Pneumatically-operated fluid pump with amplified fluid pressure, and related methods

a fluid pump and pneumatic operation technology, applied in the direction of positive displacement liquid engines, pump control, piston pumps, etc., can solve the problem of fluid being expelled from the subject fluid chamber, and achieve the effect of increasing and decreasing the volume of the subject fluid chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

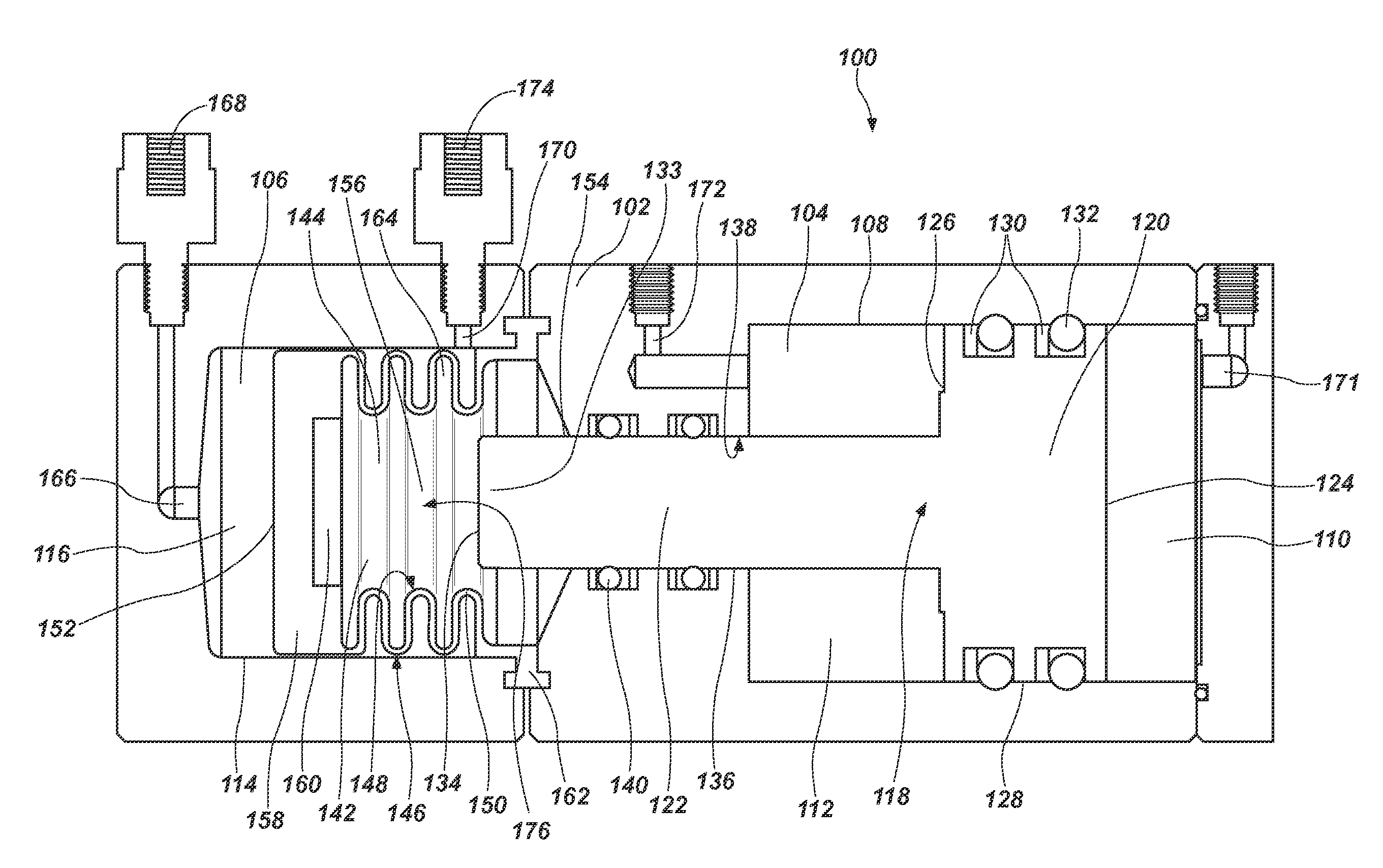

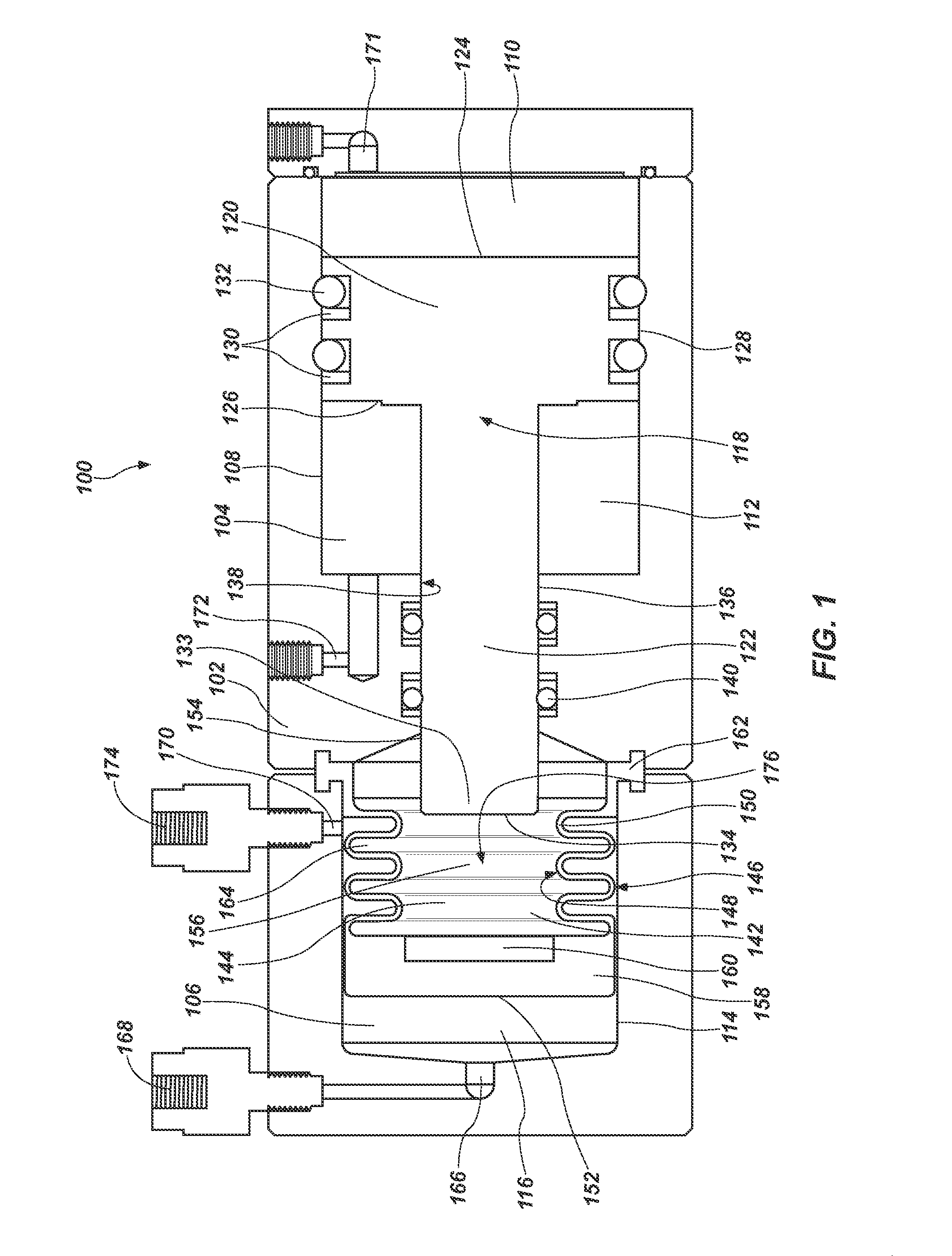

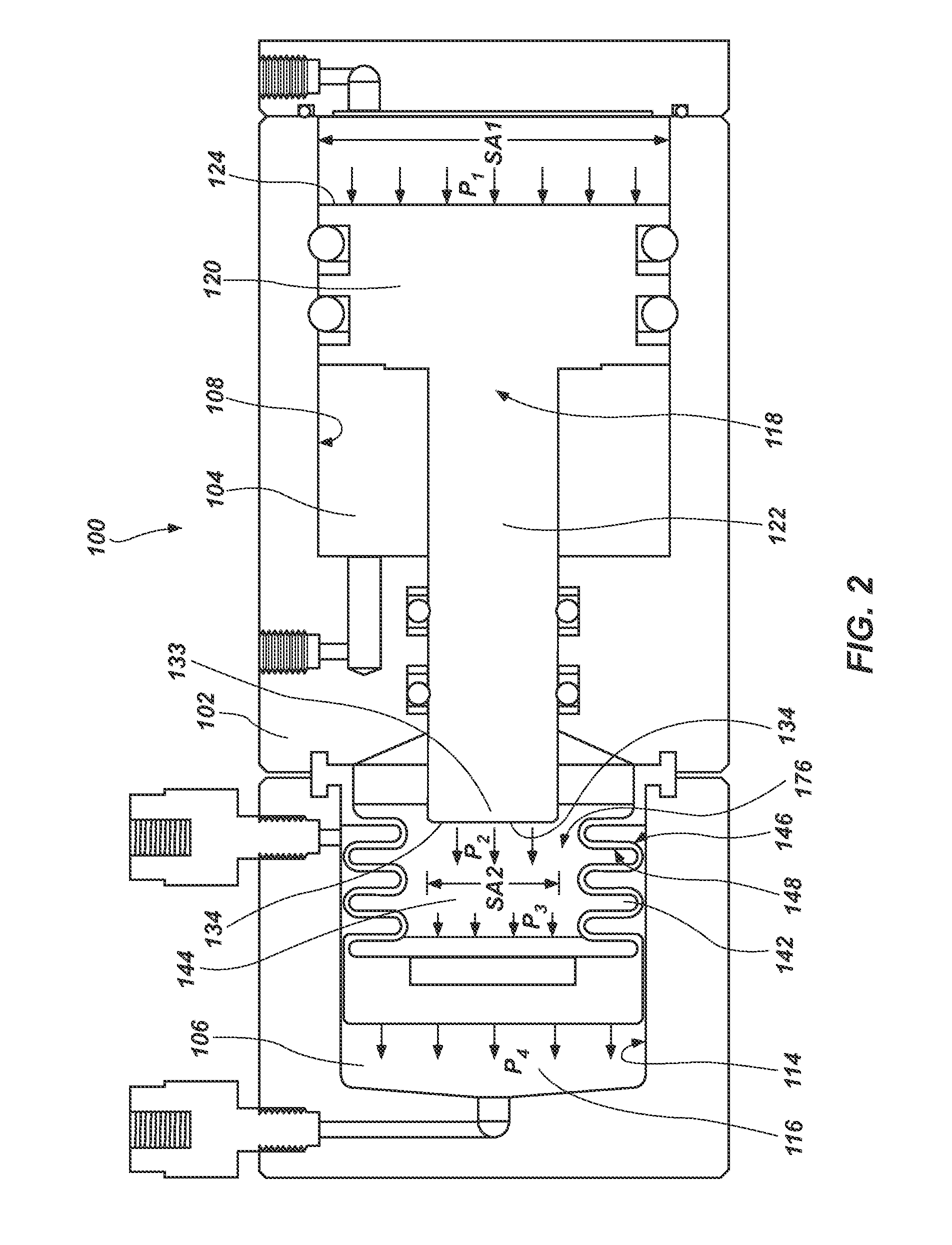

[0012]The illustrations presented herein are not meant to be actual views of any particular fluid pump 100 or component thereof, but are merely idealized representations that are used to describe embodiments of the disclosure.

[0013]As used herein, the term “substantially” in reference to a given parameter, property, or condition means and includes to a degree that one skilled in the art would understand that the given parameter, property, or condition is met with a small degree of variance, such as within acceptable manufacturing tolerances. For example, a parameter that is substantially met may be at least about 90% met, at least about 95% met, or even at least about 99% met.

[0014]Embodiments of the present disclosure include fluid pumps that include at least one drive fluid chamber, at least one subject fluid chamber, an incompressible fluid, a piston, and a flexible member for pressurizing a subject fluid to a pressure higher than a pressure to which a pressurized drive fluid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com