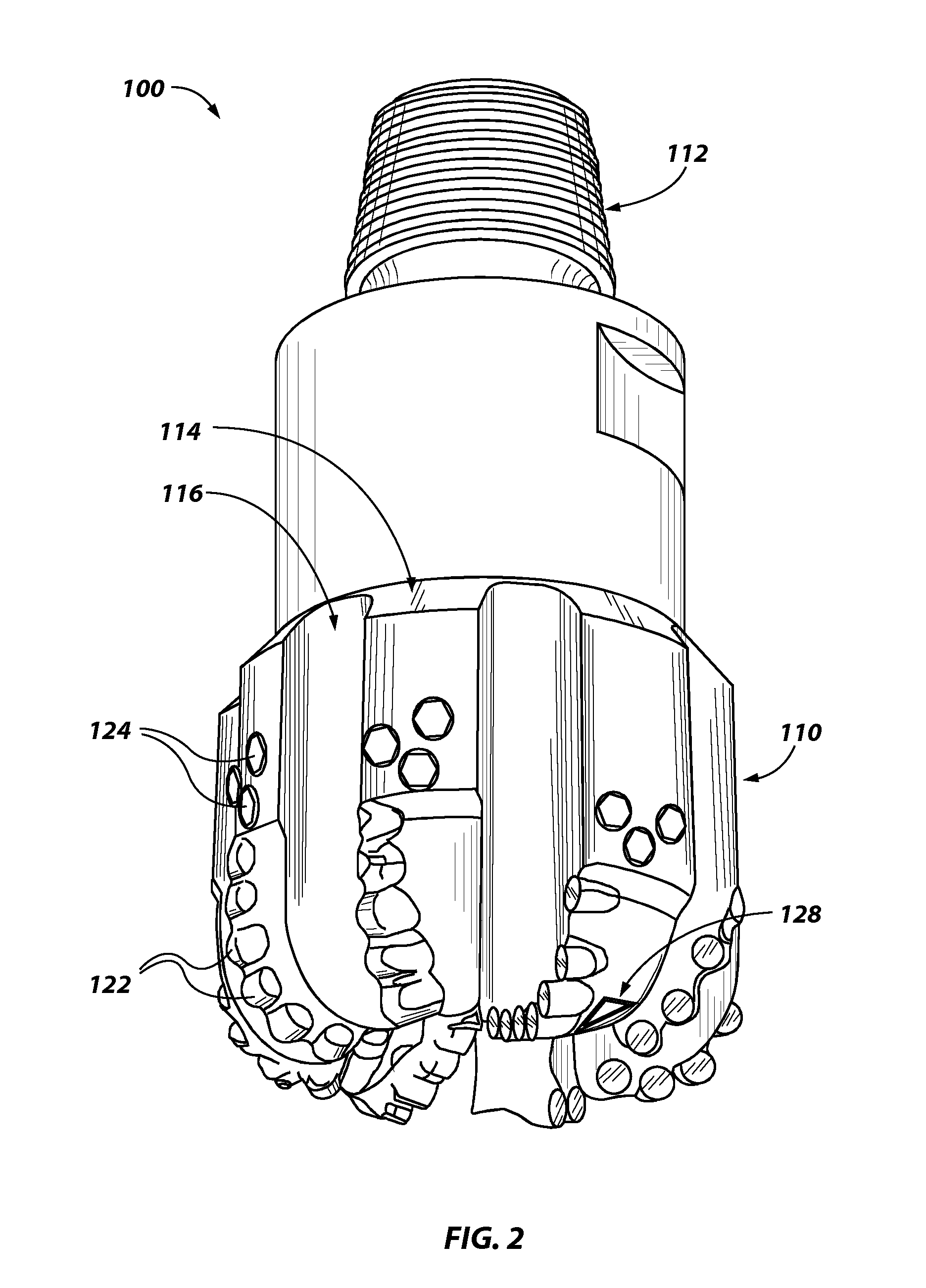

Earth-boring tools including retractable pads, cartridges including retractable pads for such tools, and related methods

ActiveUS20120318580A1Reduce protrusionDrill bitsDirectional drillingEngineeringMechanical engineering

An earth-boring tool may comprise at least one cavity formed in a face thereof. At least one retractable pad residing in the at least one cavity may be coupled to a piston located at least partially within the at least one cavity. Additionally, a valve may be positioned within the earth-boring tool and configured to regulate flow of an incompressible fluid in contact with the piston through an opening of a reservoir. A cartridge may comprise a barrel wall defining a first bore, and a piston comprising at least one retractable pad positioned at least partially within the first bore. The barrel wall and the piston may define a first reservoir within the first bore, and a valve may be positioned and configured to regulate flow through an opening to the first reservoir. Related methods and devices are also disclosed.

Owner:BAKER HUGHES INC

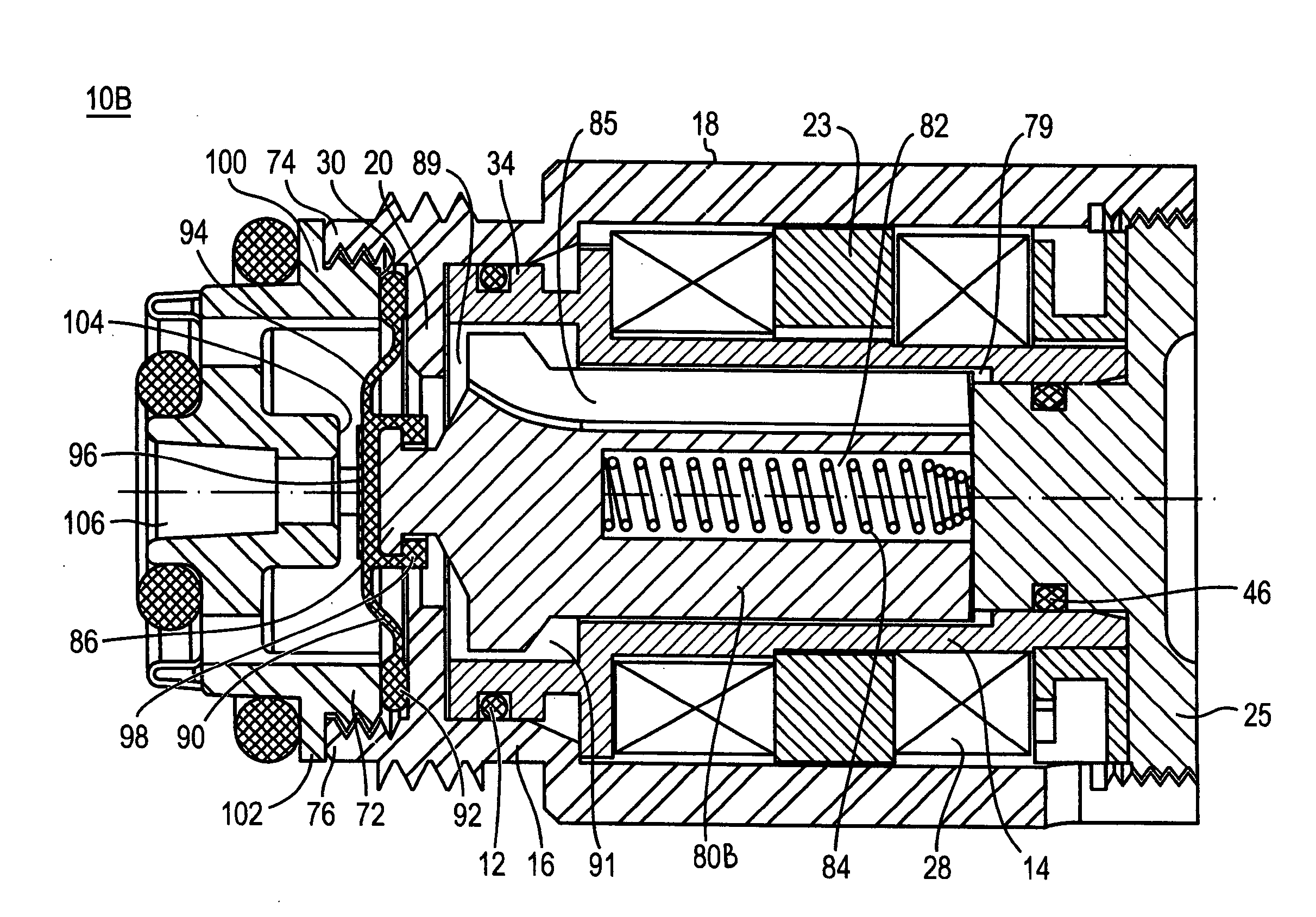

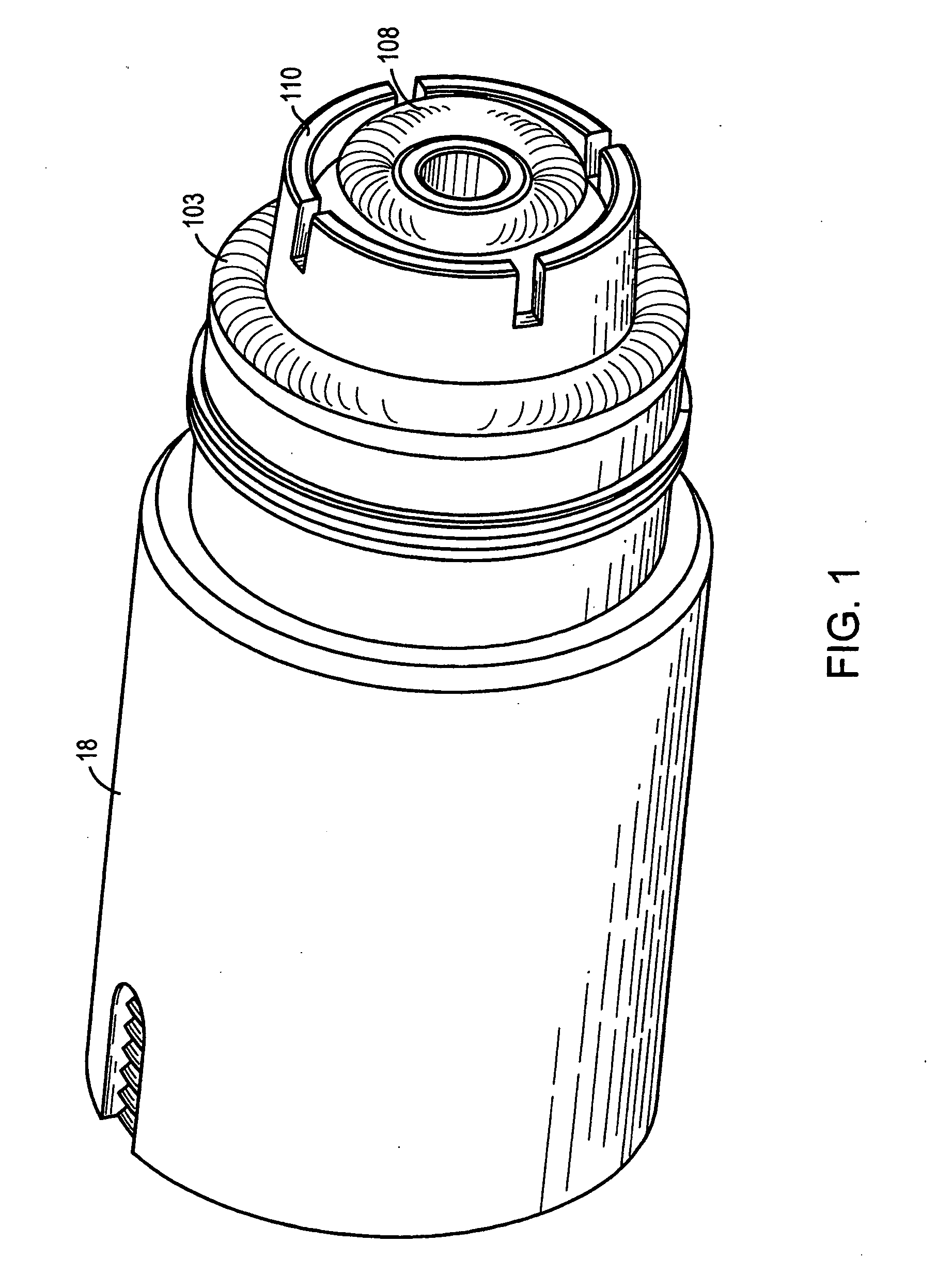

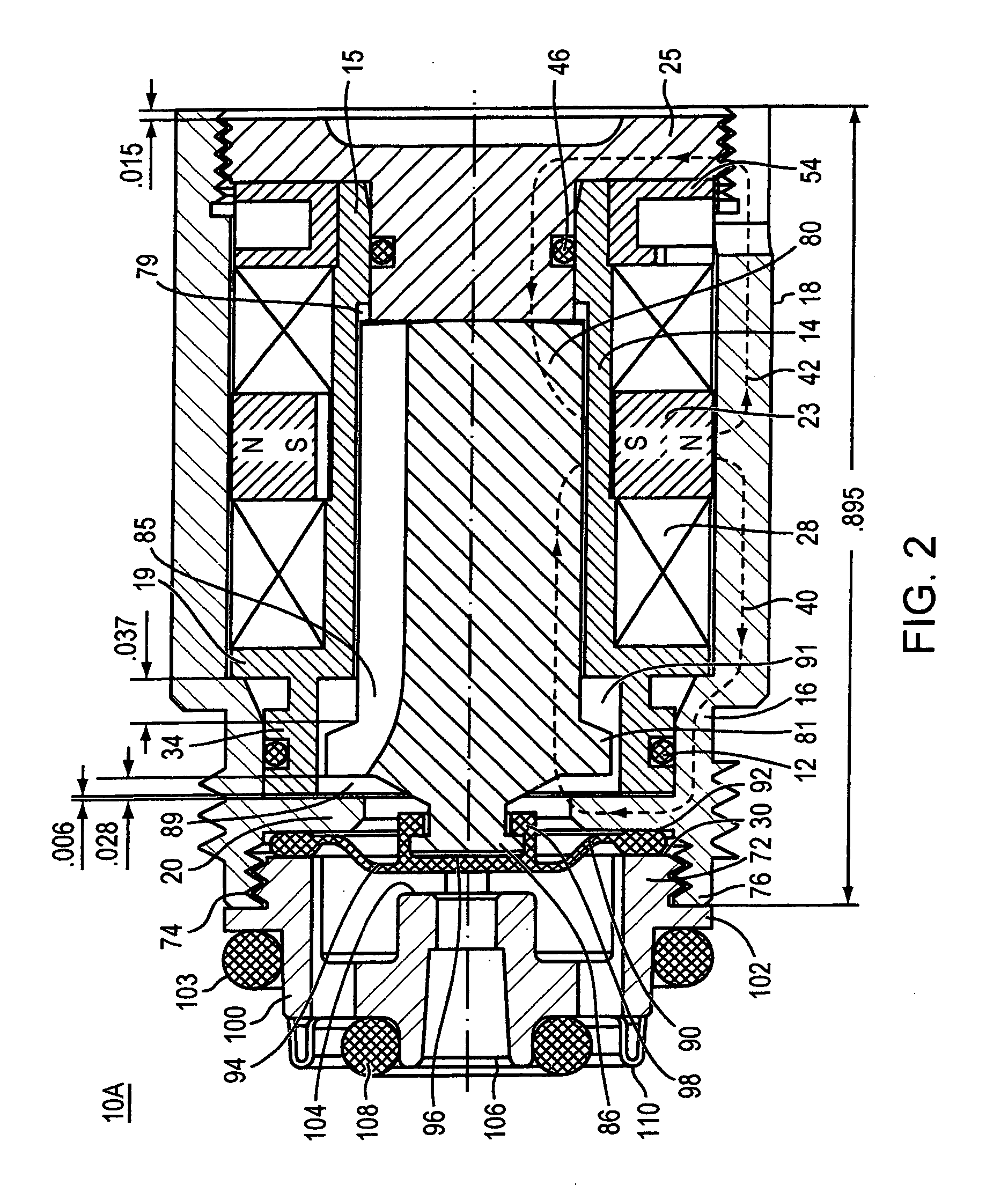

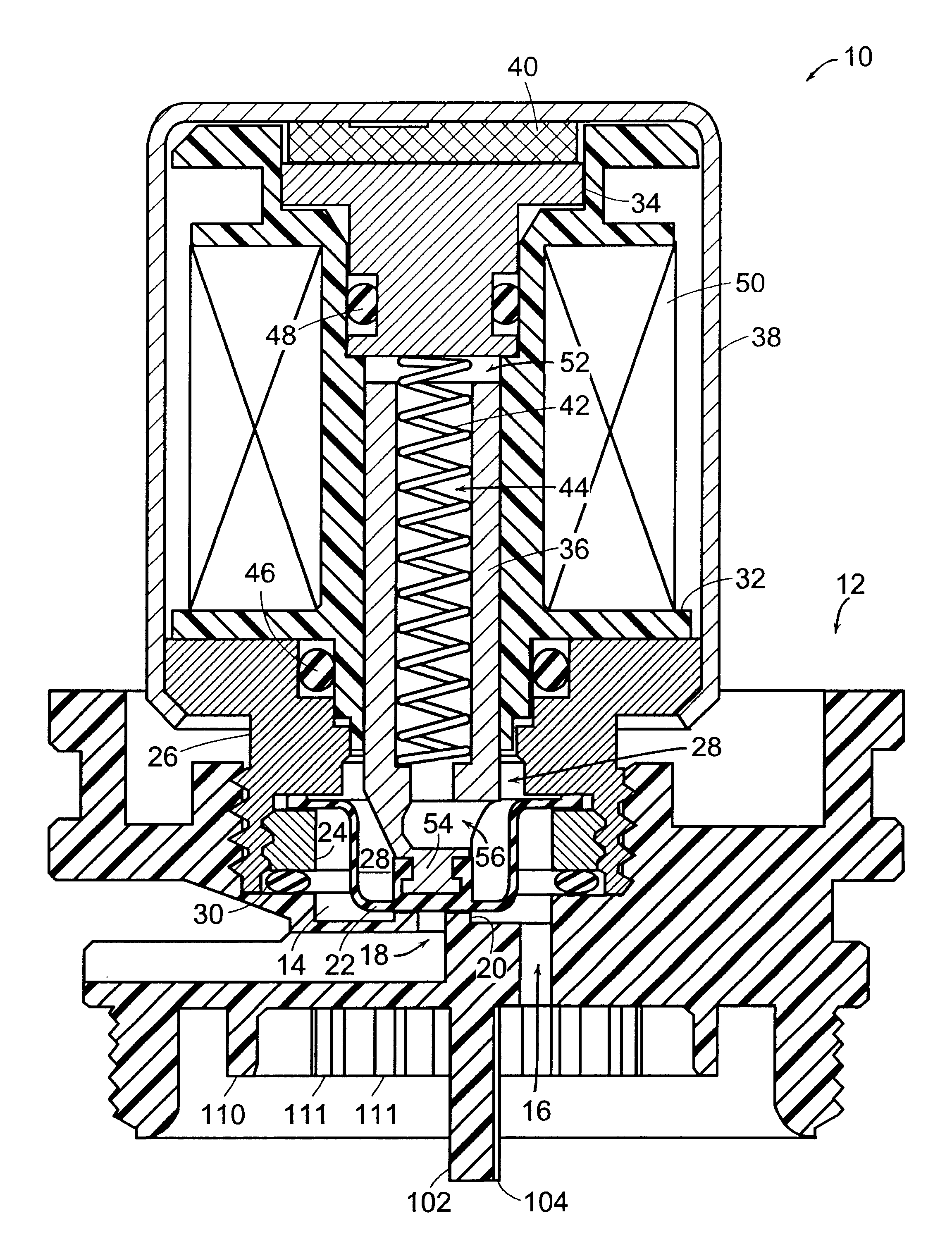

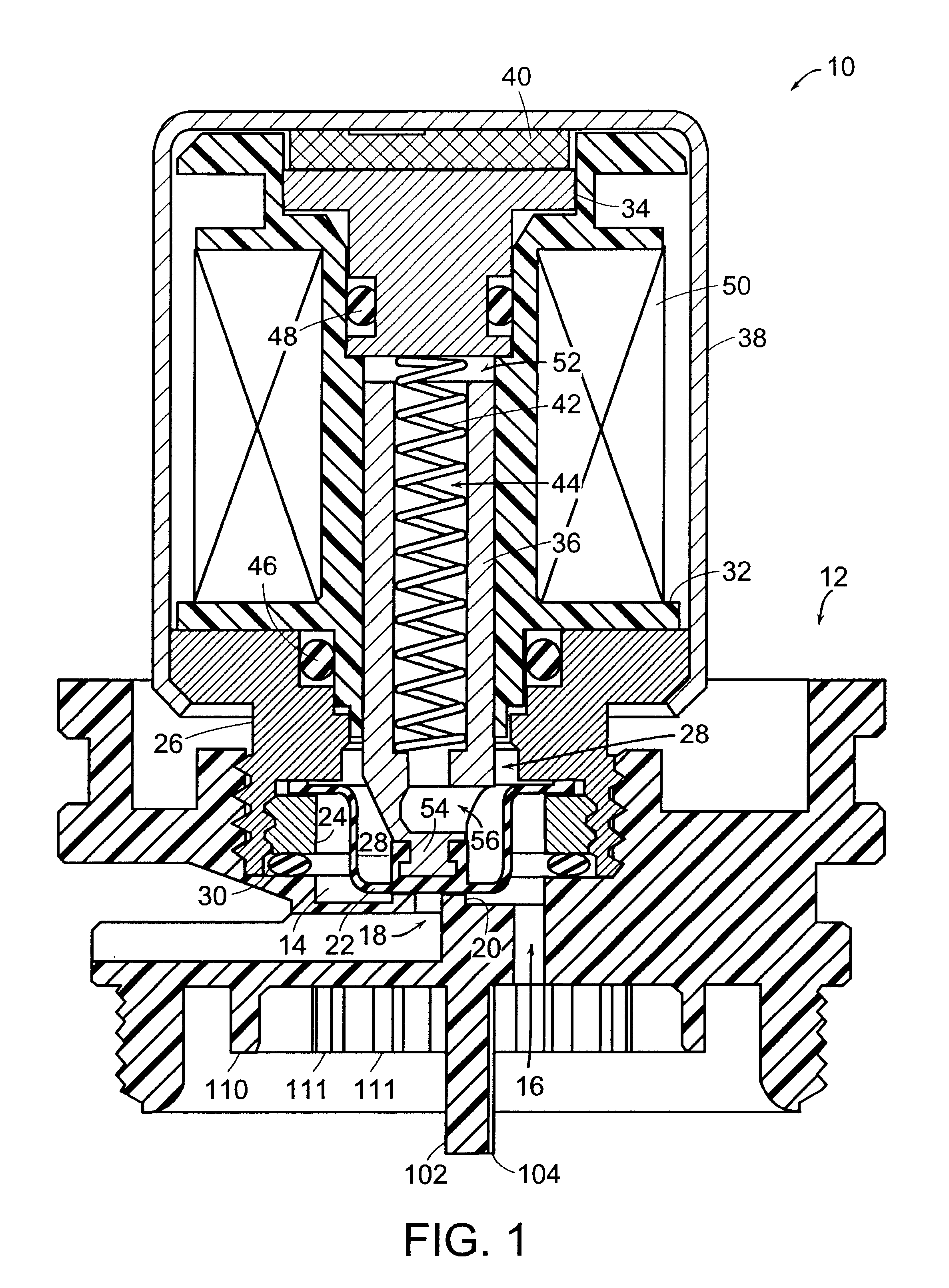

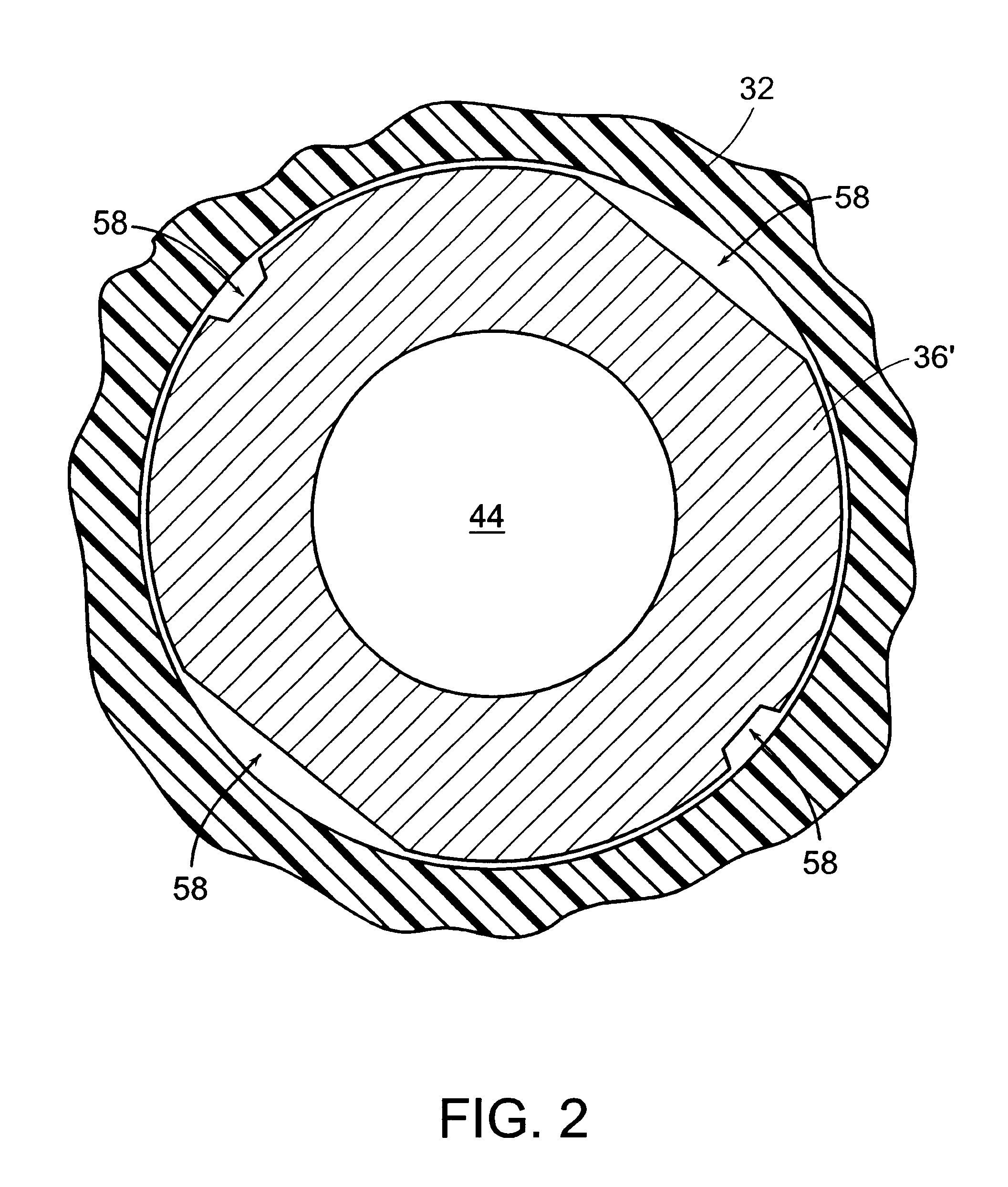

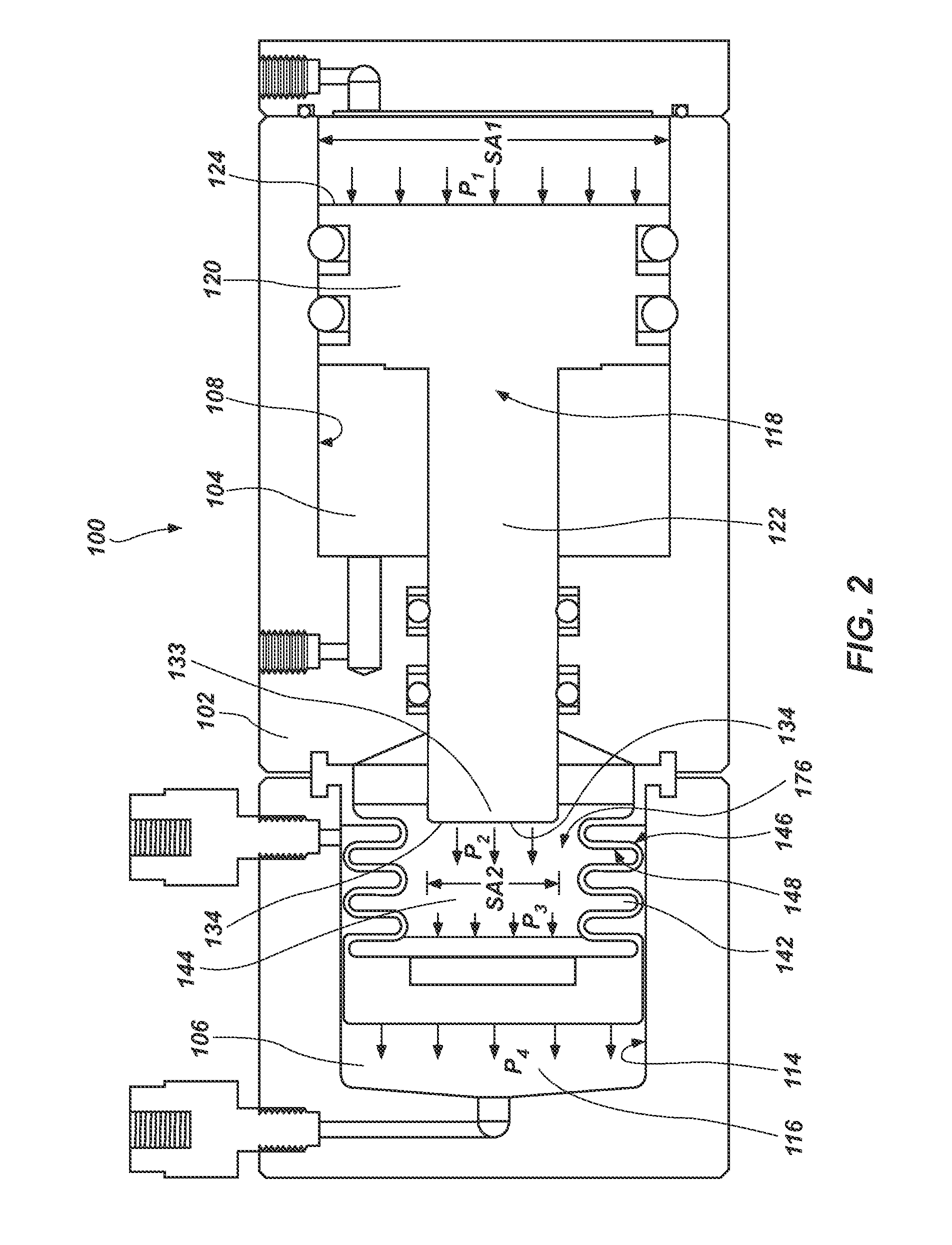

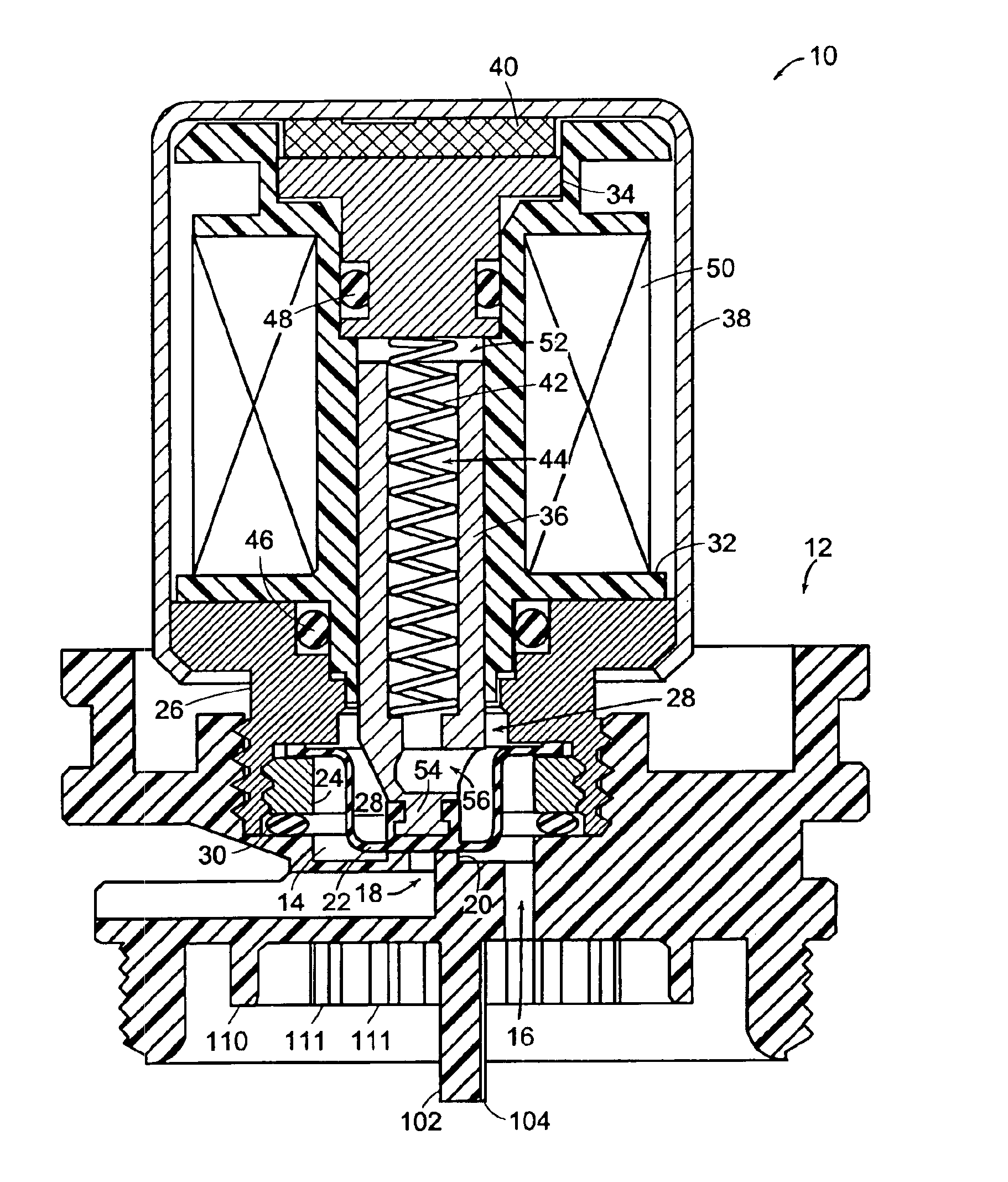

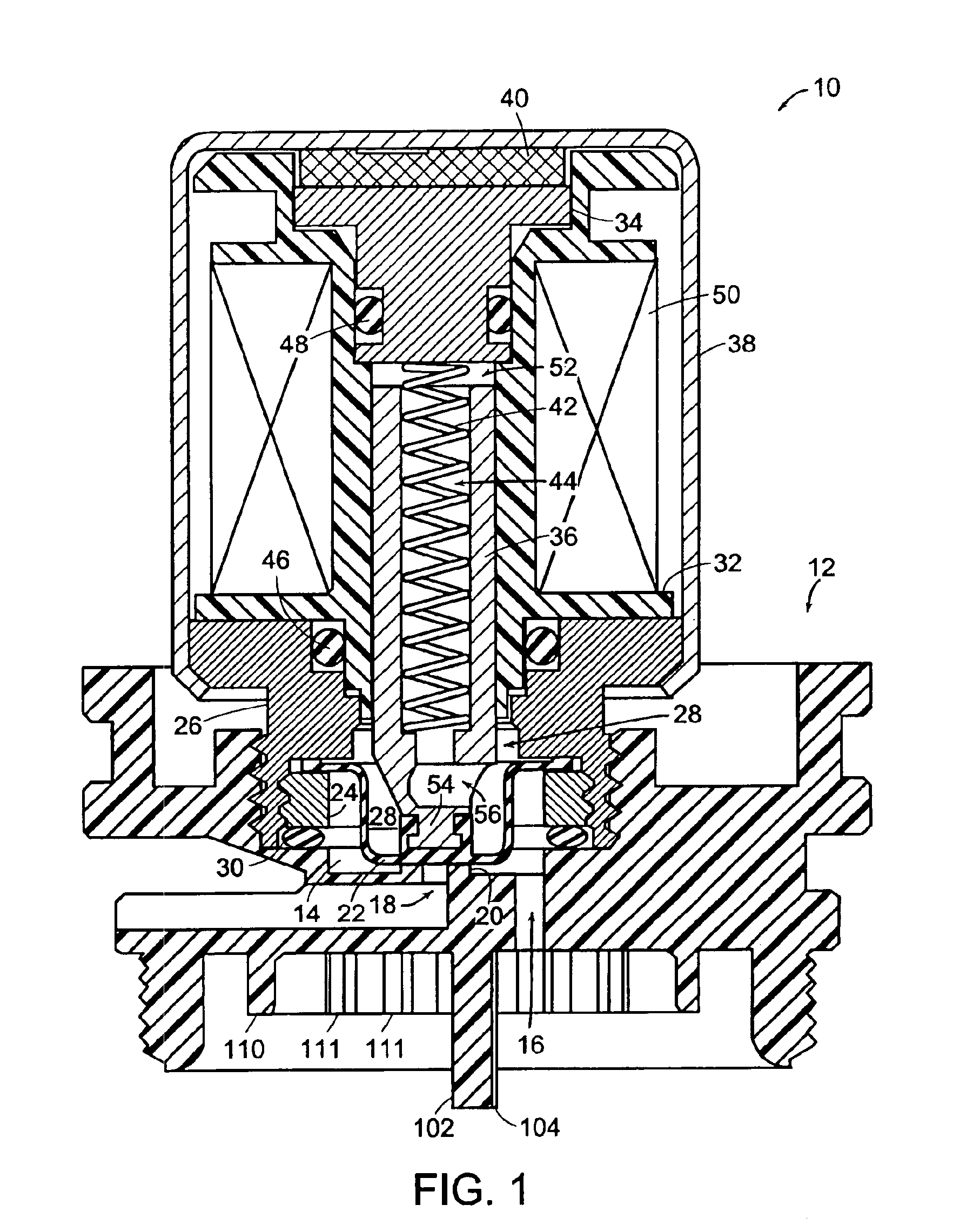

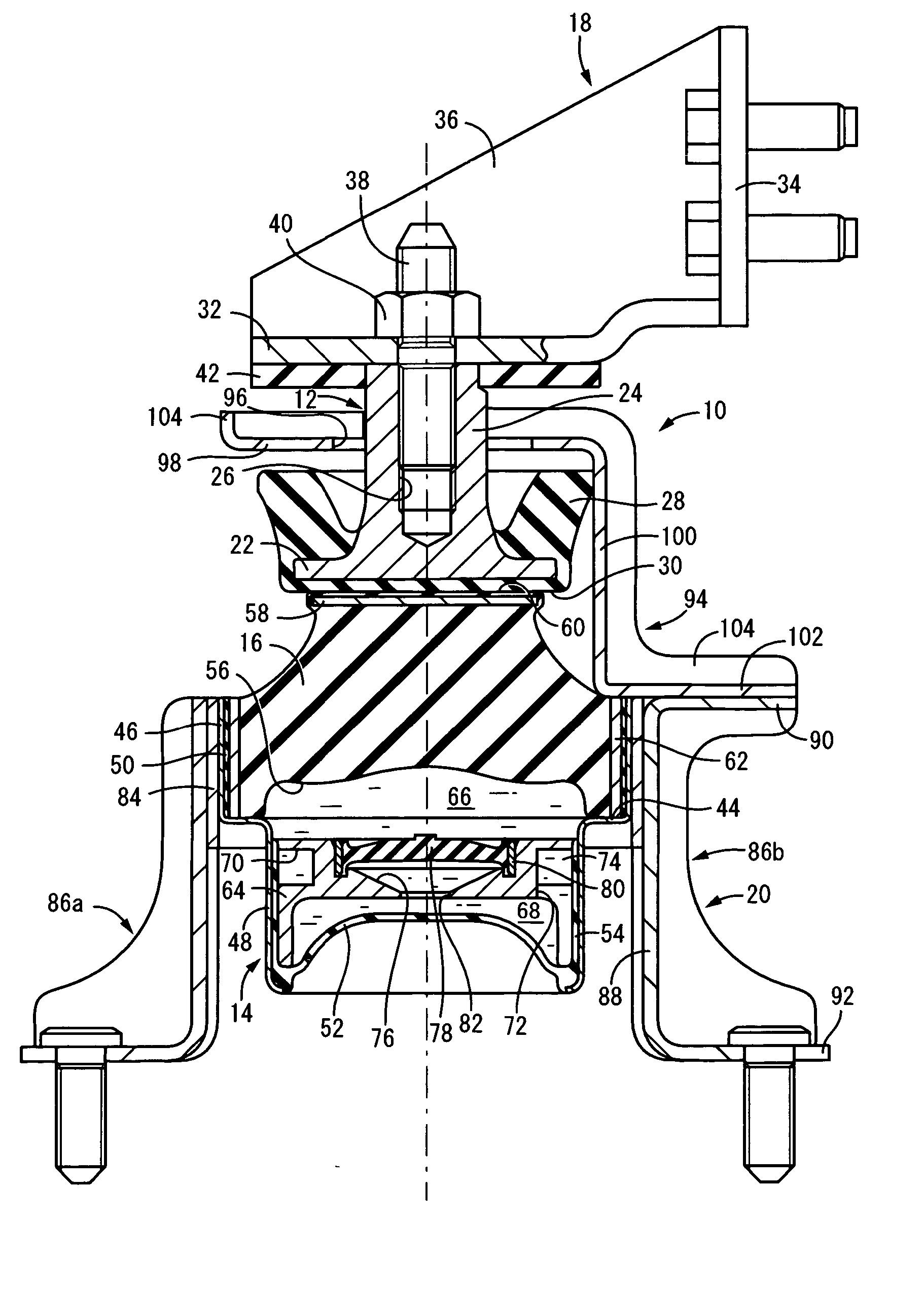

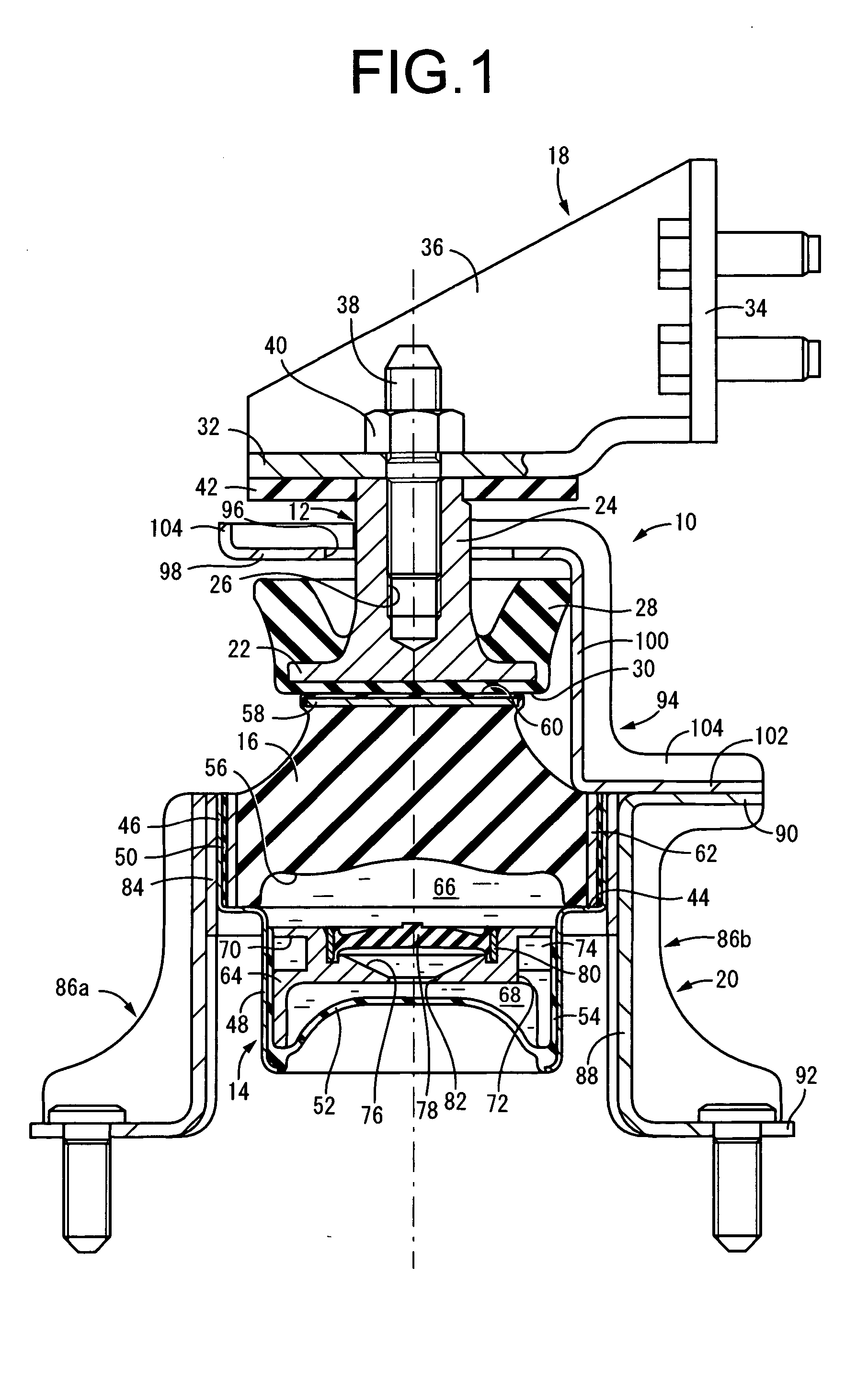

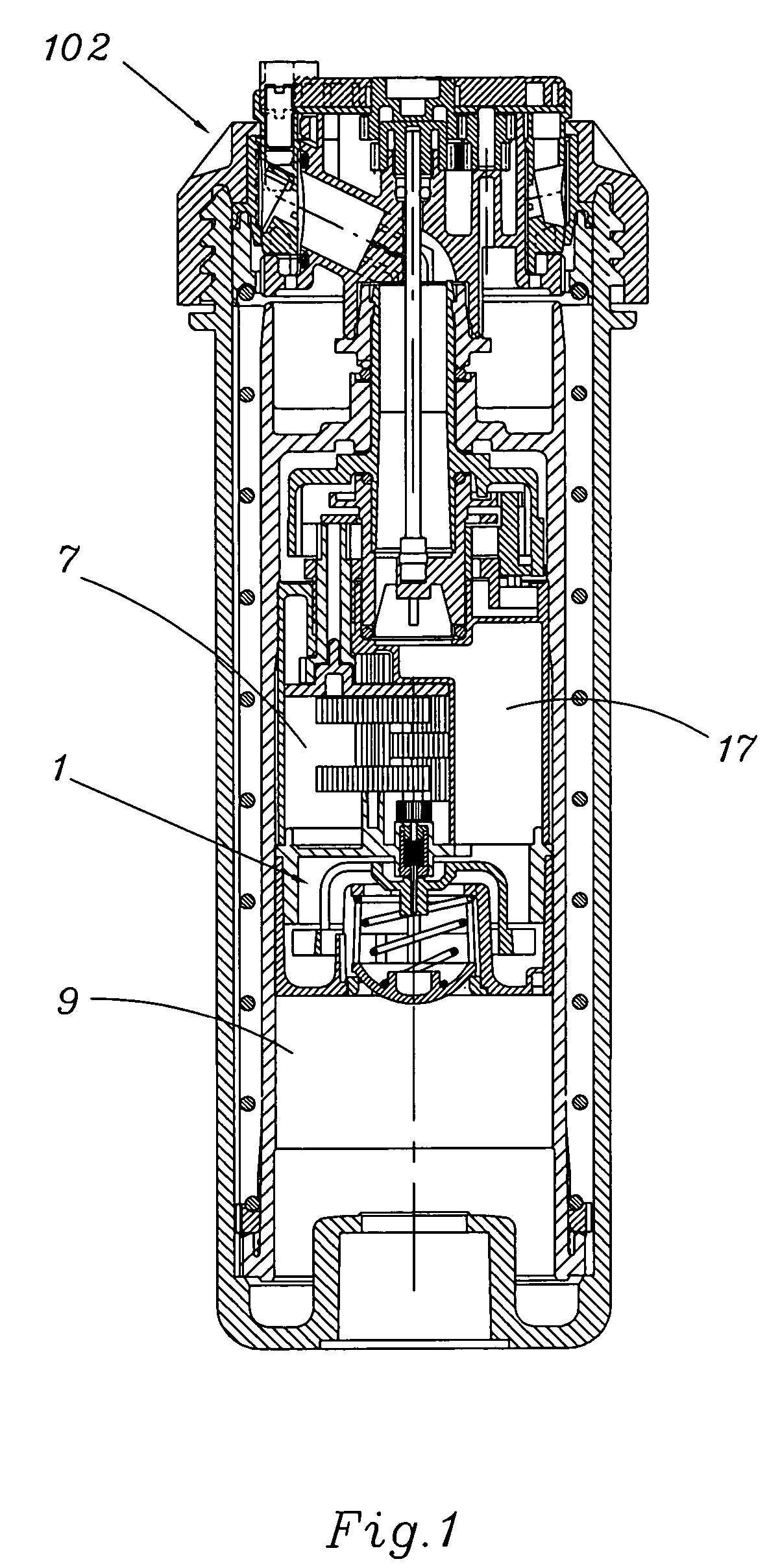

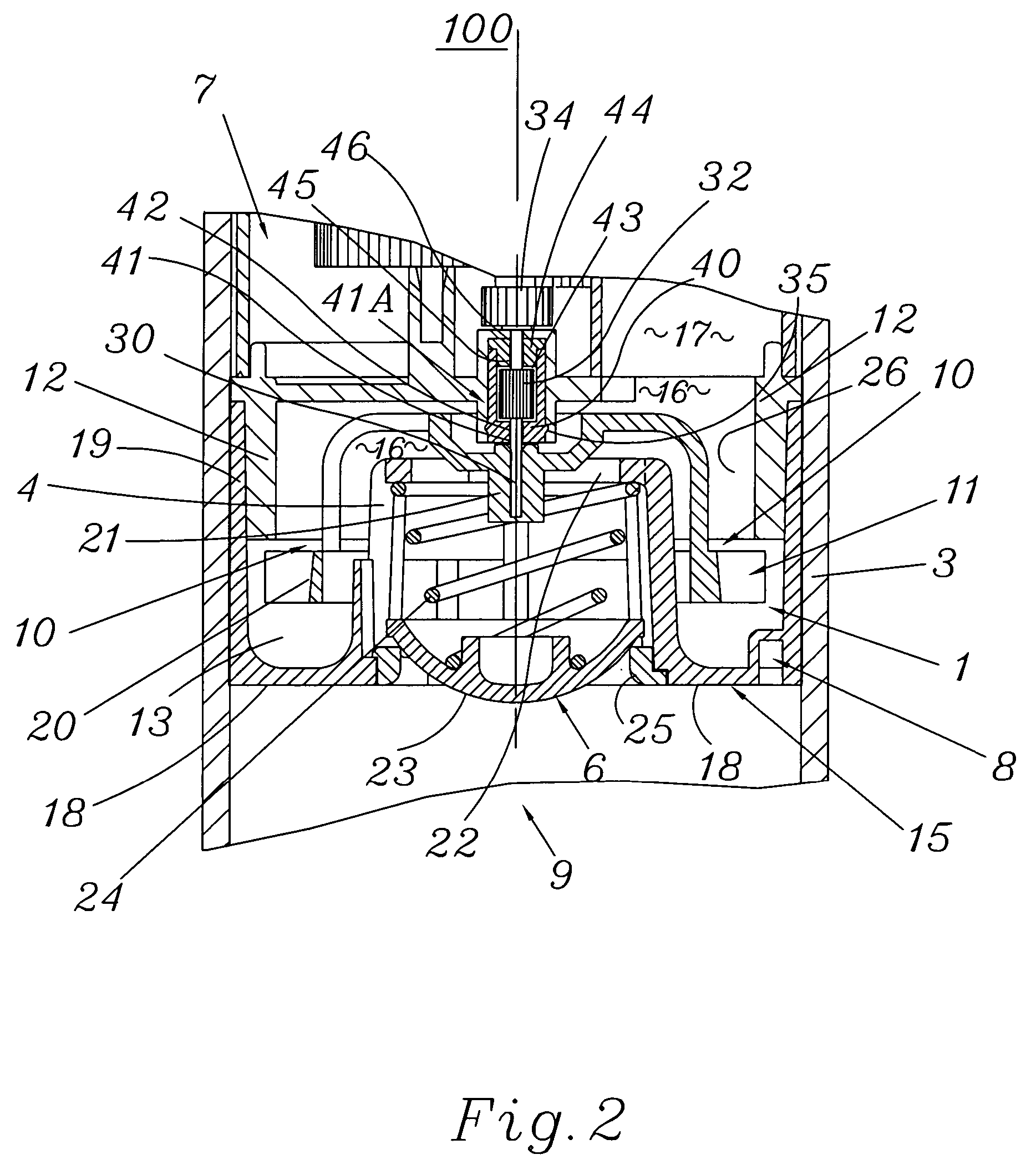

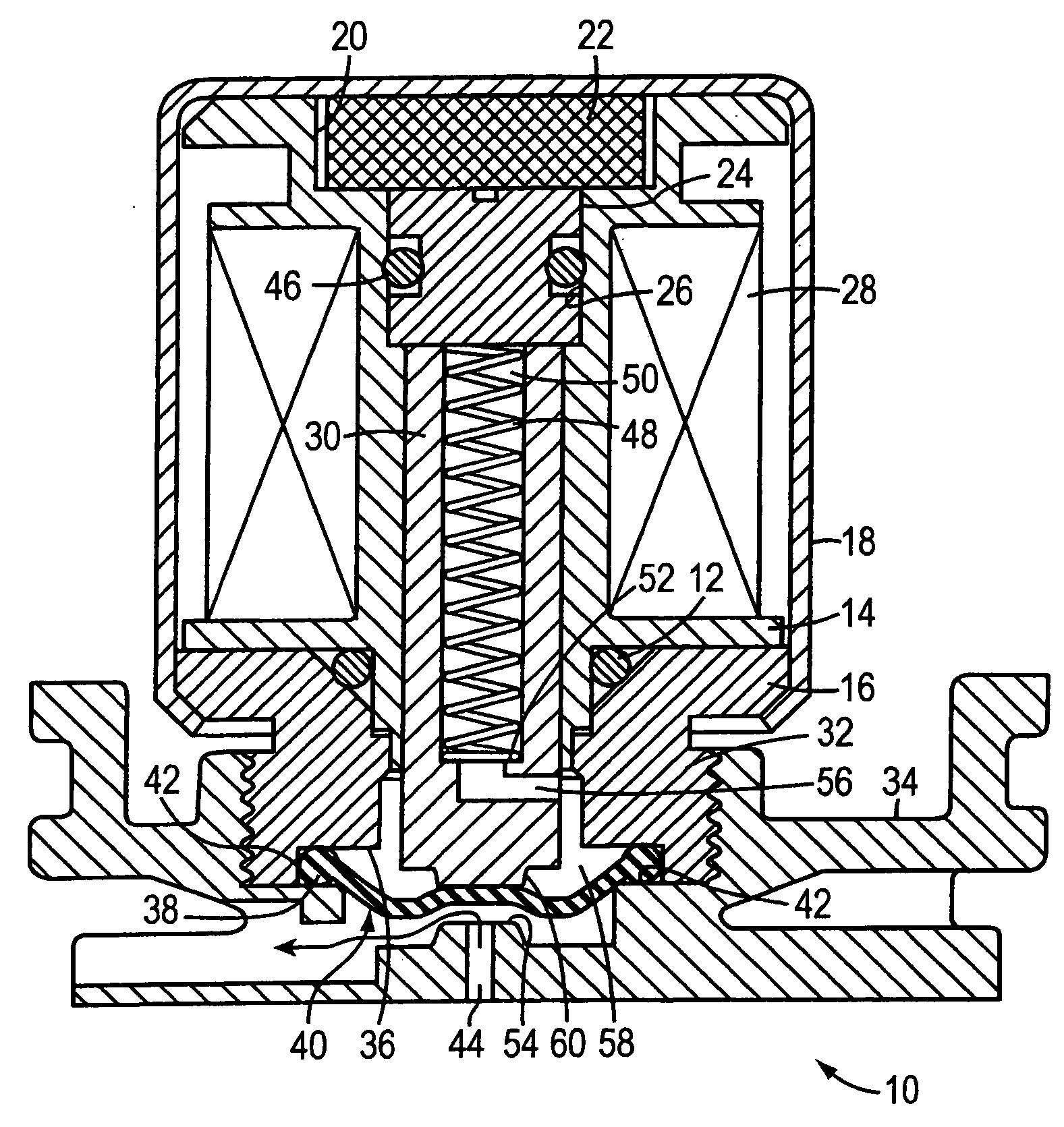

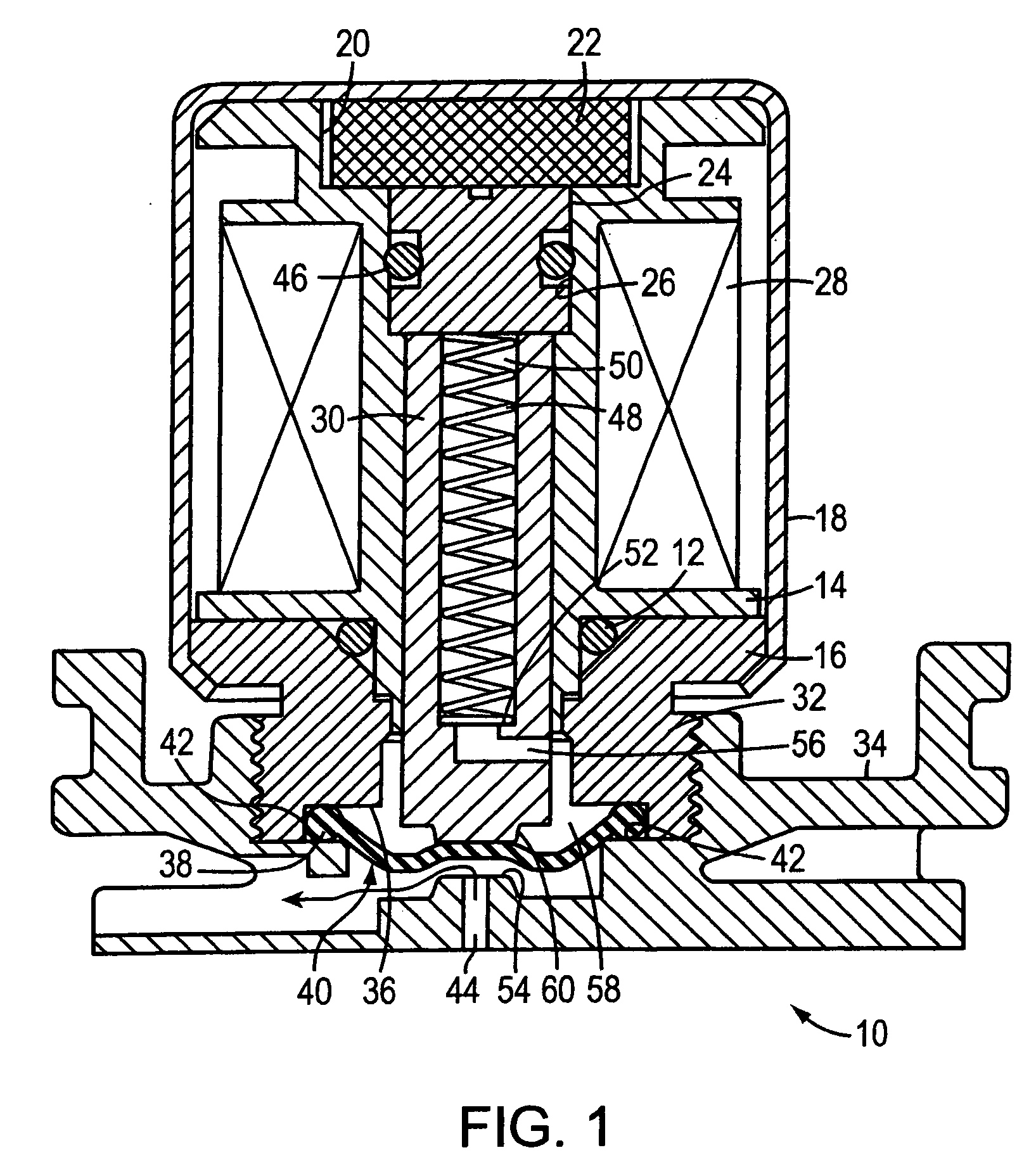

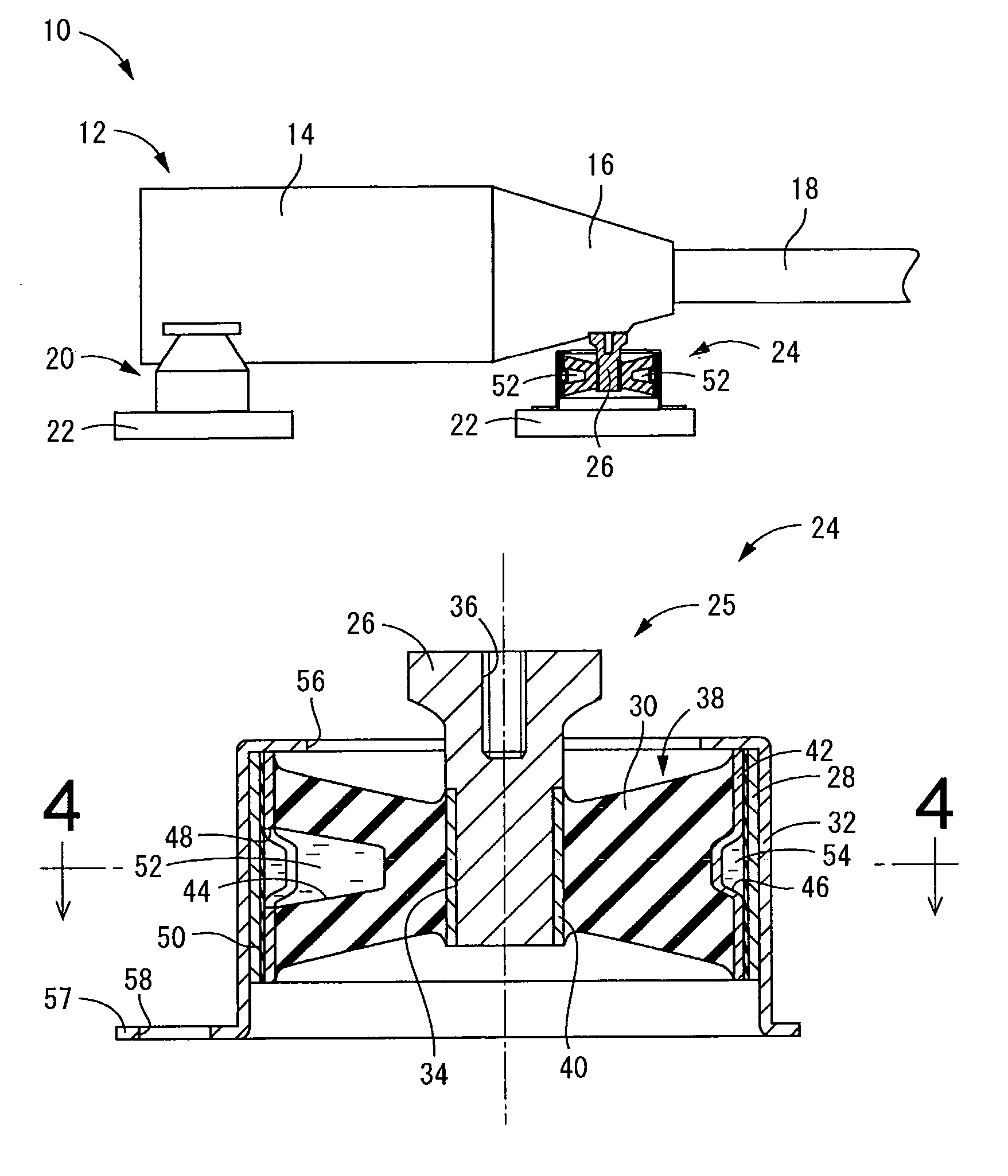

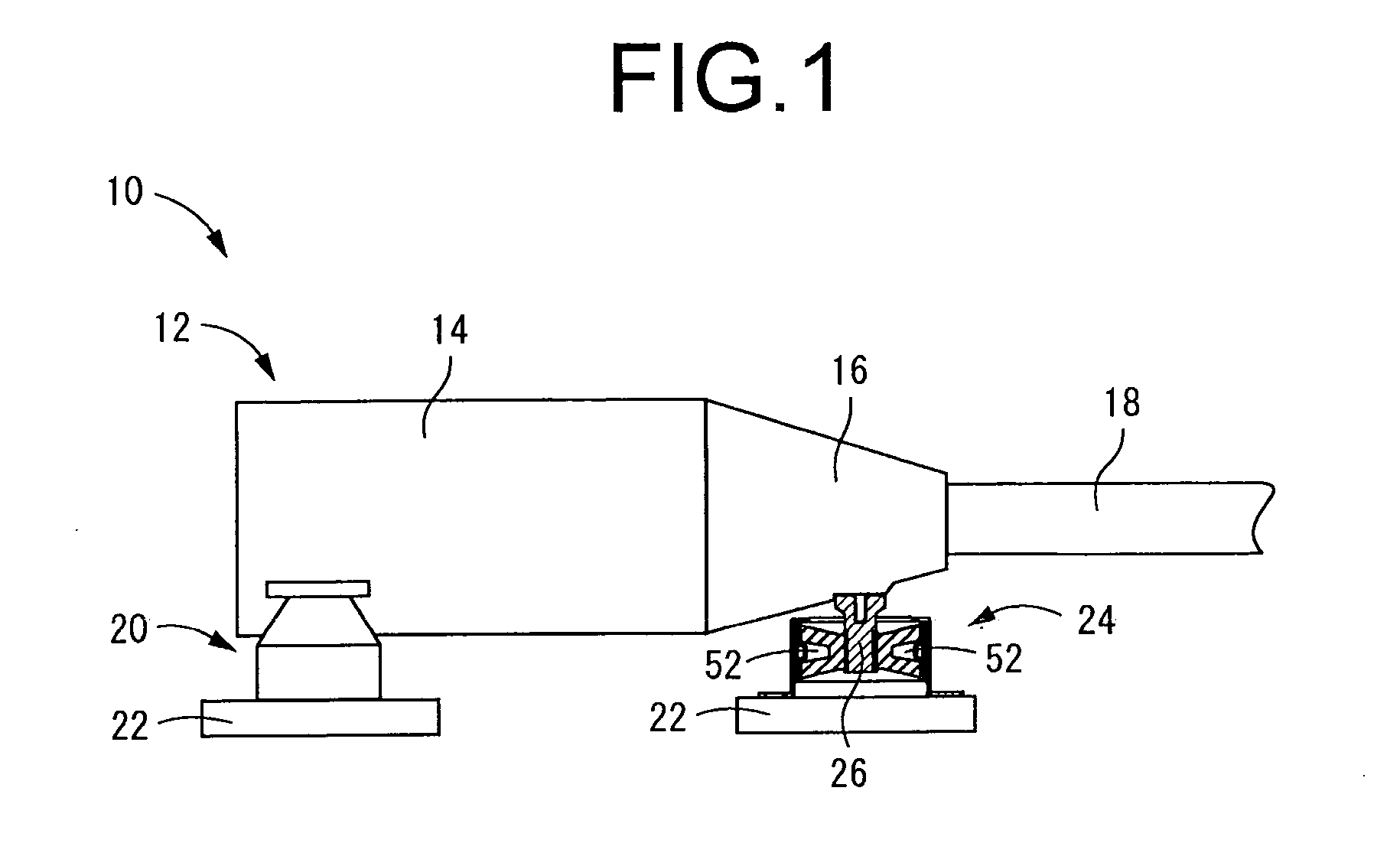

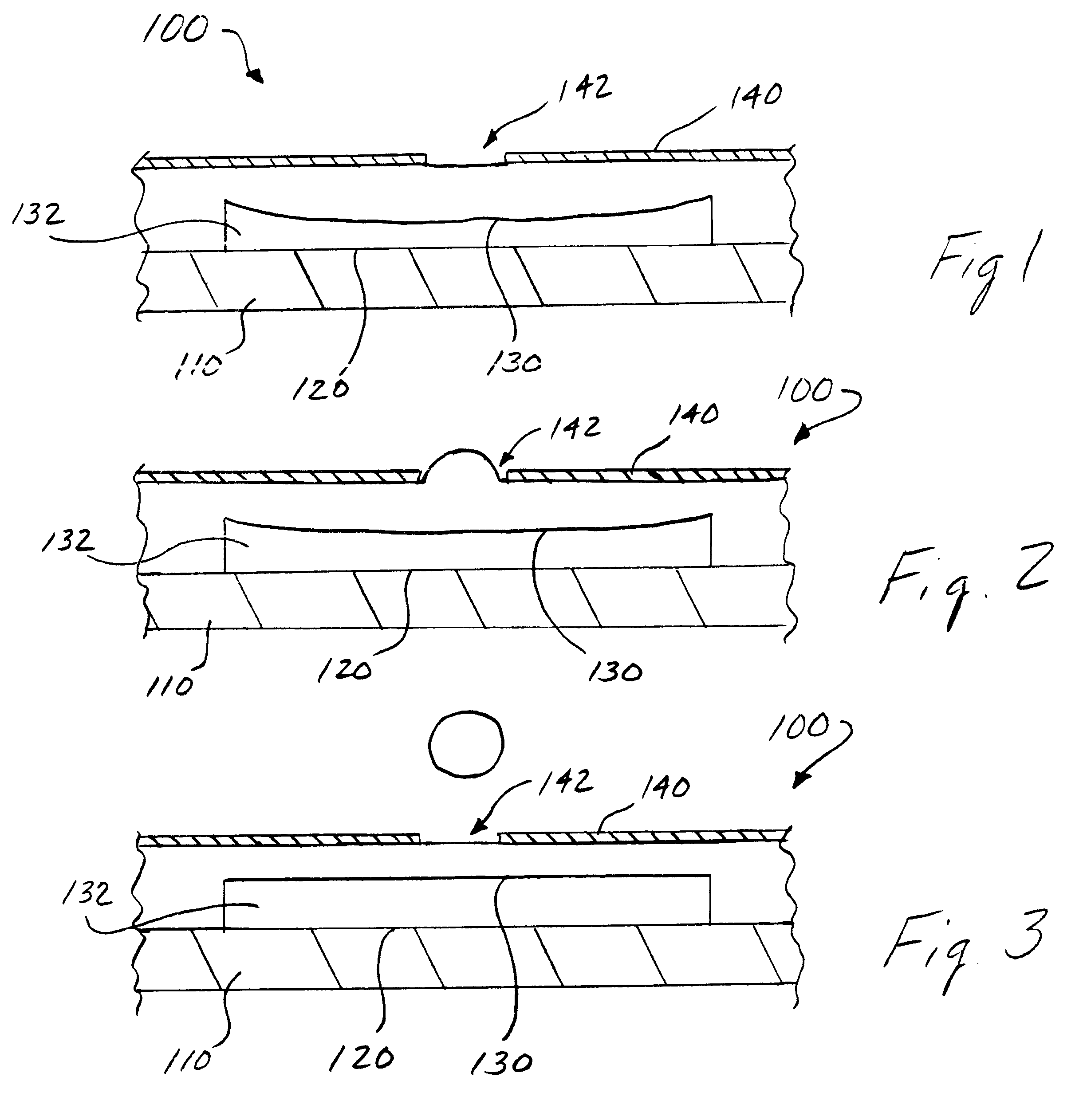

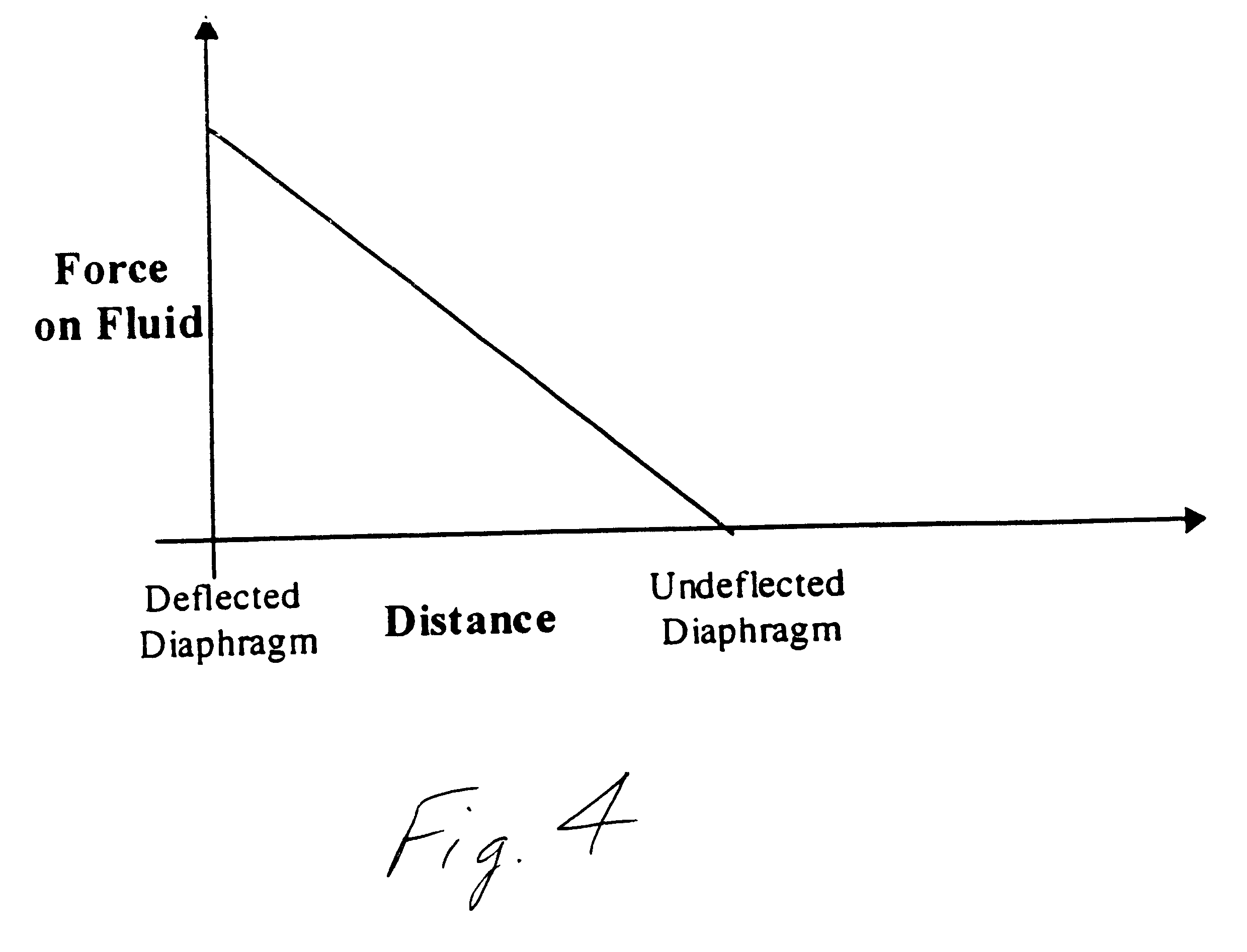

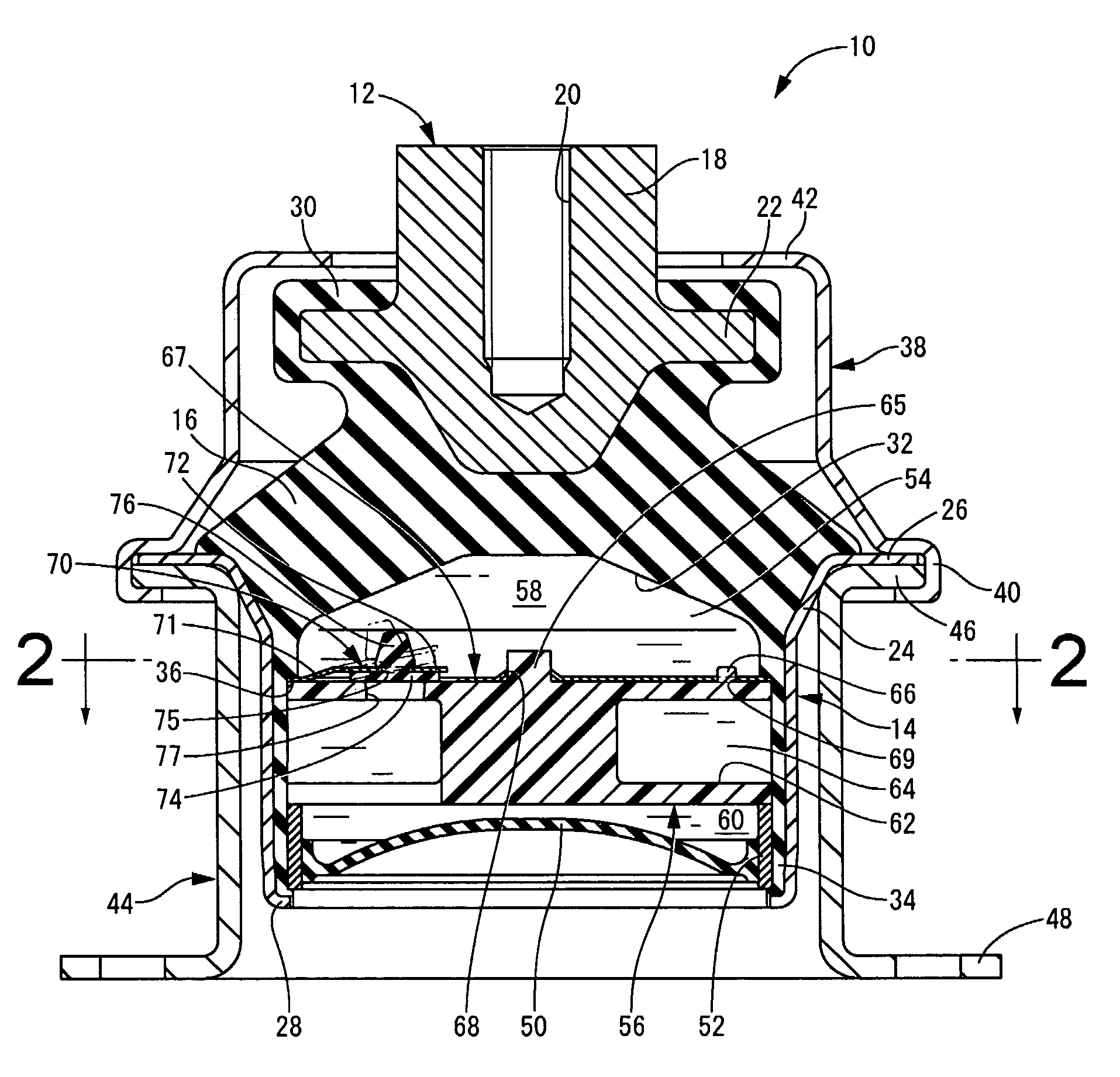

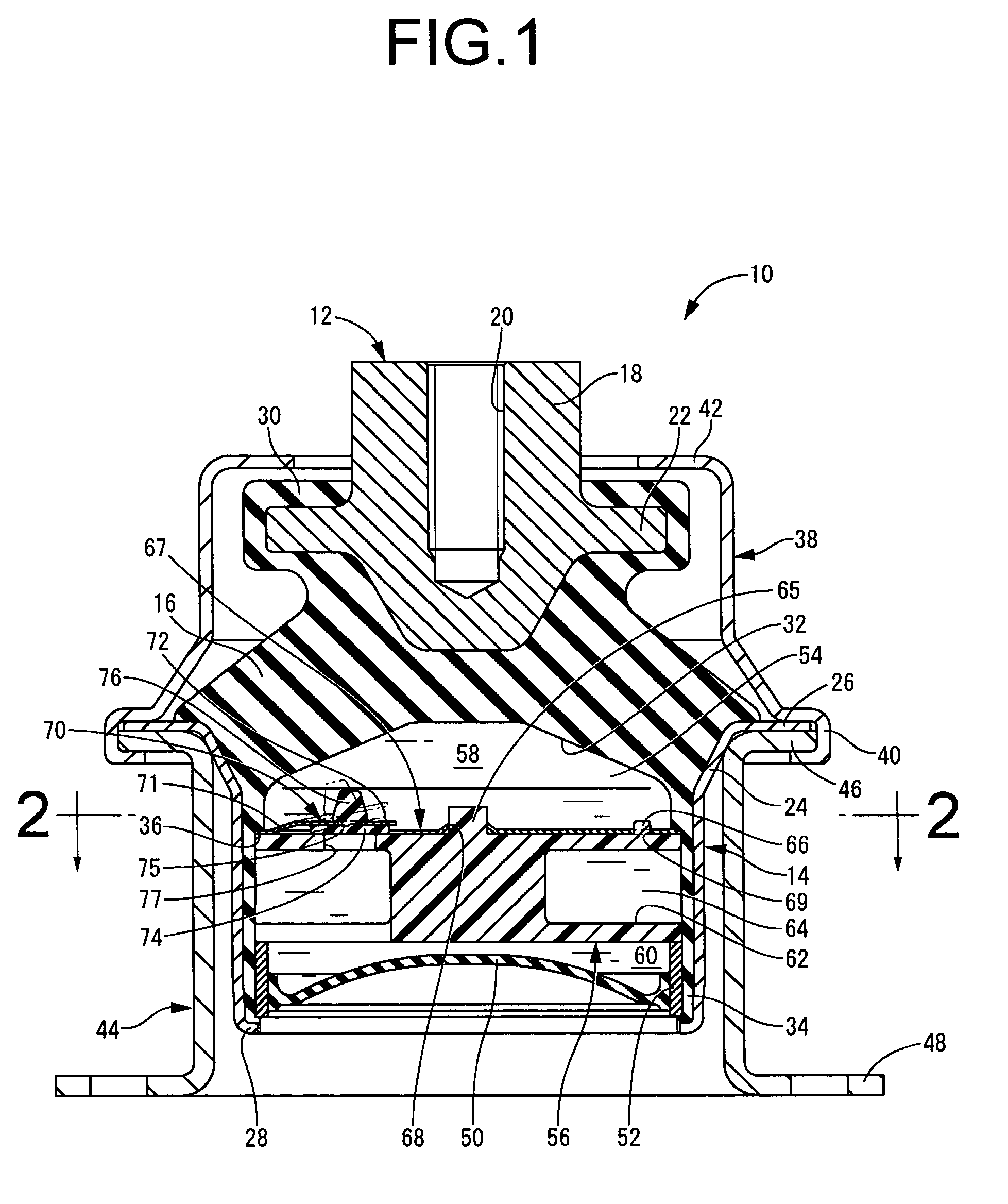

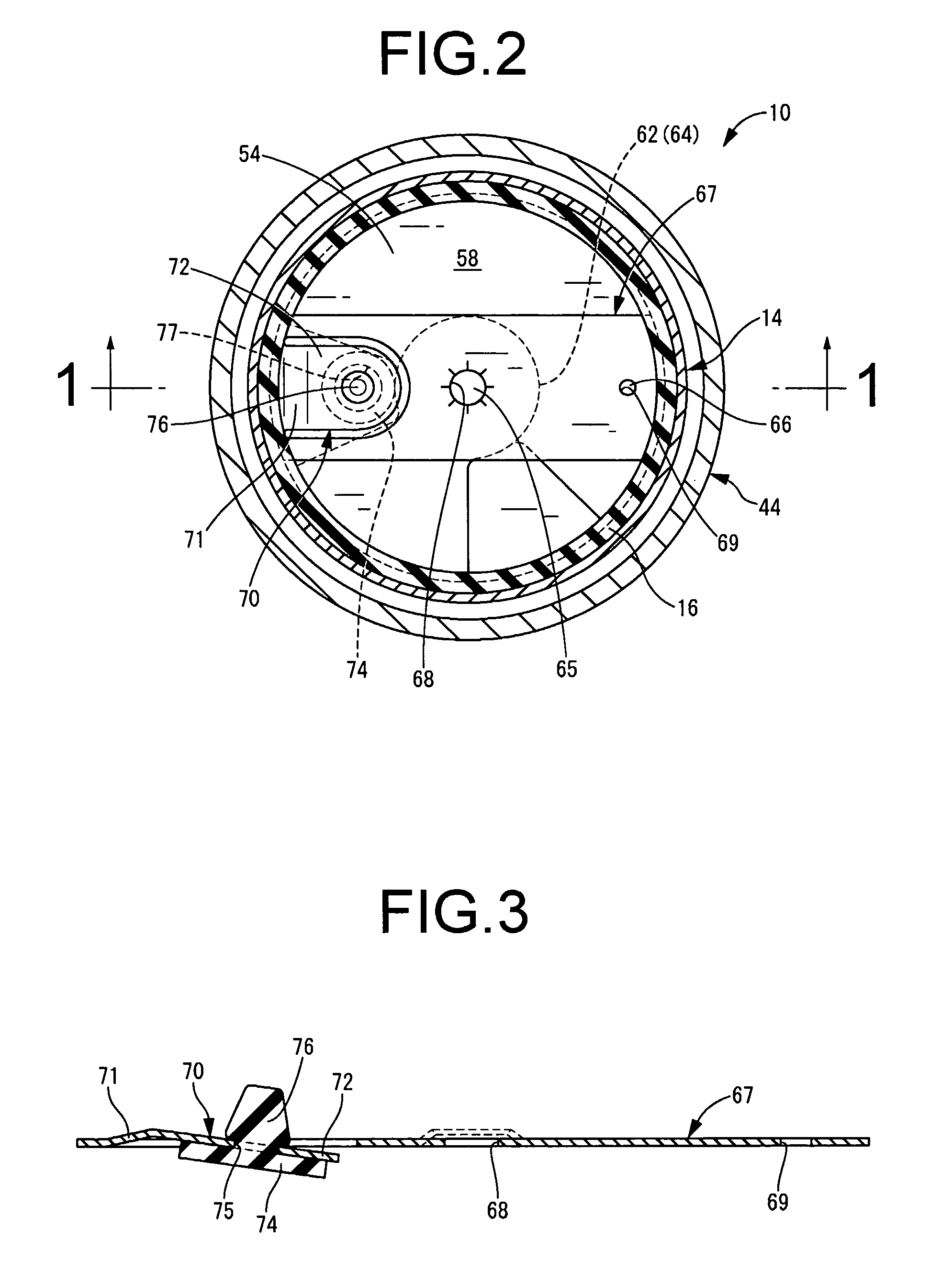

Valve actuator having small isolated plunger

InactiveUS6752371B2Operating means/releasing devices for valvesFlushing devicesValve actuatorReciprocating motion

A solenoid plunger (36) is disposed for reciprocation in a plunger pocket that is formed by the stationary parts of a solenoid-type actuator (10). A flexible diaphragm (22) closes the plunger pocket's open mouth and is deformed by movement of a plunger (36) between an open position, in which it is displaced from a valve seat (20), and a closed position, in which it is seated on the valve seat and thereby prevents flow from a valve inlet (16) to a valve outlet (18). The diaphragm thereby isolates the plunger from the fluid thereby being controlled, but a separate, incompressible fluid fills the chamber in which the plunger reciprocates. A through-plunger passage (44, 56) provides a low-flow-resistance path for the incompressible fluid to flow into and out of the portion (52) of the plunger chamber behind the plunger as the plunger moves. This reduces actuation time and thus the energy required for an actuation. The chamber in which the plunger reciprocates is formed by elements (22, 26, 32, and 34) through which the incompressible fluid can diffuse only very slowly, so the actuator can be long-lived even if it small in size.

Owner:ARICHELL TECH INC

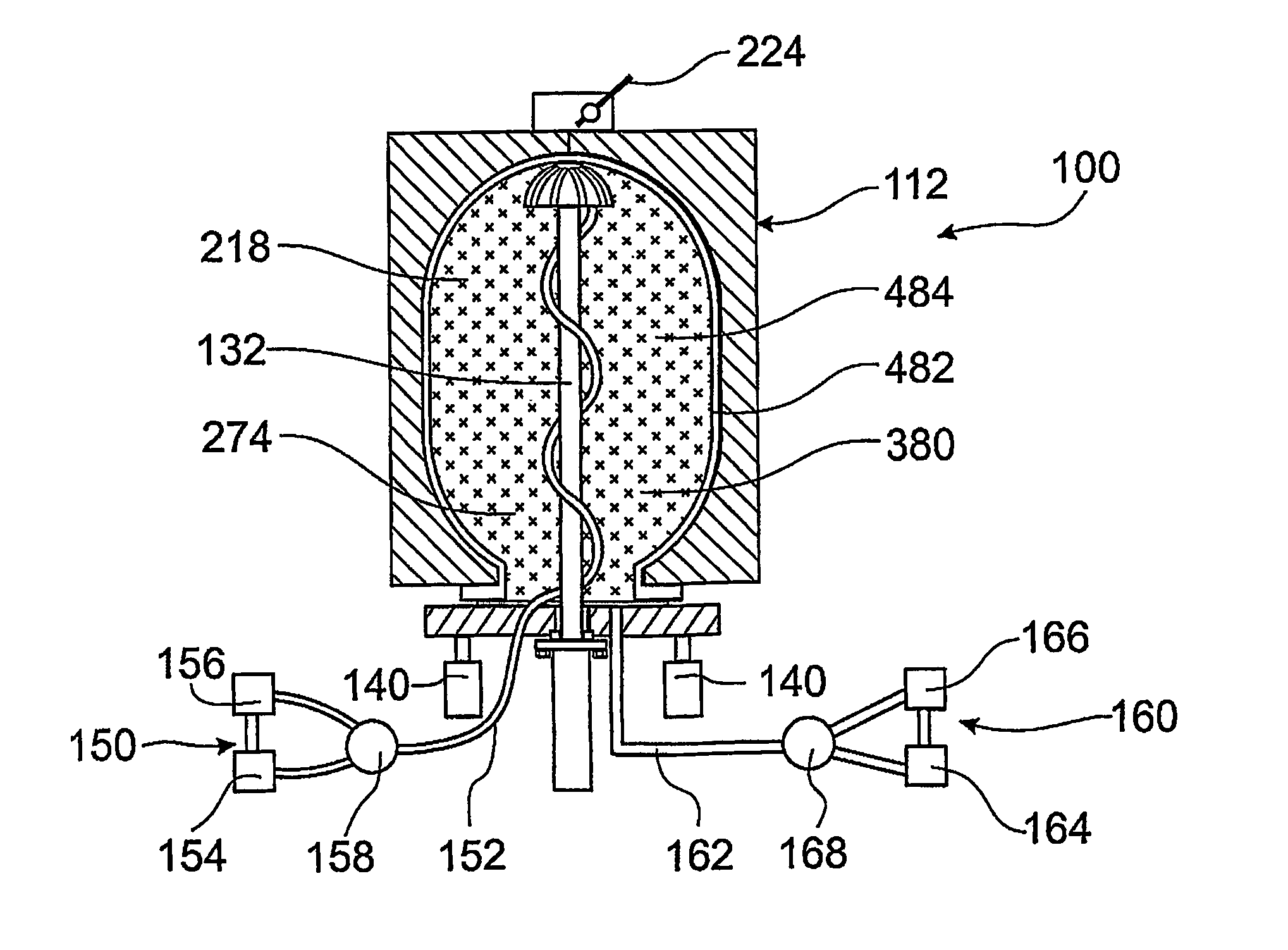

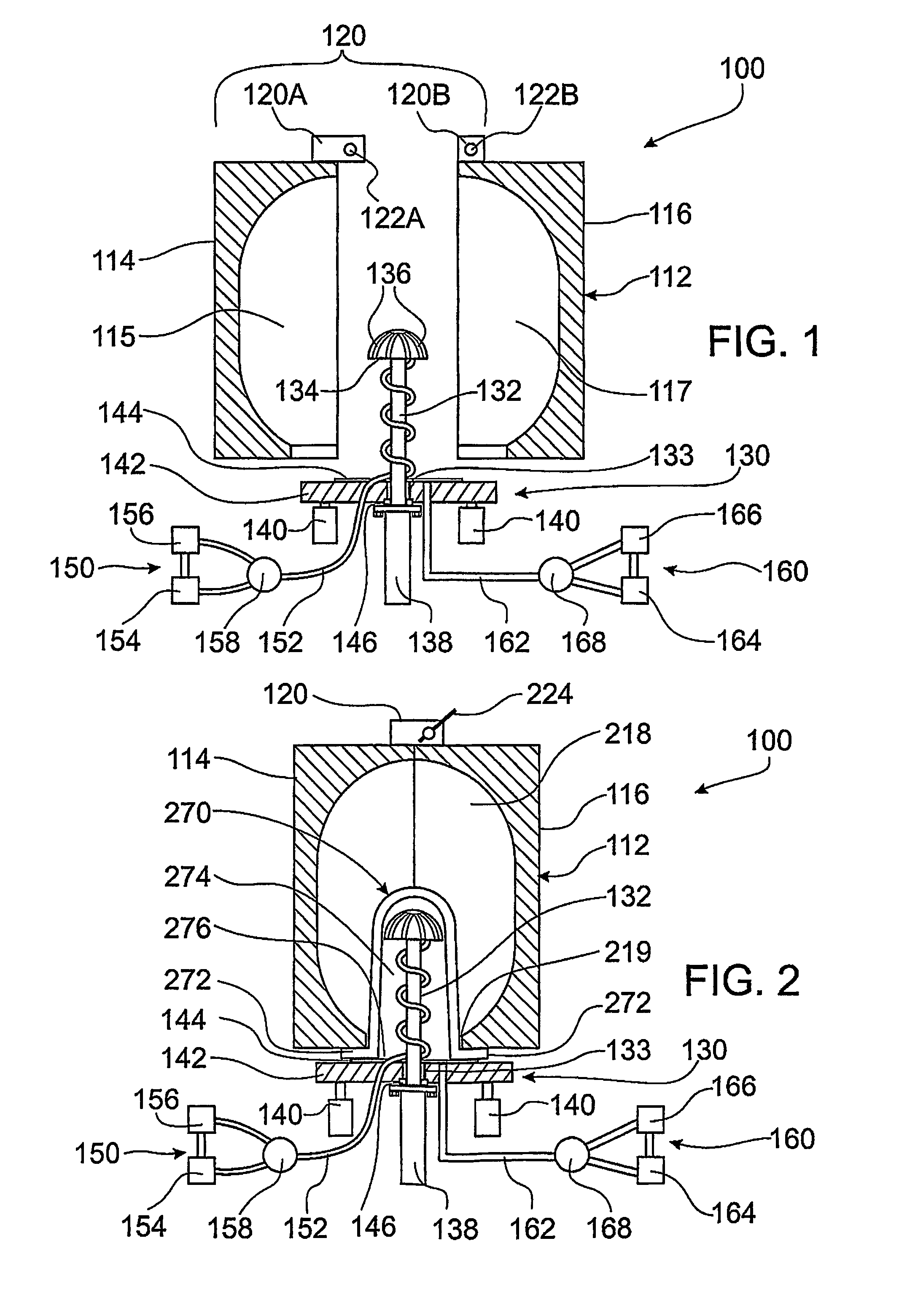

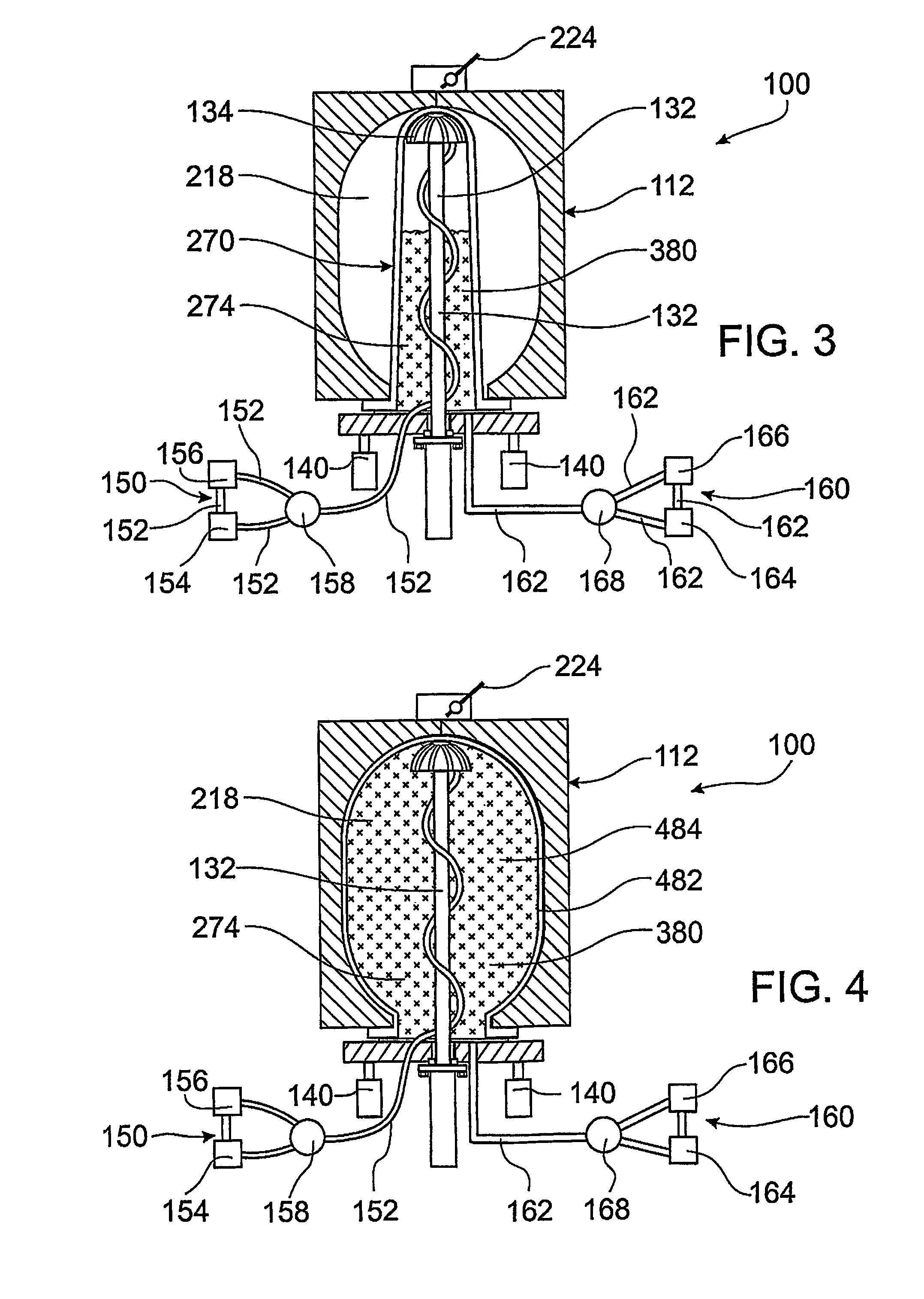

Pneumatically-operated fluid pump with amplified fluid pressure, and related methods

InactiveUS20160123313A1Increase and decrease volumeFlexible member pumpsPump controlEngineeringPiston

A fluid pump for pumping a subject fluid. The fluid pump including, a pump body, a first cavity within the pump body, a second cavity within the pump body, a flexible member, an incompressible fluid, a subject fluid chamber, and a piston. Piston may include a piston head and an elongated piston shaft. The piston may be configured to amplify a first pressure experienced on a first side of the piston head and exerted by a pressurized drive fluid to a second pressure experienced on an end surface of the elongated piston shaft and exerted on the incompressible fluid within the flexible member. The subject fluid may in turn be pressurized to a third pressure substantially equal to the second pressure.

Owner:WHITE KNIGHT FLUID HANDLING

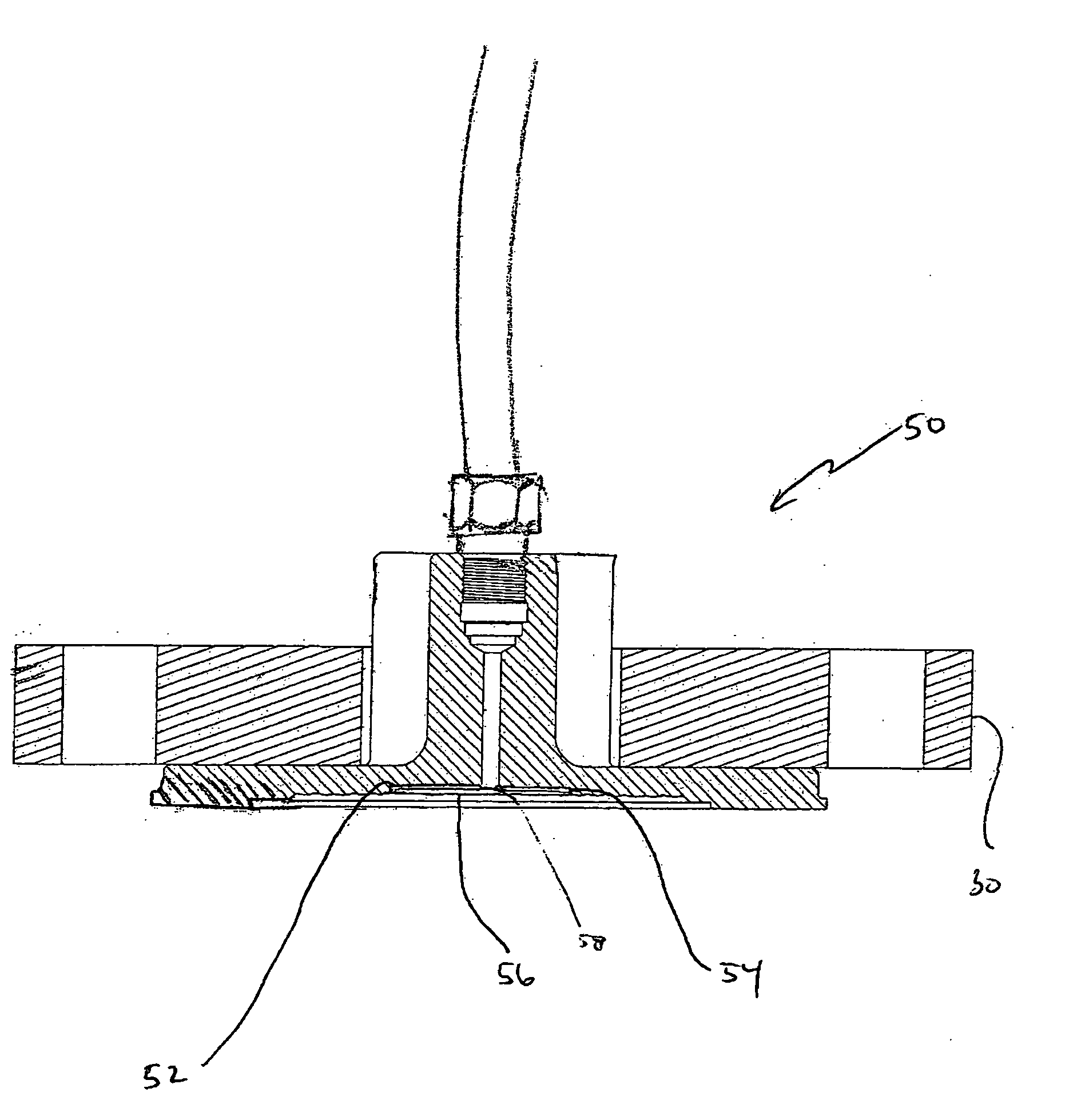

Remote process seal with improved stability in demanding applications

A remote process seal system is provided. The seal system includes at least one remote process seal assembly coupled to a process pressure transmitter via a coupling filled with an incompressible fluid. The incompressible fluid is contacted by at least one getter to reduce instabilities caused by the release of hydrogen gas accumulating over time. In one aspect, a layer of getter material is deposited or placed within the pressure transducing portion of the remote process seal assembly.

Owner:ROSEMOUNT INC

Apparatus for dispensing precise amounts of a non-compressible fluid

InactiveUS20050072815A1Easy to useMaterial is facilitatedContracting/expanding measuring chambersMovable measuring chambersMotor driveEngineering

A dispensing apparatus has a motor drive that moves an output member along an axis in a first chamber. A shuttle valve controls flow between a first chamber and either a reservoir of material or an output port. Extending the output member discharges precise volumes of material through an output port. Retracting the output member fills the first chamber.

Owner:CAREW DENNIS +2

Method and Apparatus for Surgical Electrocautery

ActiveUS20090182333A1Surgical instruments for heatingSurgical forcepsElectrocauterizationEngineering

The invention provides a surgical electrocautery method and apparatus that achieves sealing along the entire tissue length, and that also is able to deliver adequate force to produce an effective electrocautery seal. This problem is solved by using an incompressible fluid contained in a sac or sacs positioned to support the one or more electrodes used for electrocauterization. The profile of the electrodes thus conforms to the tissue surface and thickness variations, while exerting an optimized pressure along the entire length of the surface.

Owner:AESCULAP AG

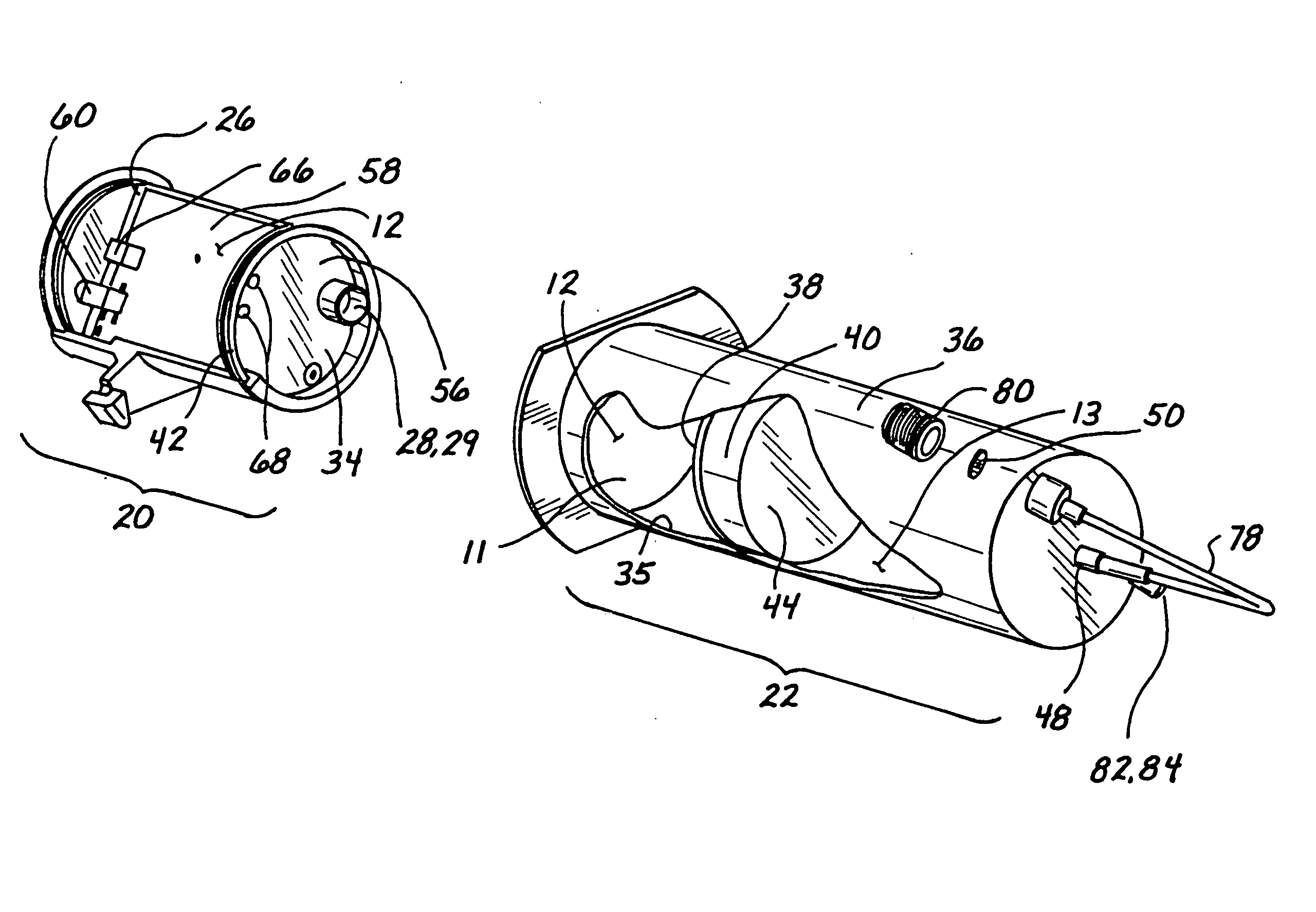

Ferromagnetic/fluid valve actuator

InactiveUS6932316B2Diaphragm valvesOperating means/releasing devices for valvesValve actuatorReciprocating motion

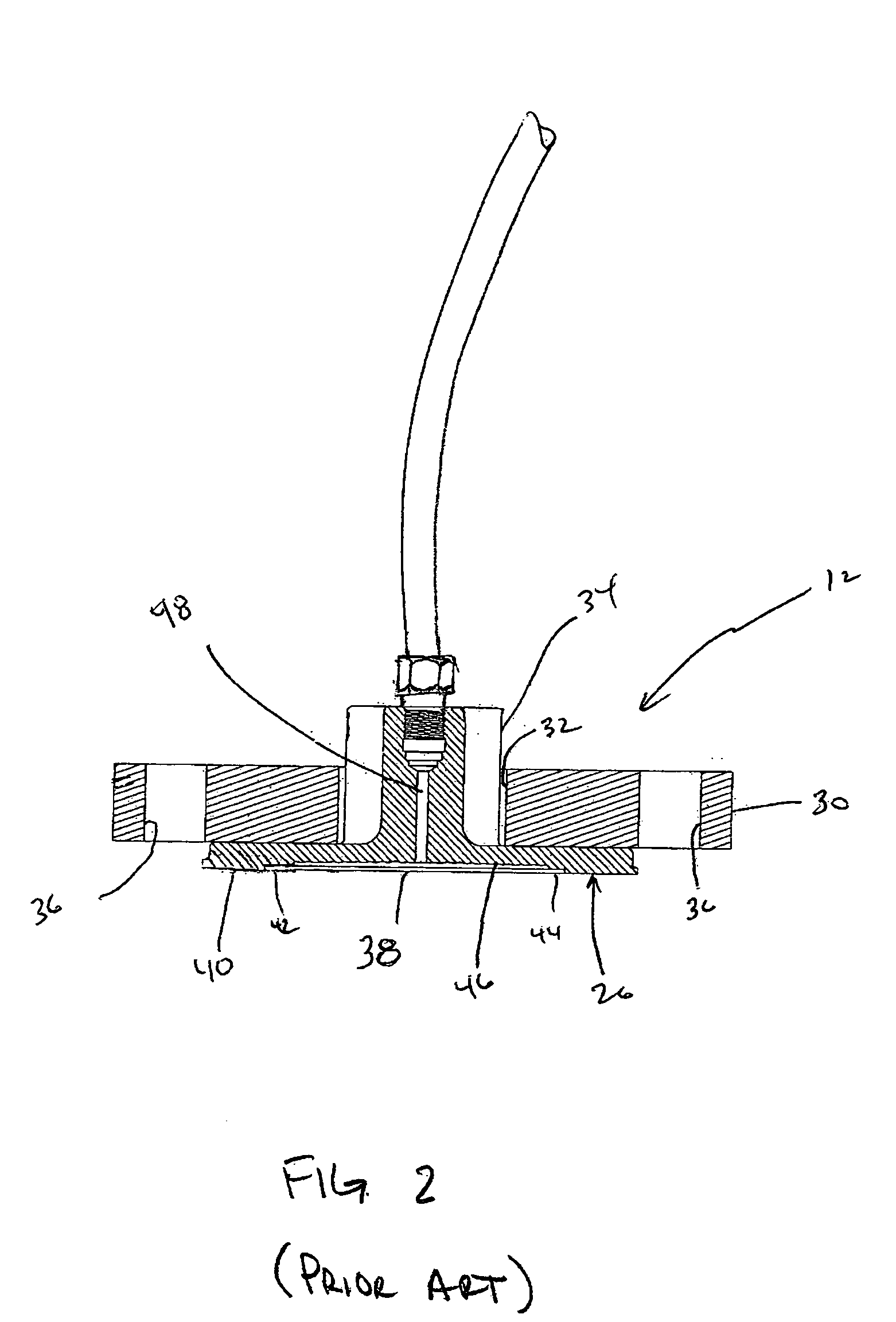

A solenoid plunger (36) is disposed for reciprocation in a plunger pocket that is formed by the stationary parts of a solenoid-type actuator (10). A flexible diaphragm (22) closes the plunger pocket's open mouth and is deformed by movement of a plunger (36) between an open position, in which it is displaced from a valve seat (20), and a closed position, in which it is seated on the valve seat and thereby prevents flow from a valve inlet (16) to a valve outlet (18). The diaphragm thereby isolates the plunger from the fluid thereby being controlled, but a separate, incompressible fluid fills the chamber in which the plunger reciprocates. A through-plunger passage (44, 56) provides a low-flow-resistance path for the incompressible fluid to flow into and out of the portion (52) of the plunger chamber behind the plunger as the plunger moves. This reduces actuation time and thus the energy required for an actuation. The chamber in which the plunger reciprocates is formed by elements (22, 26, 32, and 34) through which the incompressible fluid can diffuse only very slowly, so the actuator can be long-lived even if it small in size.

Owner:ARICHELL TECH INC

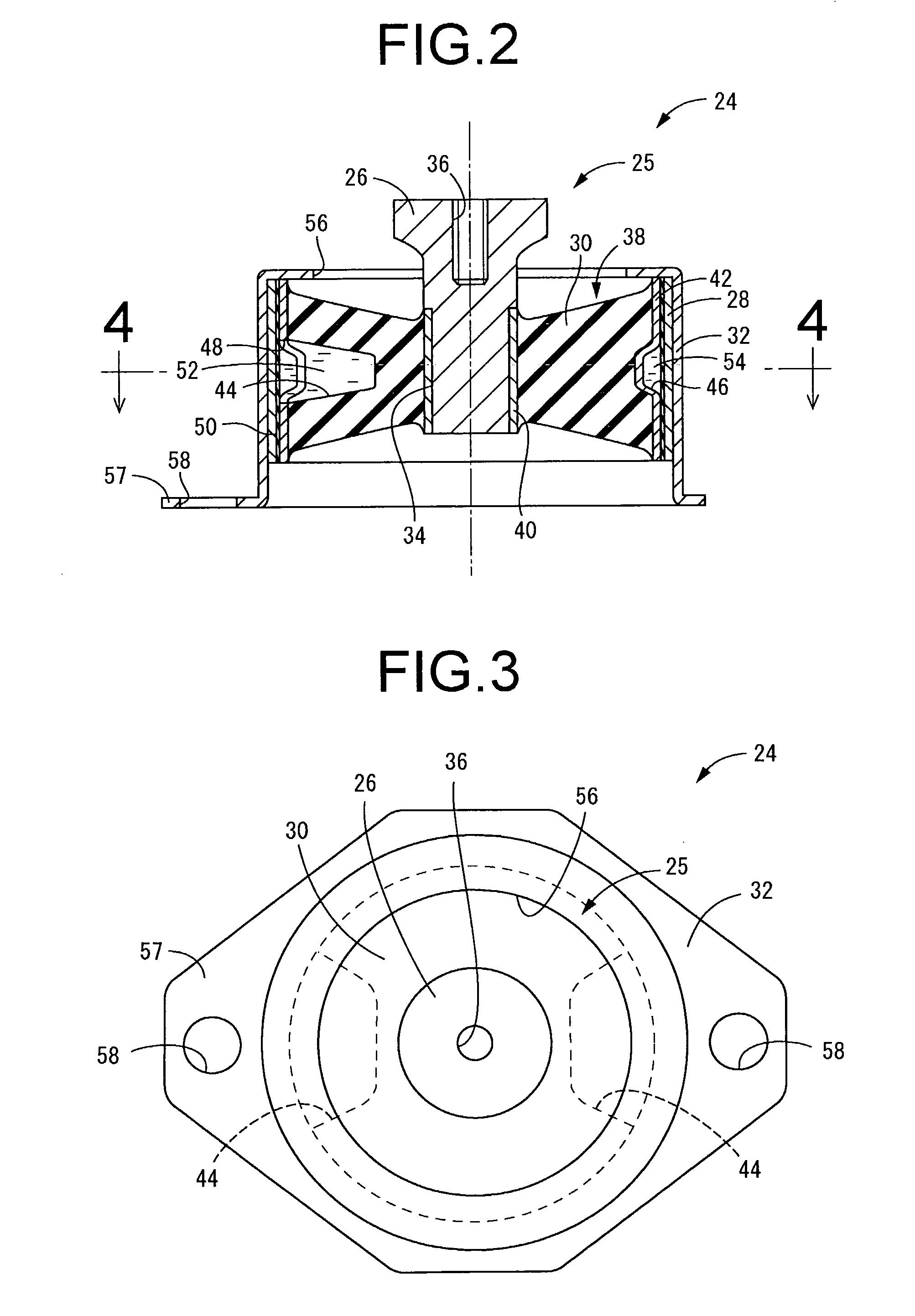

Fluid filled vibration damping device

InactiveUS20040262830A1Moderating deterioration in damping performancePortable framesLiquid springsElastomerEngineering

A fluid filled vibration-damping device includes an elastic body disposed between a first mounting member and a second mounting member and partially defines a fluid chamber having a non-compressible fluid sealed therein, and exhibits vibration damping action on the basis of flow action of the non-compressible fluid created within the fluid chamber during vibration input. At least one mounting member from among the first and second mounting members is formed independently of the elastic body and is disposed in abutment with the elastic body in an initial load acting direction, while making the mounting member displaceable away from the rubber elastic body in a opposite direction from the initial load acting direction. A rebound stop mechanism for limiting displacement of the mounting member away from the rubber elastic body in a cushion-wise fashion is disposed between the first and second mounting members.

Owner:SUMITOMO RIKO CO LTD

Stretch blow moulding method and apparatus

InactiveUS7981356B2More reliabilityProduced economicallyDomestic articlesHollow articlesMaterials scienceIncompressible flow

Owner:INVOPLAS

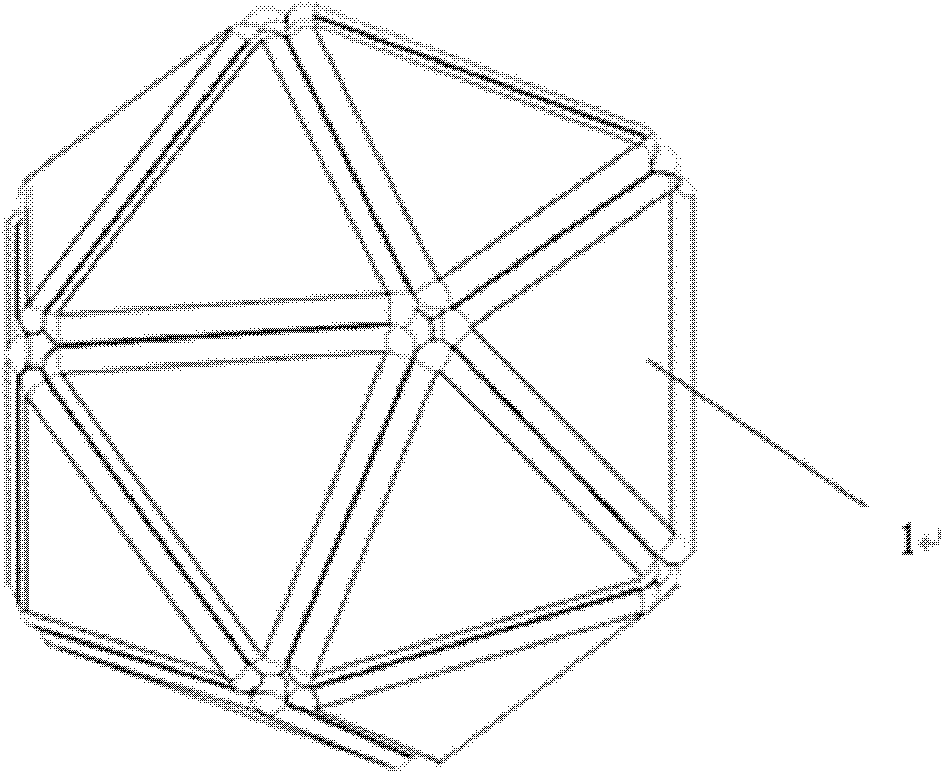

Bionic soft robot based on hydrostatic skeleton mechanism property

ActiveCN102176152AReduced form factor designAchieve progressProgramme total factory controlCell cavityEngineering

The invention relates to a bionic soft robot, and in particular relates to a bionic soft robot based on the hydrostatic skeleton mechanism property which is applied to non-structuring operation environments, such as pipeline overhauling, medical treatment, ruins searching and rescuing, military reconnaissance, aiming to provide the bionic soft robot based on the hydrostatic skeleton mechanism property which can be deformed continuously, and is convenient to use in non-structuring occasions. The bionic soft robot is provided with an elastic outer shell which is internally provided with an incompressible fluid and a loading device which is used for accomplishing the specific tasks of the robot; the elastic outer shell is composed by the splicing of cell units; each cell unit is provided with an elastic cell outer wall and a cell cavity; the cell cavity is internally provided with a magnet rheological fluid, a micro electromagnetic driving device and a cell unit controller, wherein the micro electromagnetic driving device is used for generating electromagnetic field for promoting the magnet rheological fluid to generate 'solid-liquid form conversion'; and the cell unit controller is used for receiving and transmitting instruction signals and controlling the operation of the micro electromagnetic driving device.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

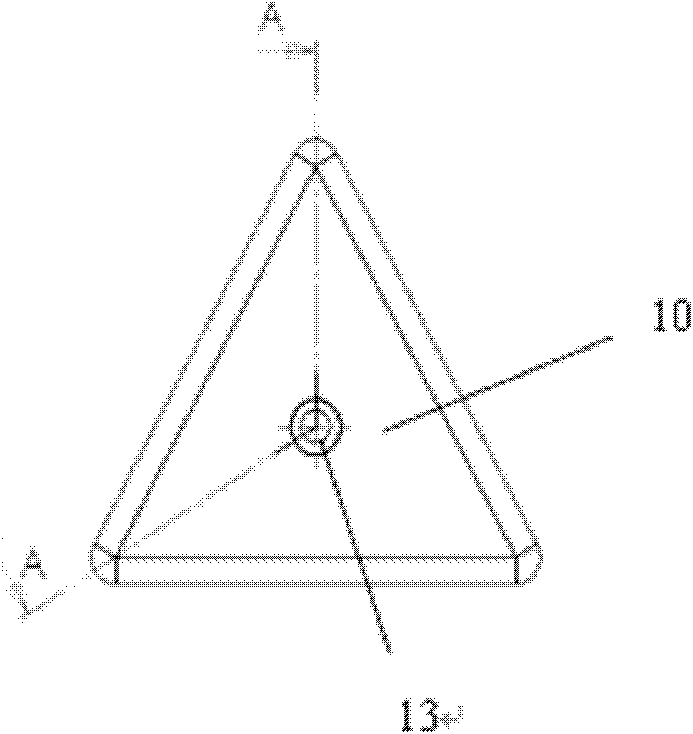

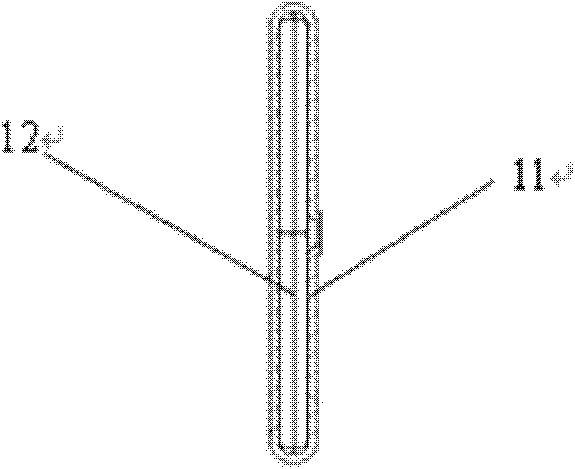

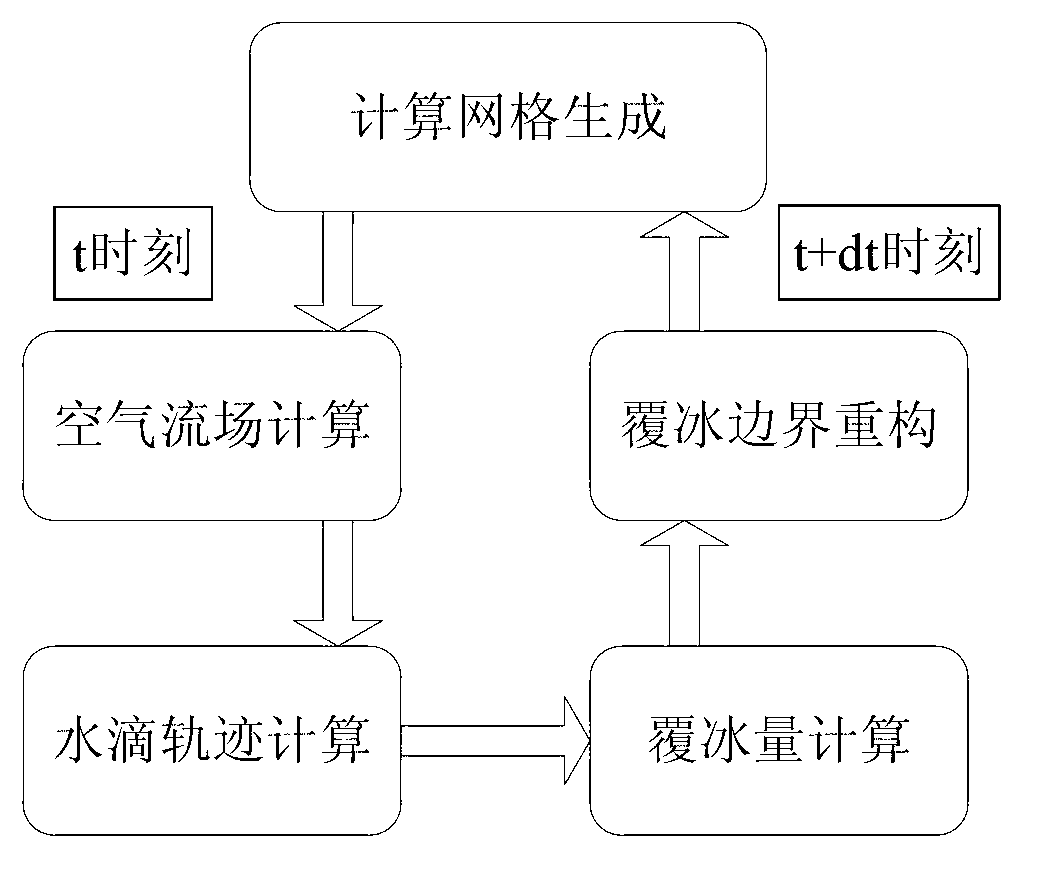

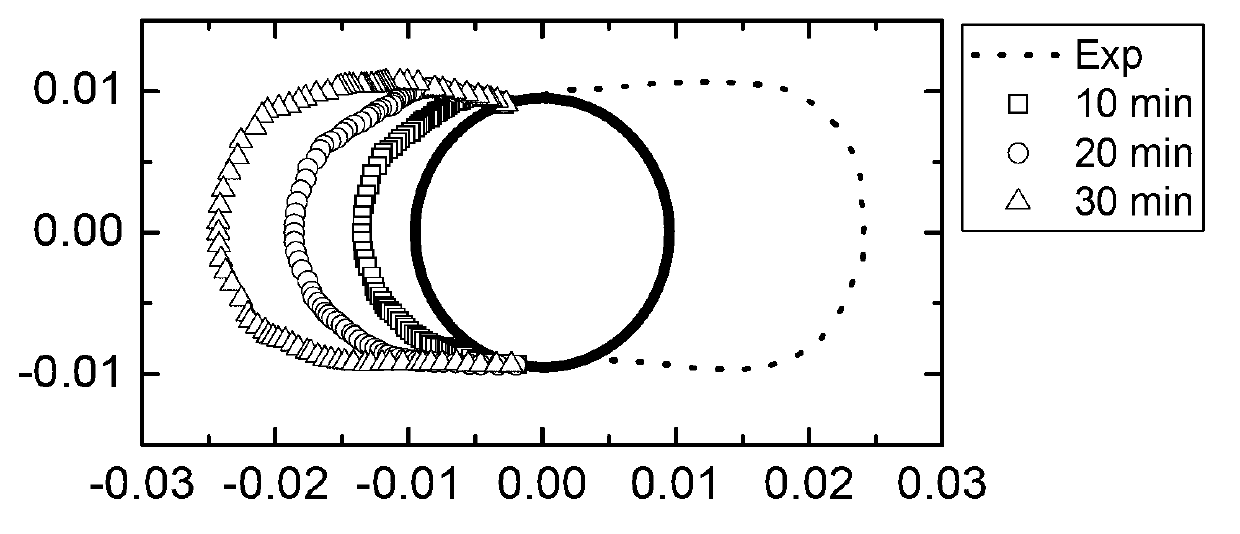

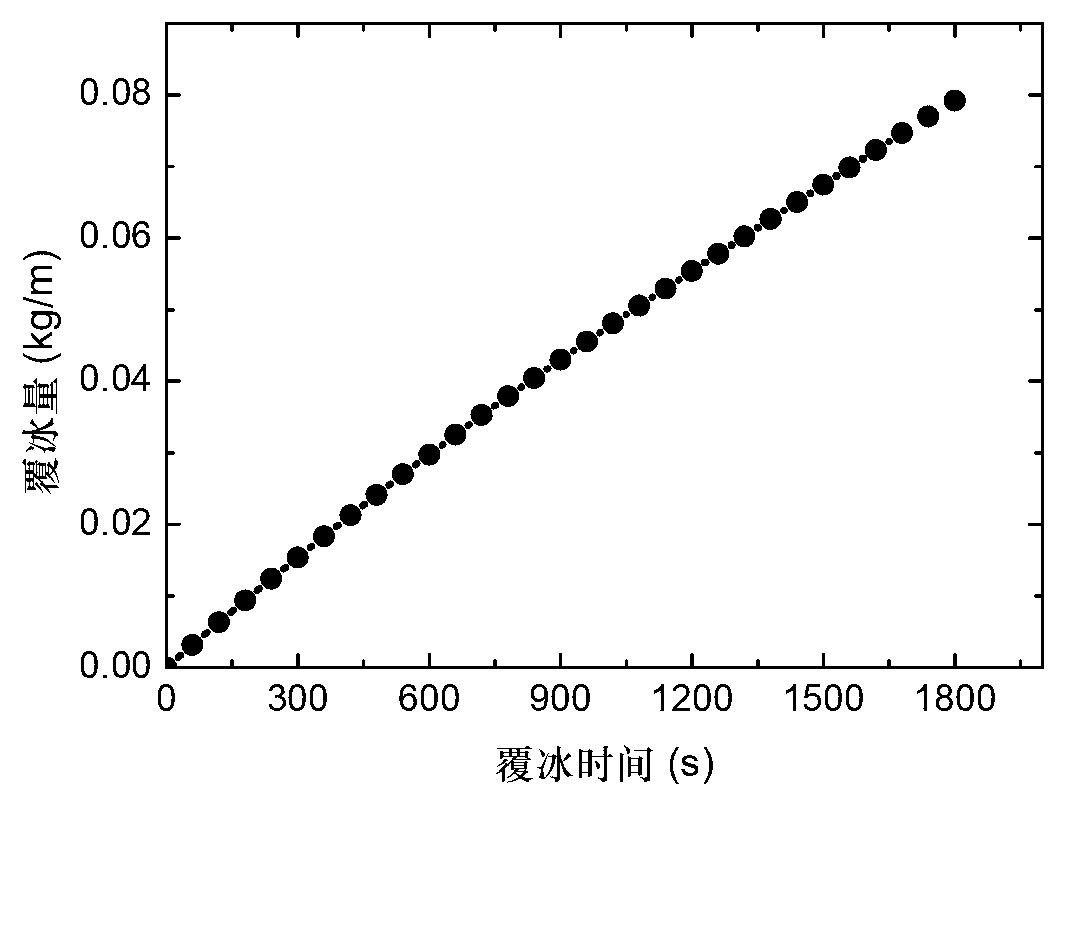

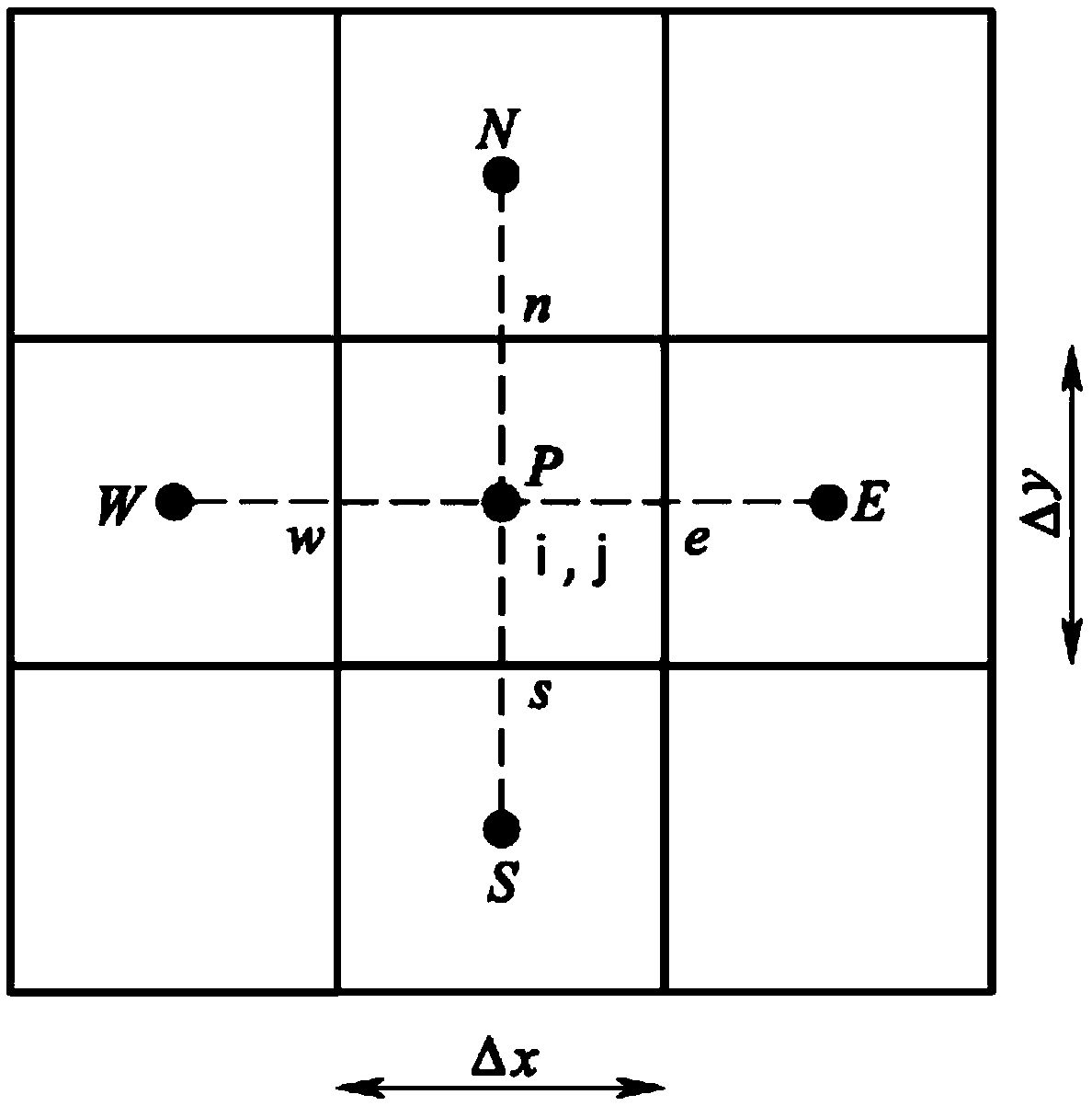

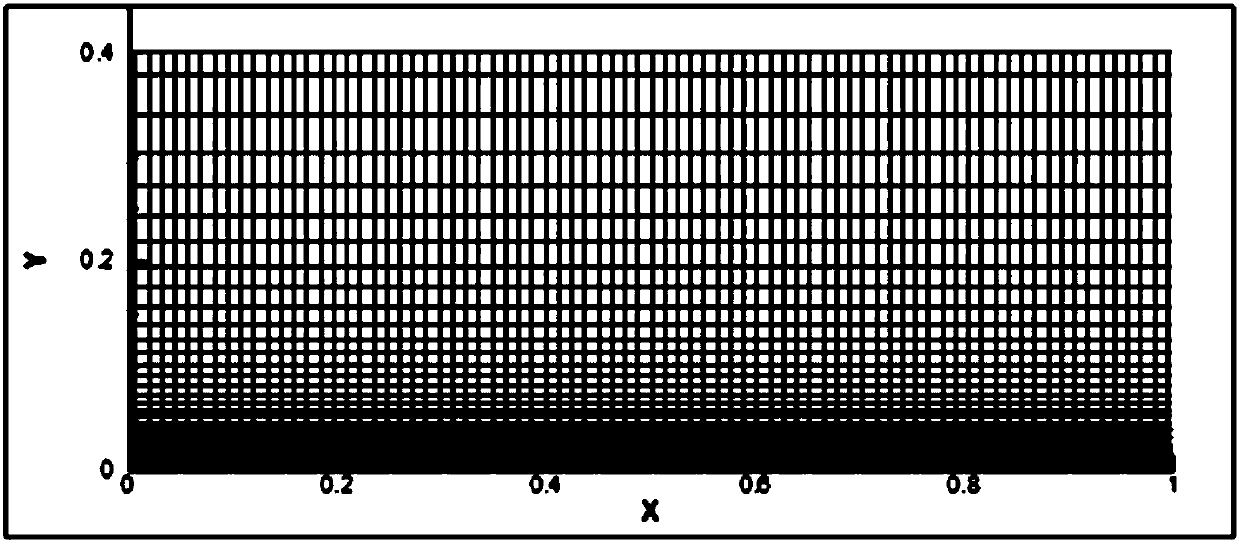

Two-dimensional numerical simulation method for icing process of power transmission line

The invention belongs to the field of electric power systems and relates to a two-dimensional numerical simulation method for an icing process of a power transmission line. Based on the lagrangian method, the invention provides the two-dimensional numerical simulation method for a surface rime icing process of the power transmission line. A Reynolds-averaged Navier-Stokes (RANS) equation and shear-stress-transport-k-omega (SST-k-omega) turbulence model of non-steady incompressible flow is solved by adopting a semi-implicit method for pressure linked equations (SIMPLE) algorithm on a staggered grid so as to obtain an air flow field; movement tracks of super-cooled water droplets in the flow field are tracked by adopting the lagrangian method to obtain the transient local collision rate of all control volumes on the surface of the power transmission line; solving is performed based on an icing thermodynamic equation established by a Messinger control volume method so as to obtain the rime icing temperature of all the control volumes, and the icing process is simulated by combining an icing time marching method. Indicated by results, predicted ice shapes are better fitted with test measurement data in literature, and therefore, the two-dimensional numerical simulation method for the icing process of the power transmission line is feasible and effective.

Owner:STATE GRID CORP OF CHINA +2

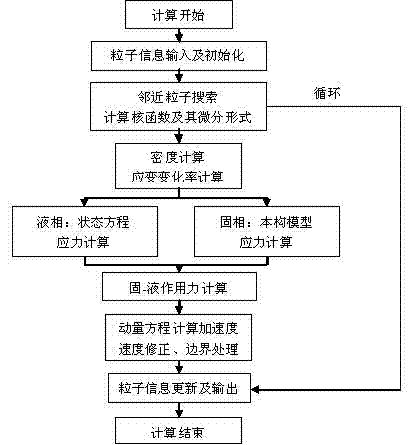

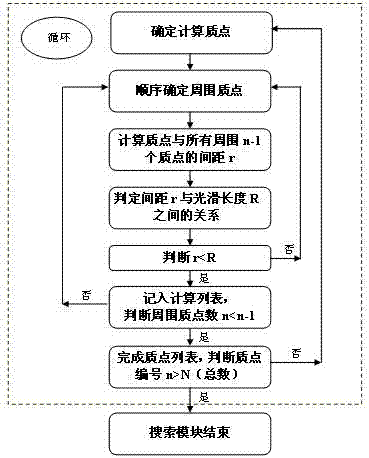

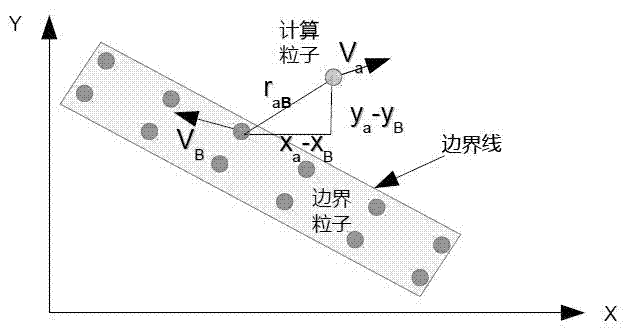

Computational simulation method of flow slide catastrophe of rock and soil material

ActiveCN102819650AAccurate calculation of impact loadsReasonable prediction of flow-slip distanceSpecial data processing applicationsSmoothed-particle hydrodynamicsSoil mechanics

The invention relates to a computational simulation method of a flow slide catastrophe of a rock and soil material, belonging to the technical fields of computational rock and soil mechanics, geologic hazard prevention and control and geologic environment protection. Aiming at the limitation that the conventional grid-based computing method is only suitable for small-deformation analysis, the invention discloses a computational simulation method of an entire flow slide catastrophe process of the rock and soil material based on smoothed particle hydrodynamics (SPH). According to the method, a Navier-strokes equation is used as a control equation, solid phase and liquid phase of the rock and soil material are described by using a sub-load face Cambridge model and an incompressible fluid constitutive model respectively, porous medium theory and darcy law are introduced to calculate solid-liquid coupling acting force, and a computation model, which considers the full coupling of water and soil, of the flow slide catastrophe of the rock and soil material, is established. According to the computational simulation method, the entire process of large-deformation flow damage of the rock and soil material can be effectively represented, and the fluidization characteristic of the rock and soil material is captured, so that powerful scientific basis is provided for engineering design, engineering construction, disaster prevention and reduction and the like of high-risk areas of the flow slide disaster, and meanwhile, application of the computational rock and soil mechanics in the technical fields of actual engineering construction, geologic hazard prevention and control and the like is forcefully promoted.

Owner:TONGJI UNIV

Speed limiting for rotary driven sprinkler

InactiveUS7232078B2Speed is limitedReduce speedWatering devicesMovable spraying apparatusViscous dampingLow speed

A speed limiting mechanisms for turbine-driven fluid distribution apparatus usable with compressible fluid such as compressed air and incompressible fluid such as water. Dynamic viscous damping of the turbine output power train is used to control the rotational speed of the turbine. This prevents overspeeding when the turbine is air driven, and also when the turbine is water driven, under abnormal conditions such as blockage of a bypass area designed to control the turbine speed by limiting flow to the turbine. The same mechanism can be used to impose a lower rotational speed in the turbine during normal operation in conjunction with a turbine optimized for lower speed operation to reduce the required gear reduction in the power train.

Owner:KAH JR CARL L

Method and apparatus for surgical electrocautery

ActiveUS20070213711A1Effective electrocautery sealSufficient forceSurgical instruments for heatingSurgical forcepsFulgurationElectrocauterization

Owner:AESCULAP AG

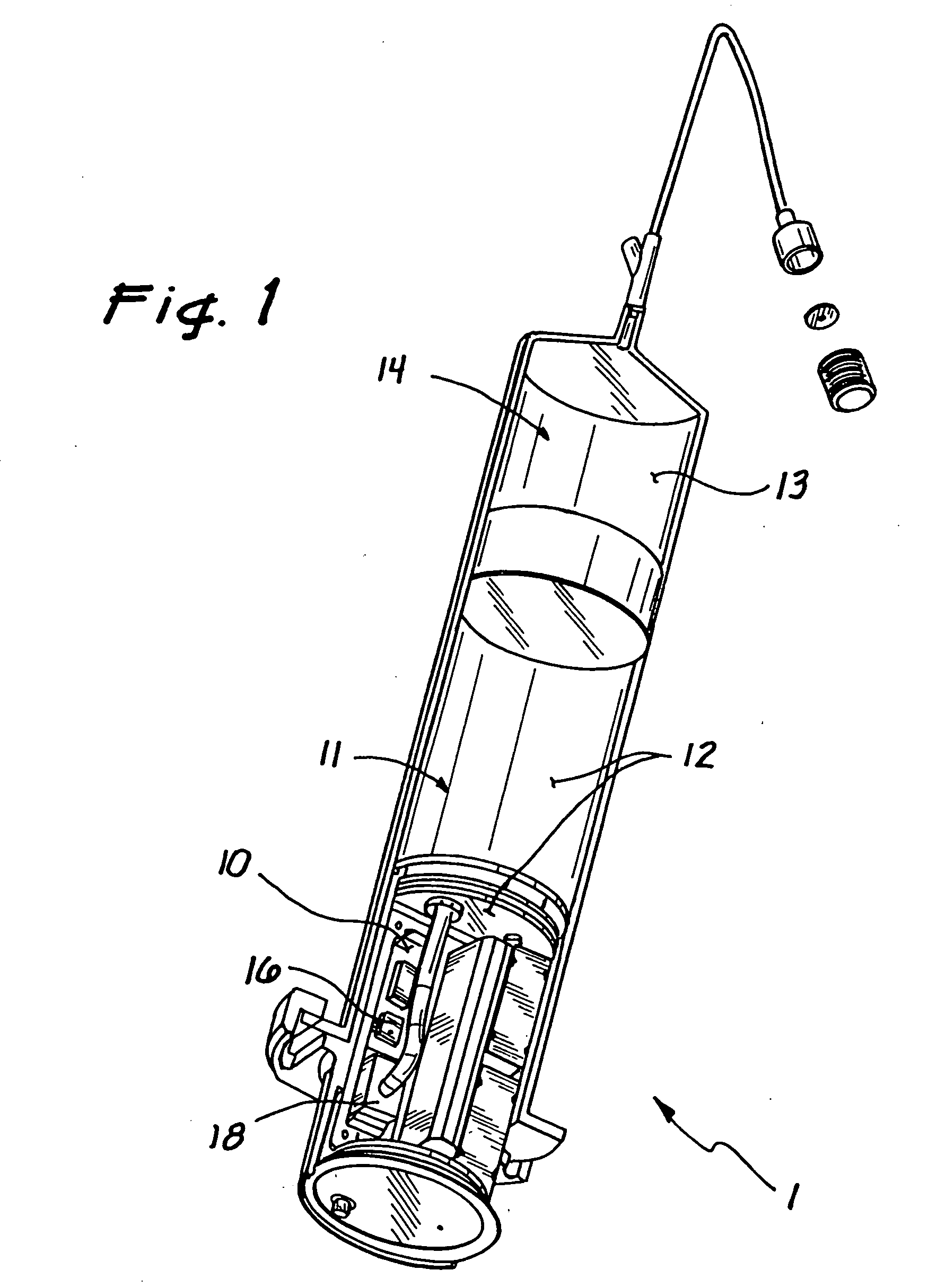

Device for injecting high viscosity material

InactiveUS20080243129A1High materialHigh viscosityMedical devicesPressure infusionViscosityBiomedical engineering

A device for injecting a high viscosity material into a cannula, comprising a container being non-compliant and having an outlet adapted to communicate with the cannula for transferring the high viscosity material thereto, a pressure applicator in fluid communication with the container, the pressure applicator defining a fluid flow path through which an incompressible fluid is displaceable, and a material-moving member interrupting the fluid flow path and defining an incompressible fluid receiving portion on one side thereof in communication with the fluid flow path and a high viscosity material receiving portion in communication with the outlet of the container on an opposed side. The material-moving member being displaceable by a pressure of the incompressible fluid acting thereagainst to force the high viscosity material out of the high viscosity material receiving portion of the container and into the cannula.

Owner:GIANNITSIOS DEMETRIOS +2

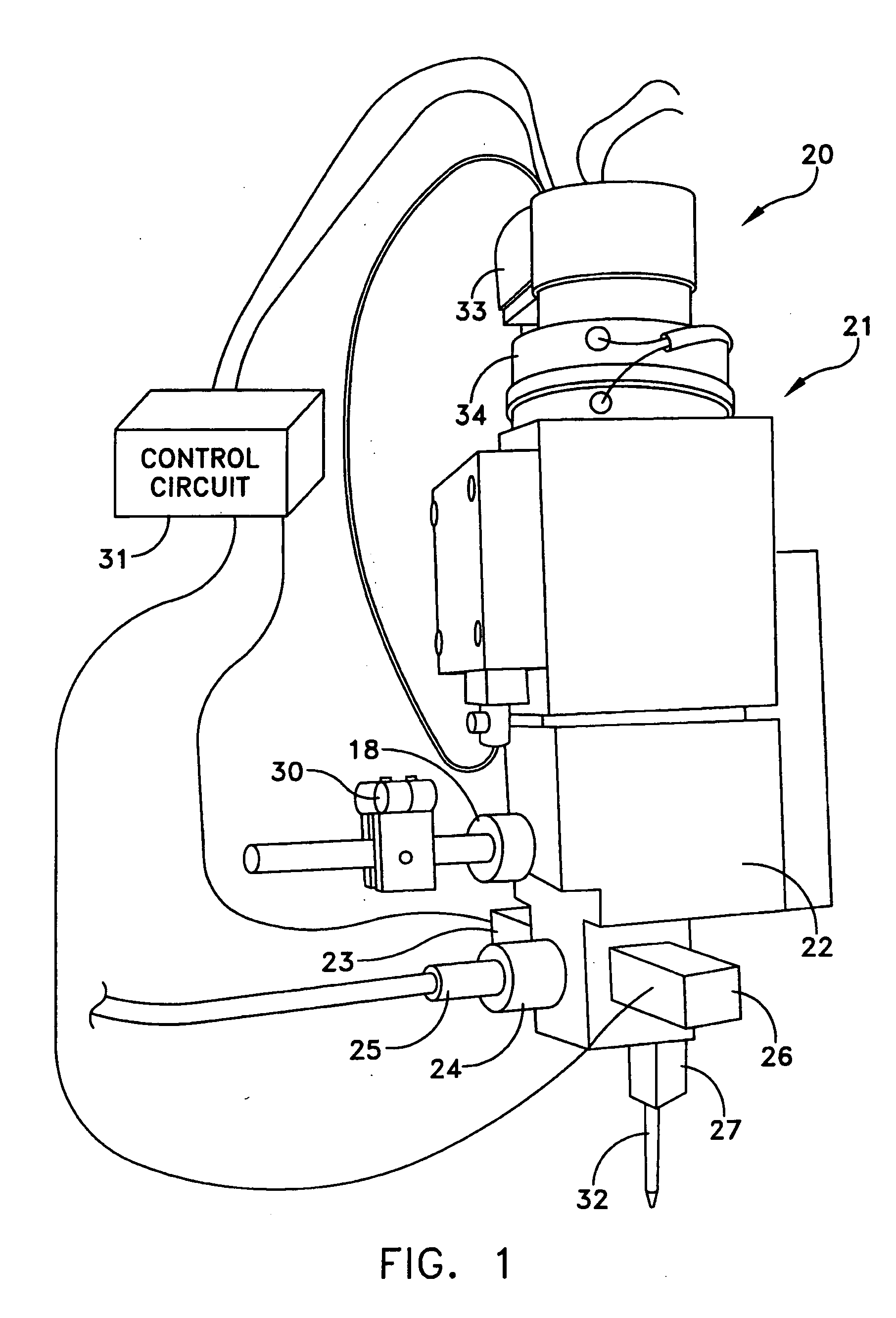

Apparatus and method for controlling fluid flow

InactiveUS20060108552A1Reduce energy wasteReduce energy consumptionSpindle sealingsDiaphragm valvesBobbinEngineering

An actuator base, bobbin, and pole piece form a pocket for an armature that a flexible membrane encloses to form an armature chamber filled with an incompressible fluid. The membrane protects the armature from exposure to corrosive fluids flowing in a conduit. Conduit flow can be stopped by driving the membrane against a valve seat. Pressure from the controlled fluid in the conduit is transmitted through the membrane to the fluid within the armature chamber so that the armature does not need to counteract force applied to the membrane by the conduit fluid's pressure.

Owner:ARICHELL TECH INC

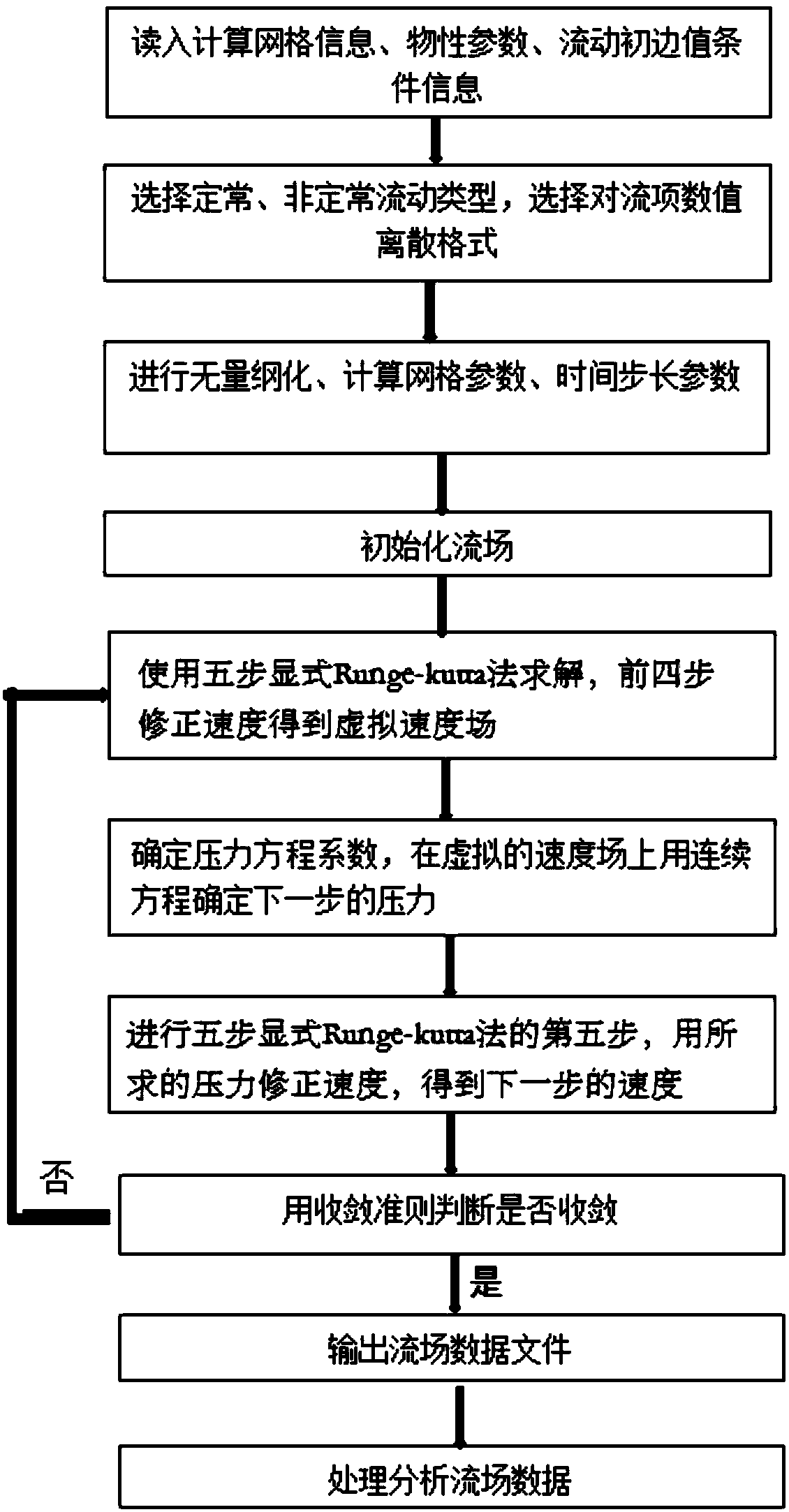

A numerical simulation method for obtaining a flow field of an incompressible flow

PendingCN108984874ADesign optimisation/simulationSpecial data processing applicationsMomentumBoundary values

The present disclosure provides a numerical simulation method for obtaining a flow field of an incompressible flow. The method comprises the steps: reading computational mesh information of a simulation object, physical property parameters of a fluid working medium and flow initial boundary value condition information, and calculating mesh parameters and time step parameters; initializing the velocity field and the pressure field; using m-step explicit Runge-Kutta to solve the momentum equation of incompressible fluid to obtain the virtual velocity field of the simulated object, where m represents the number of steps used and m>=2; based on the virtual velocity field and the read parameters and information, deducing the pressure equation from the continuity equation, and determining the next pressure by the pressure equation; when the last step of the m-step explicit Runge-Kutta is carried out, correcting the velocity field by the obtained pressure, and obtaining the next velocity; using the convergence criterion to judge whether the numerical solution is convergent or not, and if so, outputting the flow field data information, and if it is not convergent, repeating the iterative process until the numerical solution converges.

Owner:AERO ENGINE ACAD OF CHINA

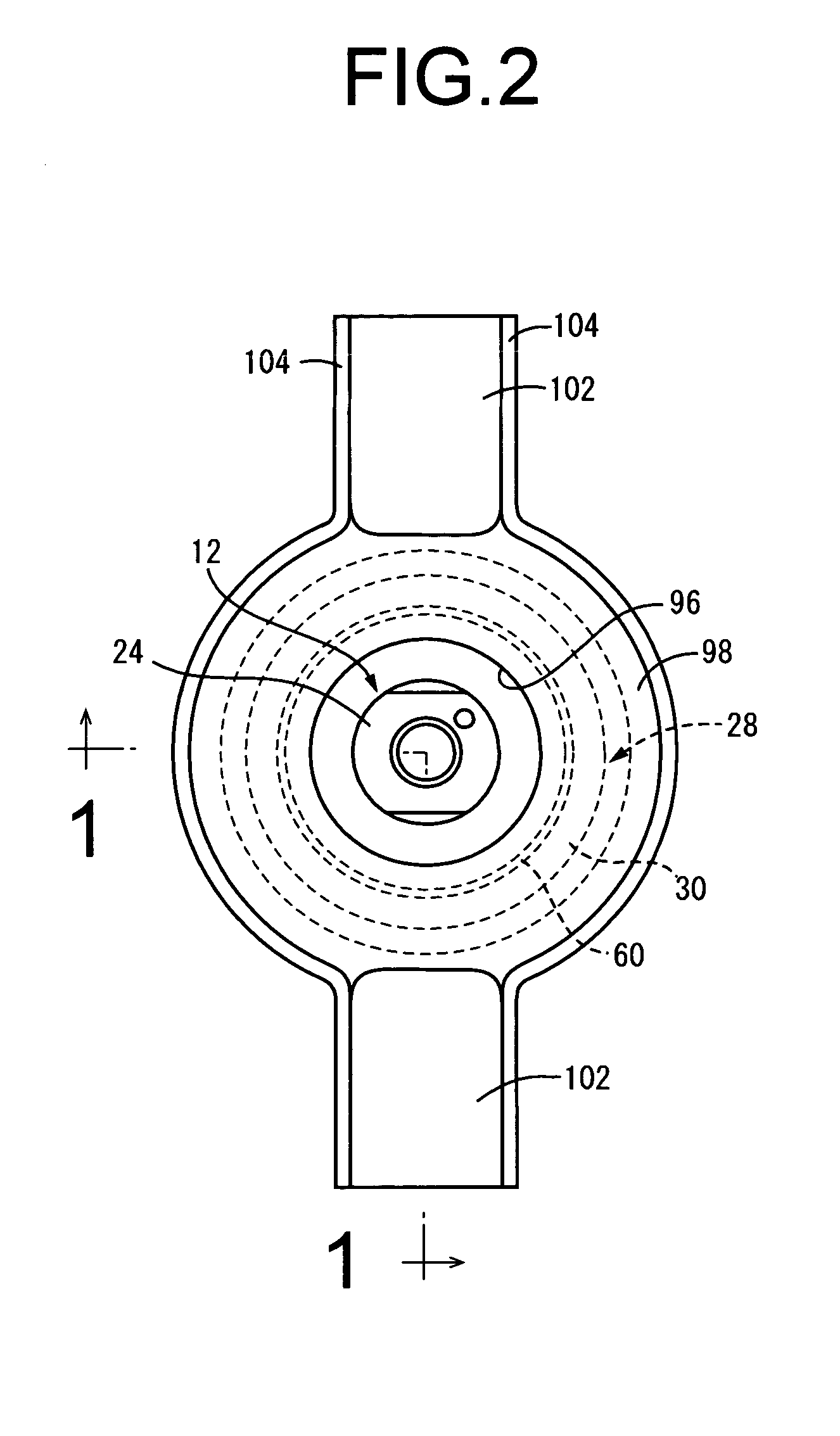

Fluid-filled vibration damping device

InactiveUS20060043657A1Improve damping performanceWide rangePortable framesLiquid springsElastomerForming face

A fluid-filled vibration damping device including: a rubber elastic body interposed between and elastically connecting an inner shaft and an outer cylinder; a pair of fluid chambers having an non-compressible fluid sealed therein and formed facing on both sides, in the inner shaft axis-perpendicular direction; an orifice passage through which the pair of fluid chambers communicate with each other; a through hole formed through the inner shaft in the axis-perpendicular direction; and a movable rubber layer fluid-tightly closing the through hole and being exposed at opposite major surfaces thereof to the pair of fluid chambers, respectively so that pressure in the respective fluid chambers are exerted against the major surfaces of the movable rubber layer.

Owner:SUMITOMO RIKO CO LTD

Power unit support structure

InactiveUS20090321202A1High attenuating actionReduce actionSpringsShock absorbersLongitudinal engineEngine mount

A power unit support structure adapted to provide vibration-damped support of an power unit of an automobile of FR longitudinal engine design on a vehicle body via engine mounts situated at two locations towards a vehicle front end and one location towards a vehicle back end, respectively. Of the engine mounts disposed at the three locations, a fluid-filled vibration-damping device exhibiting vibration-attenuating action based on flow action of non-compressible fluid filling the interior thereof is employed as a rear engine mount disposed at the vehicle back end, and the vibration-attenuating action based on the flow action of the non-compressible fluid is exhibited against vibration input in a vehicle longitudinal direction.

Owner:SUMITOMO RIKO CO LTD

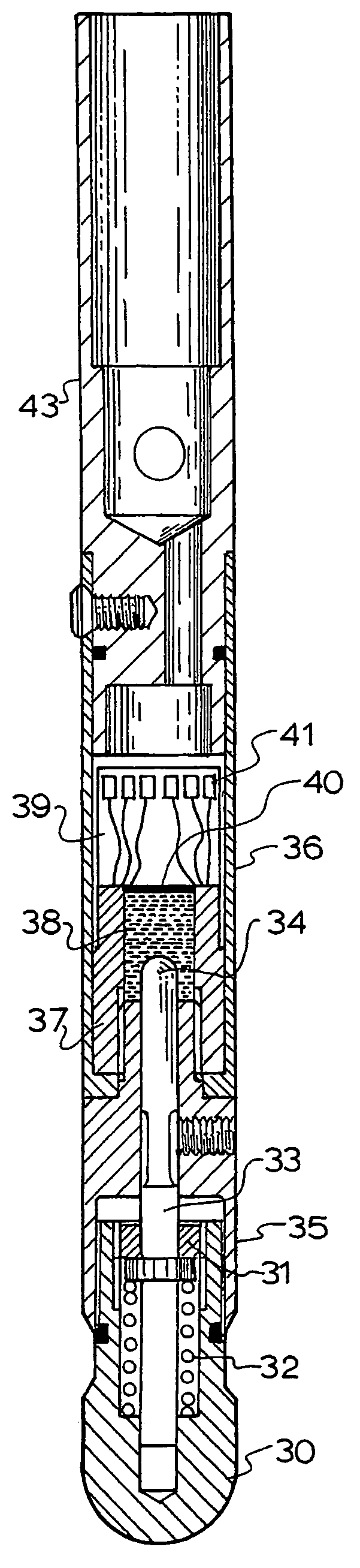

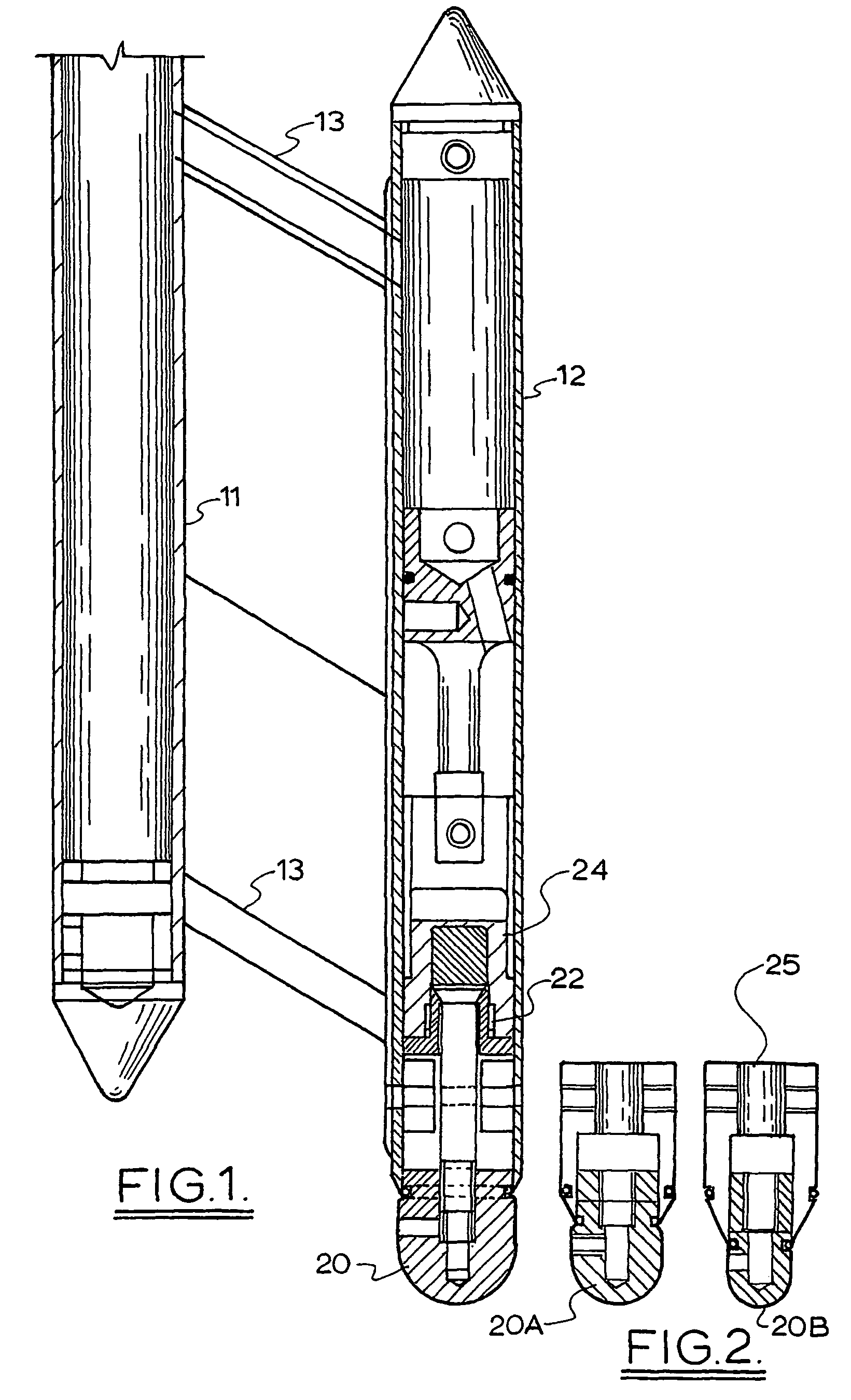

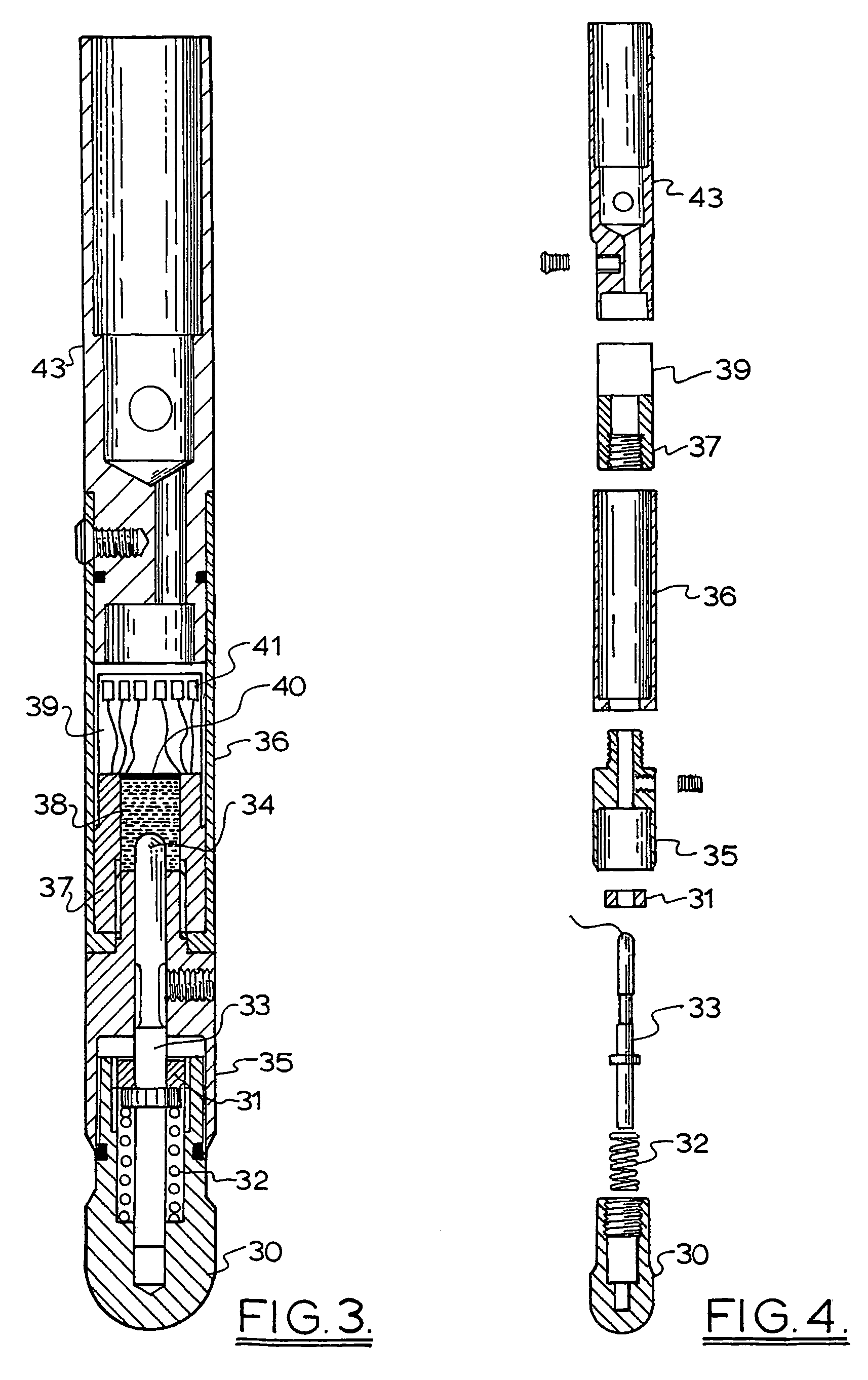

Soil or snow probe

InactiveUS7040146B2Easy to explainCancel noiseEarth material testingMaterial strength using single impulsive forceAccelerometerEngineering

A soil or snow probe which incorporates a load cell in the probe head and also an accelerometer so that a vertical strength profile of the snow or soil can be established. The device does not need to be driven at a constant speed and can be manually driven into the soil or snow. The resistance to penetration is measured using a load cell which incorporates a low duro polymer selected for its ability to behave like a non compressible fluid. The device is portable and provides data quickly.

Owner:HIMACHAL SAFETY SYST

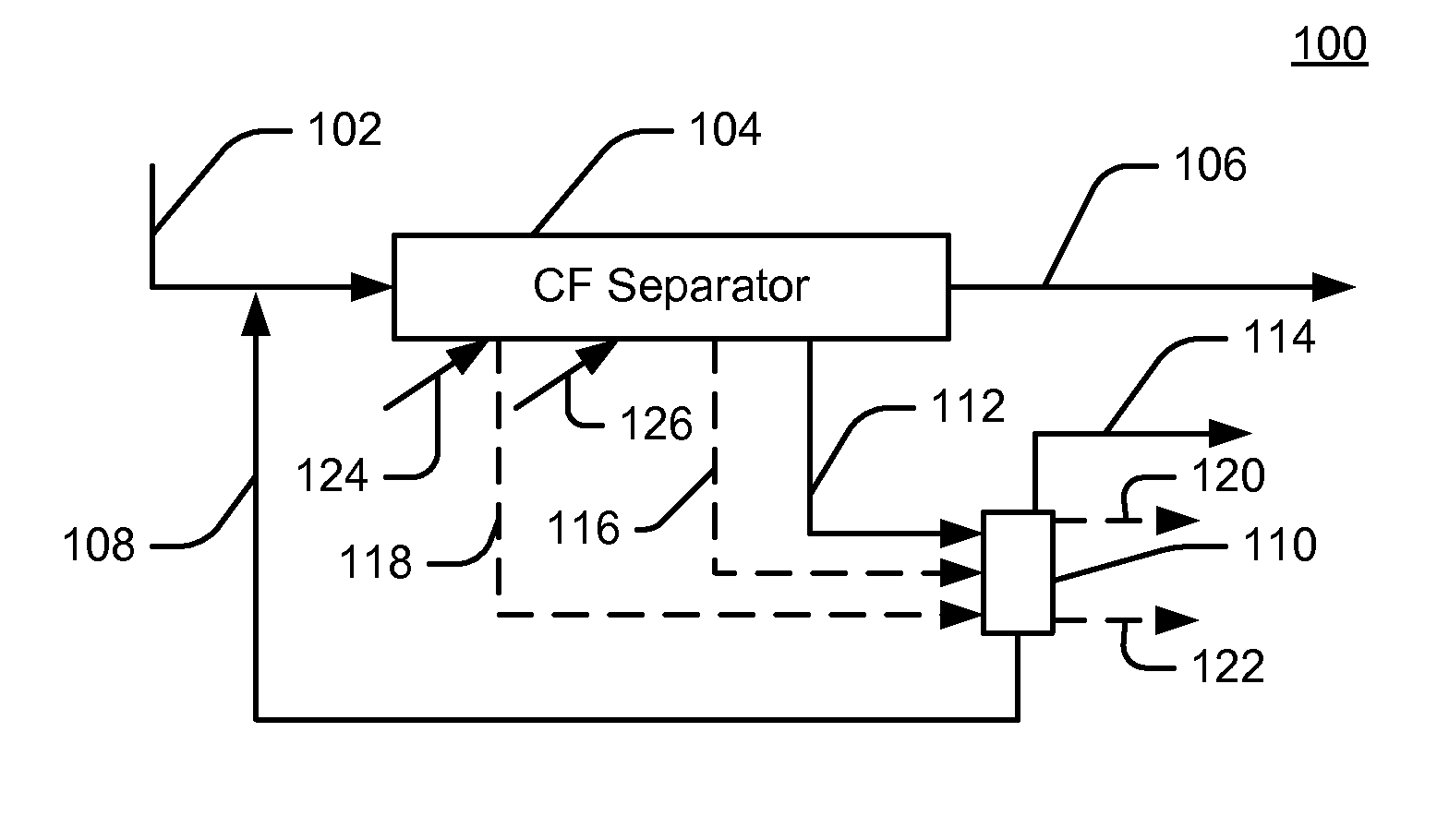

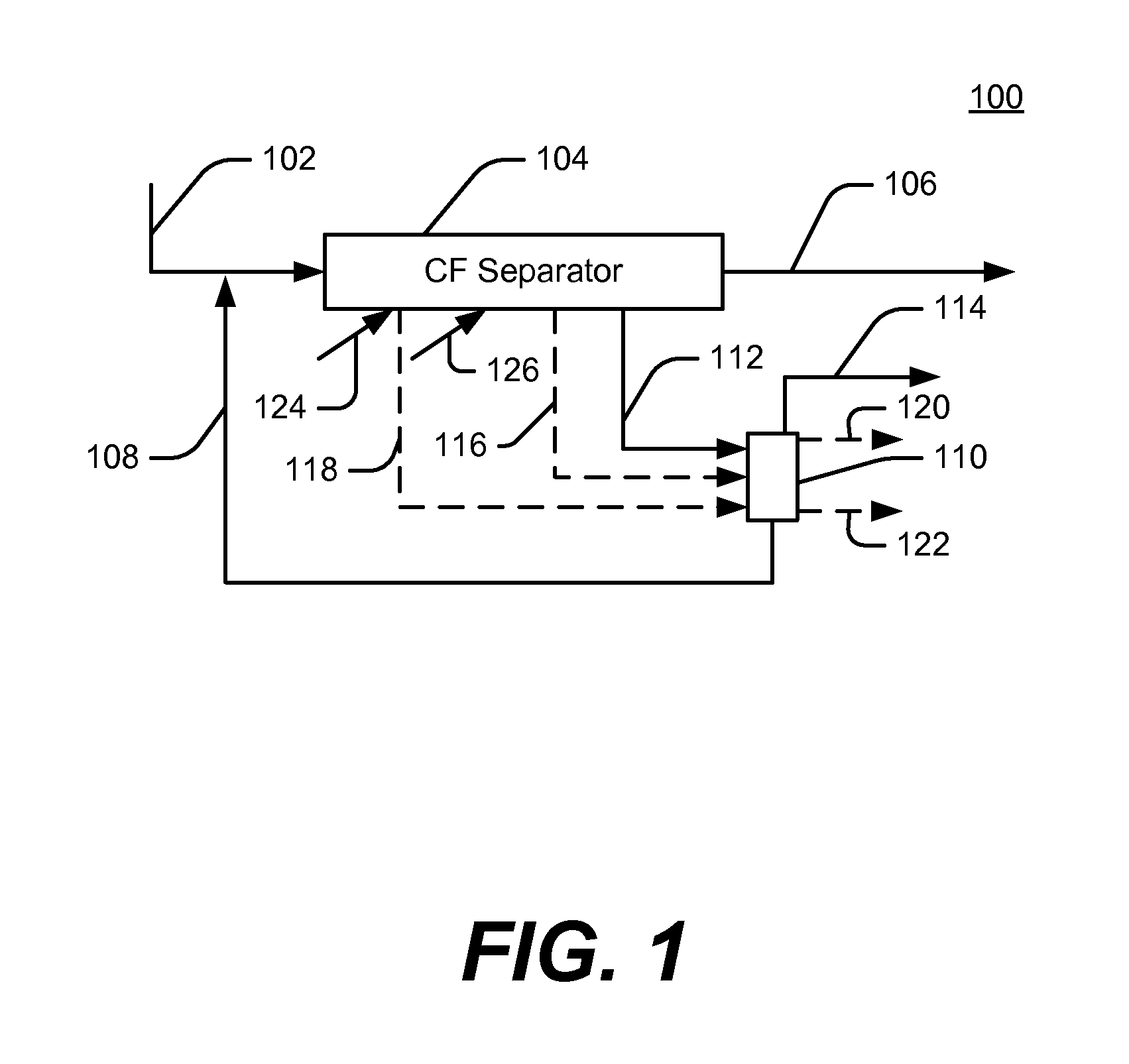

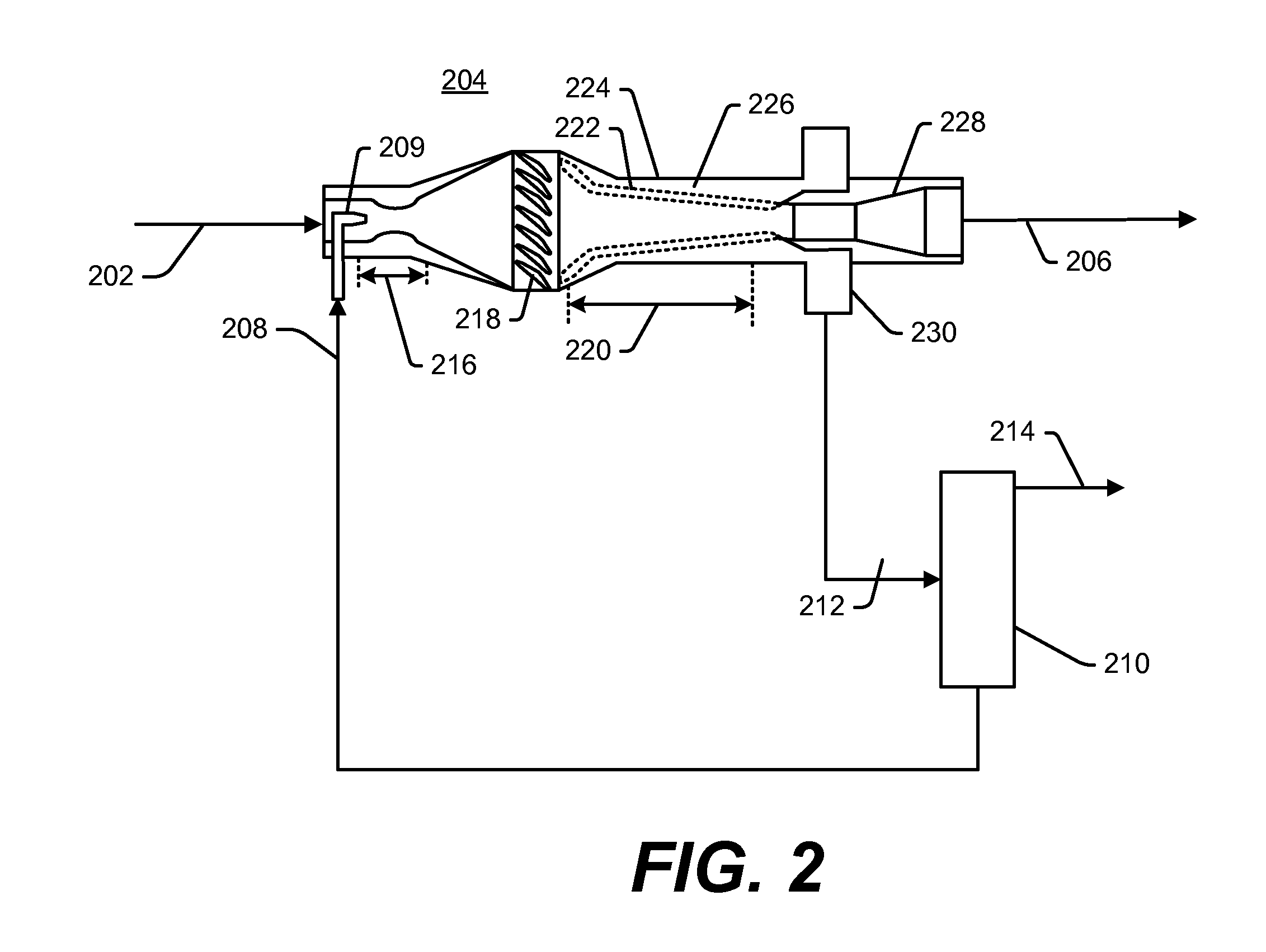

Separation of gases produced by combustion

The present invention is directed to a method and a system for separating gas components of a combustion gas. A compressible feed stream derived from a combustion gas that contains at least one target compressible component and at least one non-target compressible component is mixed in a substantially co-current flow with an incompressible fluid stream comprising an incompressible fluid in which the target component(s) is / are capable of being preferentially absorbed. Rotational velocity is imparted to the mixed streams, separating an incompressible fluid in which at least a portion of the target component is absorbed from a compressible product stream containing the non-target compressible component(s). The compressible feed stream may be provided at a stream velocity having a Mach number of at least 0.1.

Owner:SHELL OIL CO

Bi-directional fluid ejection systems and methods

A bi-directional fluid ejector according to the systems and methods of this invention operates on the principle of electrostatic attraction. In various exemplary embodiments, the fluid ejector includes a sealed dual diaphragm arrangement, an electrode arrangement that is parallel and opposite to the sealed diaphragms, and a structure which contains the fluid to be ejected. A diaphragm chamber containing a relatively incompressible fluid is situated behind, and is sealed by, the diaphragms. At least one nozzle hole is formed in a faceplate of the ejector over one of the diaphragms. A drive signal is applied to at least one electrode of the electrode arrangement to generate an electrostatic field between the electrode and a first one of the diaphragms. The first diaphragm is attracted towards the electrode by an electrostatic force into a deformed shape due to the electrostatic field. Upon deforming, pressure is transmitted to a second one of the sealed diaphragms. The transmitted pressure and the relatively incompressible nature of the fluid contained within the sealed diaphragm chamber causes the second diaphragm to deflect in the opposite direction to force fluid through at least one of the at least one nozzle hole. After a drop is ejected, the movement is reversed, either through normal resilient restoration actions of the deformed diaphragm and / or through an applied force.

Owner:SANDIA +1

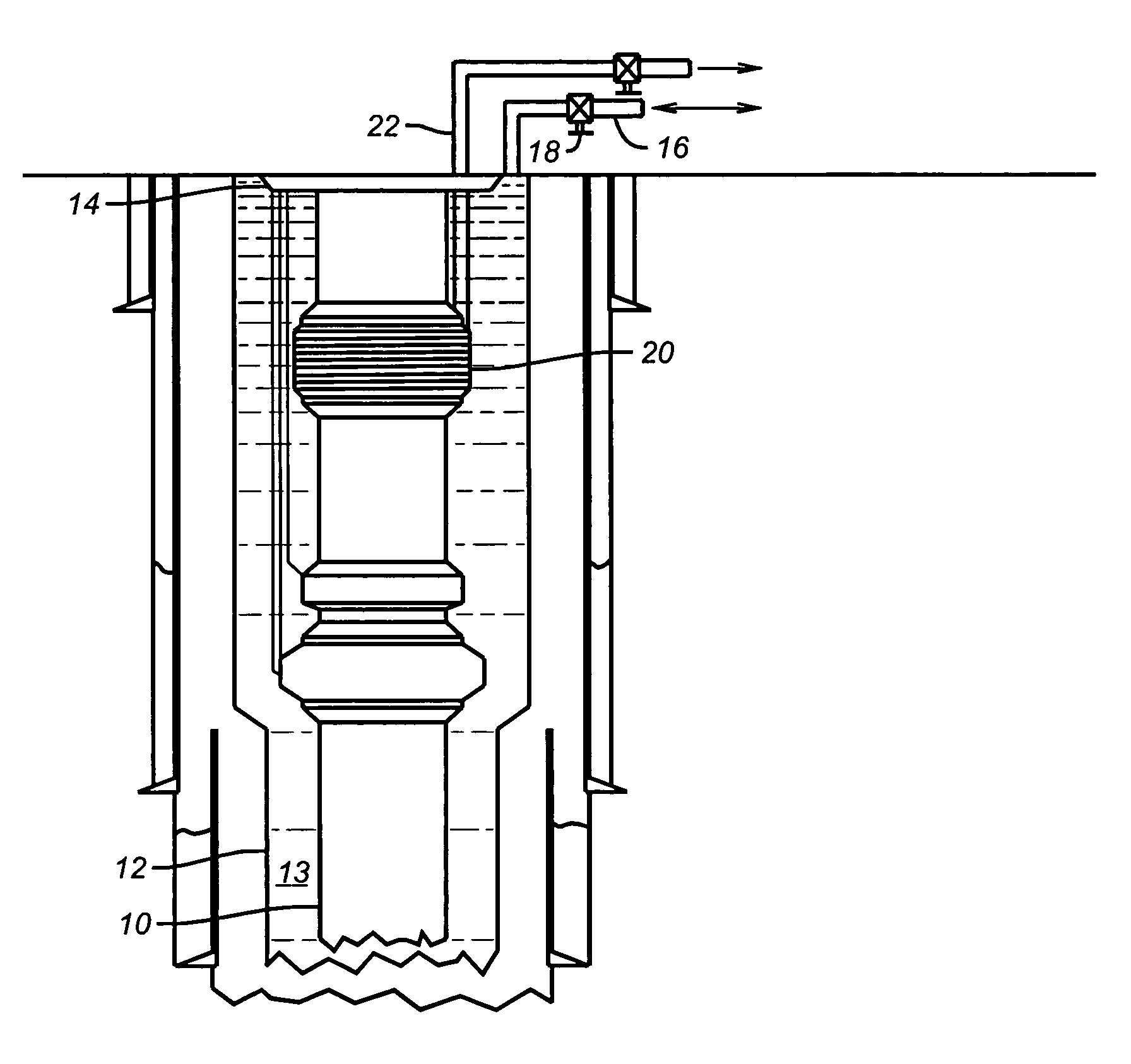

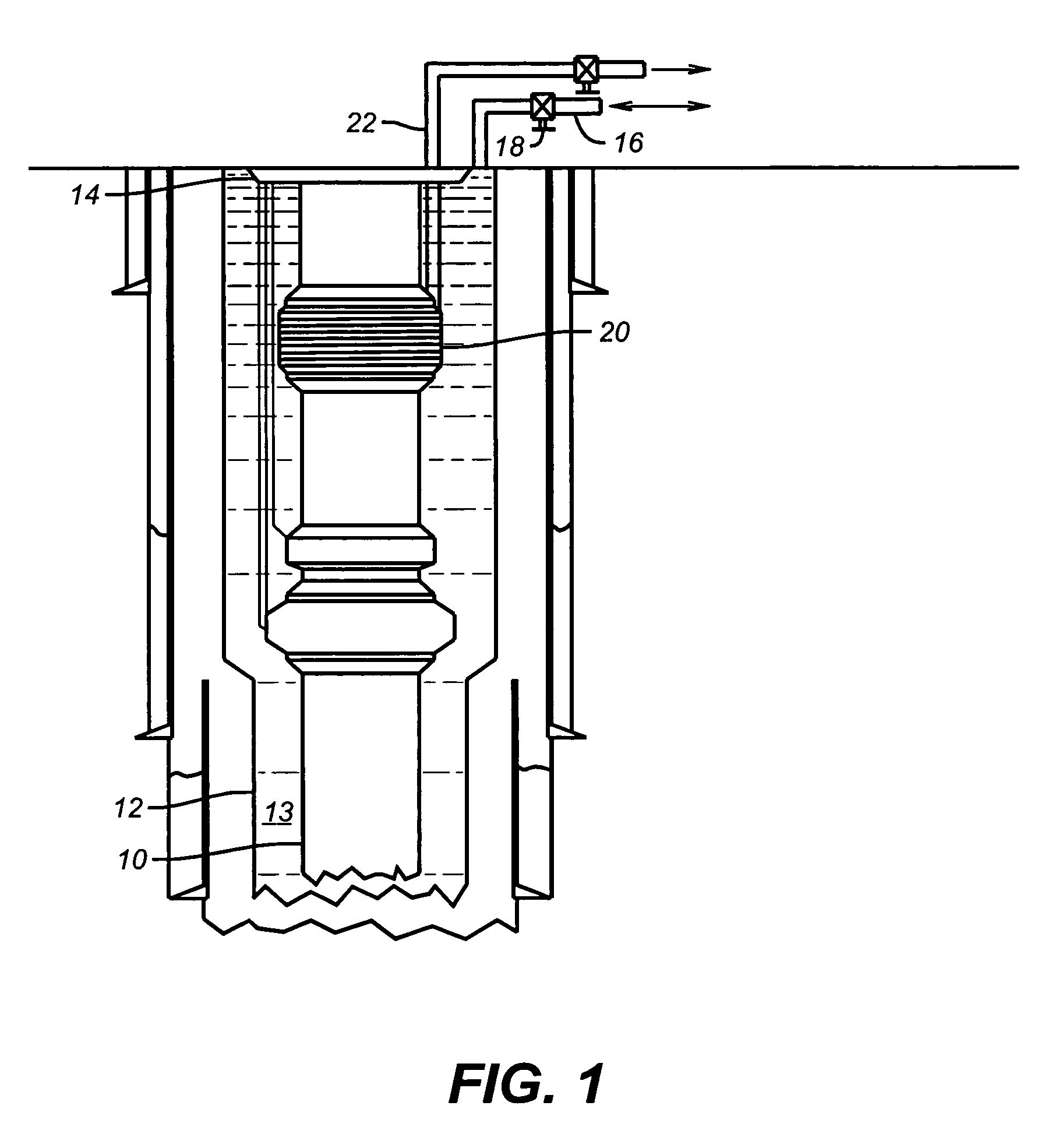

Annulus pressure control system for subsea wells

InactiveUS7048059B2Avoid cloggingMinimizes thermal effectFluid removalUnderwater drillingOcean bottomControl system

The annulus pressure is controlled by displacing incompressible fluid with compressible fluid in the annulus. The displaced fluid is filtered to avoid clogging small lines. The presence of compressible fluid minimizes the thermal effect of warm fluid in the production tubing on annulus pressure. As a result, thinner wall casing can be used, for considerable savings in material and installation cost.

Owner:BAKER HUGHES INC

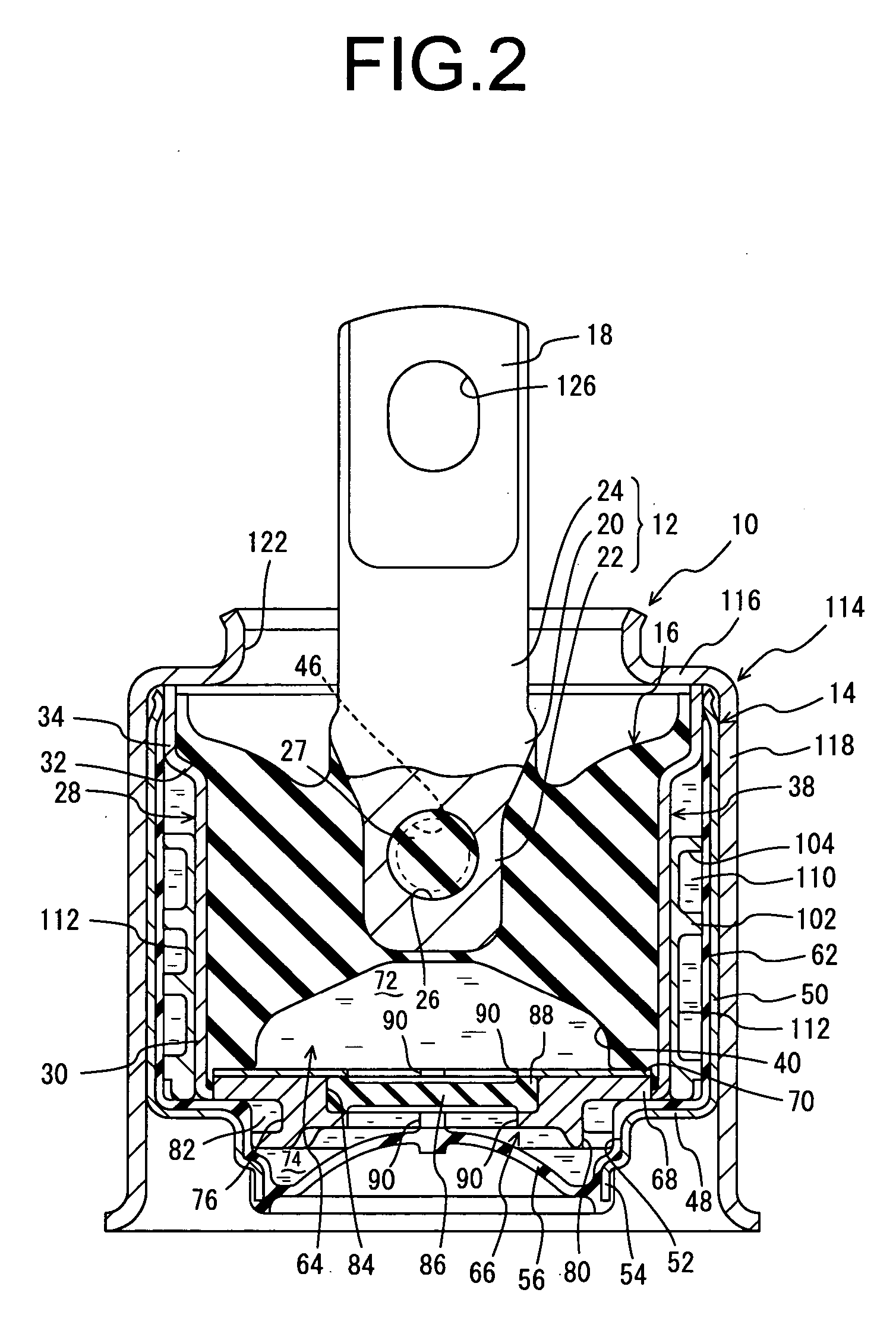

Fluid-filled type vibration damping device

Owner:SUMITOMO RIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com