Patents

Literature

67 results about "Conduit flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flow occurs because there is a longitudinal pressure difference along the conduit. Open channel conduit flow is the transport of water by gravity with a free surface open to atmospheric pressure in which the channel determines the size, shape, and slope of the conduit.

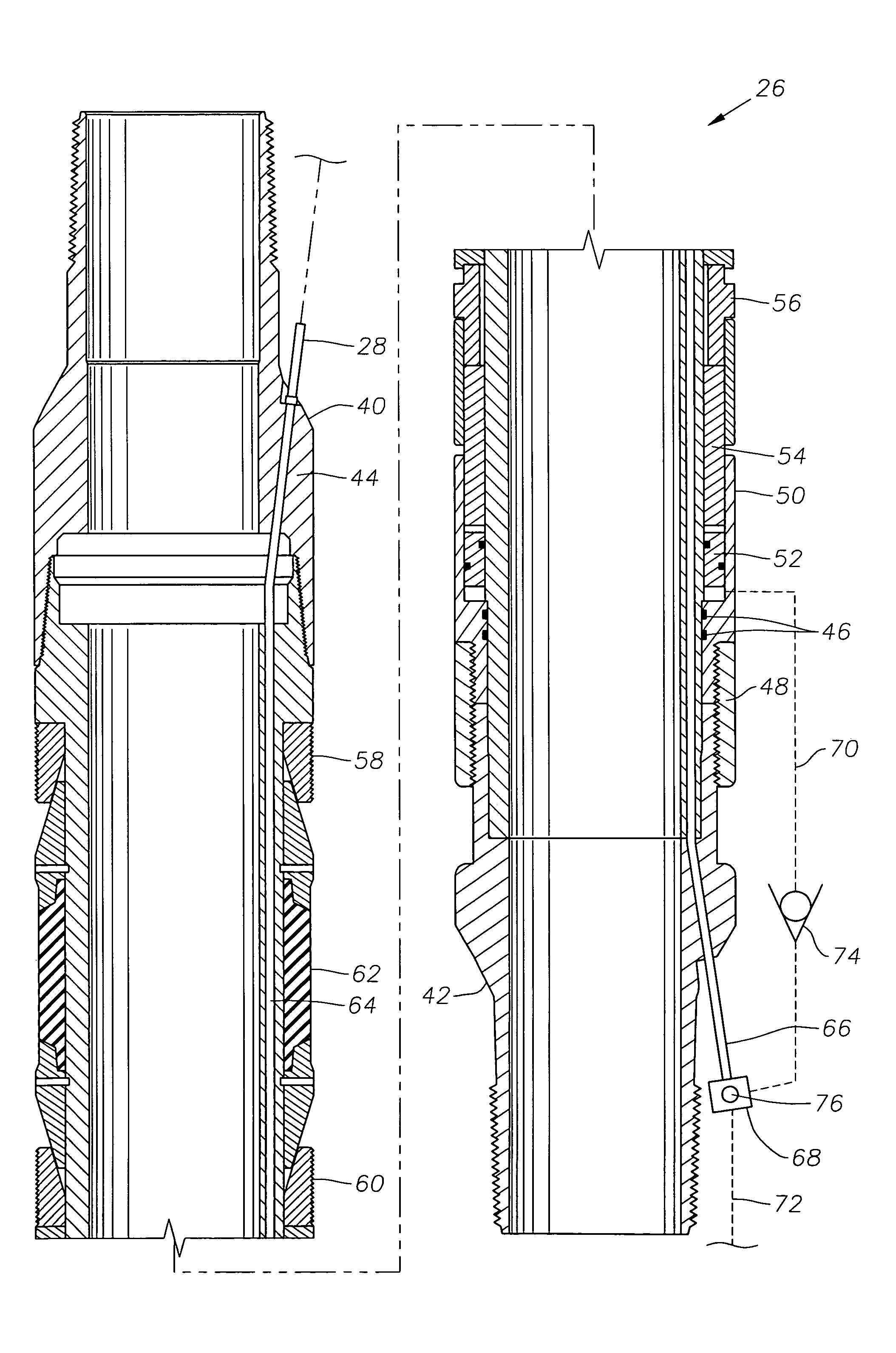

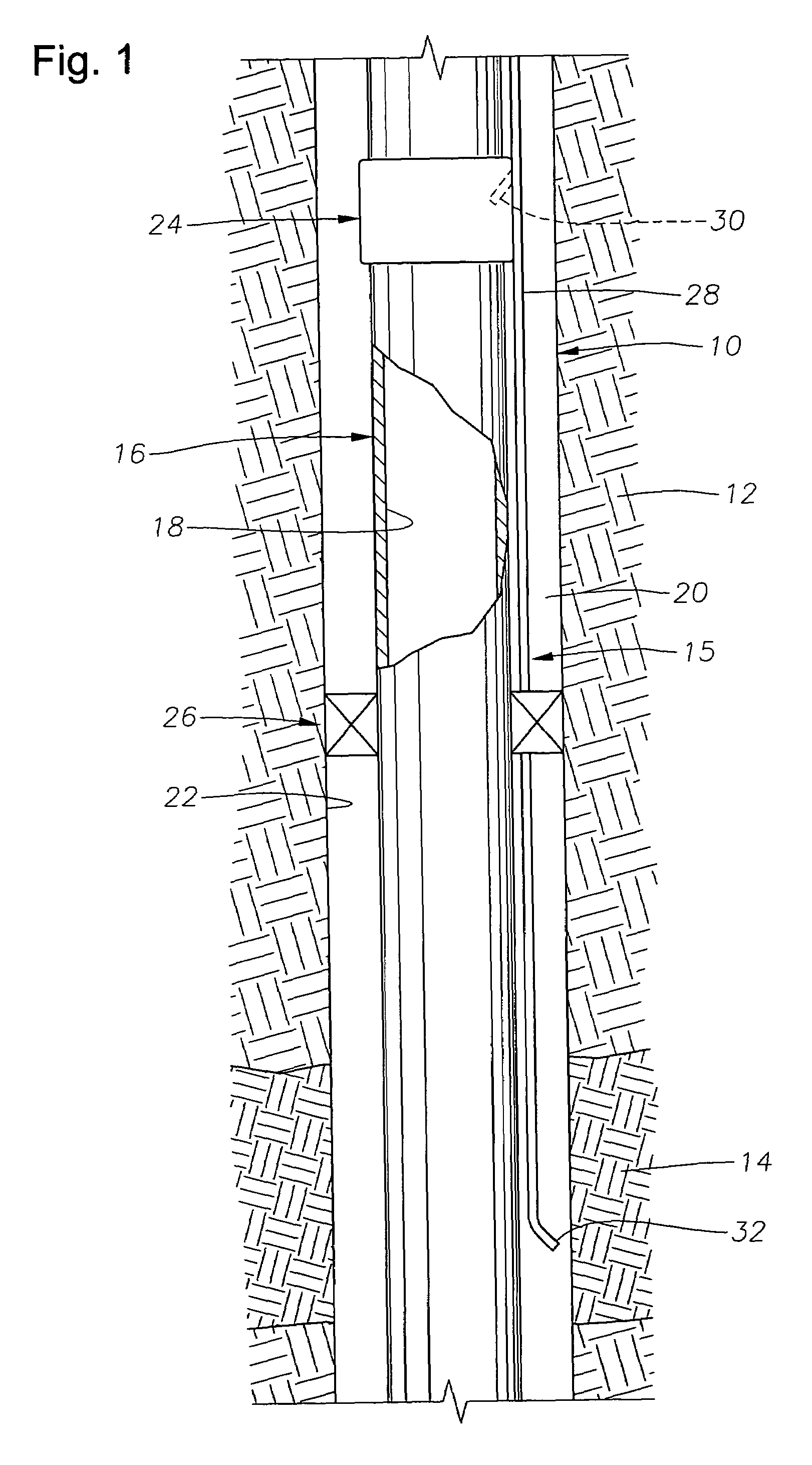

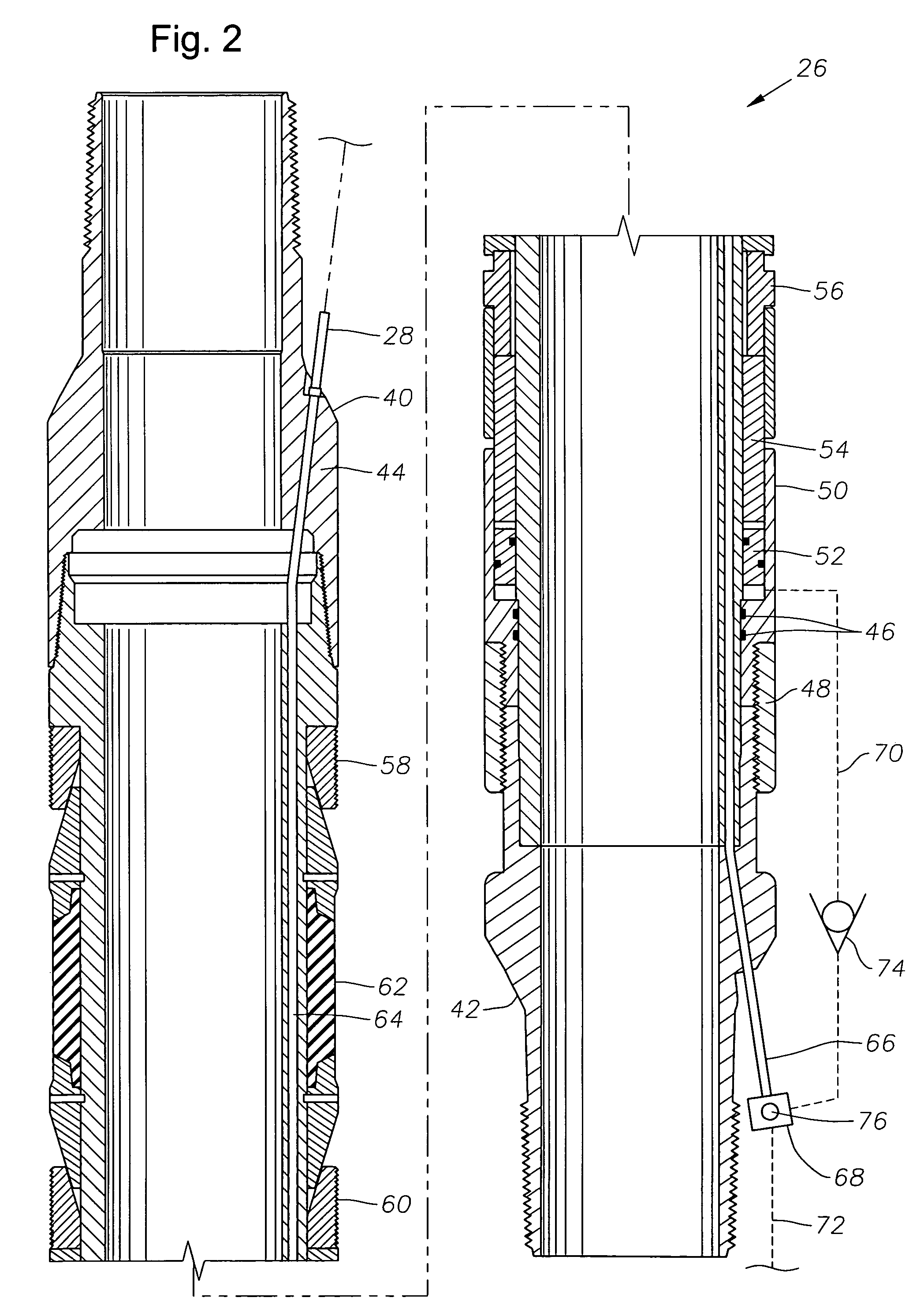

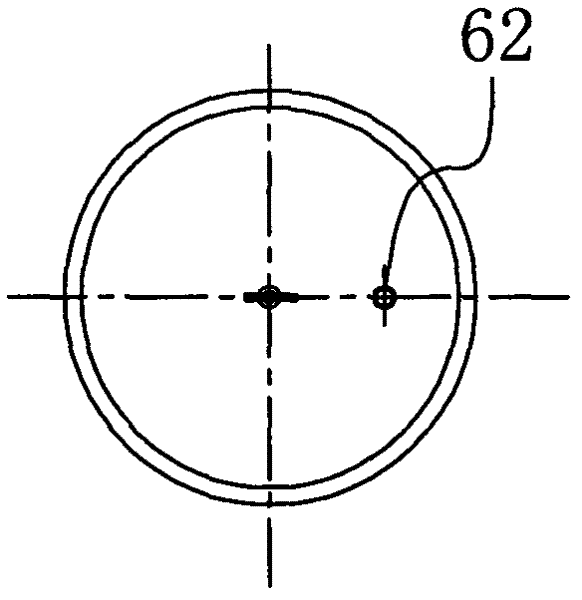

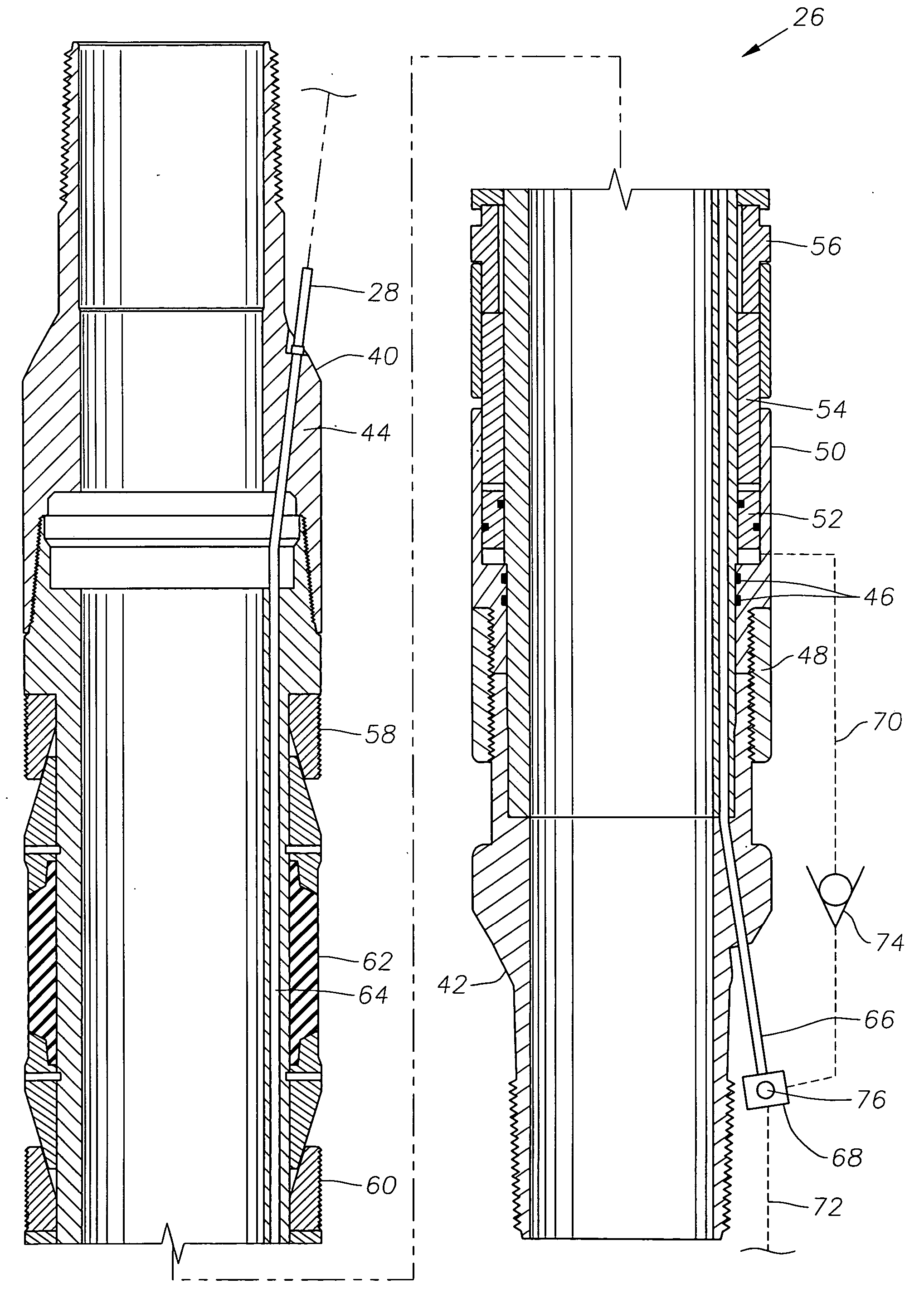

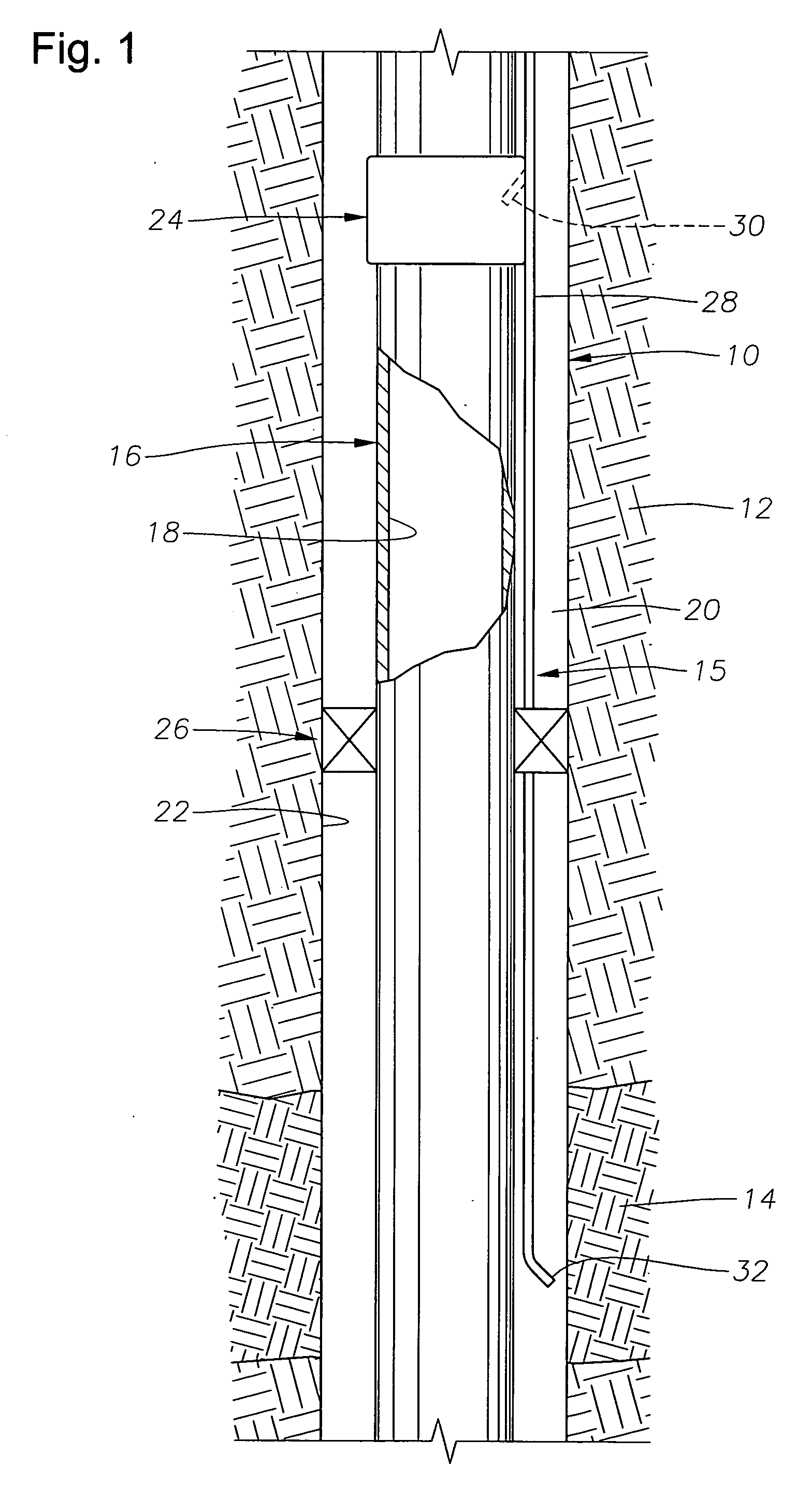

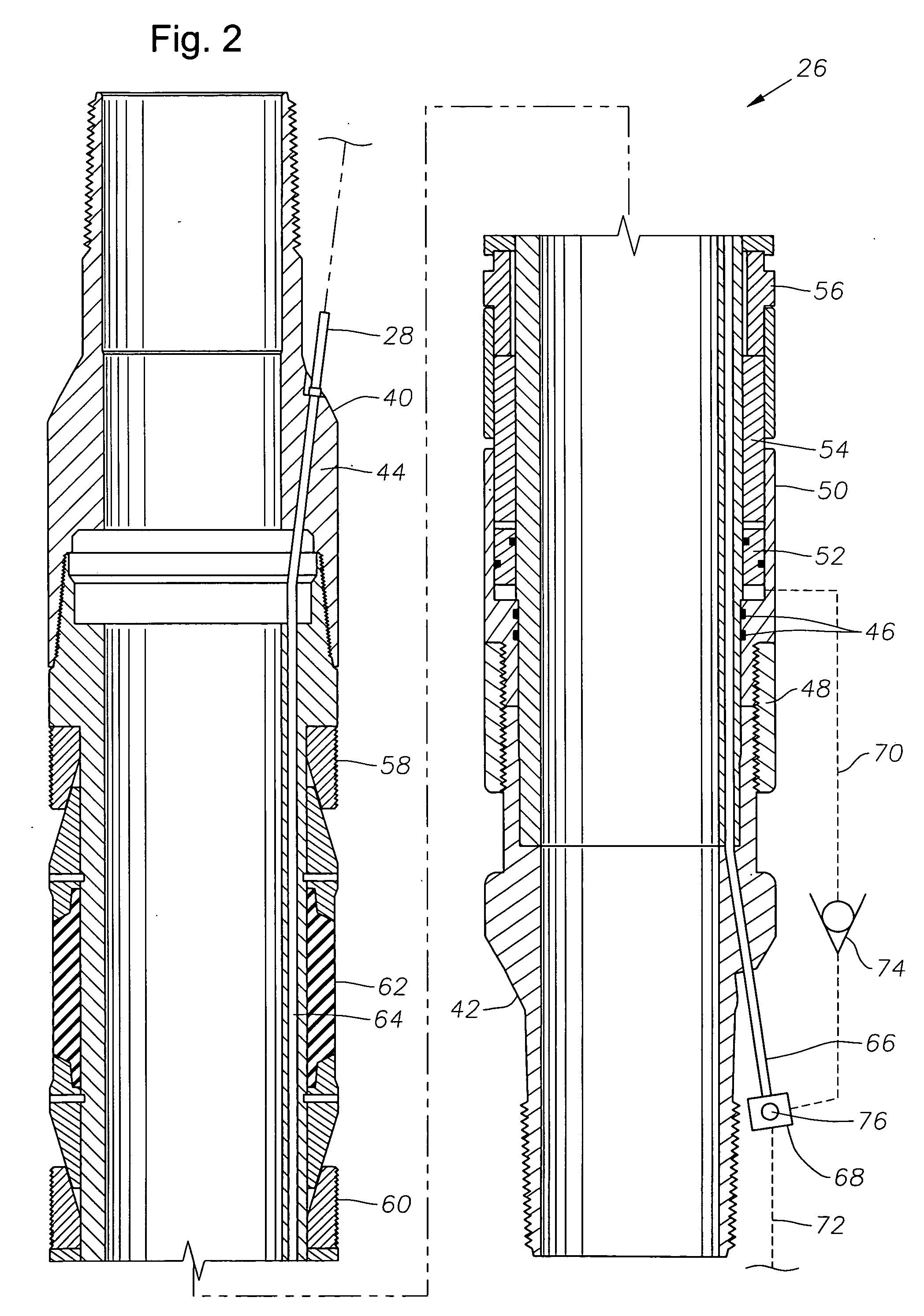

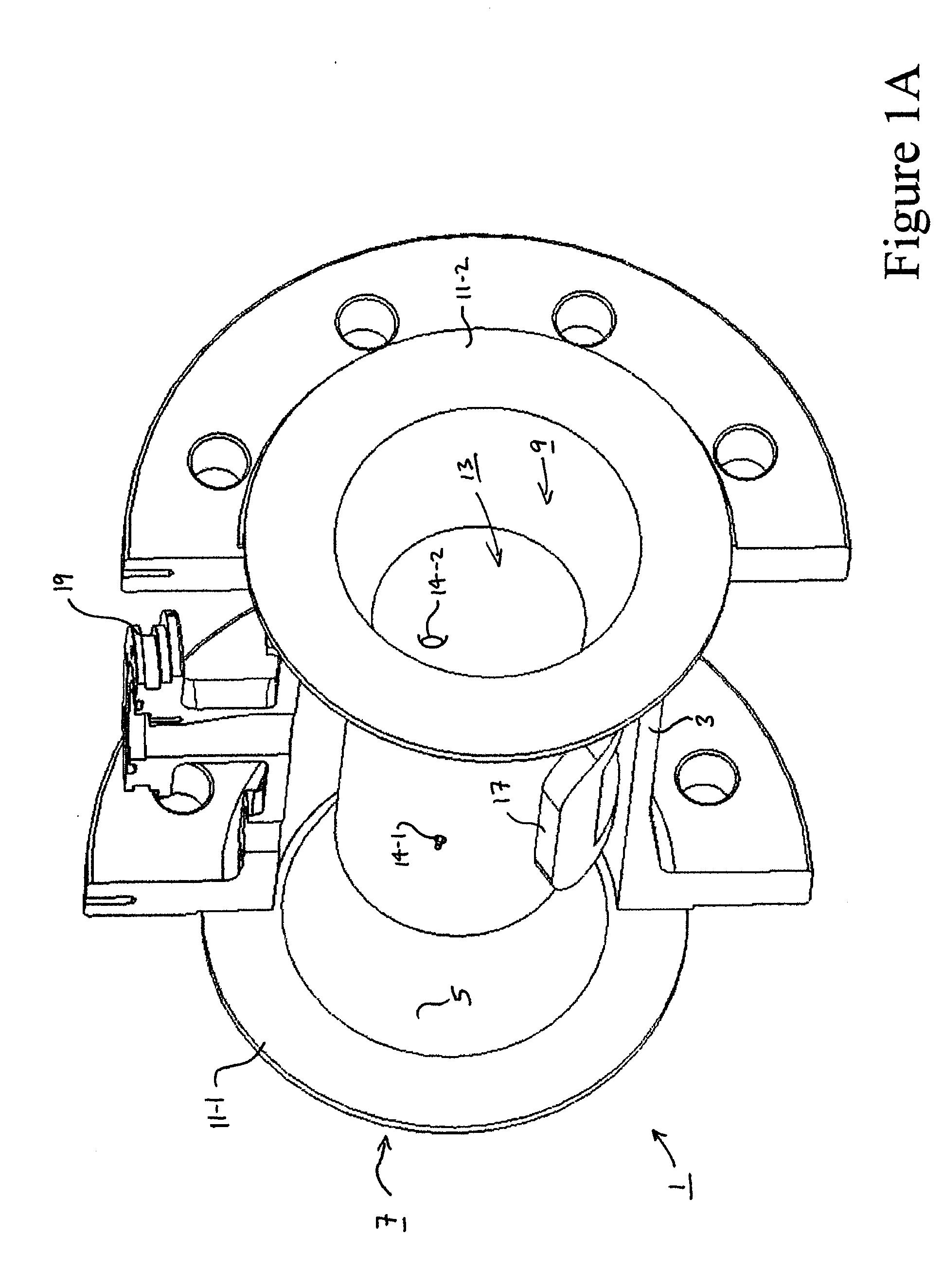

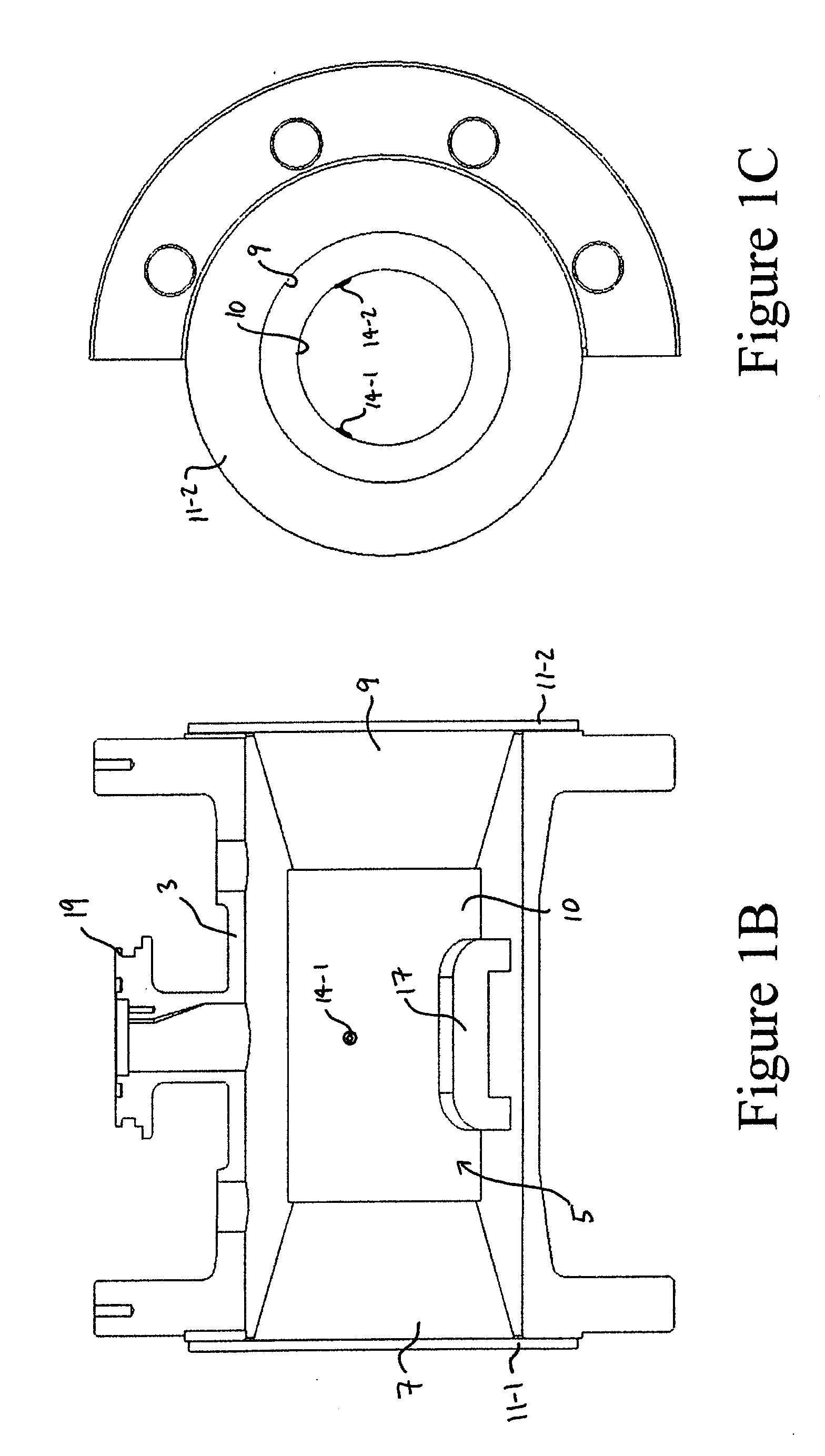

Alternative packer setting method

Fluid setting pressure is delivered to a hydraulically set well packer through an external conduit strapped to the exterior of a well workstring above the packer assembly. The continuity of the external conduit is continued past the packer assembly by following a flow channel along the mandrel sleeve thickness. Representatively, the external conduit may serve a primary well function other than packer setting (e.g. well chemical delivery). A calibrated rupture element in the external conduit is disposed to initially obstruct external conduit flow past the packer element. Consequently, fluid pressure transferred down the external conduit is first channeled to the packer setting pressure chamber. After setting, the fluid pressure in the external conduit is increased to rupture the calibrated element. When the external conduit flow channel is opened by rupture of the calibrated element, and the additional well service function may be accomplished.

Owner:BAKER HUGHES INC

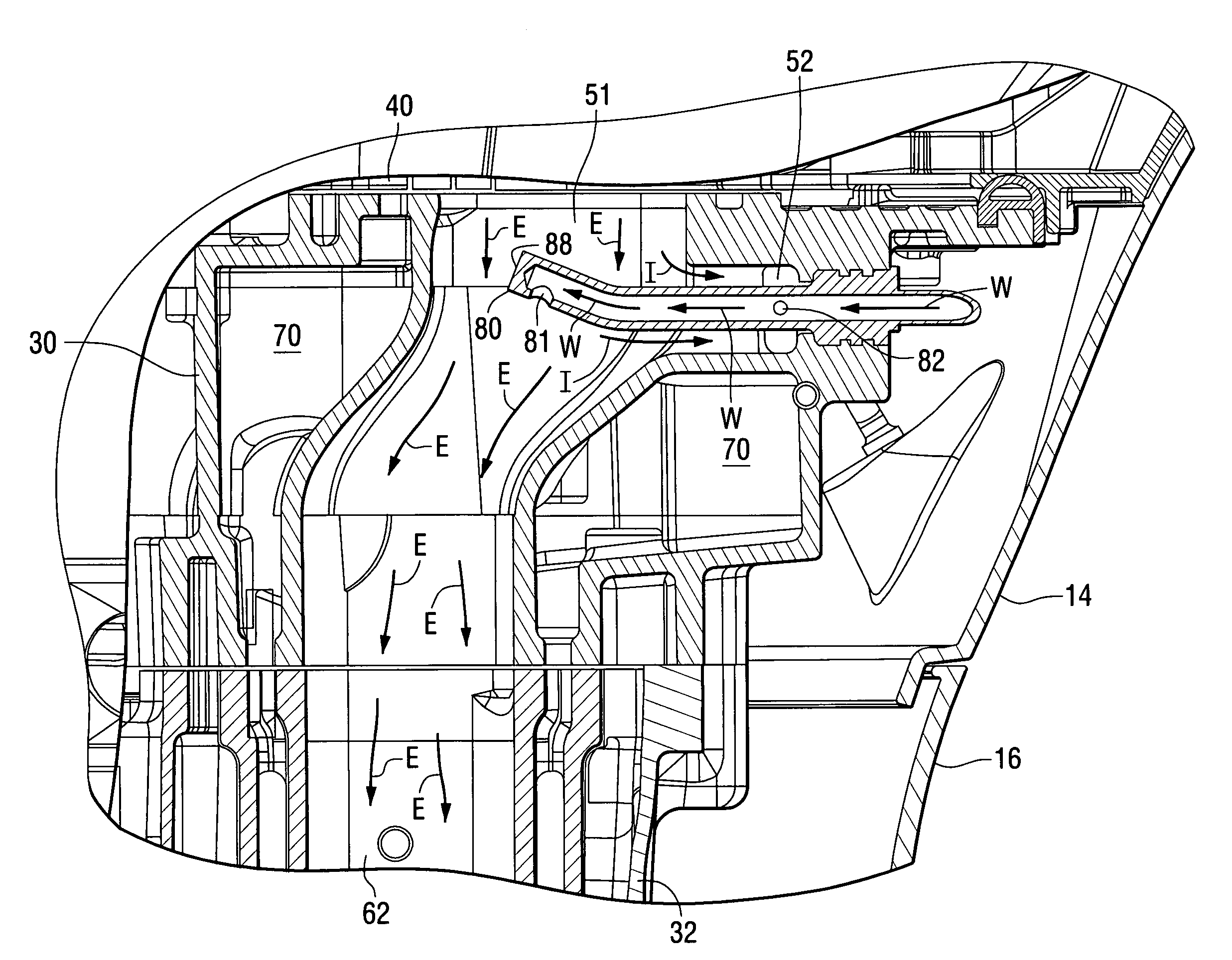

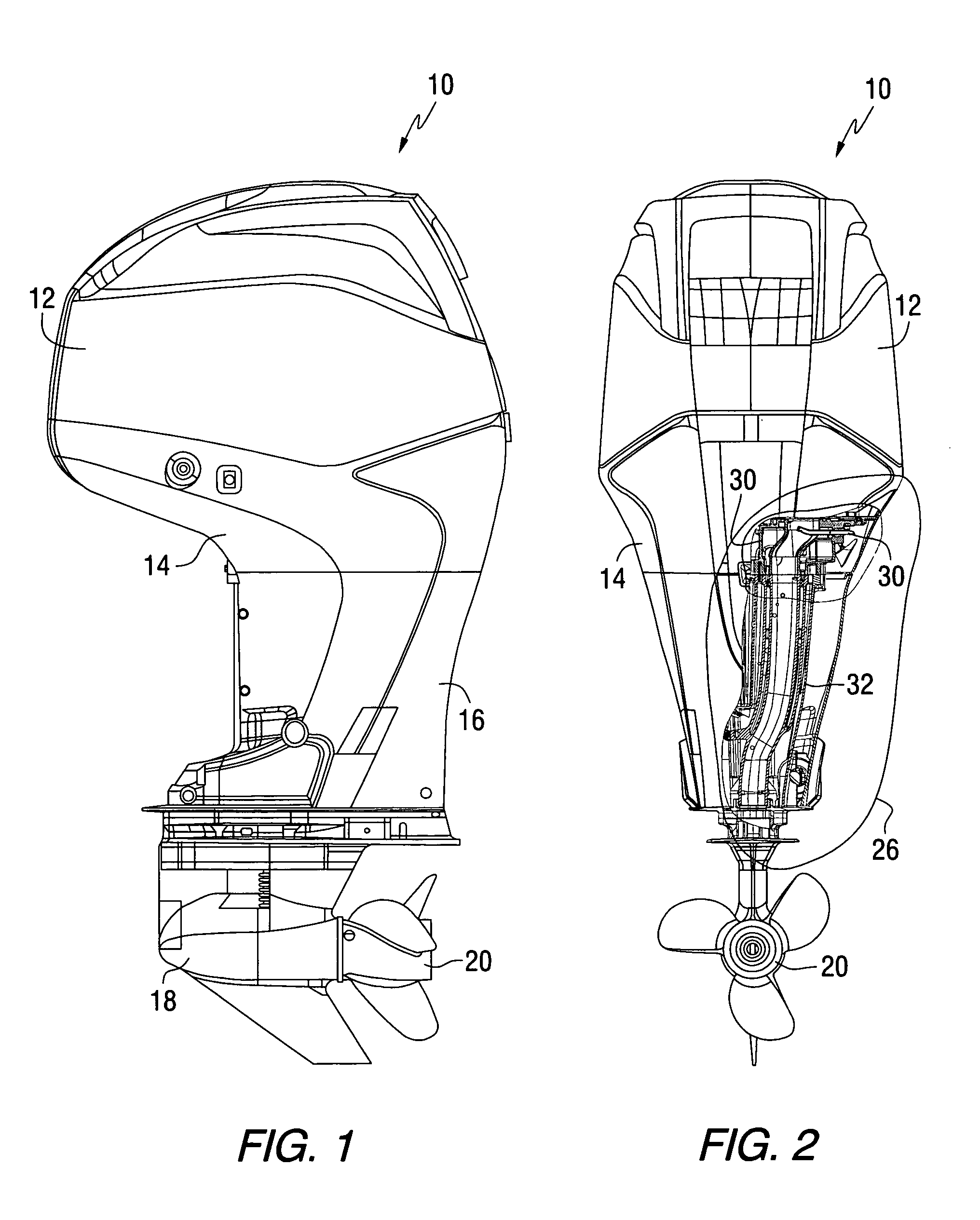

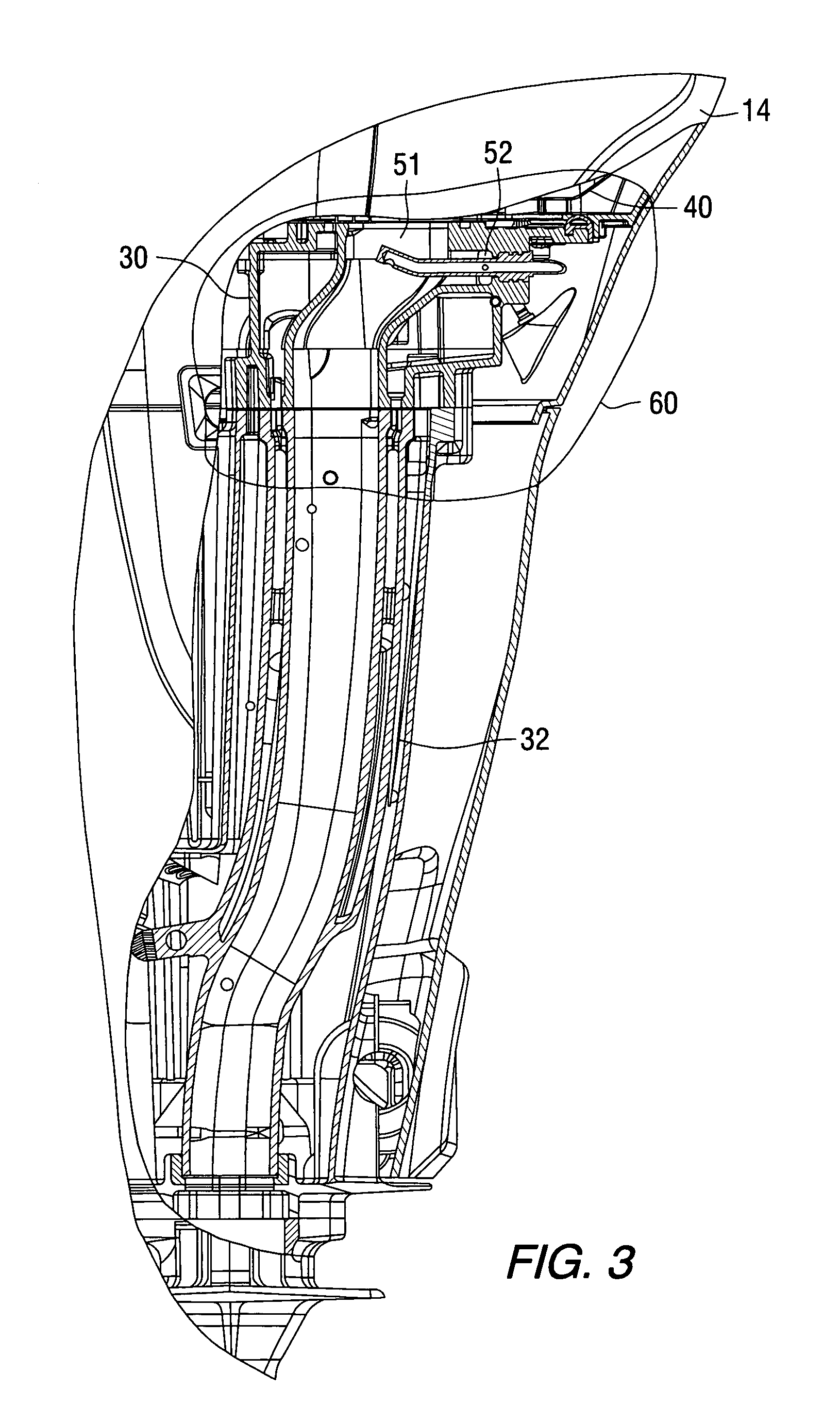

Dual water injector for primary and idle relief exhaust passages

A water cooling system for an outboard motor provides a water conduit that extends through both an idle exhaust relief passage and a primary exhaust passage. Water within the water conduit flows through first and second openings to distribute sprays or streams of water into first and second exhaust conduits which can be the primary and idle exhaust relief passages of an outboard motor.

Owner:BRUNSWICK CORPORATION

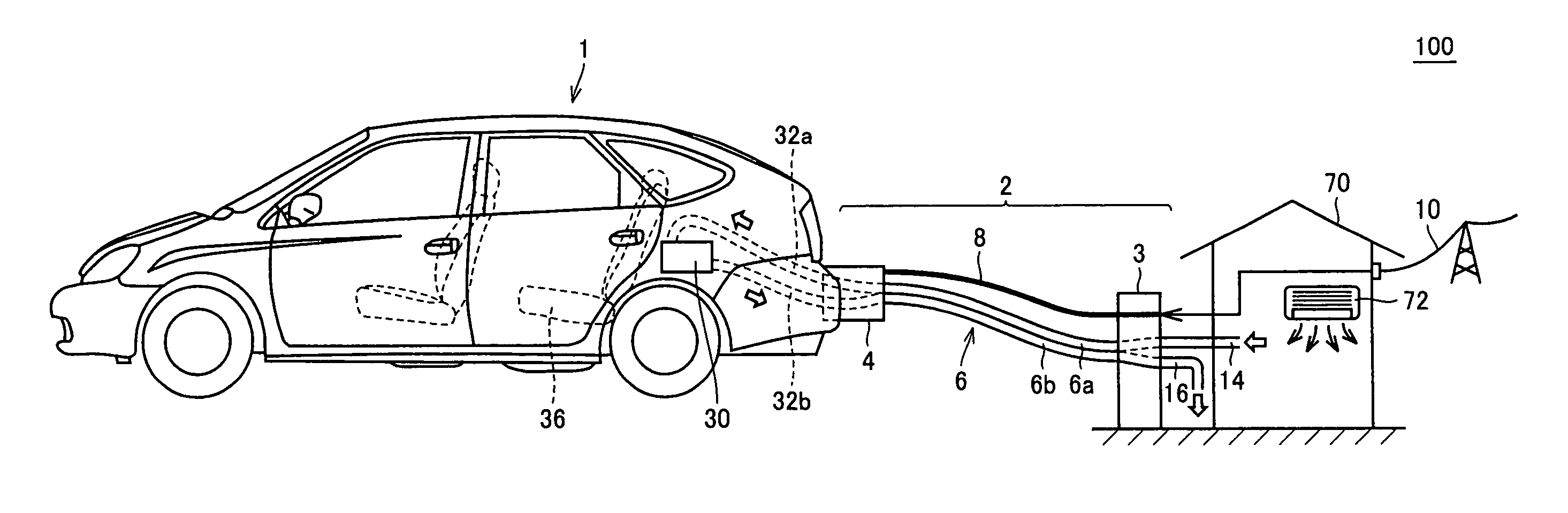

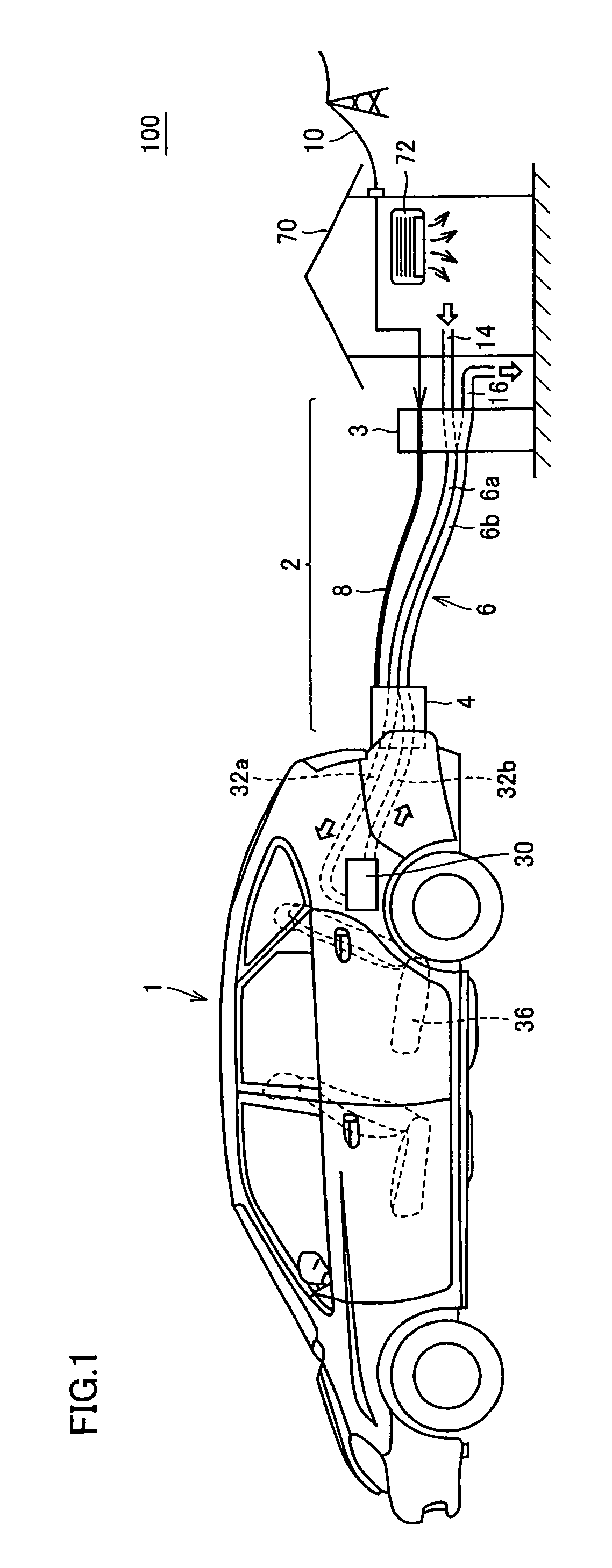

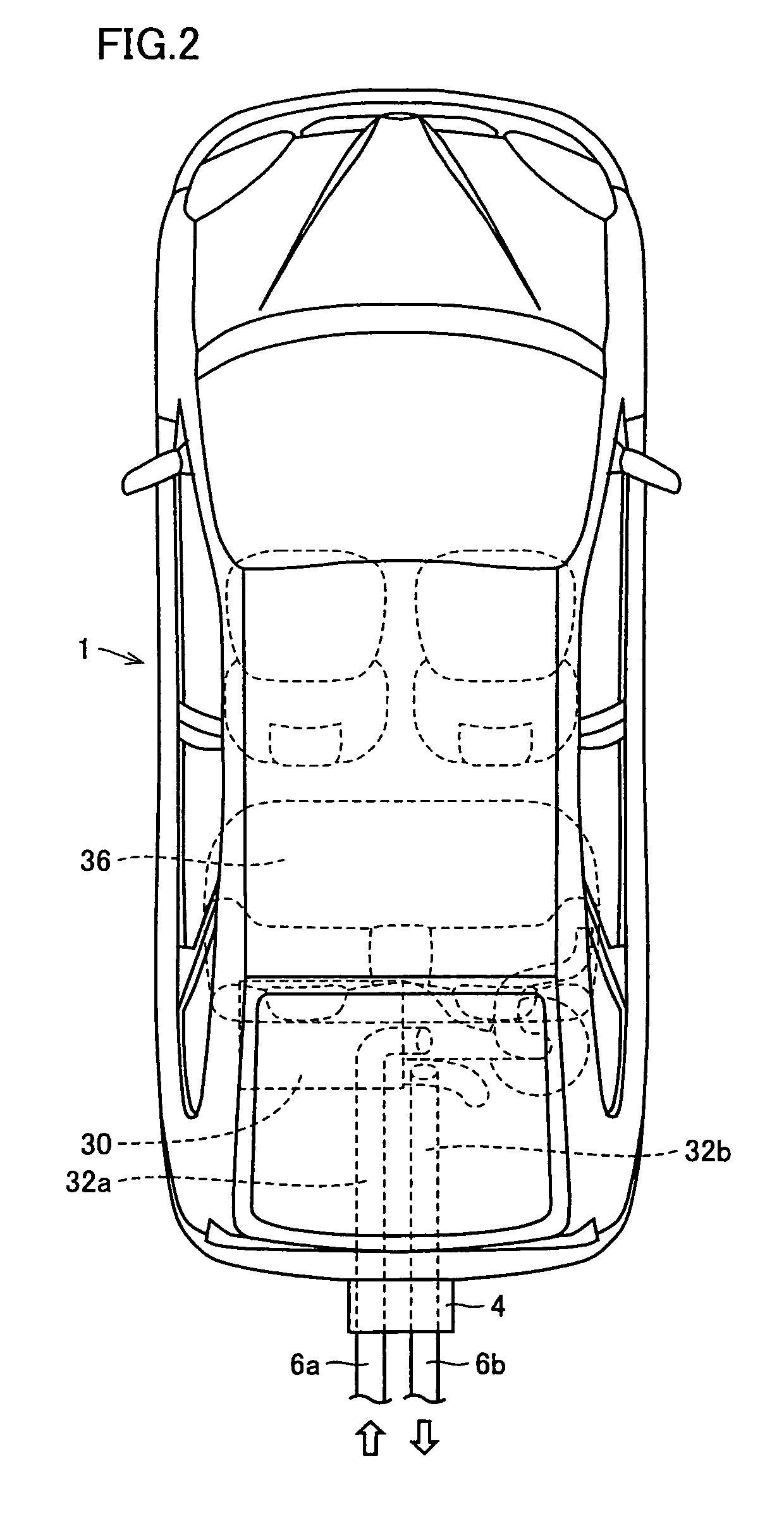

Vehicle charging system, vehicle charging device and electric vehicle

ActiveUS8098044B2Reduce usageInhibition retentionBatteries circuit arrangementsCharging stationsElectric vehicleShock absorber

Owner:TOYOTA JIDOSHA KK

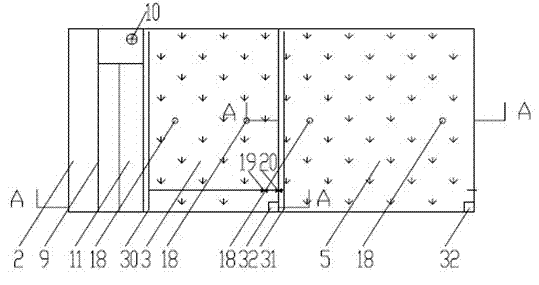

City life residential area rainwater shunting, collecting and treating system

ActiveCN102359172AExtended processing timeSmall footprintGeneral water supply conservationSustainable biological treatmentConstructed wetlandWater quality

The invention discloses a city life residential area rainwater shunting, collecting and treating system. The city life residential area rainwater shunting, collecting and treating system comprises a water inlet pond, an initial rainwater storage pond and a clean water pond and is characterized in that a first constructed wetland is arranged above the initial rainwater storage pond and a second constructed wetland is arranged above the clean water pond; the rainwater of the city life residential area collected by a rain sewage collecting conduit flows into the water inlet pond, flows into the initial rainwater storage pond after passing through the first constructed wetland and then flows into the clean water pond after passing through the second constructed wetland. By using the system disclosed by the invention, the initial rainwater and the later rainwater of the residential area are shunted and treated; a rainwater purification facility and a storage facility are constructed with one blow the other so that the space usage of the treatment process is reduced; the inferior rainwater in the initial rainwater storage pond is discharged into the second constructed wetland to be continuously treated by using a time slot without rain after the rain stops so that the inferior rainwater is recycled after reaching the city nondrinking water quality; and the system has the advantages of investment conservation, low operation cost and easiness in operation and management.

Owner:CHONGQING UNIV

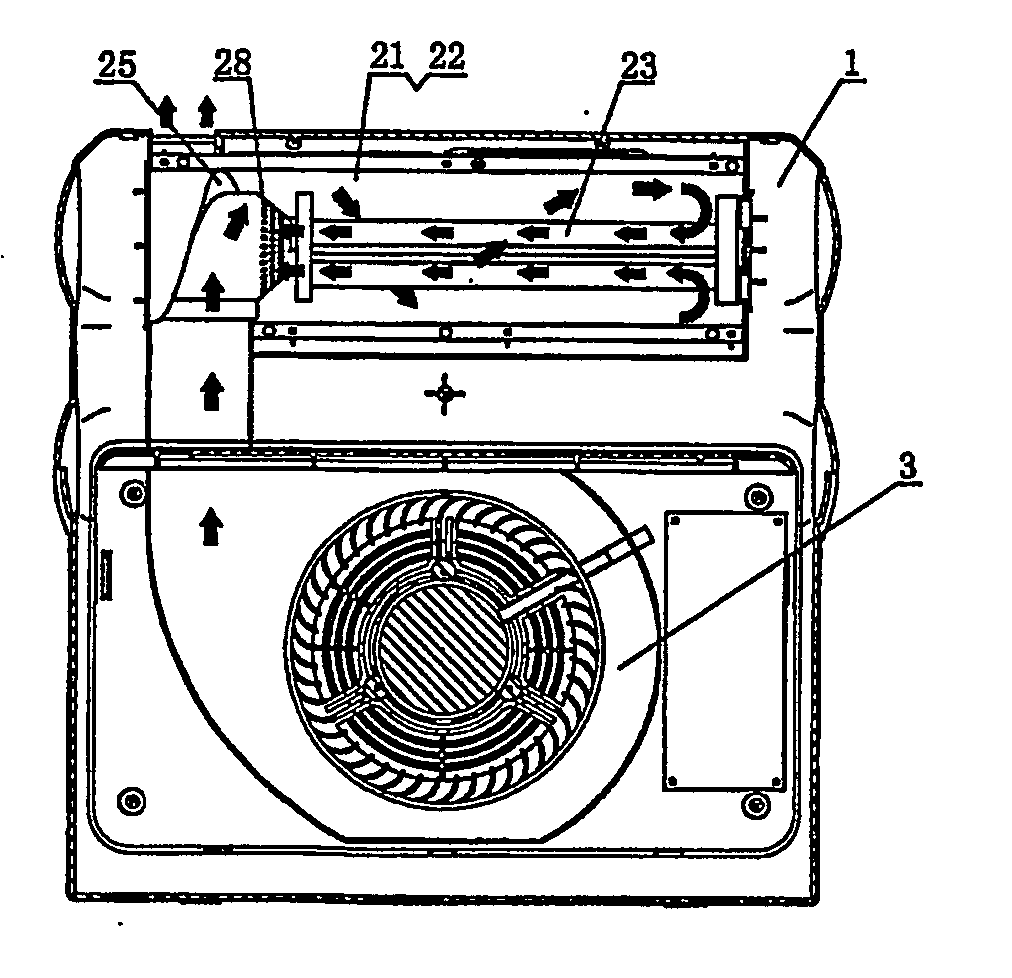

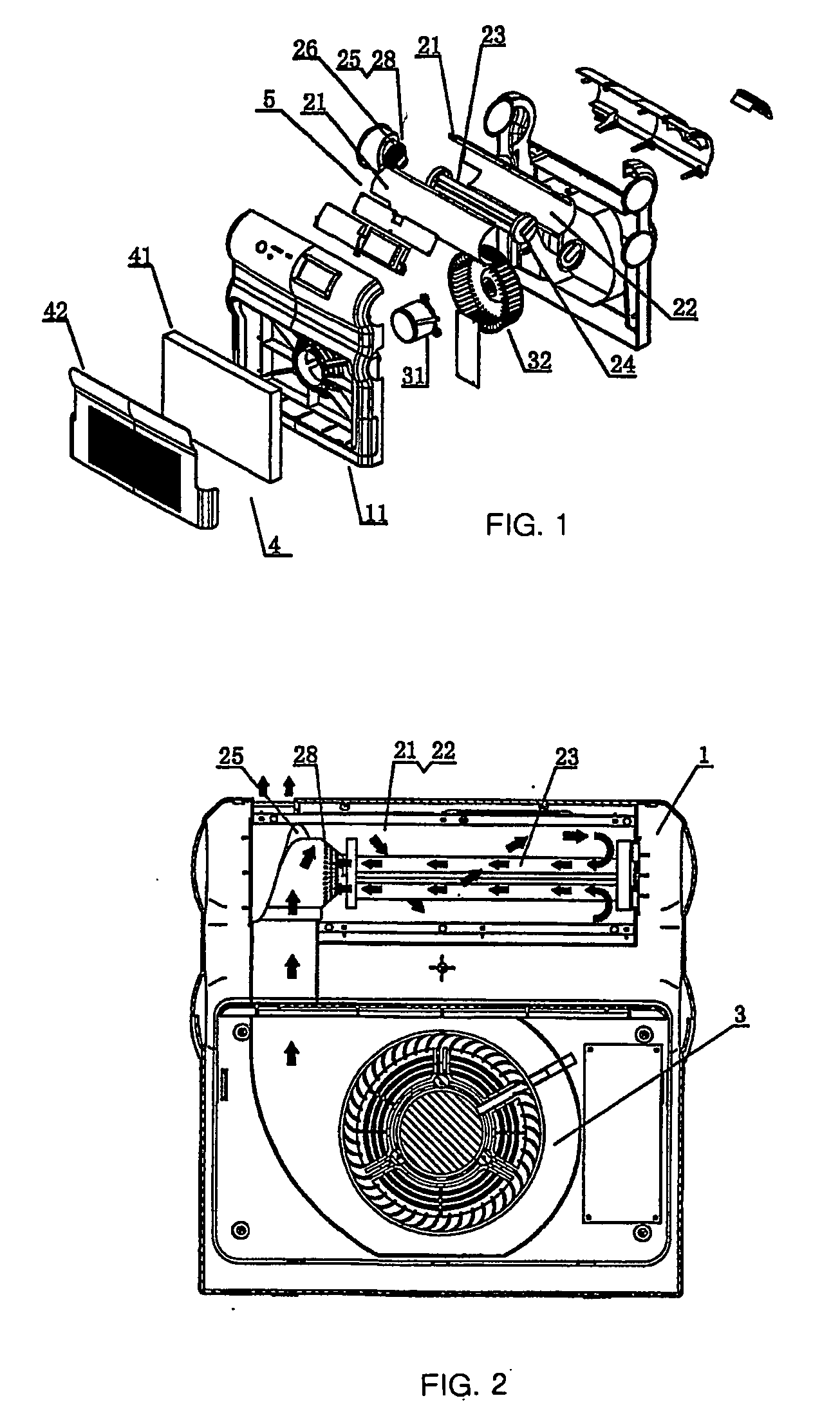

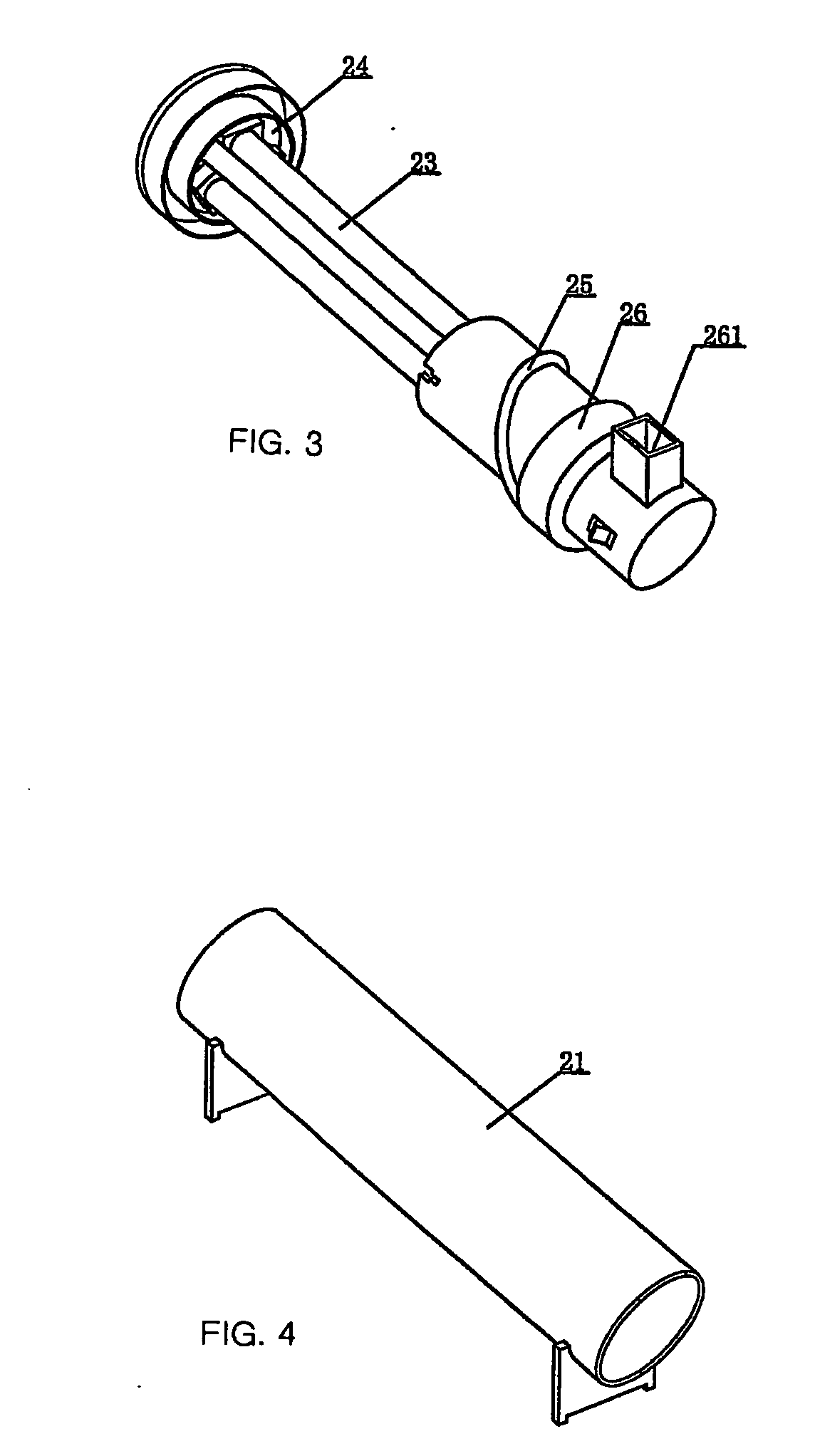

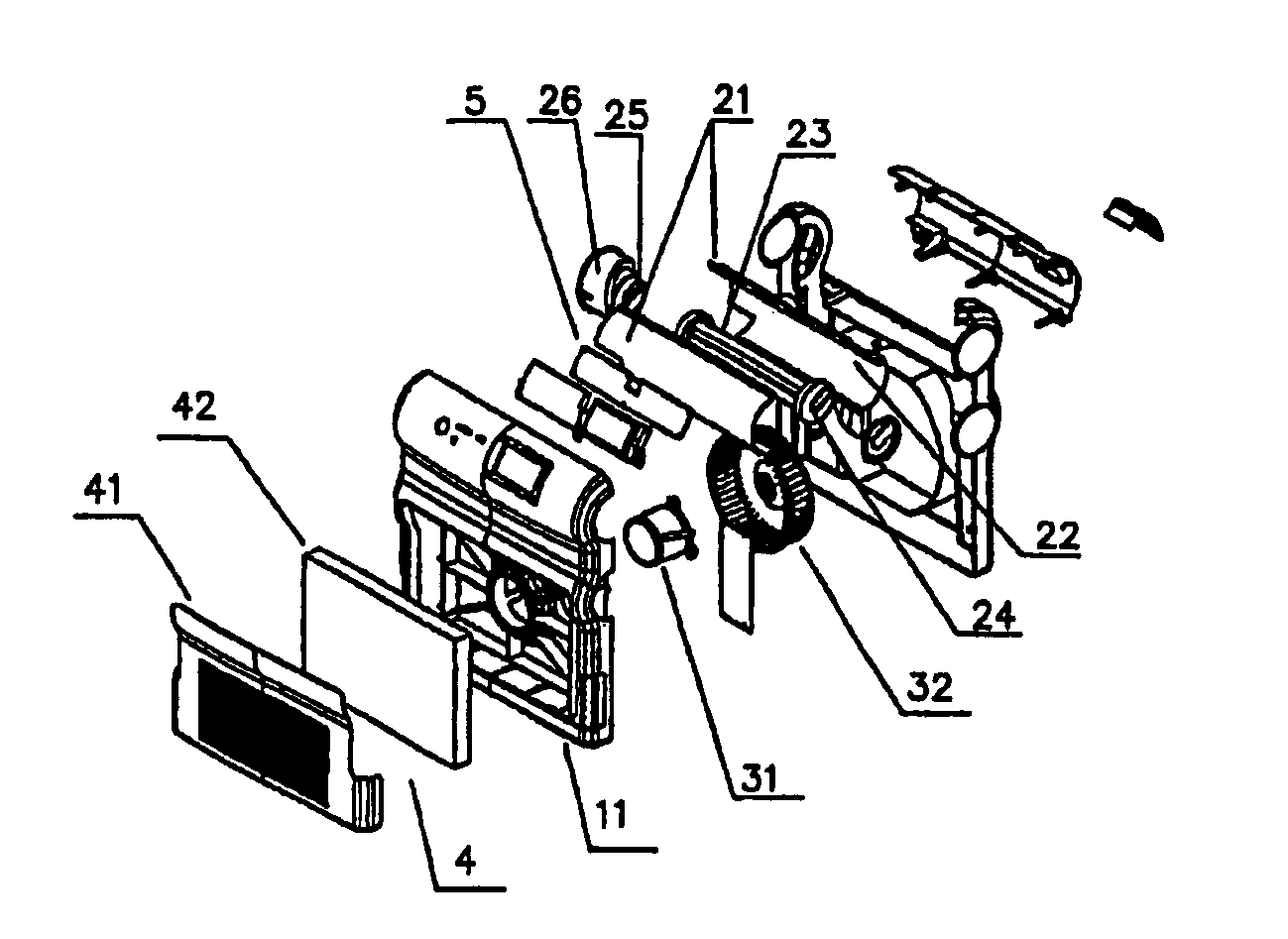

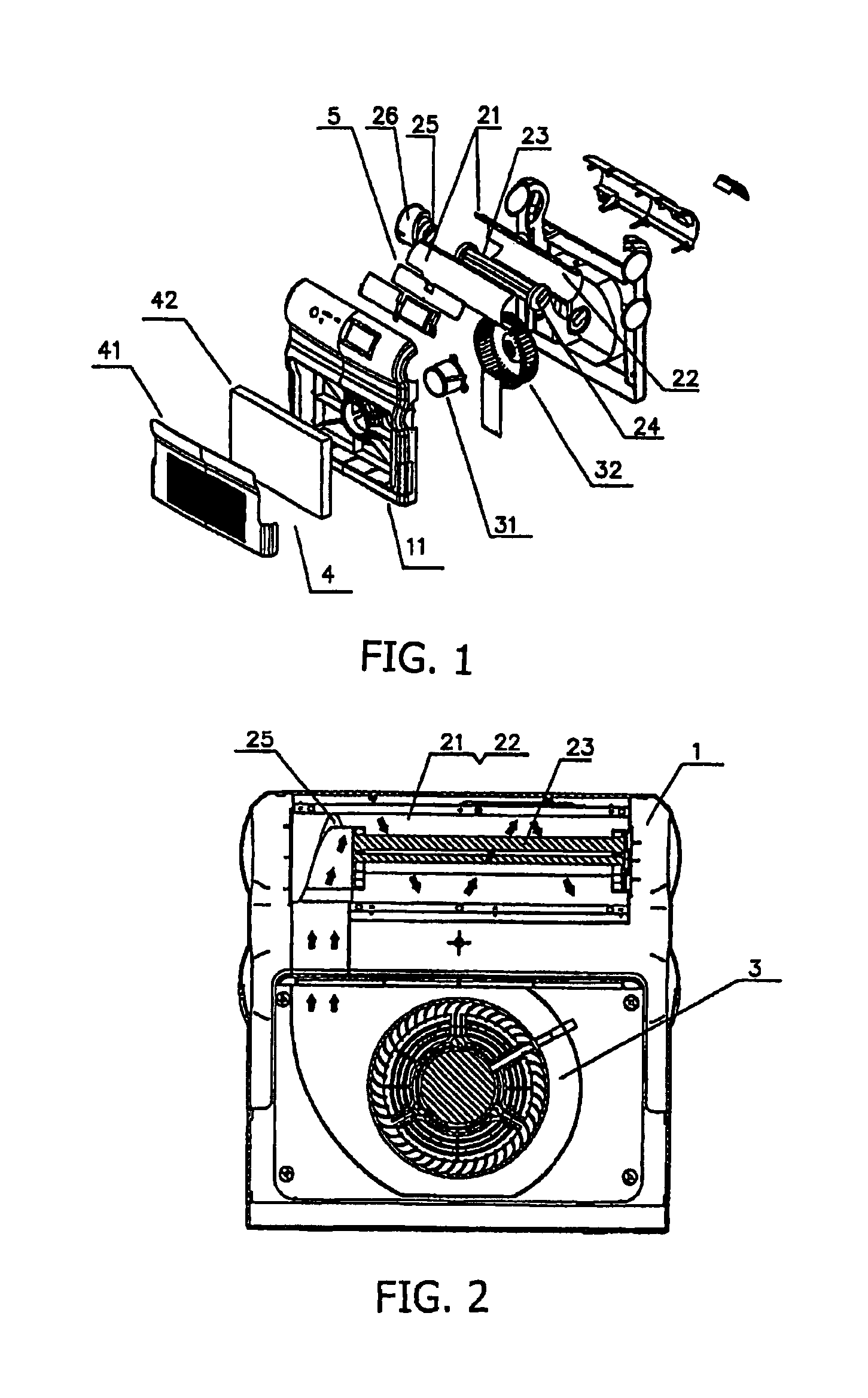

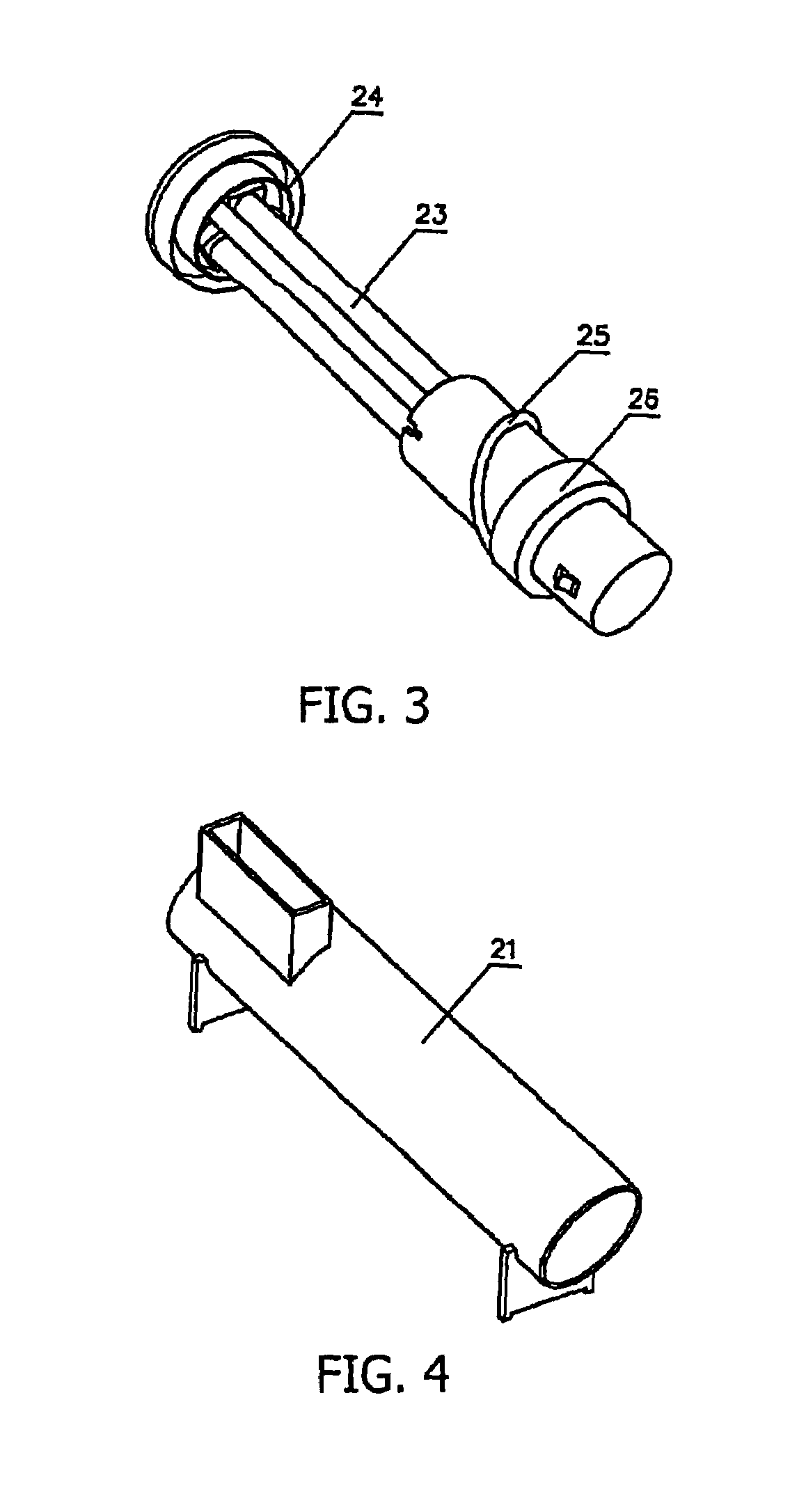

Air cleaner

InactiveUS20060159598A1Increase contactGood effectGas treatmentDispersed particle separationForced convectionConduit flow

An air cleaner includes a housing, a filter, a photocatalyst reaction unit which can form a spiral air flow, a forced convection device, and an electrocircuit controller. The forced convection device is located between the filter and the photocatalyst reaction unit. Because the air cleaner uses a longitudinal air conduit, an air inlet along a tangential direction of the air conduit, and spiral guide vanes at the inlet, air passing through a fan and into the air conduit flows spirally in the conduit to increase the time during which air contacts the photocatalyst and enables the light of the ultraviolet lamp to radiate the photocatalyst directly so that the cleaning efficiency of the photocatalyst is increased.

Owner:CHIAPHUA INDS

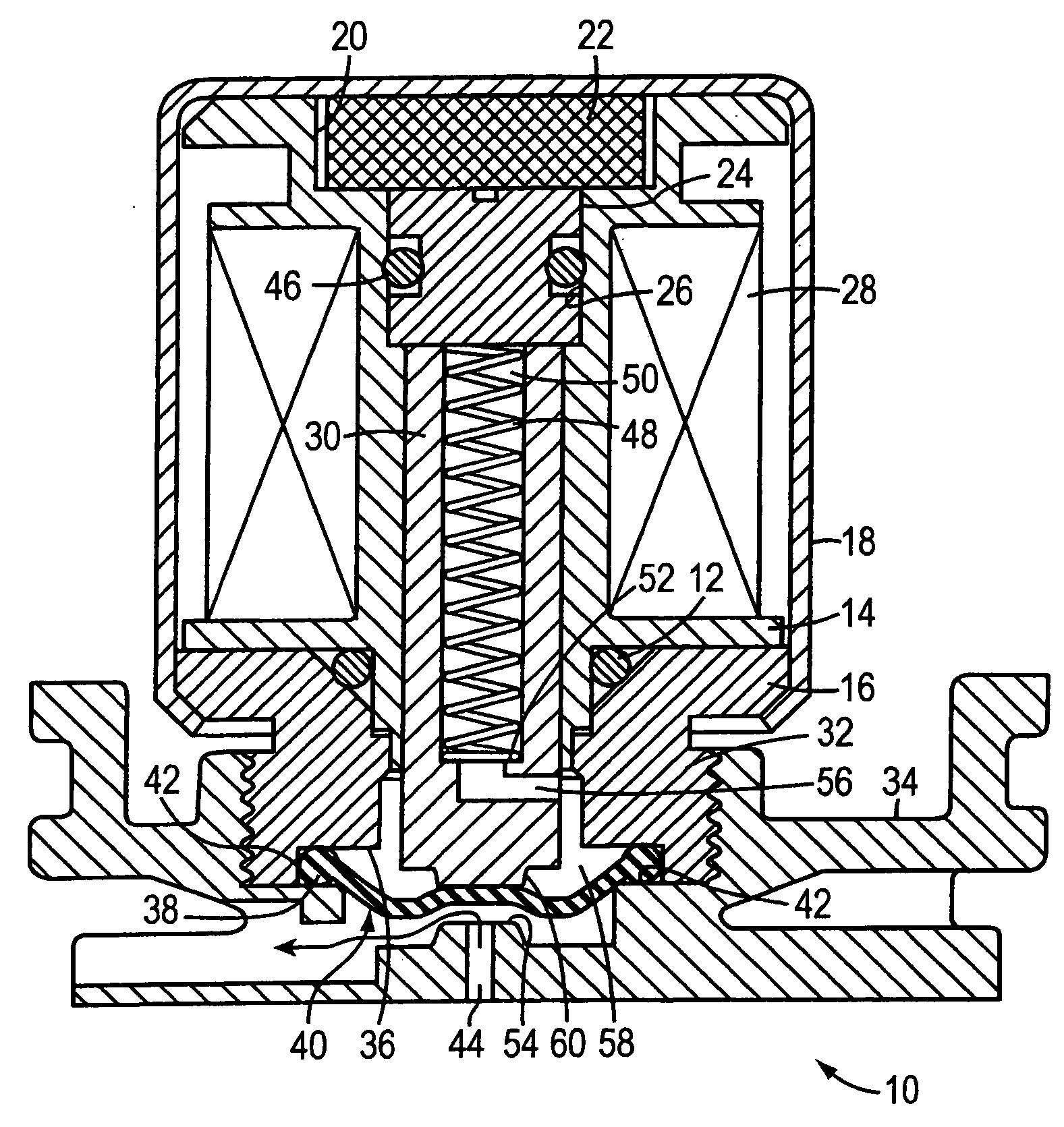

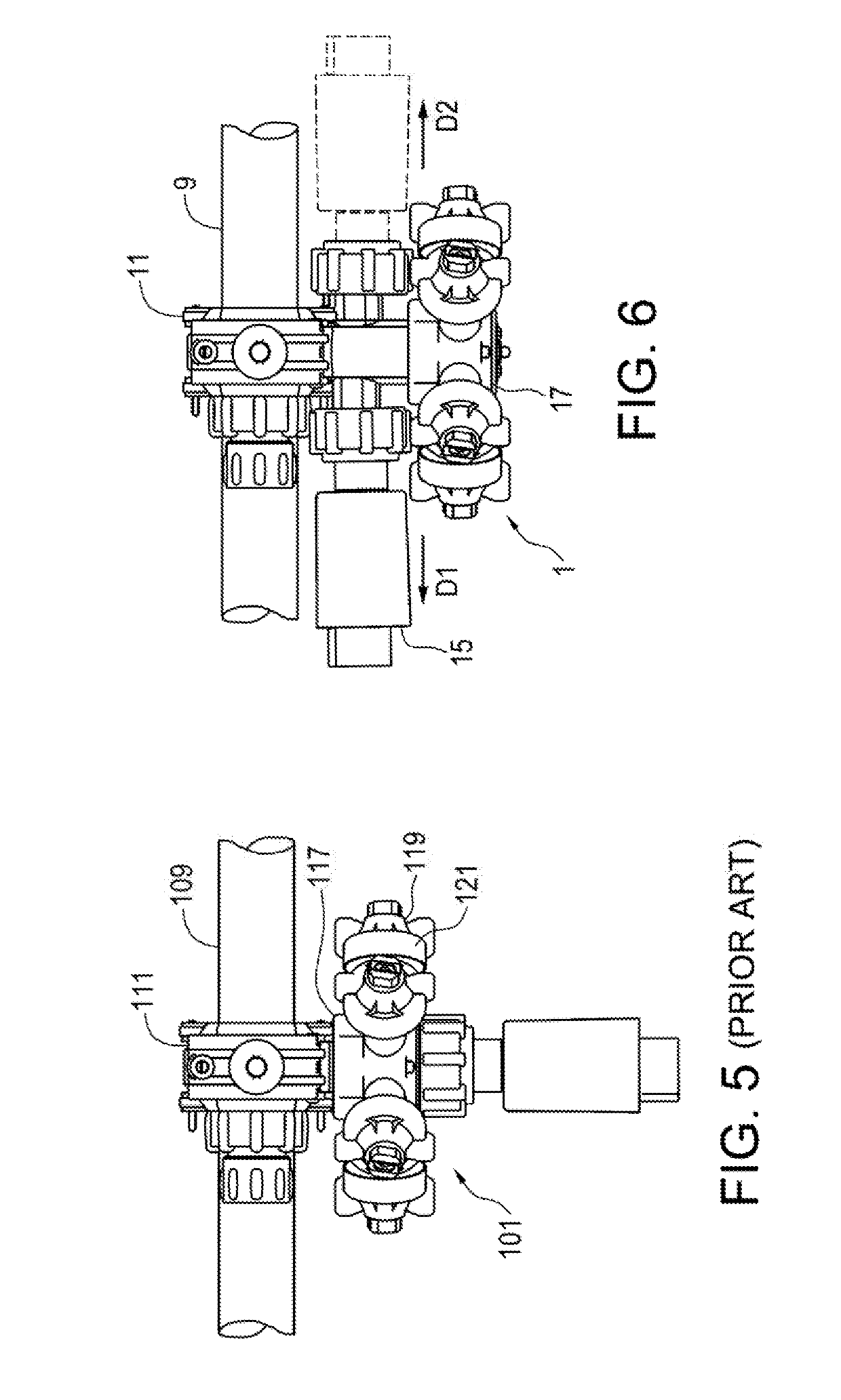

Apparatus and method for controlling fluid flow

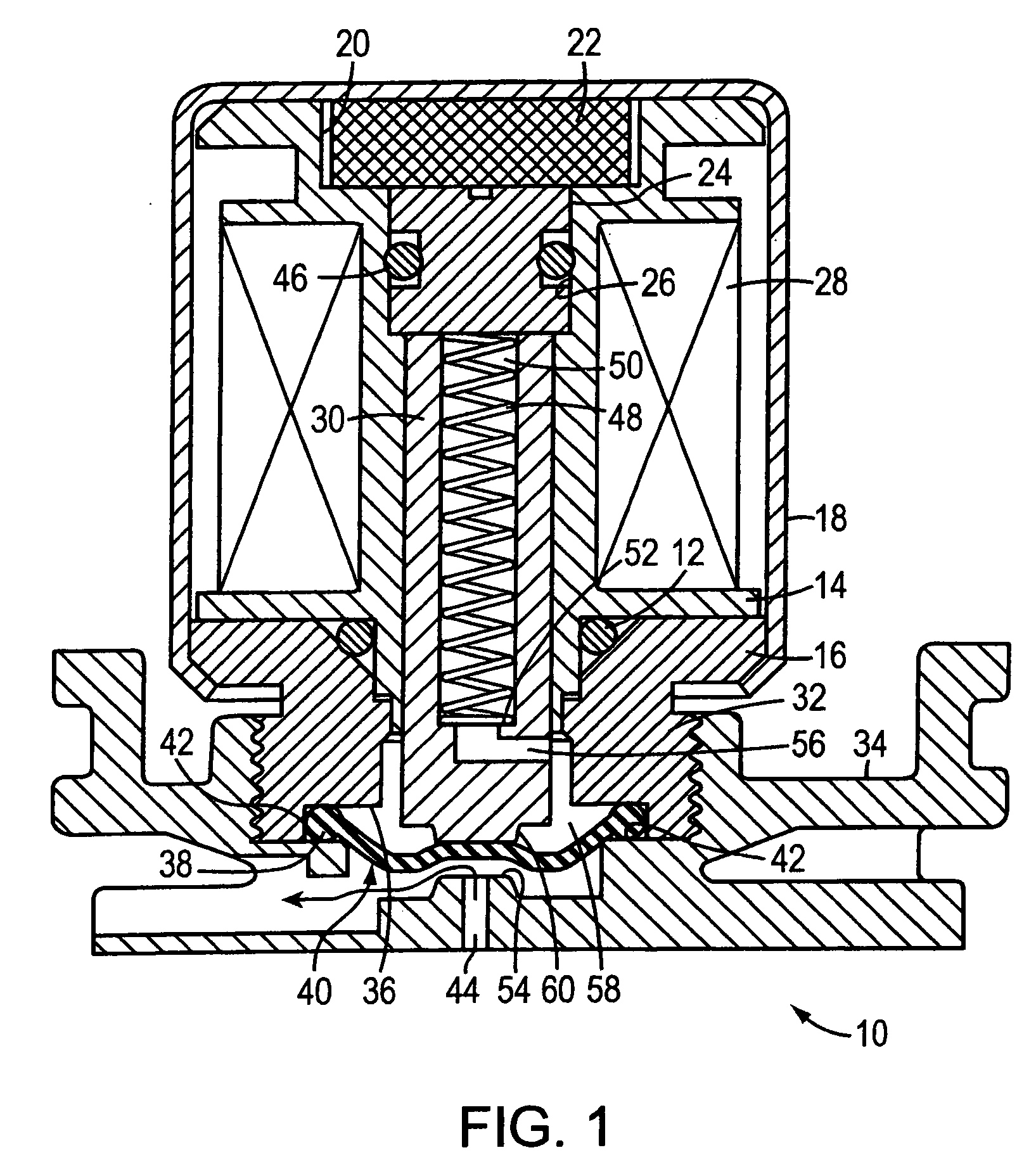

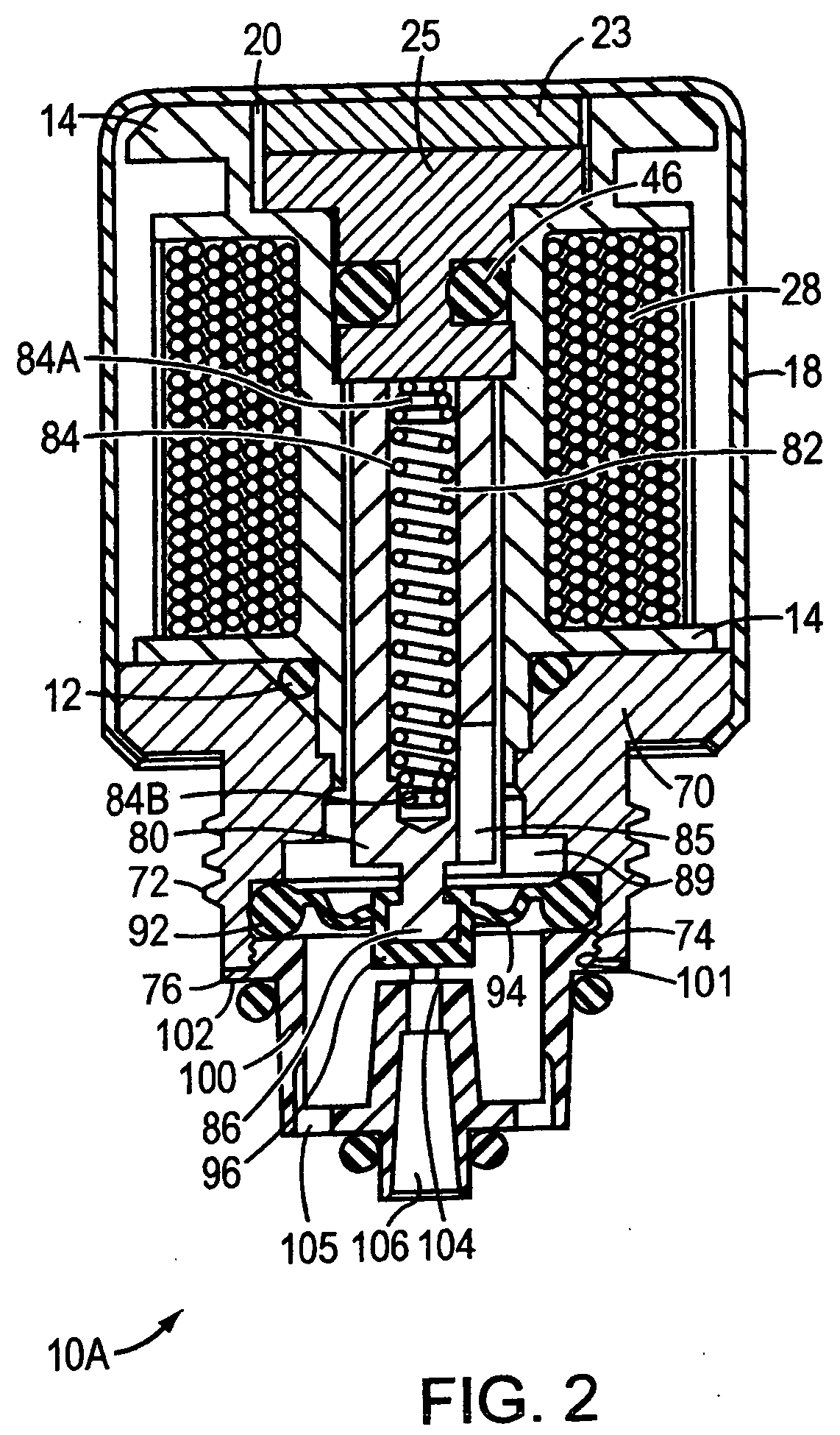

InactiveUS20060108552A1Reduce energy wasteReduce energy consumptionSpindle sealingsDiaphragm valvesBobbinEngineering

An actuator base, bobbin, and pole piece form a pocket for an armature that a flexible membrane encloses to form an armature chamber filled with an incompressible fluid. The membrane protects the armature from exposure to corrosive fluids flowing in a conduit. Conduit flow can be stopped by driving the membrane against a valve seat. Pressure from the controlled fluid in the conduit is transmitted through the membrane to the fluid within the armature chamber so that the armature does not need to counteract force applied to the membrane by the conduit fluid's pressure.

Owner:ARICHELL TECH INC

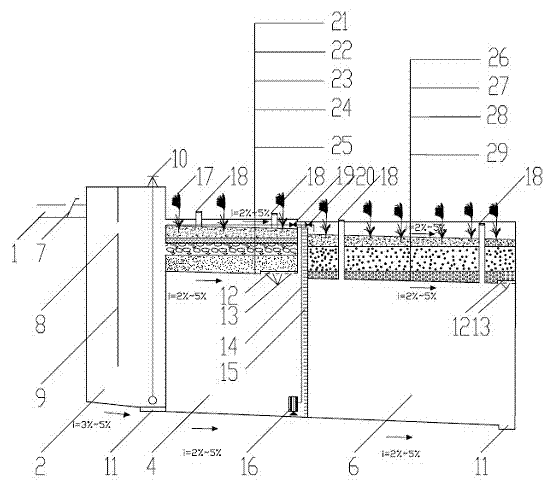

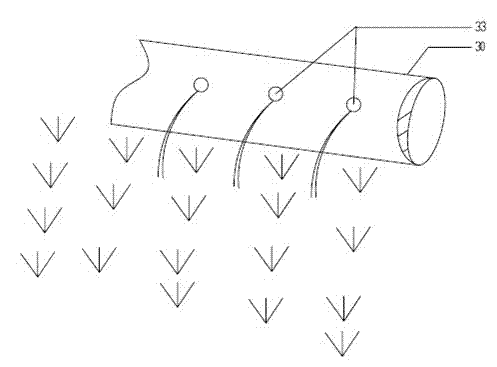

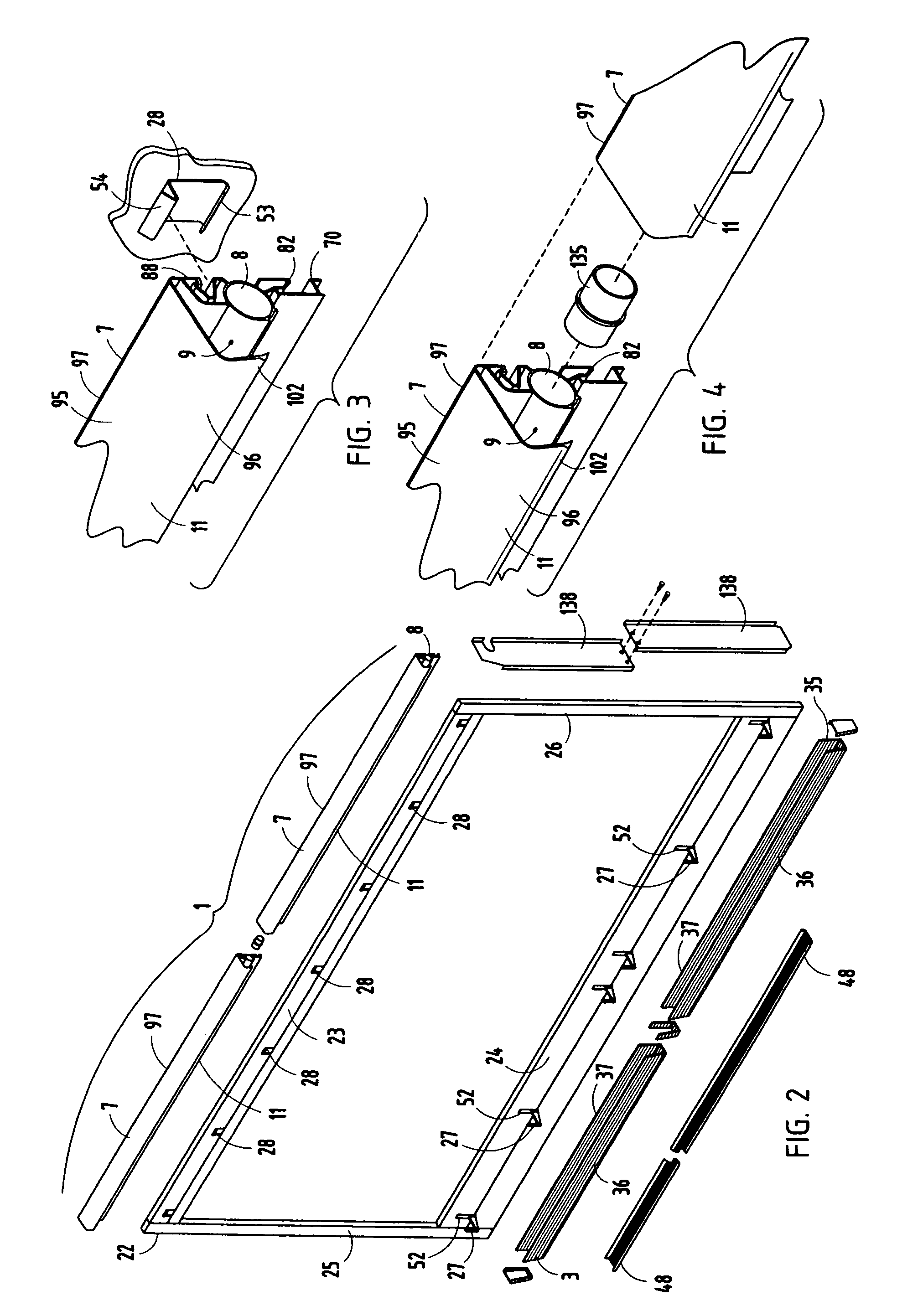

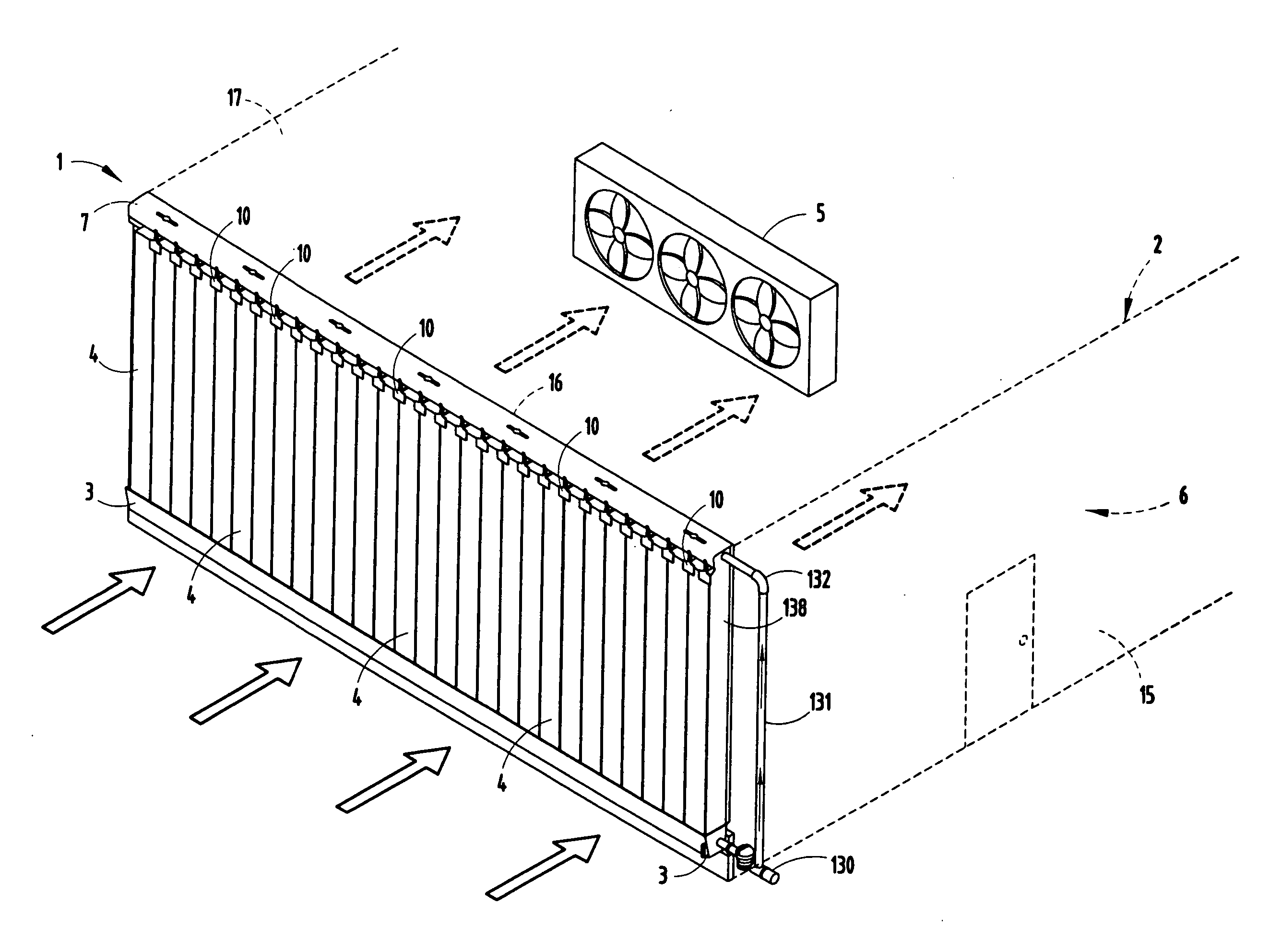

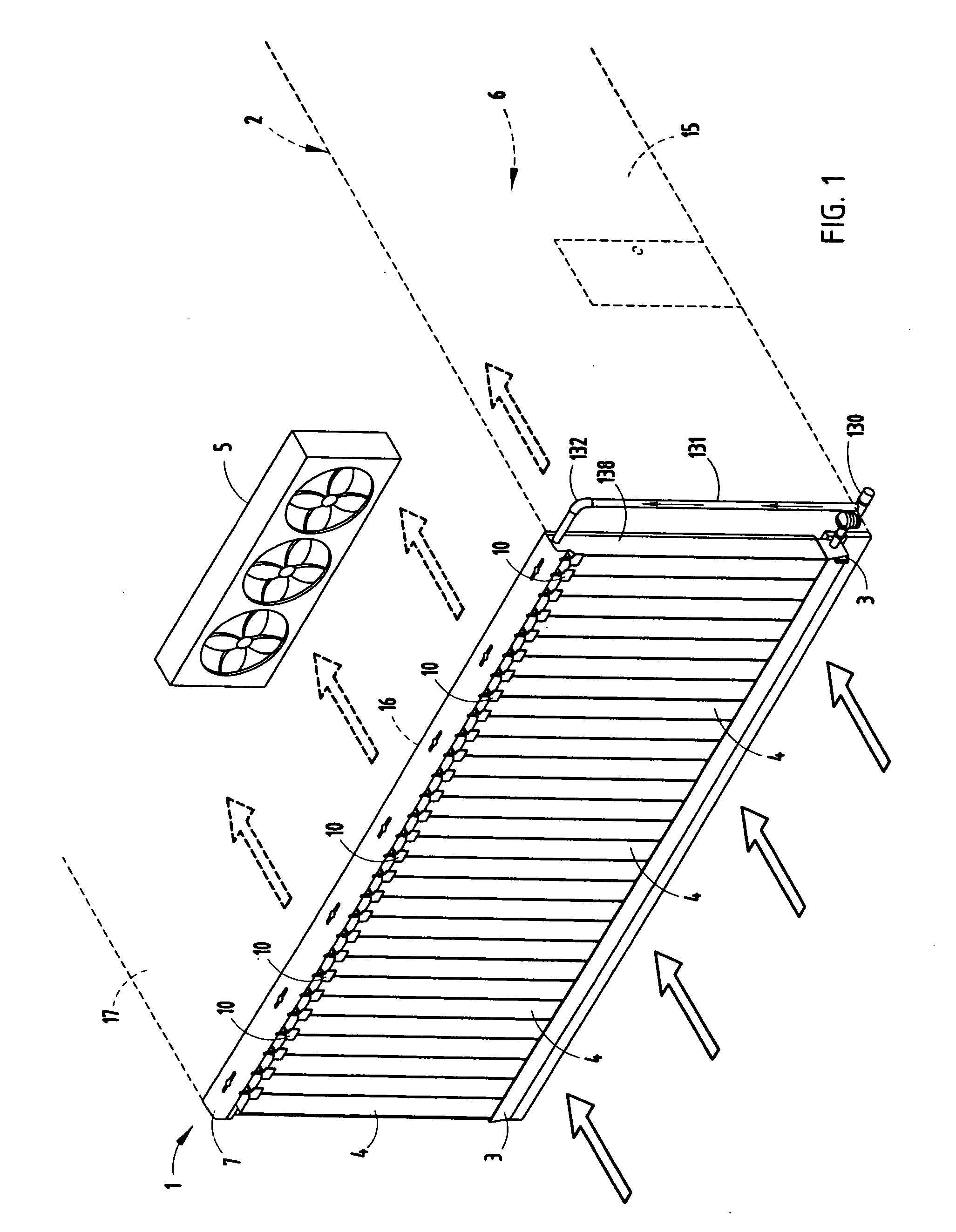

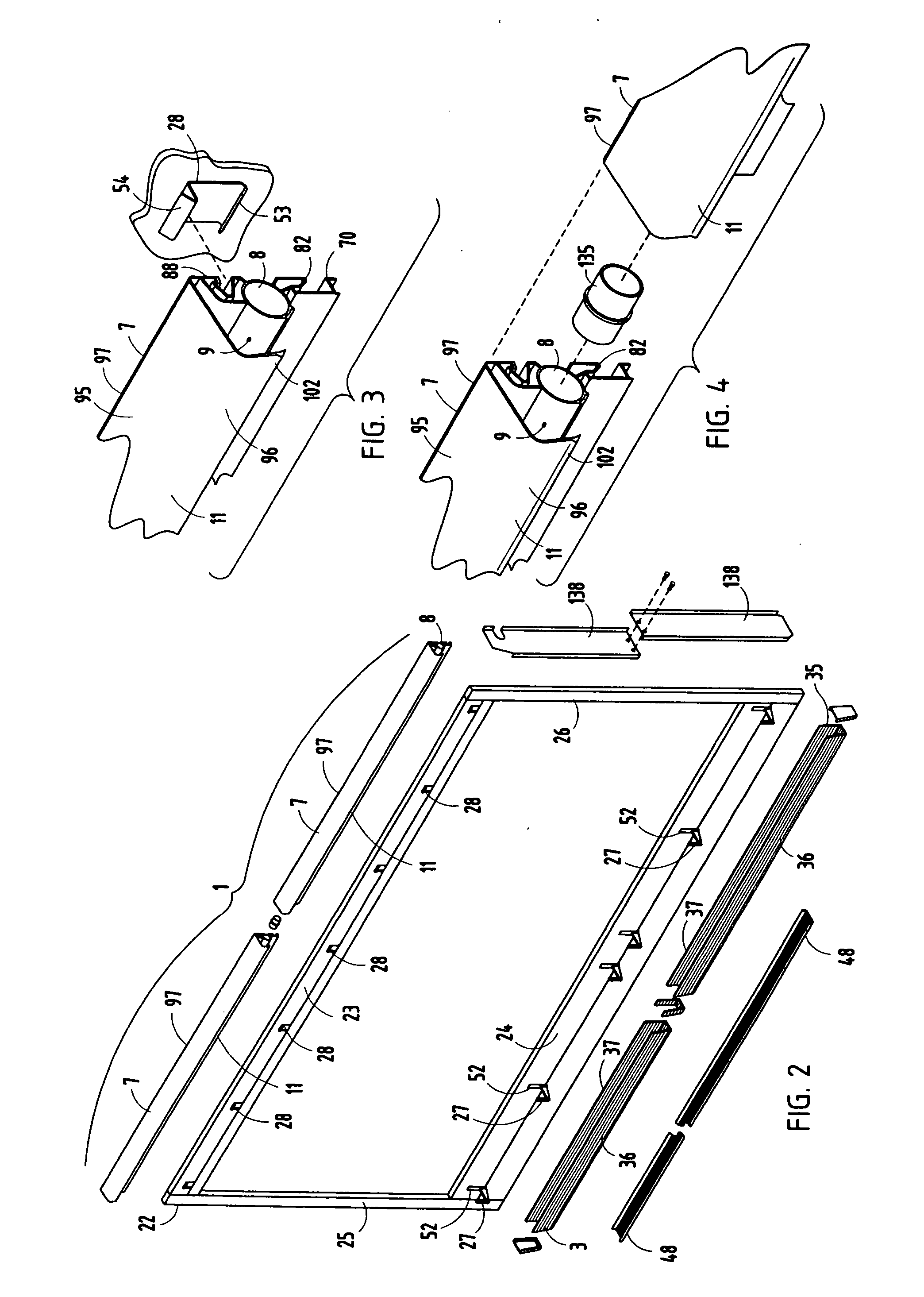

Evaporative cooling system for poultry houses and the like

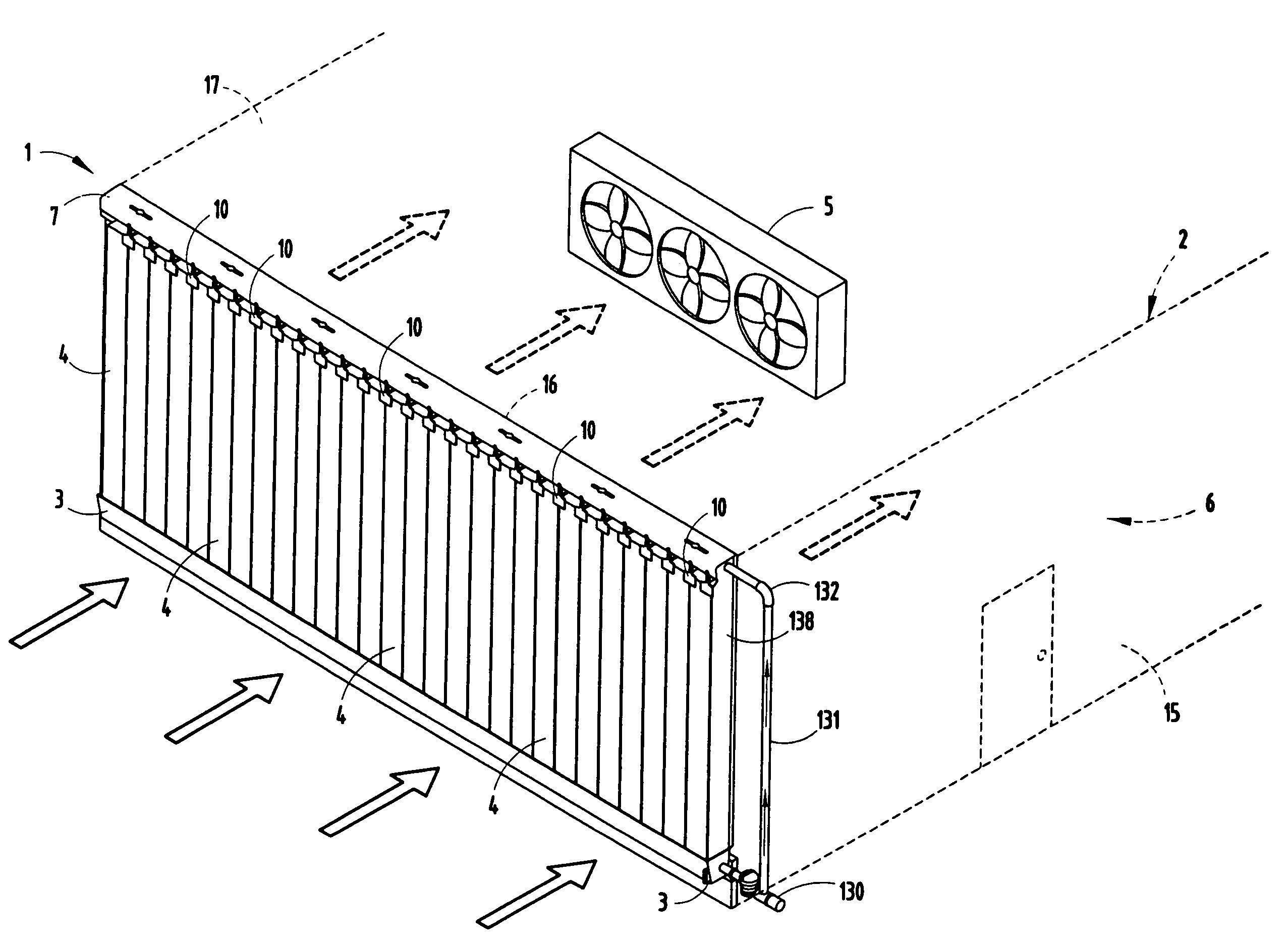

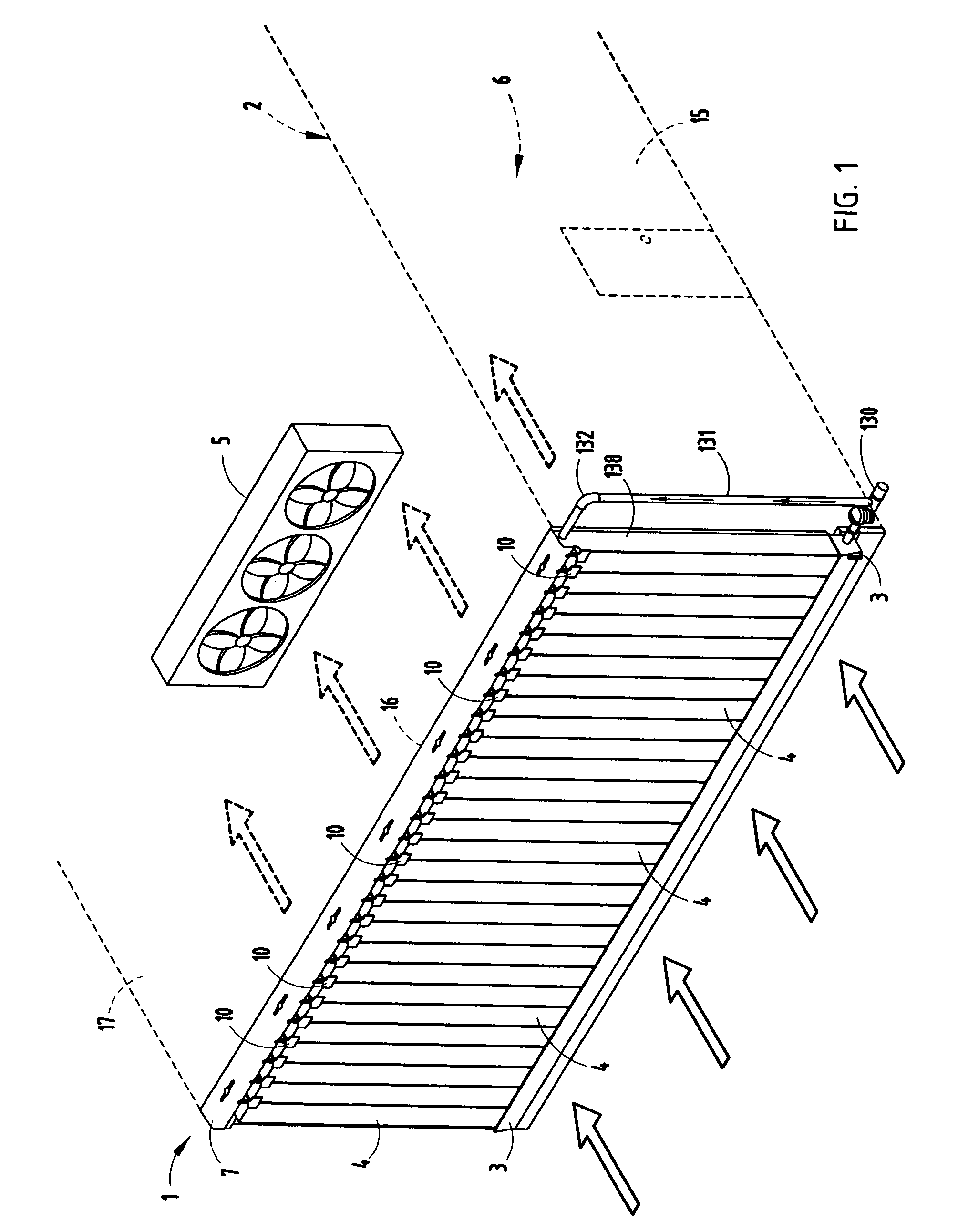

InactiveUS7350364B2Easy to useIncreased operating lifeClimate change adaptationLivestock managementWater flowPoultry house

An evaporative cooling system for poultry houses and the like includes a cooling water reservoir, at least one evaporative pad positioned directly above the reservoir, and fan disposed on one side of the pad to draw ambient air horizontally through the pad to evaporate a portion of the cooling water flowing vertically therethrough, and flow the cooled air into the interior of the poultry house. A header is disposed above and along the upper end of the pad, and includes a conduit flowing cooling water longitudinally therethrough with orifices shaped to emit streams of cooling water in an outwardly direction. A deflector extends above and outwardly of the conduit, and has a hood-shaped configuration which deflects the streams of cooling water from the orifices and disburses the same in a predetermined pattern onto and across the upper end of the pad. The deflector has a flexible portion which permits the configuration of the deflector and the spray pattern to be varied to accommodate different configurations of the pad.

Owner:BIG DUTCHMAN INC

Evaporative cooling system for poultry houses and the like

InactiveUS20070163280A1Easy to installLower manufacturing requirementsClimate change adaptationLivestock managementWater flowEngineering

An evaporative cooling system for poultry houses and the like includes a cooling water reservoir, at least one evaporative pad positioned directly above the reservoir, and fan disposed on one side of the pad to draw ambient air horizontally through the pad to evaporate a portion of the cooling water flowing vertically therethrough, and flow the cooled air into the interior of the poultry house. A header is disposed above and along the upper end of the pad, and includes a conduit flowing cooling water longitudinally therethrough with orifices shaped to emit streams of cooling water in an outwardly direction. A deflector extends above and outwardly of the conduit, and has a hood-shaped configuration which deflects the streams of cooling water from the orifices and disburses the same in a predetermined pattern onto and across the upper end of the pad. The deflector has a flexible portion which permits the configuration of the deflector and the spray pattern to be varied to accommodate different configurations of the pad.

Owner:BIG DUTCHMAN INT

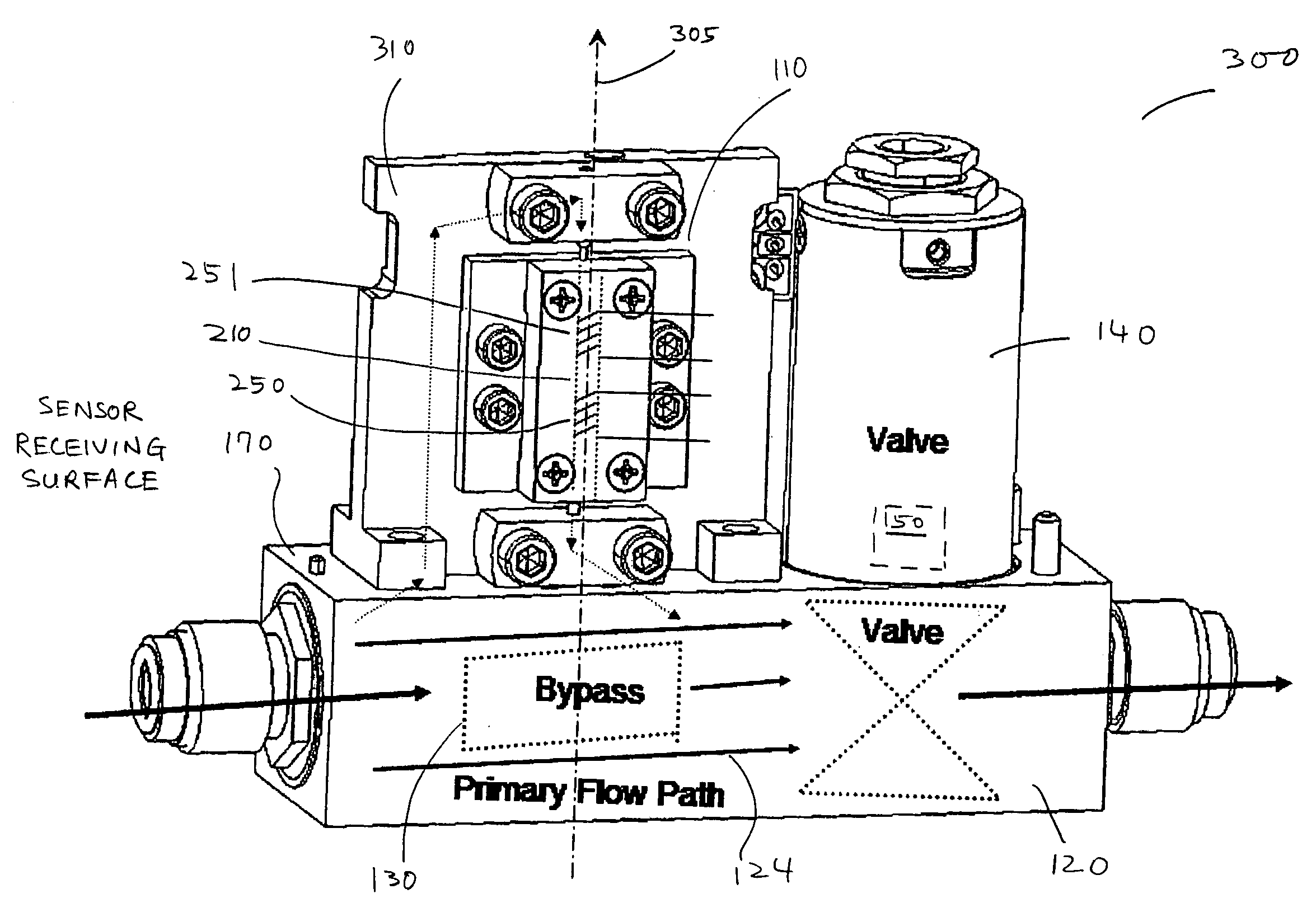

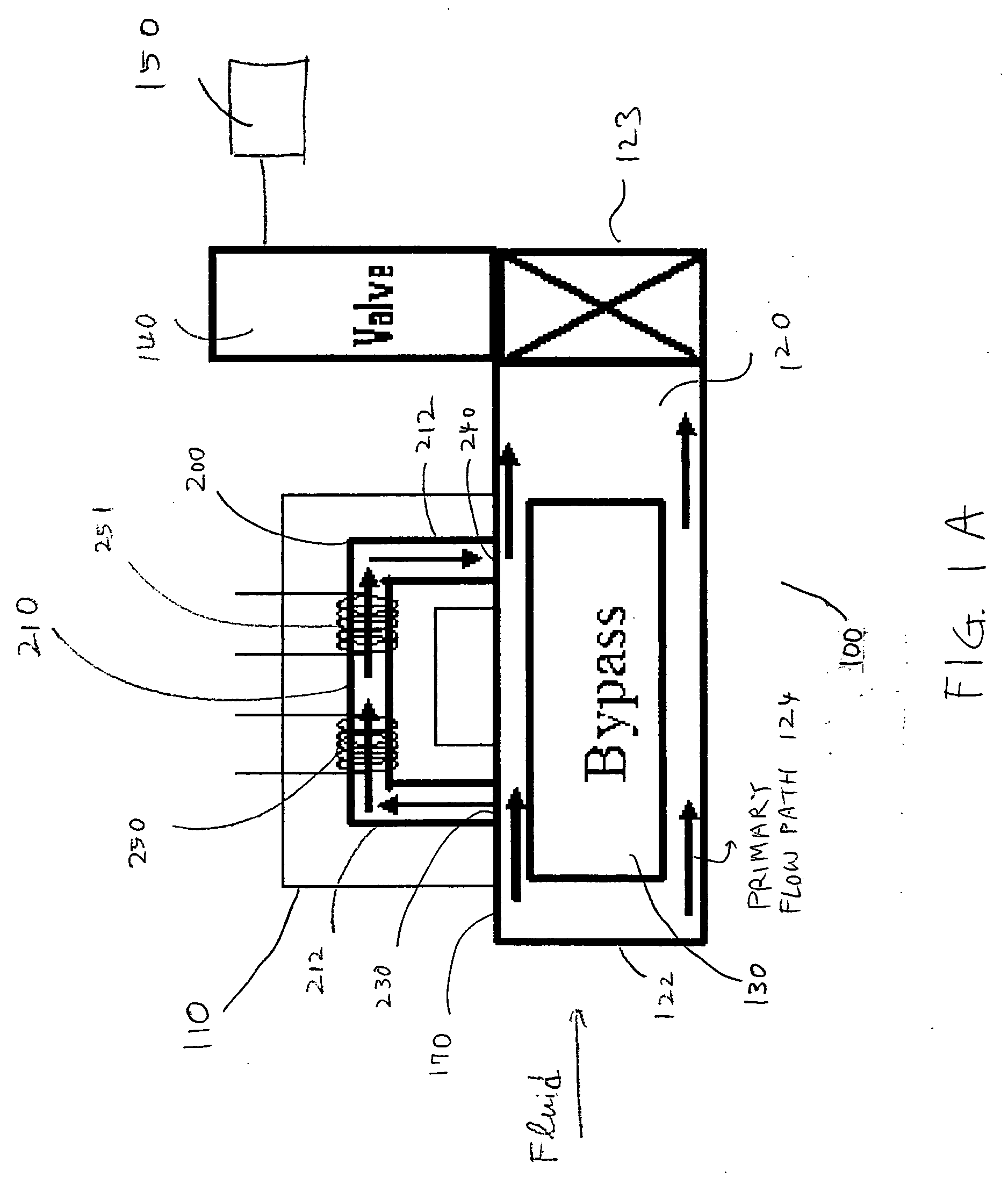

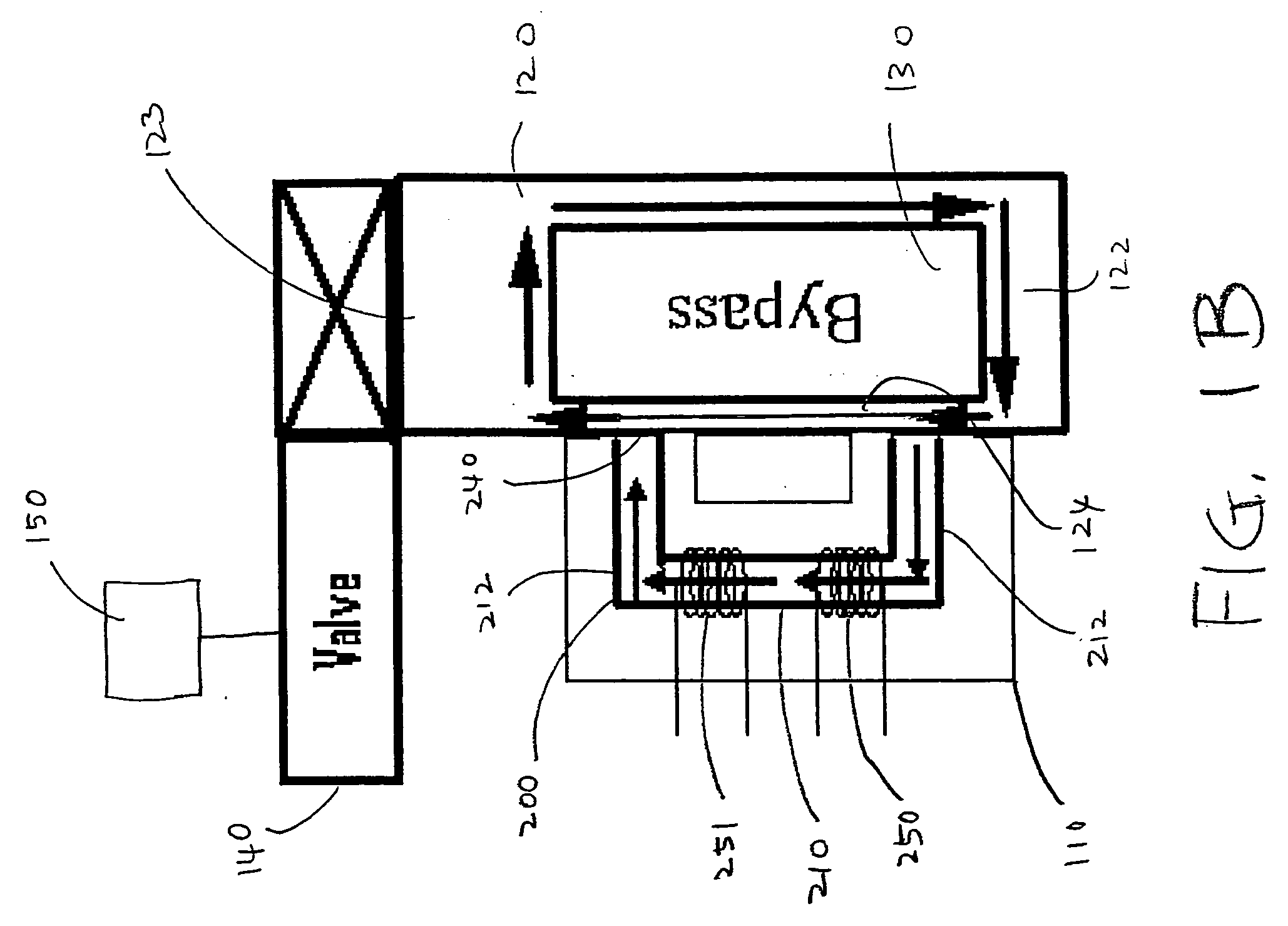

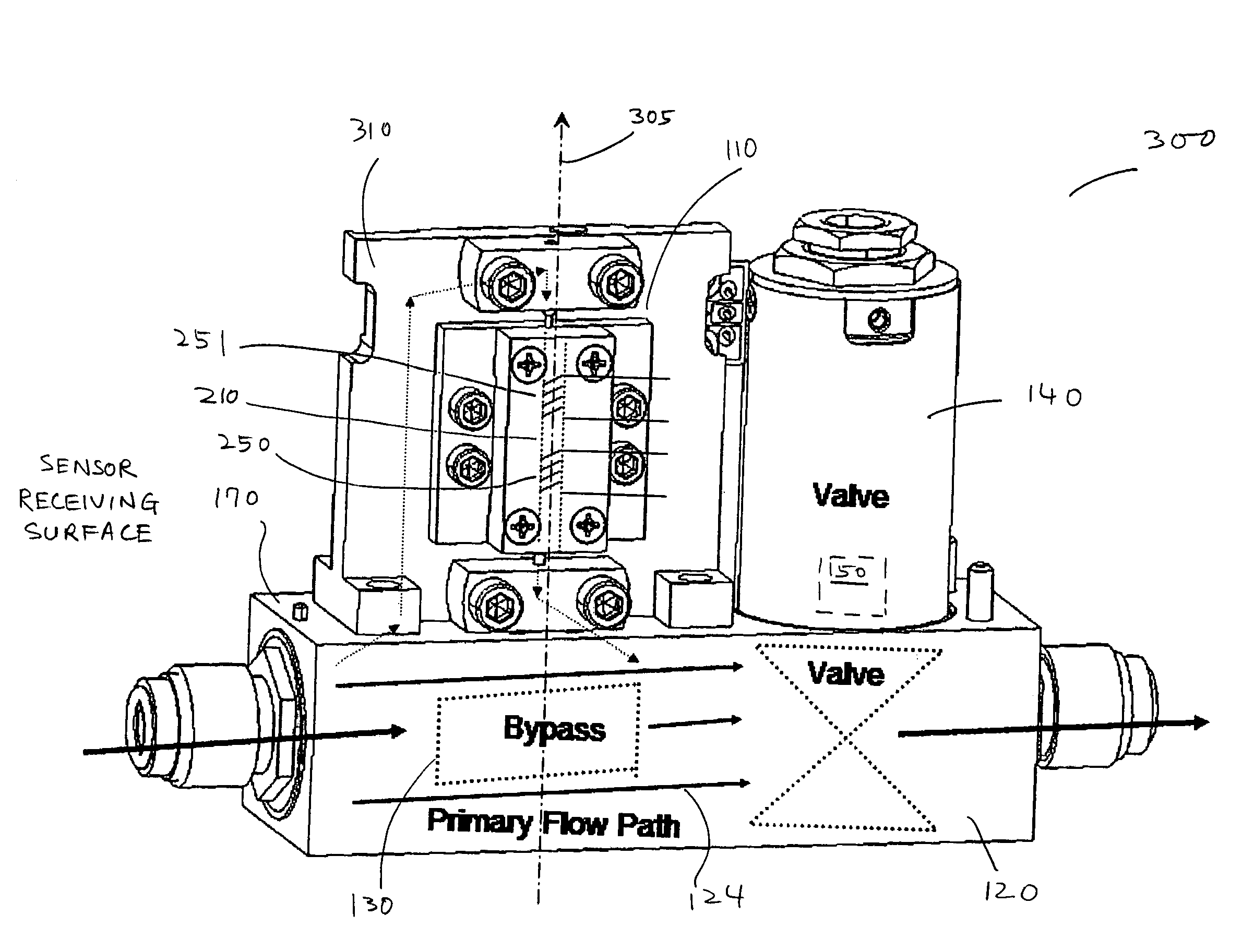

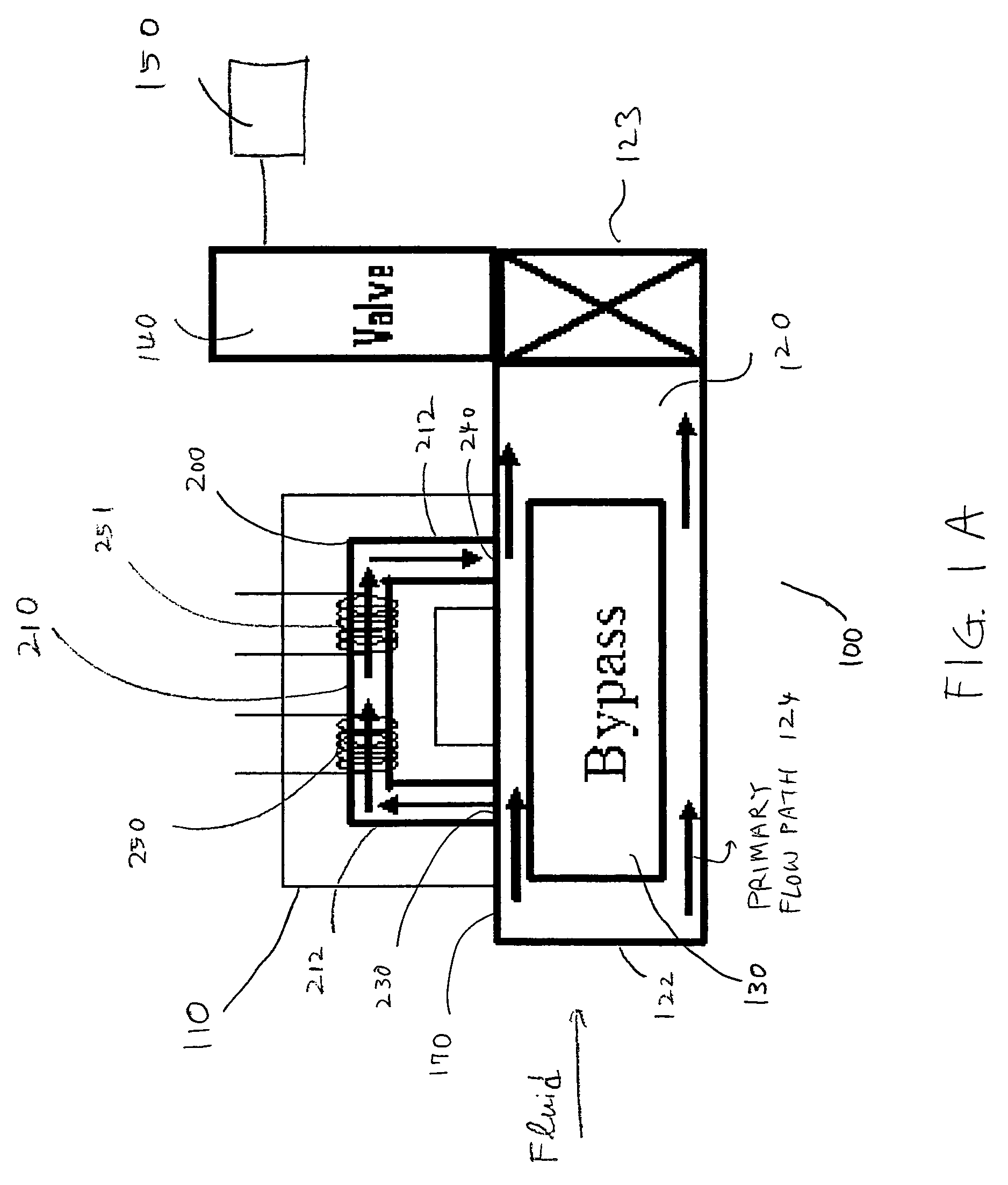

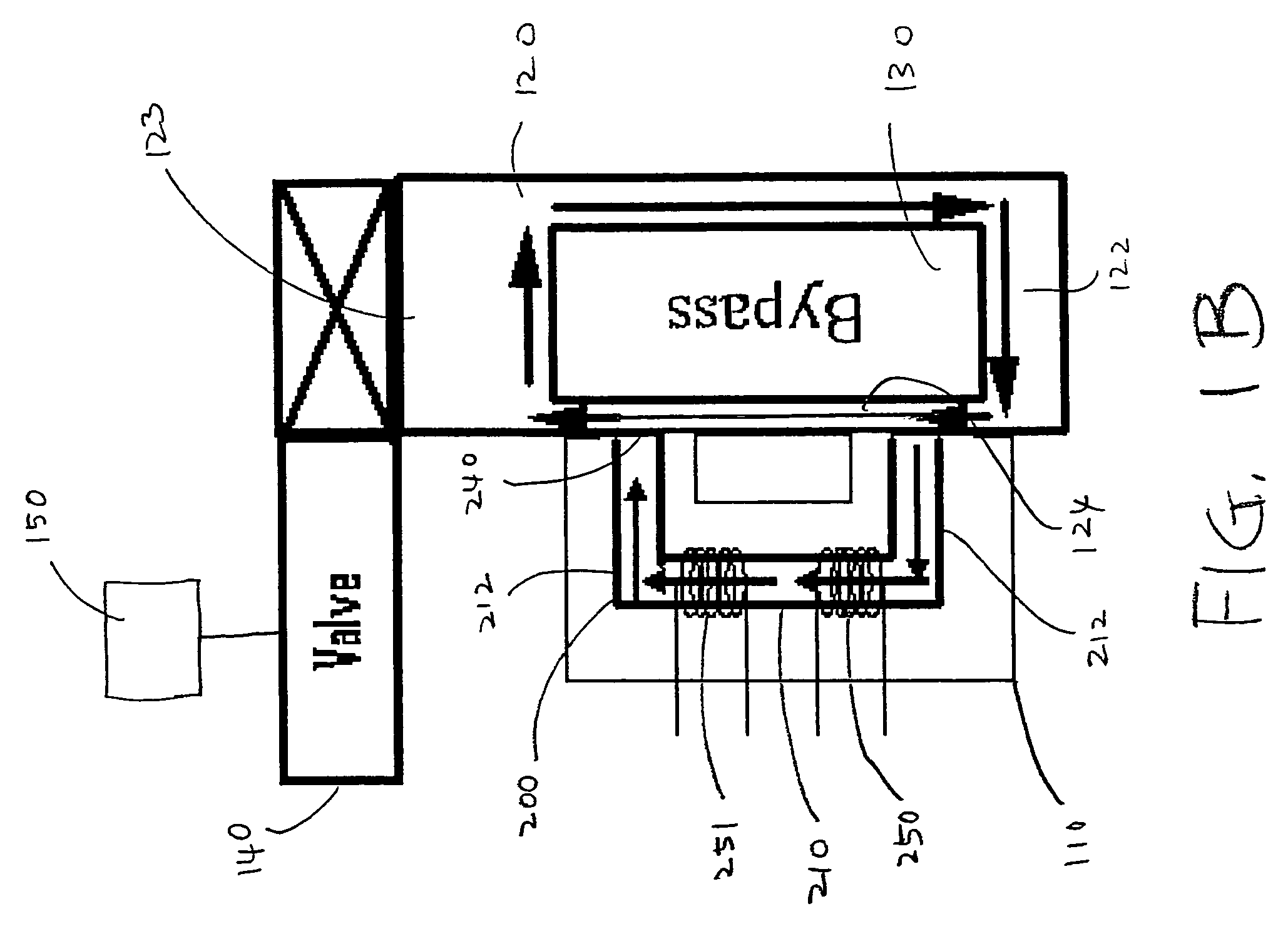

Vertical mount mass flow sensor

ActiveUS20070113641A1Prevent thermal siphoningPreventing thermal siphoningVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringMass flow sensor

A thermal mass flow meter for measuring flow rate of a fluid includes a conduit that is configured to receive the fluid and that defines a primary flow path between an inlet and an outlet of the conduit. The conduit is bound at least in part by a sensor receiving surface. A thermal sensor tube has a thermal sensing portion that is mounted relative to the sensor receiving surface in a direction substantially perpendicular to both the primary flow path and the sensor receiving surface. When the thermal mass flow meter is mounted in a vertical direction so that fluid within the conduit flows in the vertical direction along the primary flow path, fluid within the sensor tube flows in a horizontal direction so as to substantially prevent thermal siphoning when the sensor tube is heated.

Owner:MKS INSTR INC

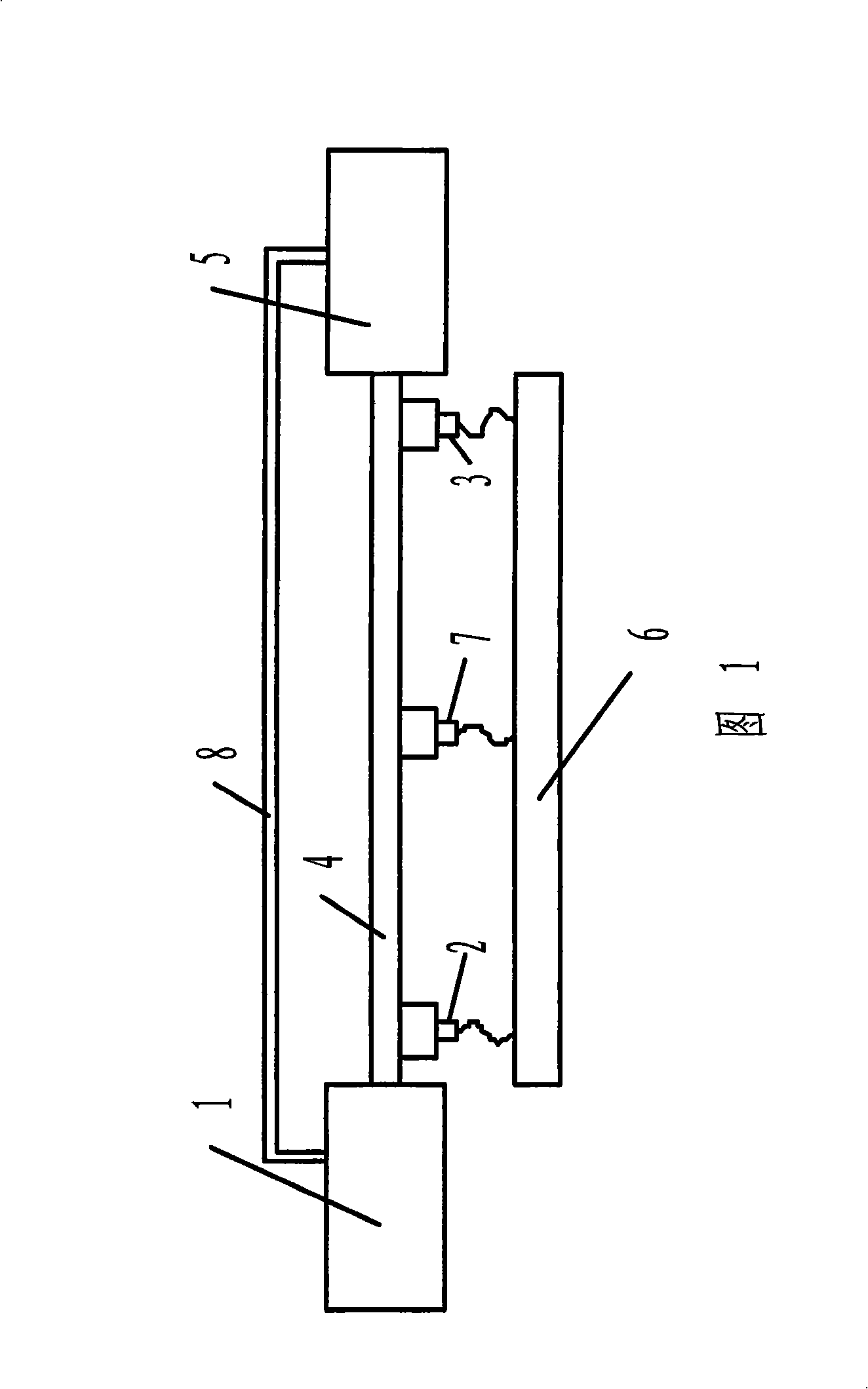

Method and device for measuring high polymer molten volume flow

ActiveCN101408443AEliminate measurement error interferenceAccurate Indirect Determination CalculationsVolume/mass flow measurementDirect flow property measurementEngineeringMeasurement precision

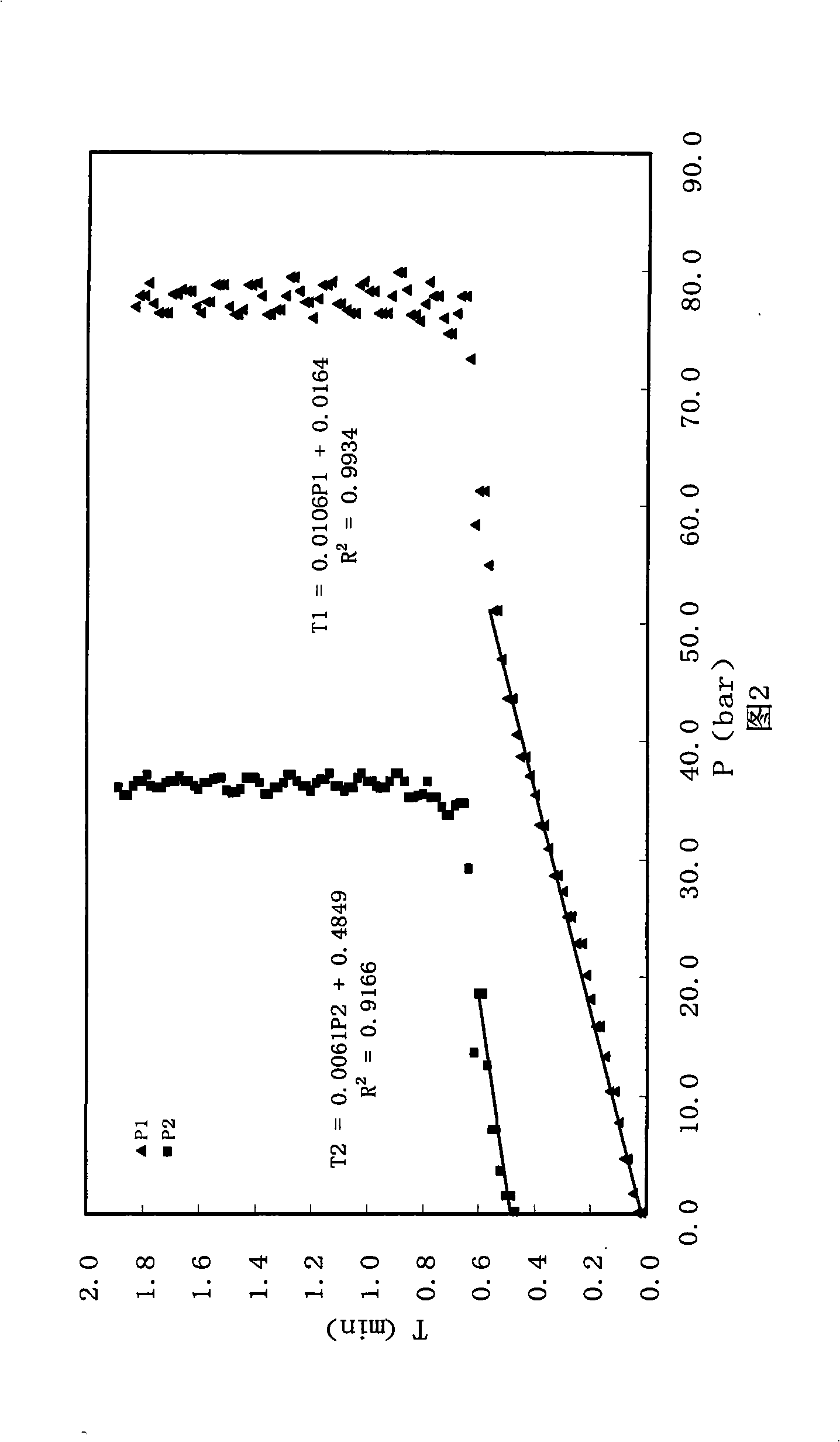

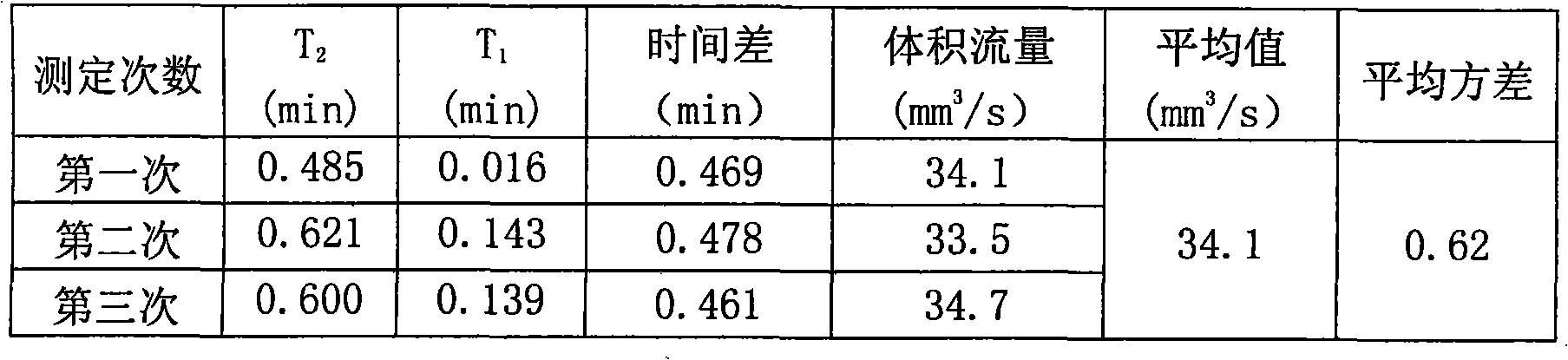

The invention discloses a measuring device for high polymer fusant volume flow and a measuring method thereof. The invention is characterized in that one end of a slit flow passage or a conduit flow passage (4) is connected with a flow passage actuating unit (1), the other end thereof is connected with a fusant external flow passage (5), the external flow passage is connected with the flow passage actuating unit by a loop flow passage (8), the slit flow passage or the conduit flow passage is provided with a temperature sensor (7) and a plurality of pressure sensors (2, 3), and the temperature sensor and a plurality of pressure sensors are respectively connected with a collecting and processing system (6) for temperature and data. The actuating unit pushes the high polymer fusant to enter the flow passage at a certain speed, and the passing time of fluid is measured by two pressure sensors, therefore, the volume flow of the high polymer in the flow passage can be obtained according to the physical dimension of the flow passage and the passing time. The measuring device of the invention can measure the volume flow of the high polymer fusant in the flow passage without the influence of the change of the pressure and the dimension of the flow passage. In addition, the invention provides a method which can improve and enhance the rheological measurement precision of the high polymer.

Owner:浙江博发新材料股份有限公司

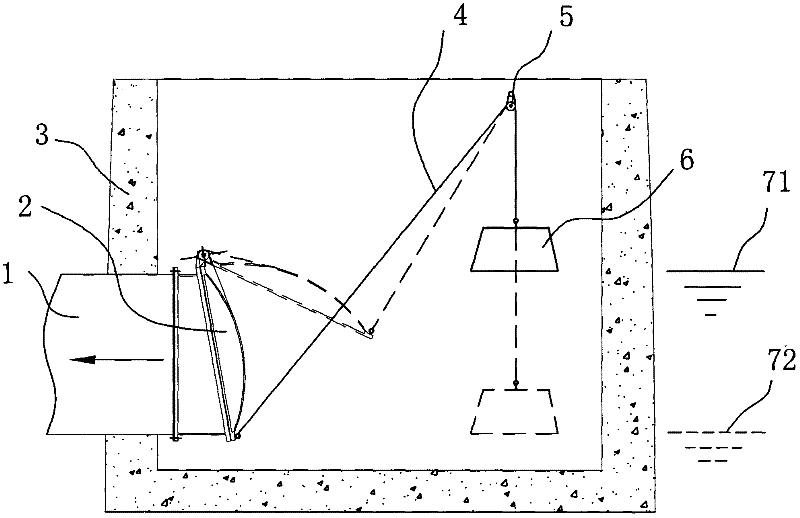

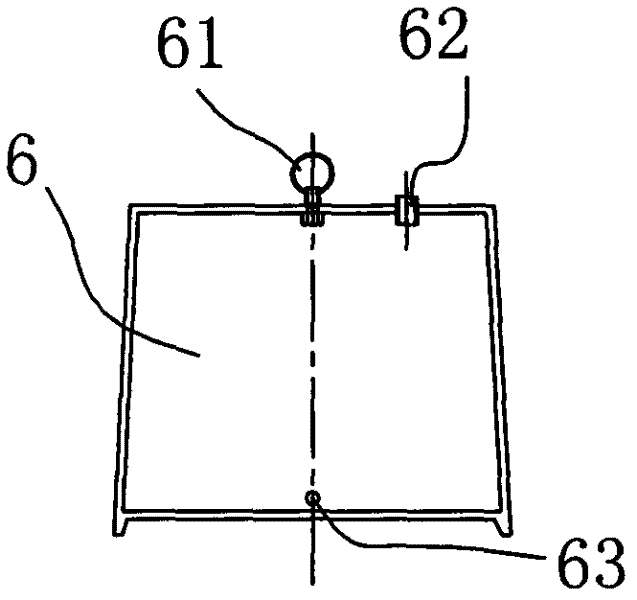

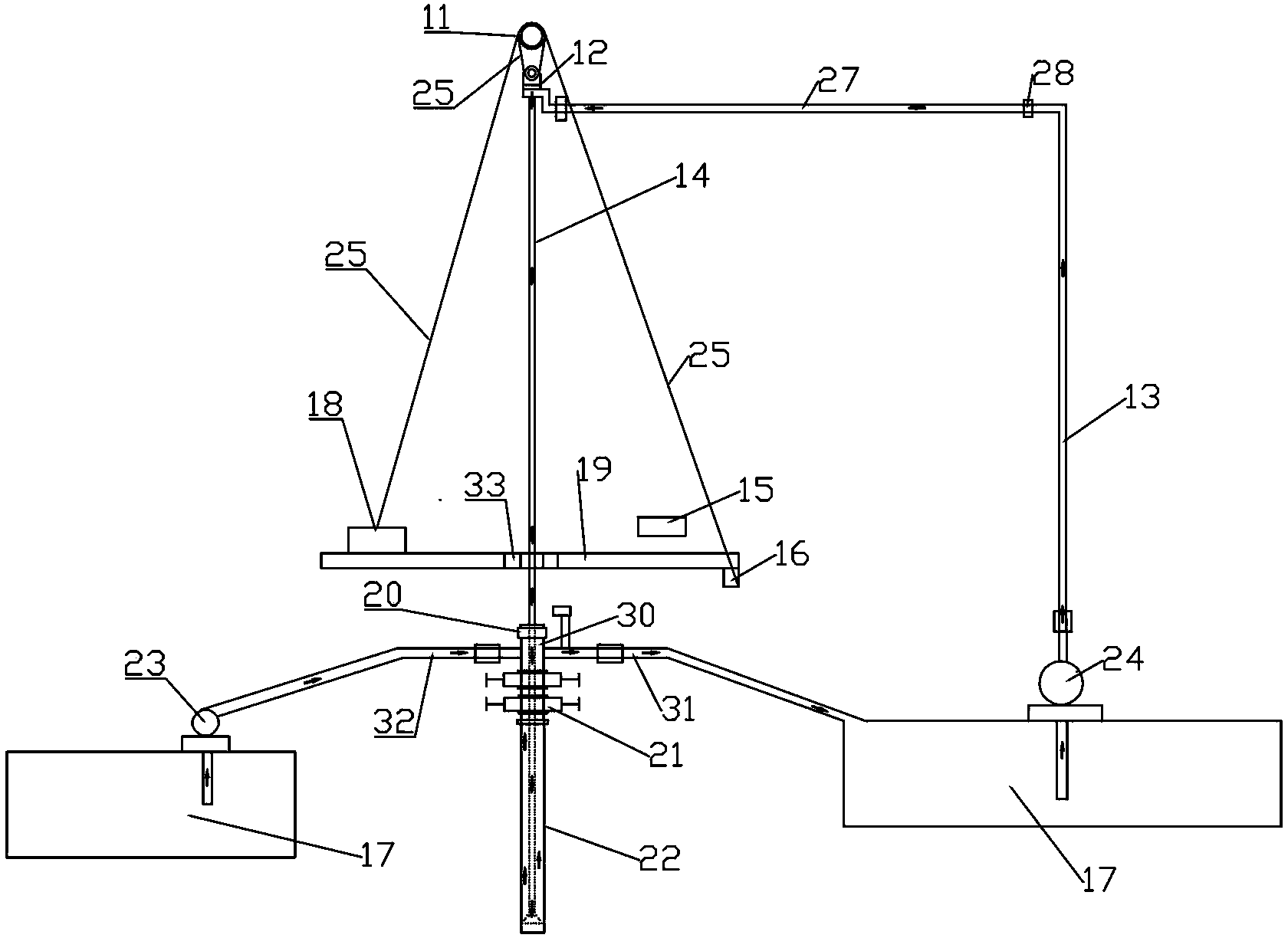

A composite shut-off door

A composite throttle valve. The invention relates to the improvement of the structure of the sewage and waste water catchment device. It can control the amount of sewage inflow to a single well to avoid excessive sewage flowing into the treatment plant and causing the treatment plant to run overloaded. It includes a well body located below the ground and connected to the sewage pipe, and also includes a flap door, a cable, a suspension pulley and a counterweight buoy; the flap door is movably connected to the sewage pipe mouth; The upper part of the wellhead in the body; the cable is wound on the suspension pulley, one end of the cable is connected to the lower edge of the flap door, and the other end of the cable is connected to the counterweight buoy. The present invention is provided with flap door in the well body, and it itself has the function of preventing excessive water from entering the pipeline. In the present invention, it is required to be in the open state under normal conditions, so the present invention also adds a counterweight buoy that can make it in the open state. Under normal circumstances, some domestic wastewater flows through the well body and flows into the sewage treatment plant through pipelines for centralized treatment.

Owner:扬州市天雨玻璃钢制品厂有限公司

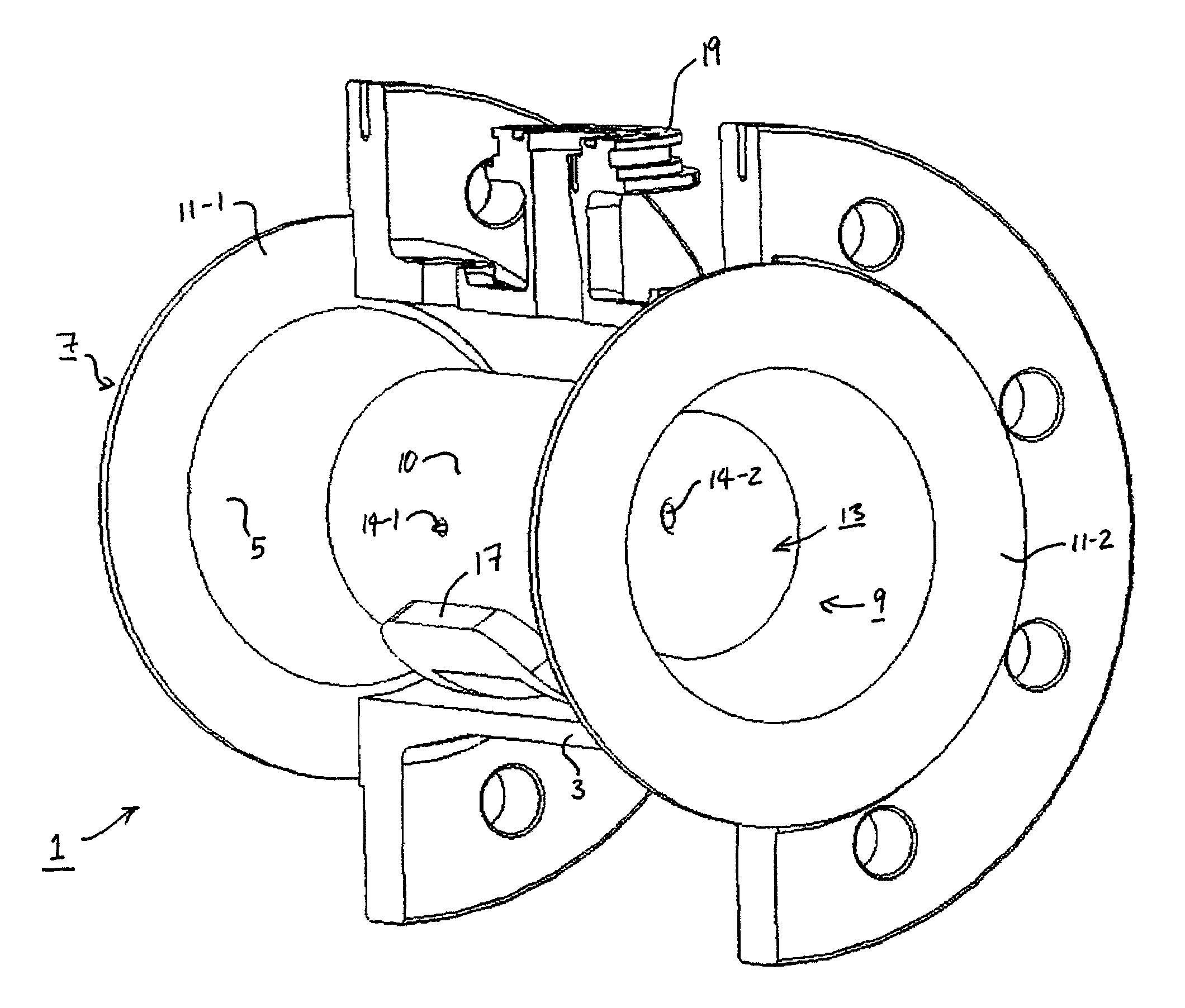

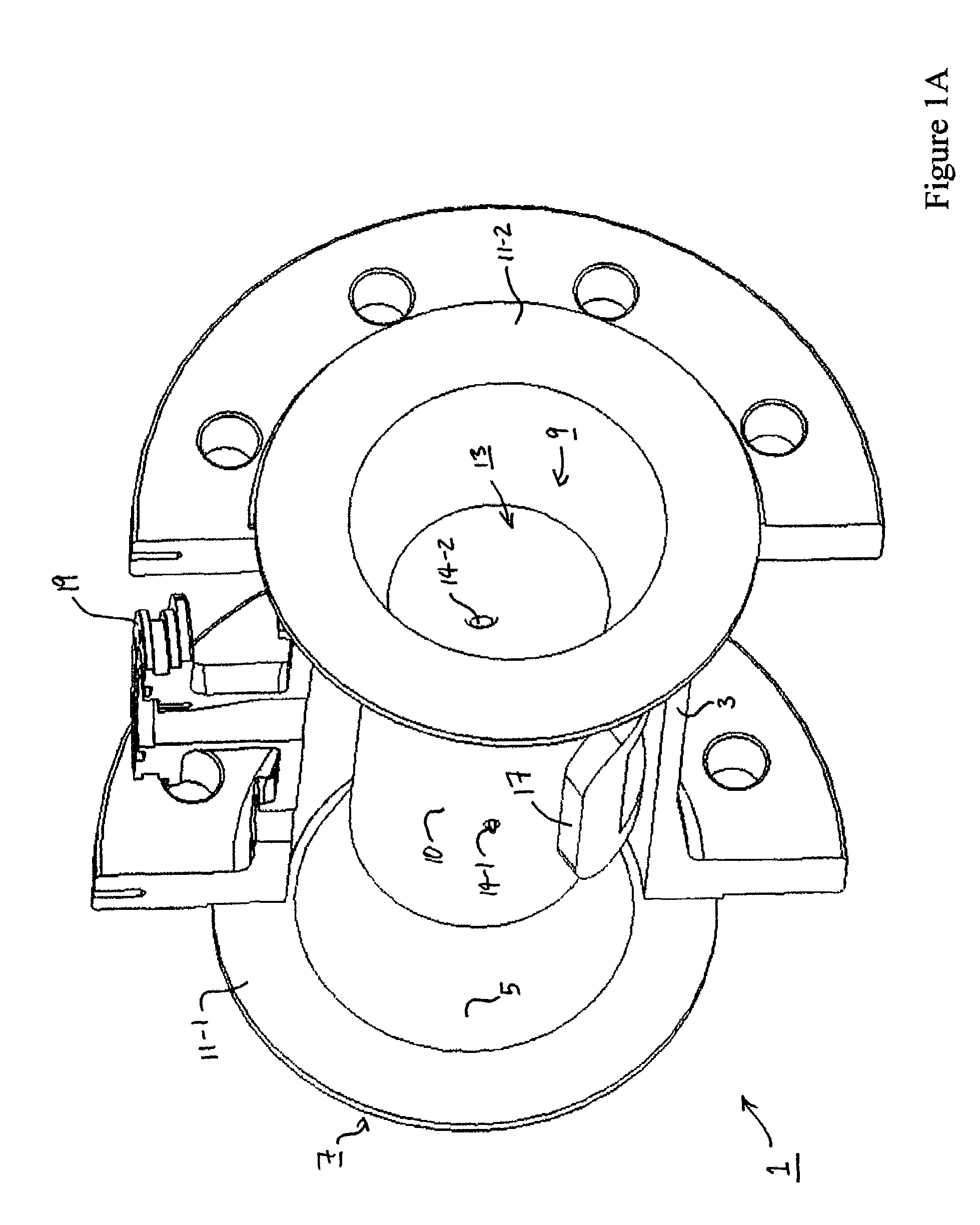

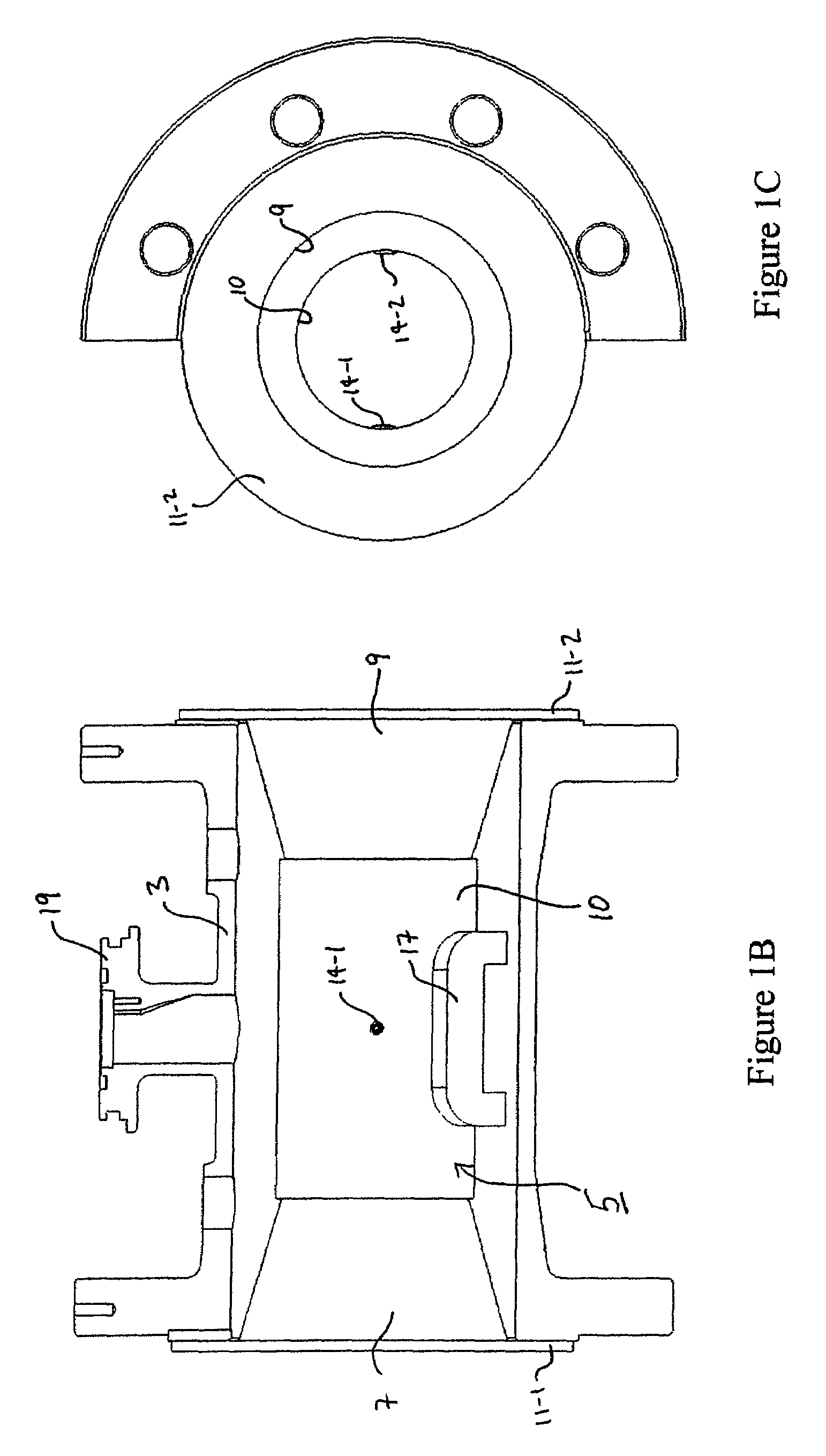

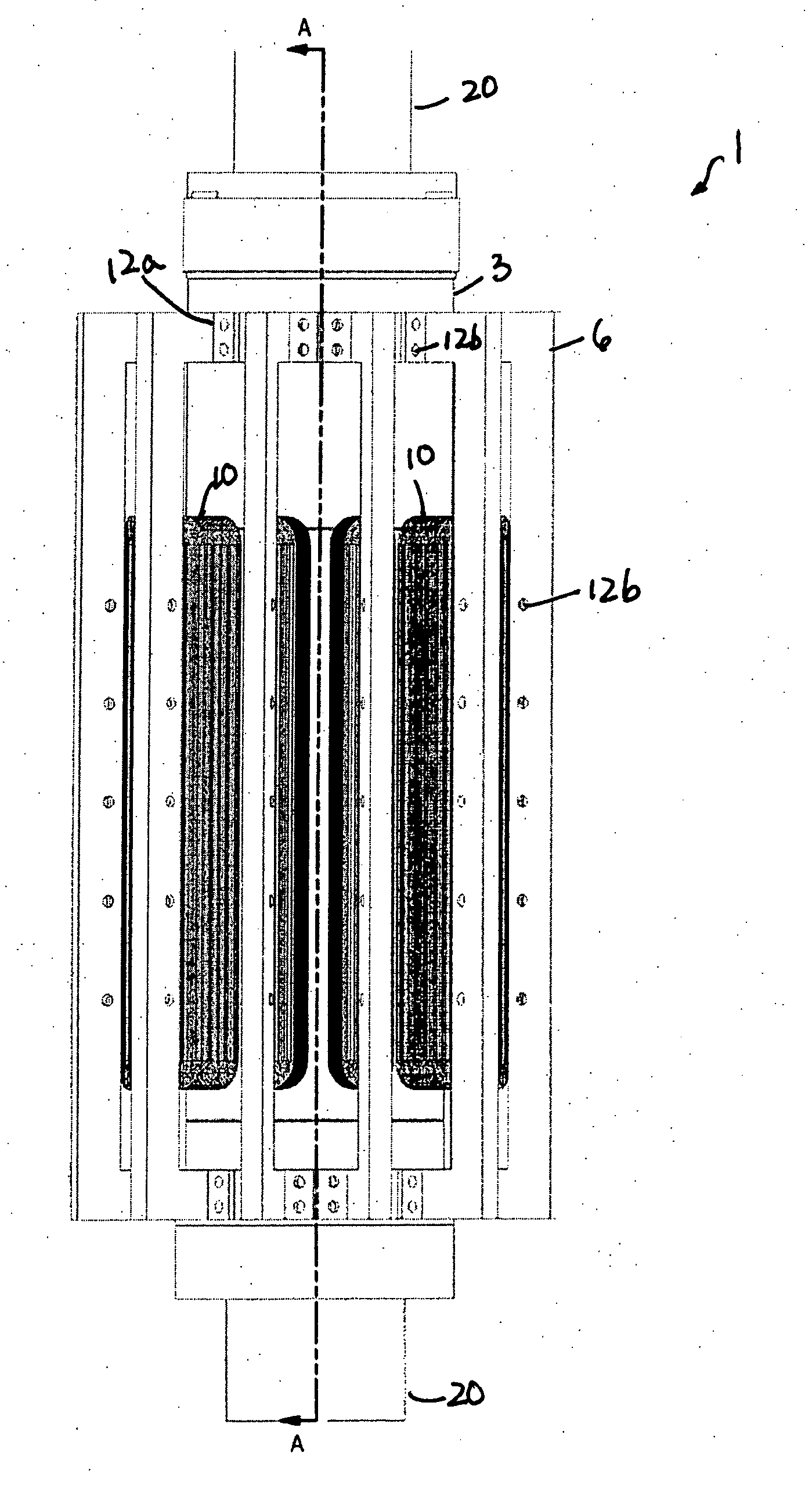

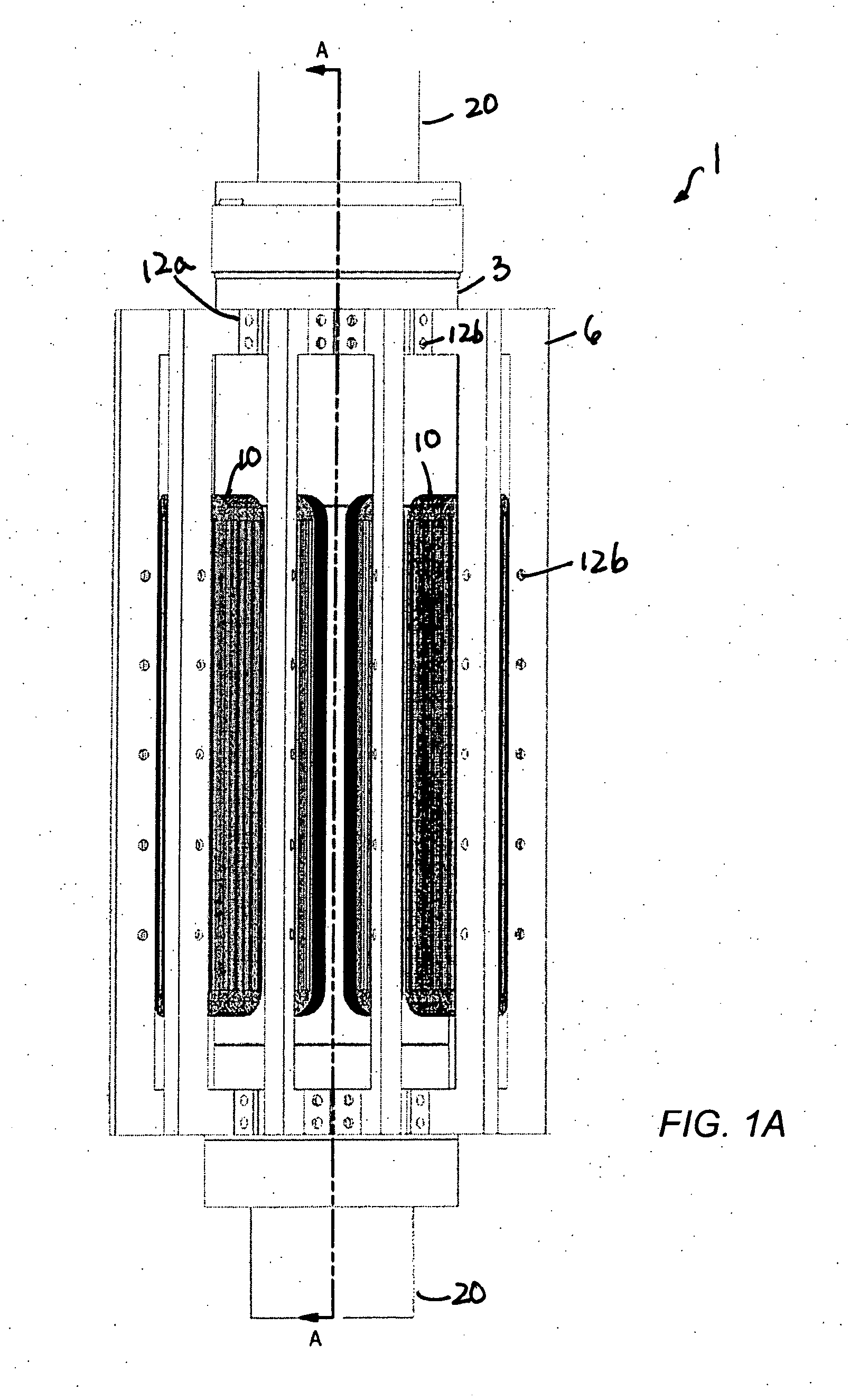

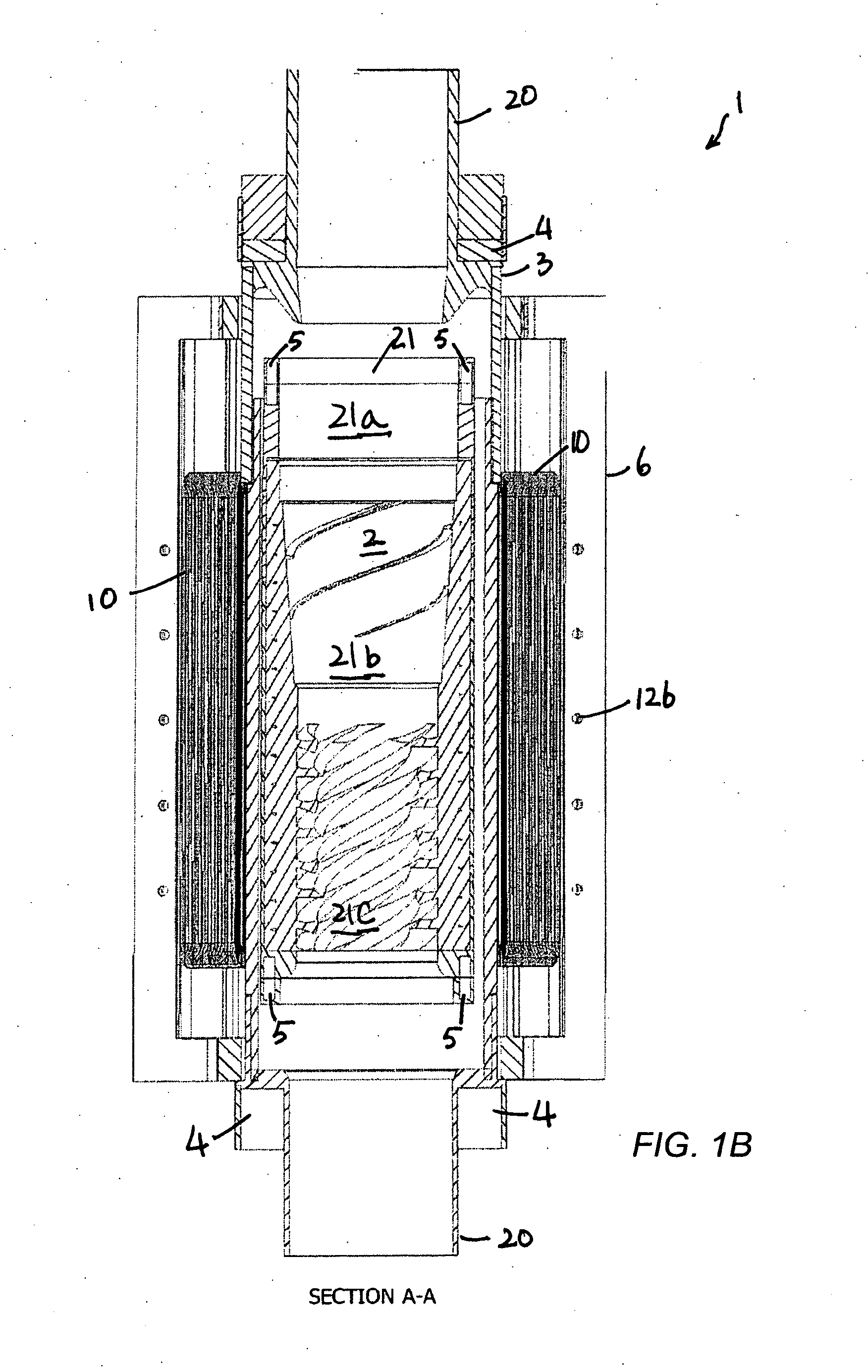

Alternative packer setting method

Fluid setting pressure is delivered to a hydraulically set well packer through an external conduit strapped to the exterior of a well workstring above the packer assembly. The continuity of the external conduit is continued past the packer assembly by following a flow channel along the mandrel sleeve thickness. Representatively, the external conduit may serve a primary well function other than packer setting (e.g. well chemical delivery). A calibrated rupture element in the external conduit is disposed to initially obstruct external conduit flow past the packer element. Consequently, fluid pressure transferred down the external conduit is first channeled to the packer setting pressure chamber. After setting, the fluid pressure in the external conduit is increased to rupture the calibrated element. When the external conduit flow channel is opened by rupture of the calibrated element, and the additional well service function may be accomplished.

Owner:BAKER HUGHES INC

Air cleaner

InactiveUS7329313B2Increase contactGood effectCombination devicesMechanical apparatusEngineeringForced convection

An air cleaner includes a housing, a filter, a photocatalyst reaction unit which can form spiral a air flow, a forced convection device, and an electrocircuit controller. The forced convection device is located between the filter and the photocatalyst reaction unit. Because the air cleaner uses a longitudinal air conduit, an air inlet along a tangential direction of the air conduit and spiral guide vanes at the inlet, air passing through a fan and into the air conduit flows spirally in the conduct conduit to increase the time during which air contacts the photocatalyst and enables the light of the ultraviolet lamp to radiate the photocatalyst directly so that the cleaning efficiency of the photocatalyst is increased.

Owner:CHIAPHUA INDS

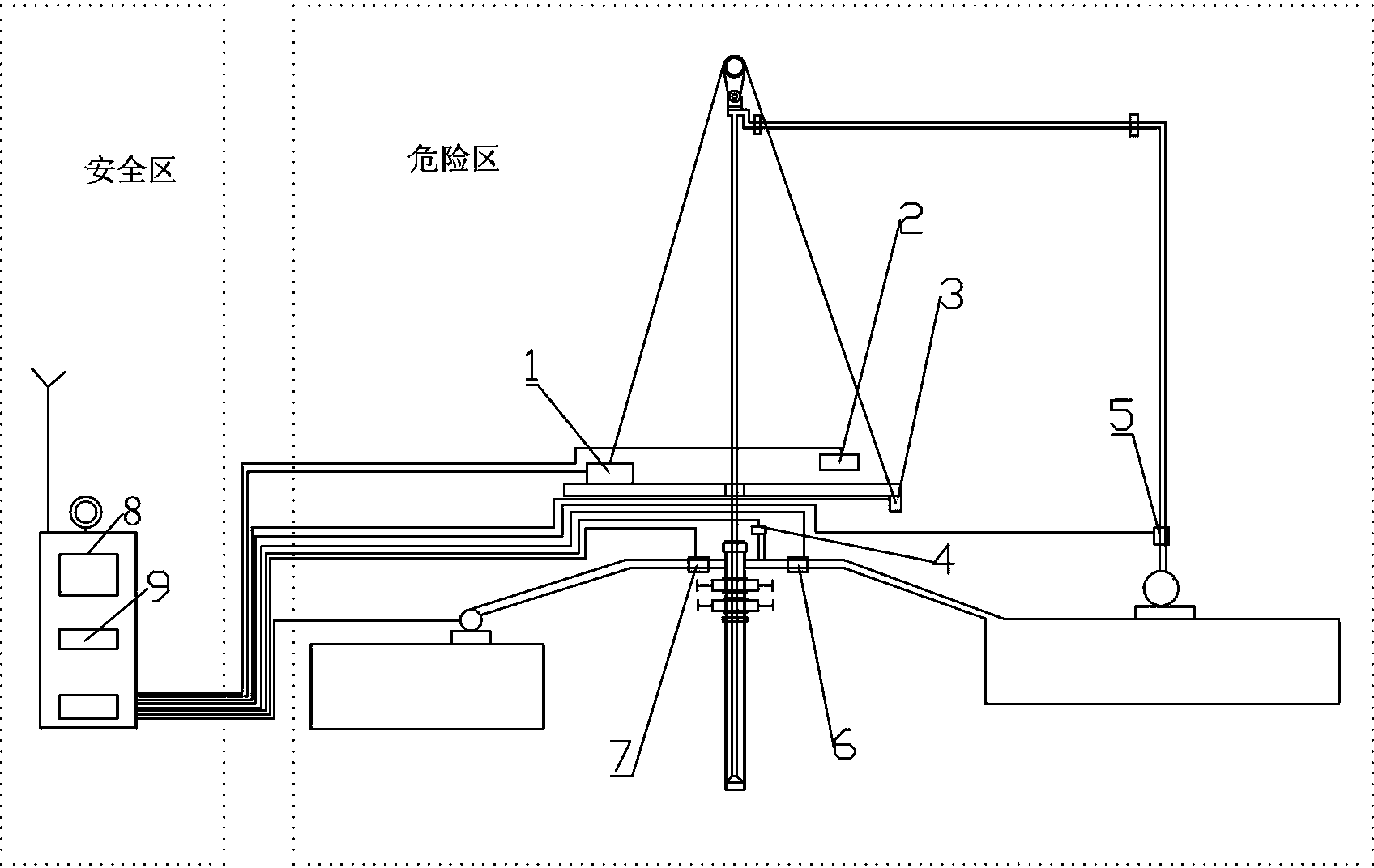

Well control project monitoring system

The invention relates to a well control project monitoring system comprising a drill floor adjusting device, a drilling tool is inserted into a borehole through the drill floor adjusting device, a sludge circulation system passes through an inner cavity of the drilling tool, circulates in the annular space of the borehole out of a circulation tank and then is pumped into the inner cavity of the drilling tool through a sludge pump to form a closed loop, an anti-spilling pipe is connected to the upper portion of the borehole, the upper end of the anti-spilling pipe is provided with a wellhead sealer, a blowout preventer is arranged at the lower portion of the anti-spilling pipe, a grout pipe and a grout pump sequentially pass through the position between the wellhead sealer and the blowout preventer and then are connected with a sludge tank, the grout pipe is provided with a grout pipe flow sensor, a guide pipe flow sensor is arranged at the position, at a guide pipe of an outlet of the anti-spilling pipe, of the sludge circulation system, and a vertical pipe flow sensor is arranged at an inlet of the sludge circulation system. The well control project monitoring system is stable in performance, can achieve recording and wireless remote transmission of on-the-spot working information in real time, and provides the basis for integration of the spot and a foundation, information sharing, remote control commanding, accident replaying and investigation treatment.

Owner:PANJIN CHUNYA PETROLEUM TECH

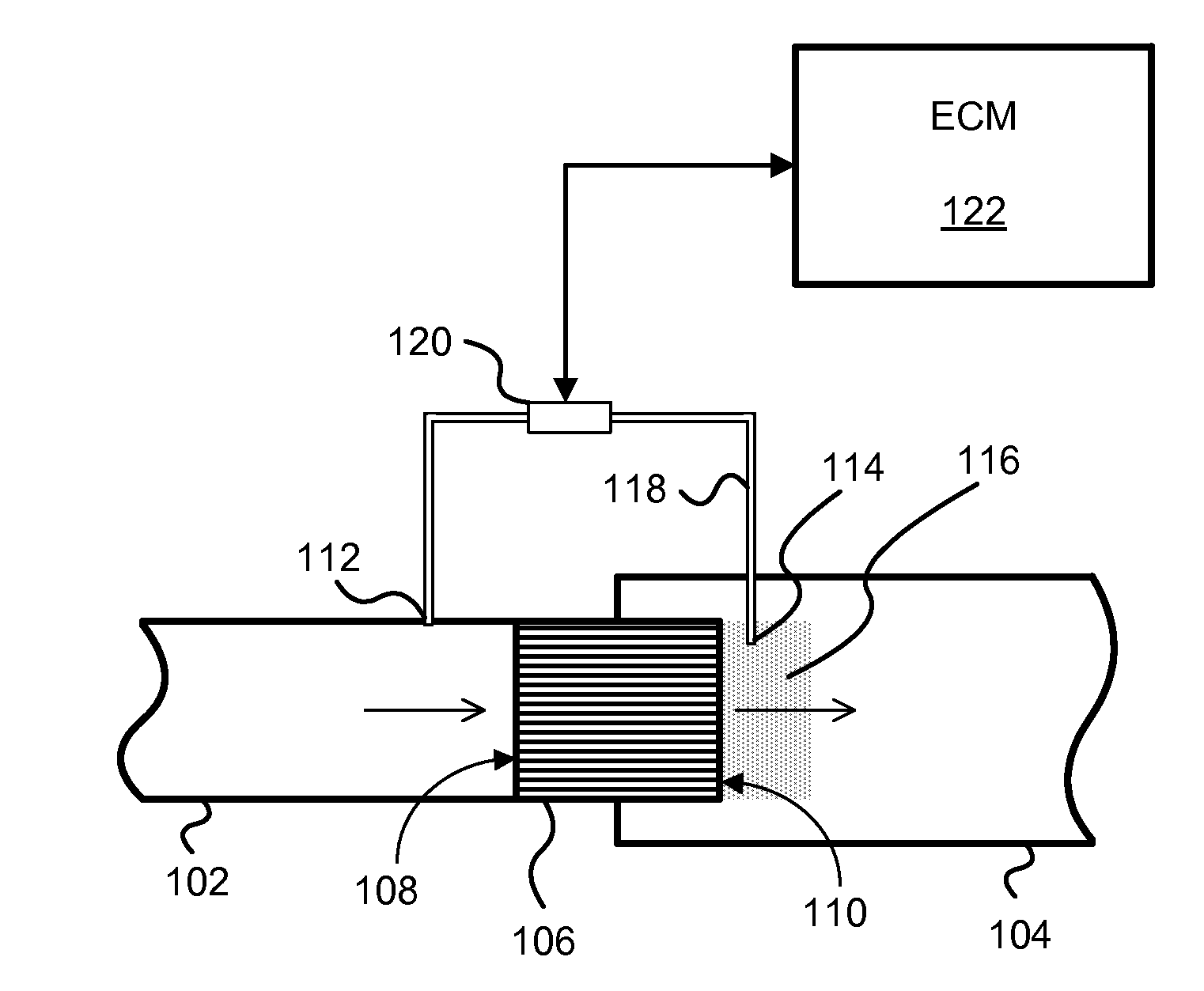

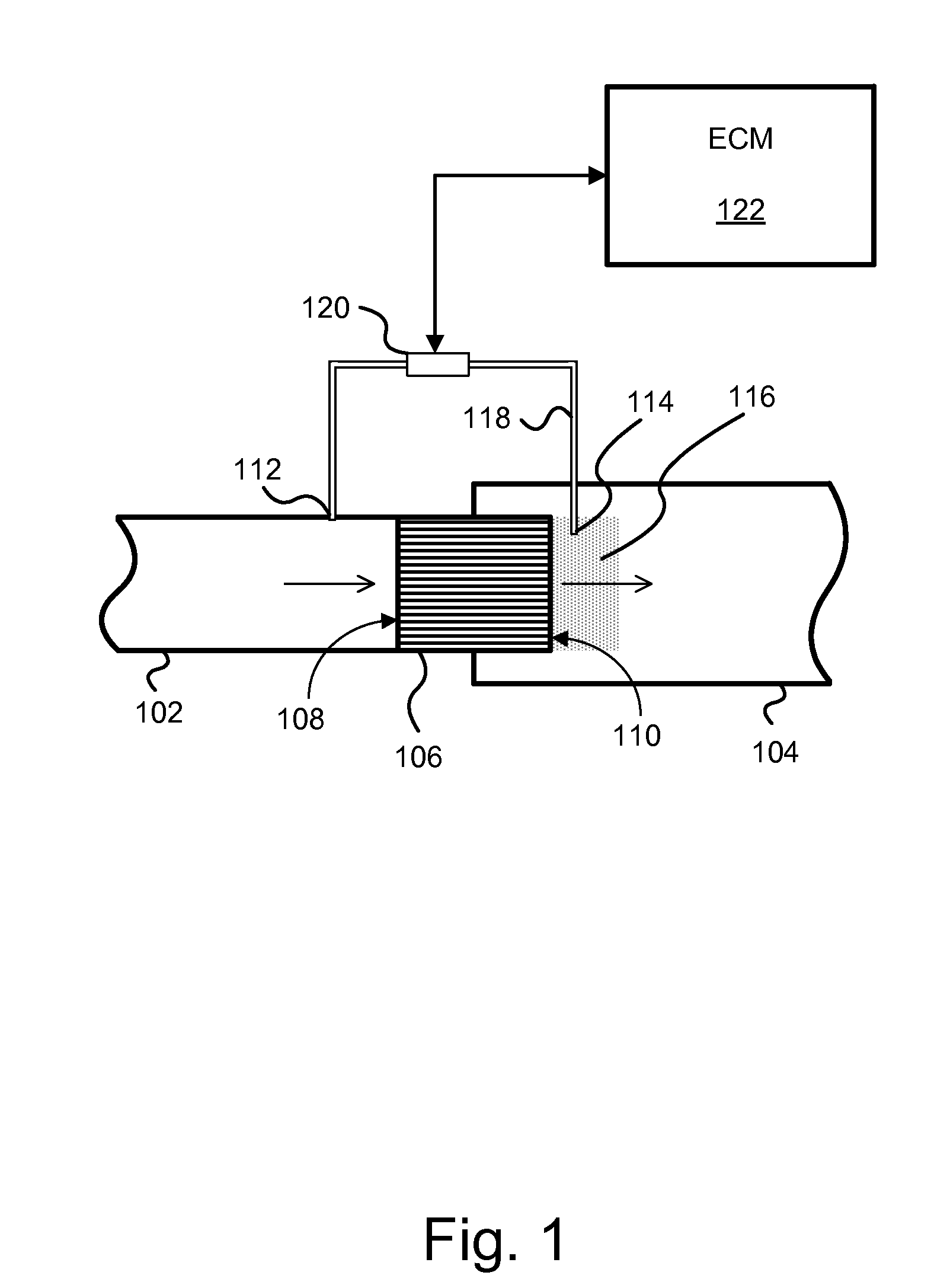

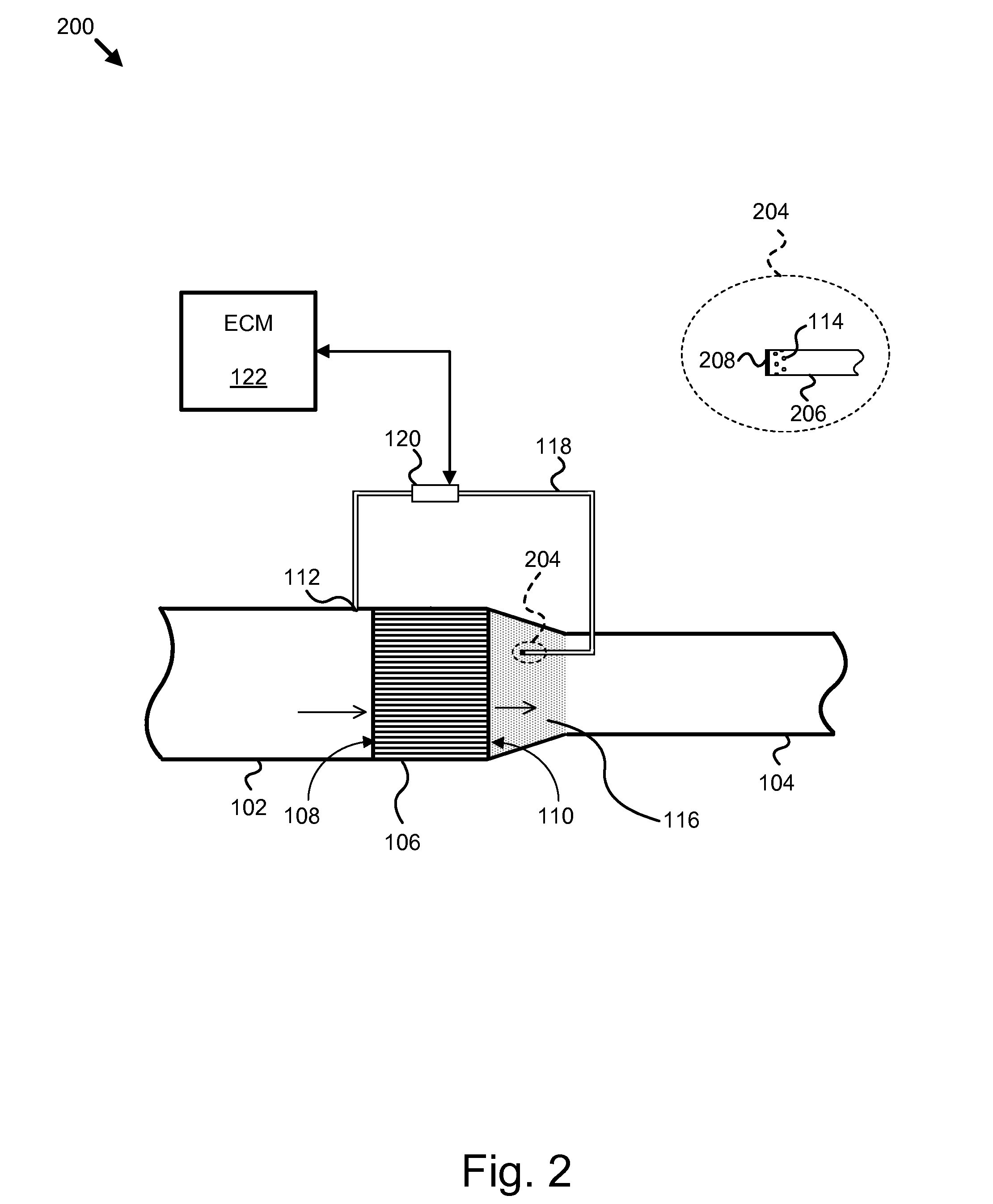

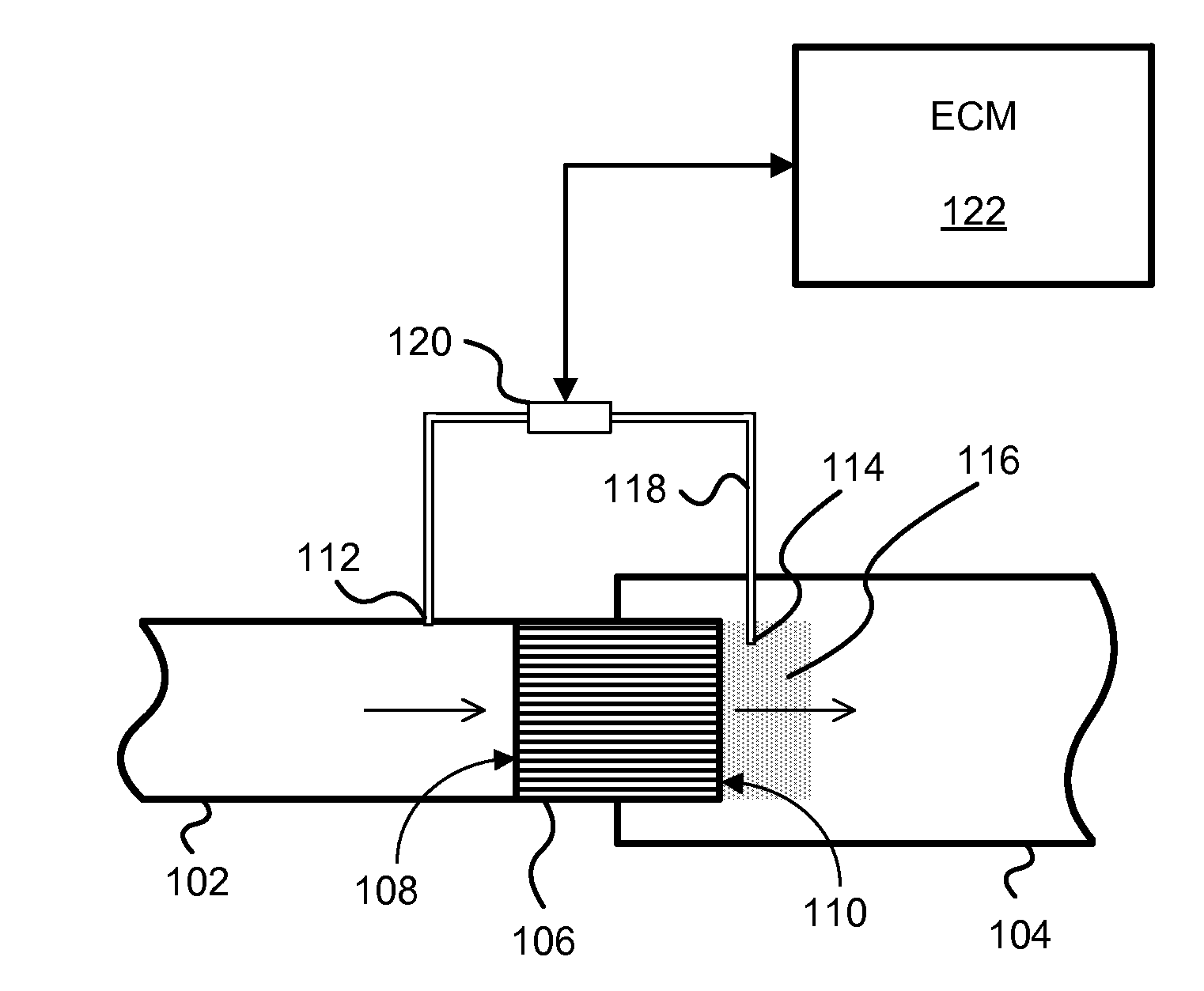

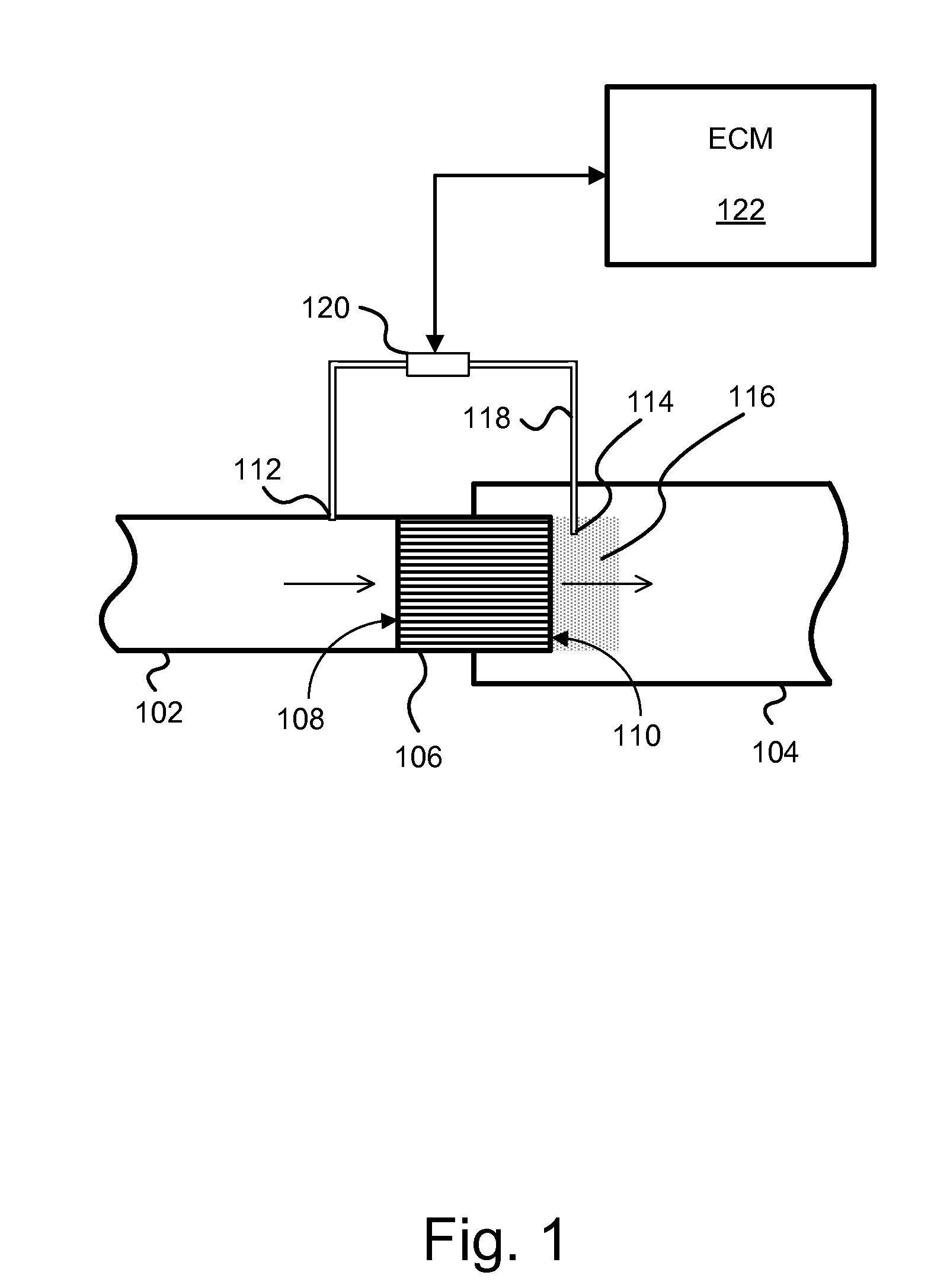

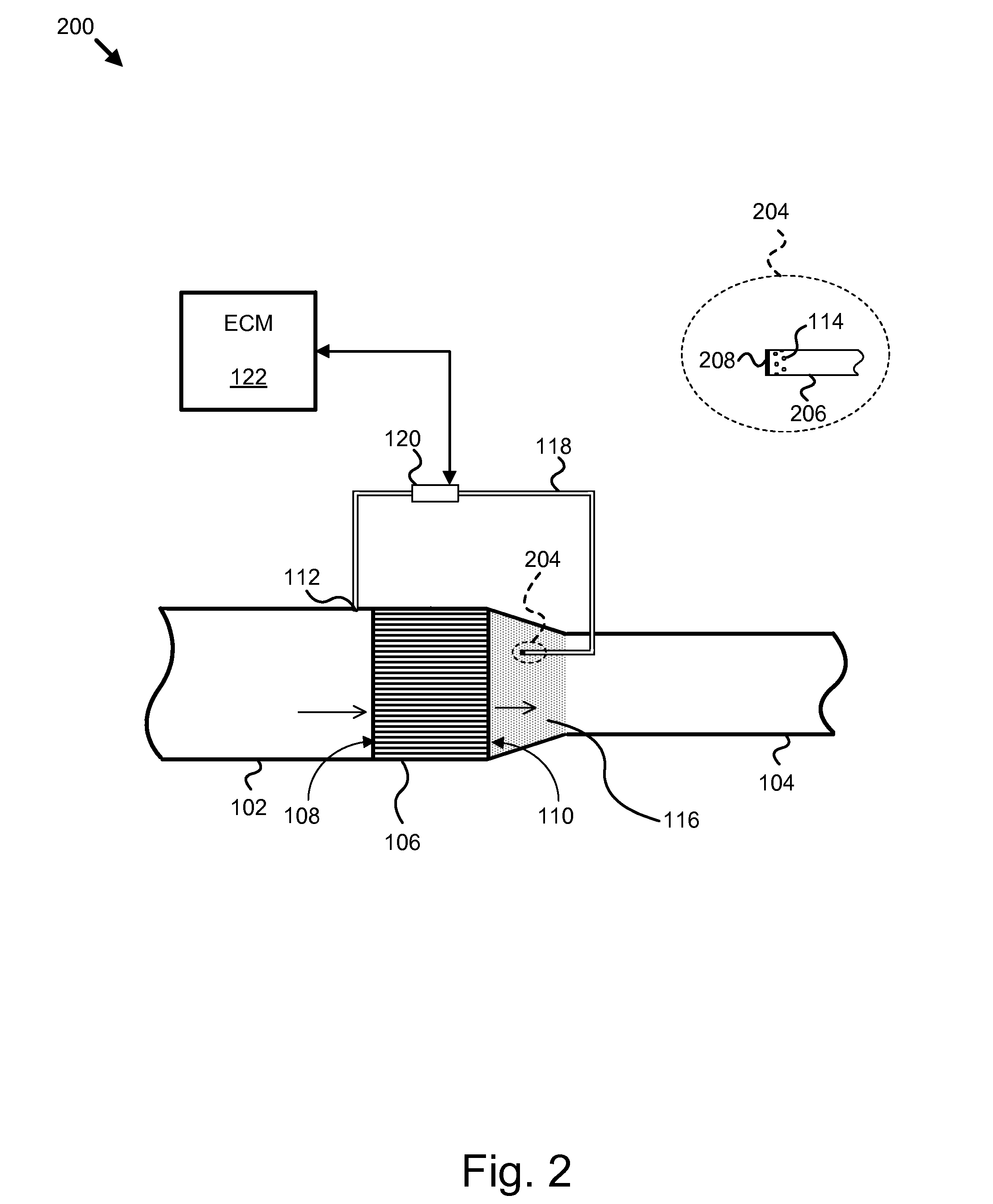

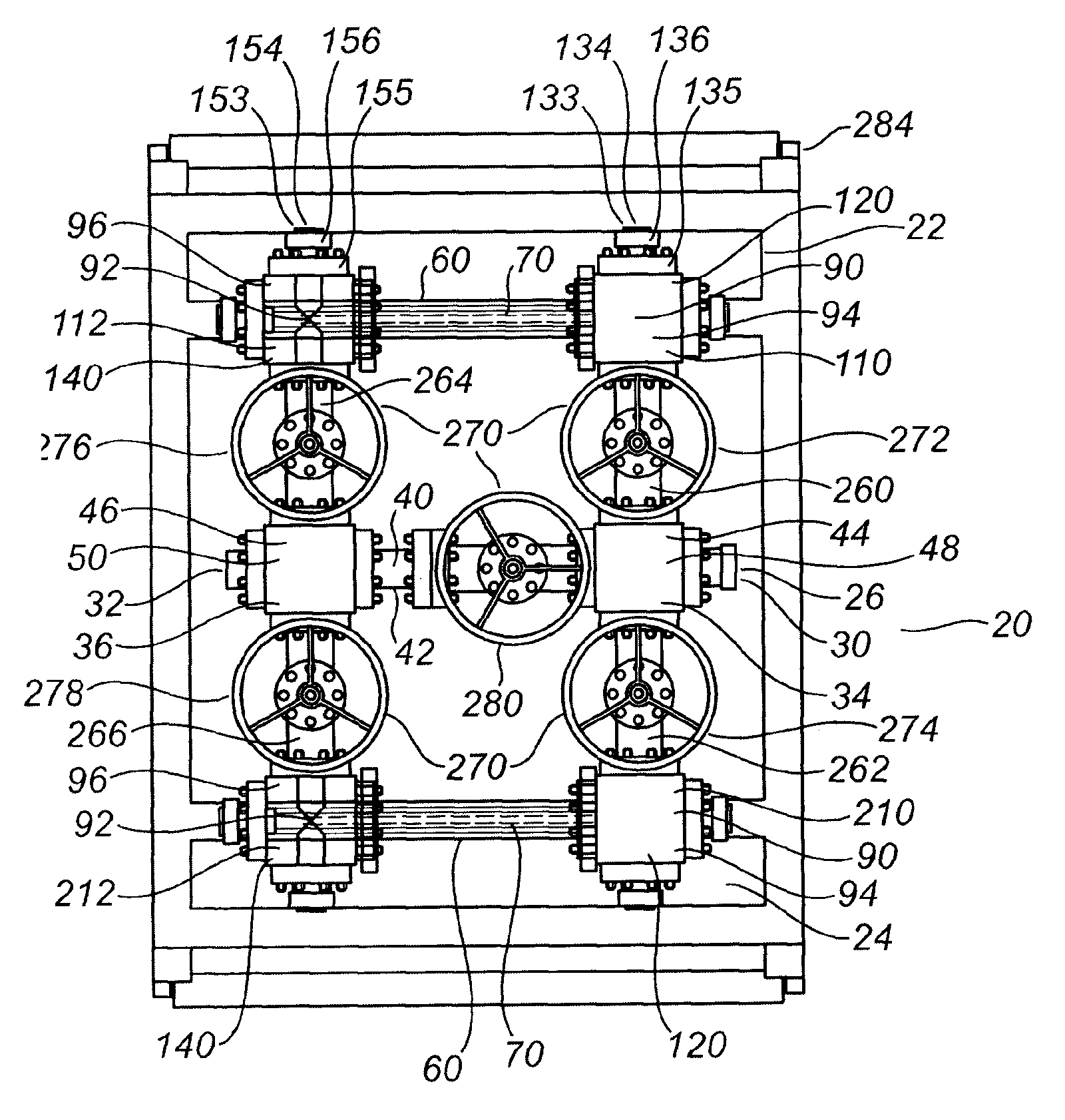

Apparatus, system, and method for differential pressure measurement across a conduit flow area change

An apparatus, system, and method are disclosed for differential pressure measurement across a fluid conduit flow area change. The apparatus may include a particulate filter, a differential pressure sensor, and a fluid conduit size change downstream of the particulate filter. The apparatus may include a tube configured to place the downstream differential pressure sensor port in fluid contact with a uniform flow region of the fluid conduit downstream of the particulate filter. An apparatus is thereby provided to measure differential pressure across a fluid conduit flow area change such that the differential pressure measurement is minimally affected by the change in flow characteristics induced by the change in cross-sectional flow area.

Owner:CUMMINS FILTRATION IP INC

Apparatus, system, and method for differential pressure measurement across a conduit flow area change

An apparatus, system, and method are disclosed for differential pressure measurement across a fluid conduit flow area change. The apparatus may include a particulate filter, a differential pressure sensor, and a fluid conduit size change downstream of the particulate filter. The apparatus may include a tube configured to place the downstream differential pressure sensor port in fluid contact with a uniform flow region of the fluid conduit downstream of the particulate filter. An apparatus is thereby provided to measure differential pressure across a fluid conduit flow area change such that the differential pressure measurement is minimally affected by the change in flow characteristics induced by the change in cross-sectional flow area.

Owner:CUMMINS FILTRATION IP INC

Vertical mount mass flow sensor

ActiveUS7296465B2Prevent thermal siphoningPreventing thermal siphoningVolume/mass flow by thermal effectsVolume flow proportion measurementEngineeringMass flow sensor

A thermal mass flow meter for measuring flow rate of a fluid includes a conduit that is configured to receive the fluid and that defines a primary flow path between an inlet and an outlet of the conduit. The conduit is bound at least in part by a sensor receiving surface. A thermal sensor tube has a thermal sensing portion that is mounted relative to the sensor receiving surface in a direction substantially perpendicular to both the primary flow path and the sensor receiving surface. When the thermal mass flow meter is mounted in a vertical direction so that fluid within the conduit flows in the vertical direction along the primary flow path, fluid within the sensor tube flows in a horizontal direction so as to substantially prevent thermal siphoning when the sensor tube is heated.

Owner:MKS INSTR INC

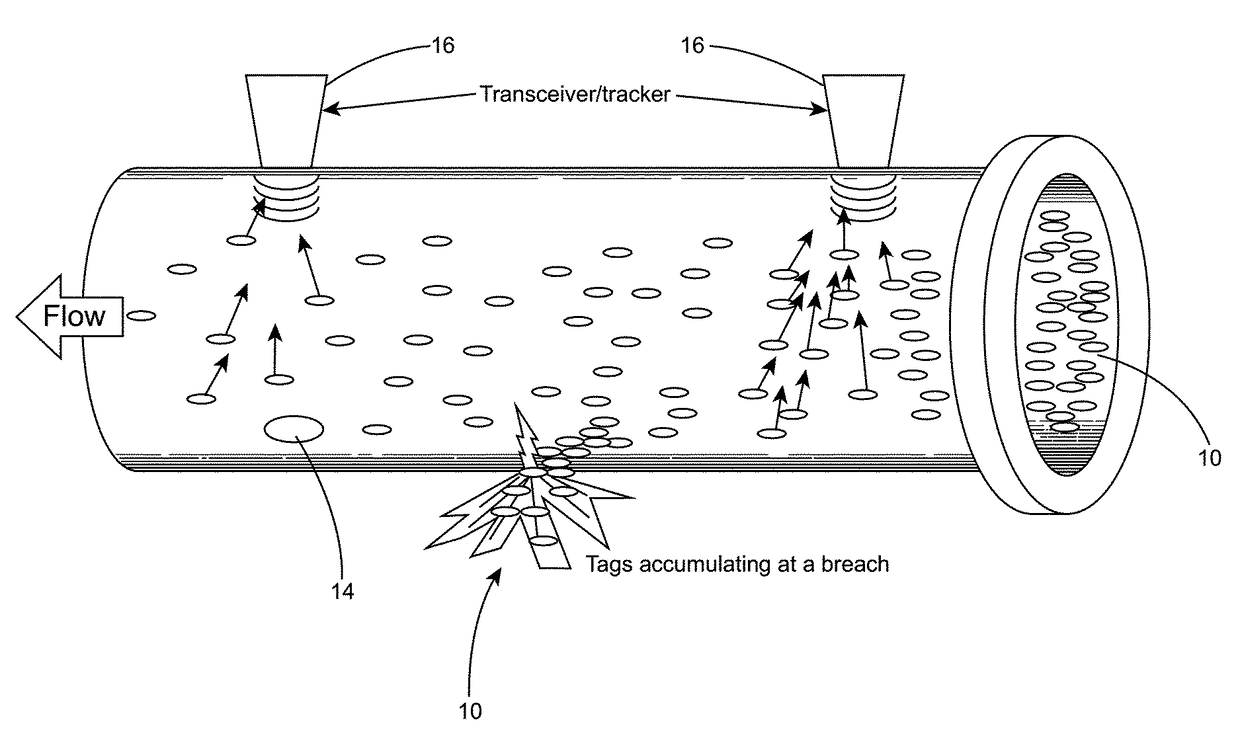

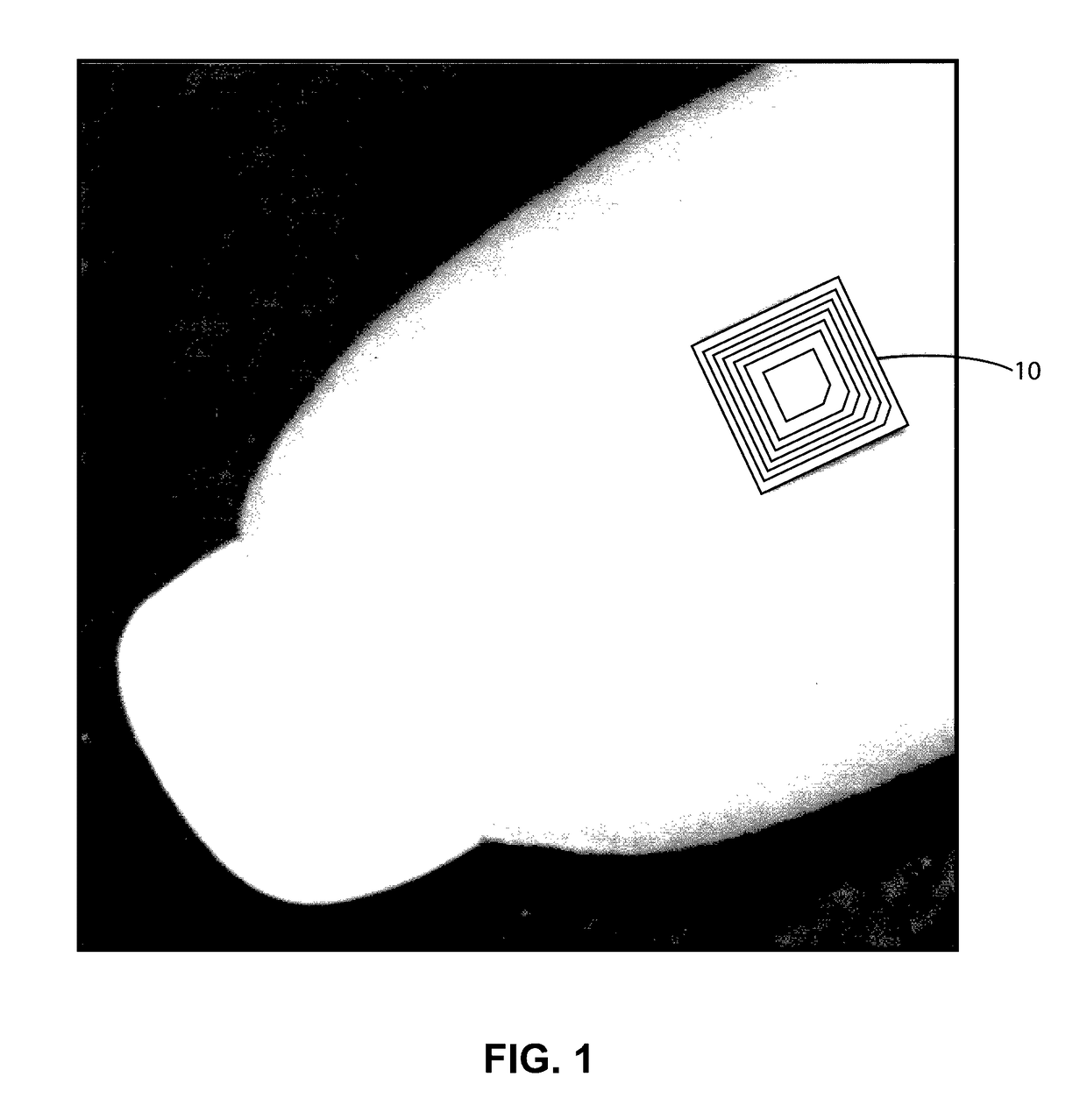

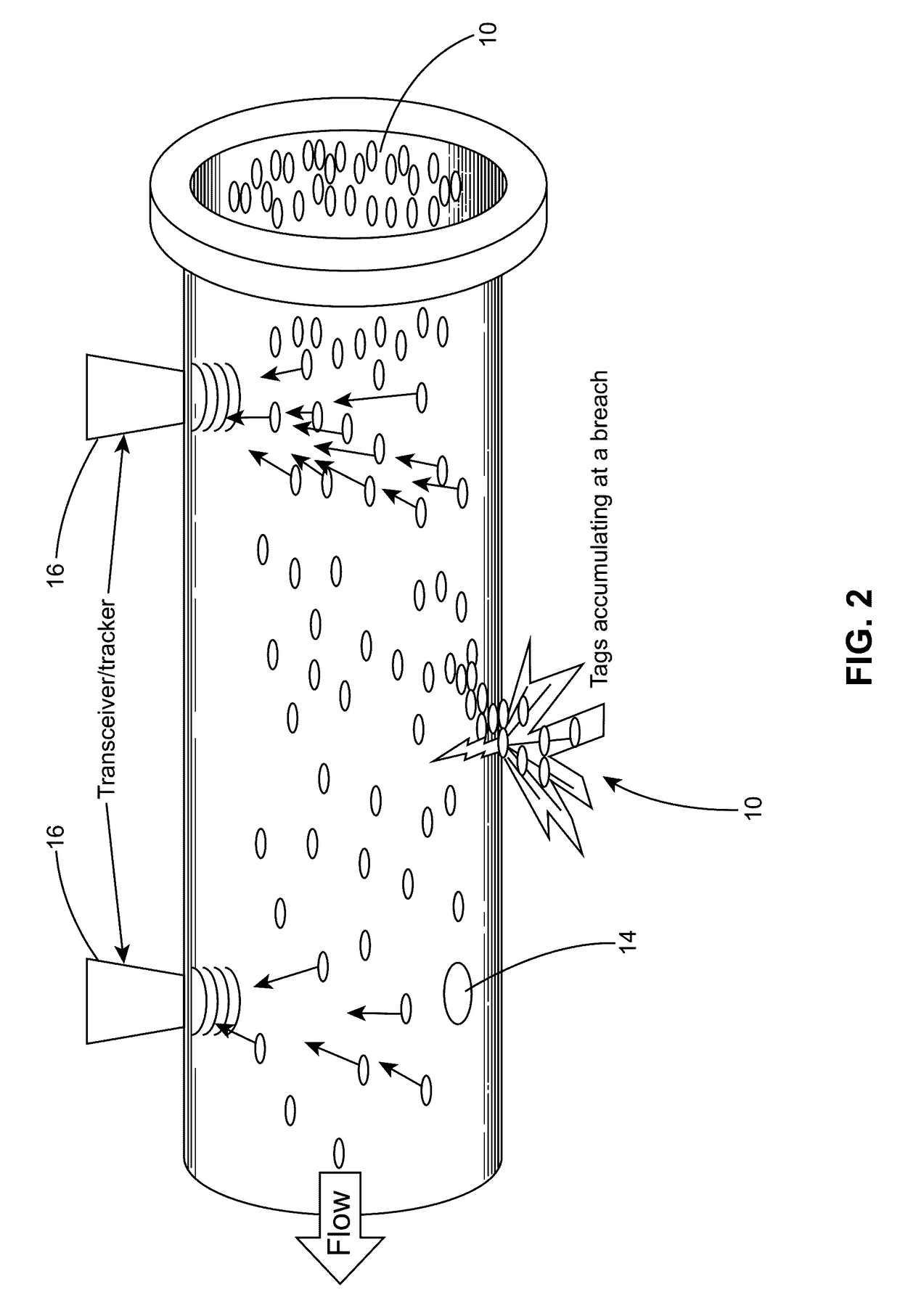

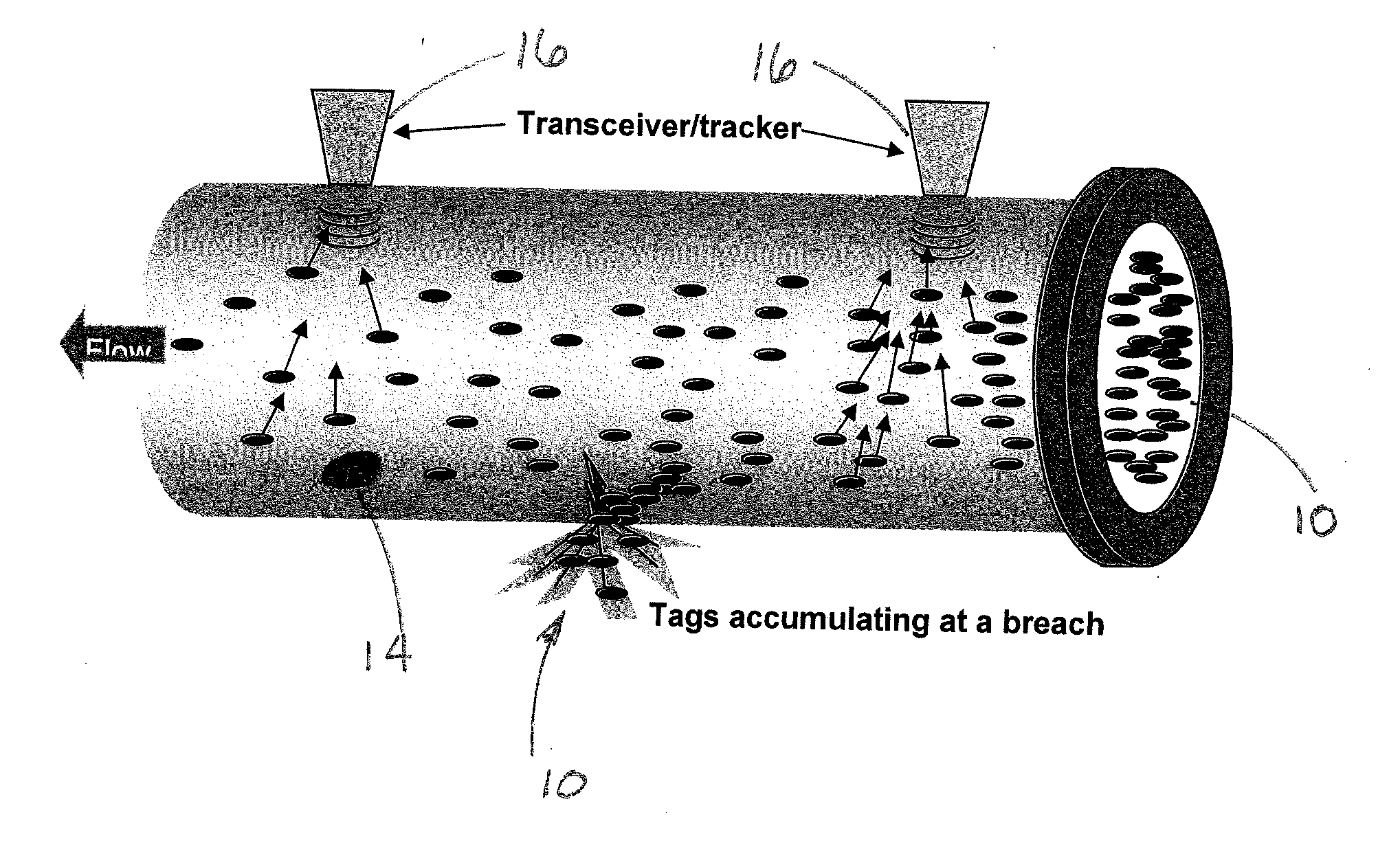

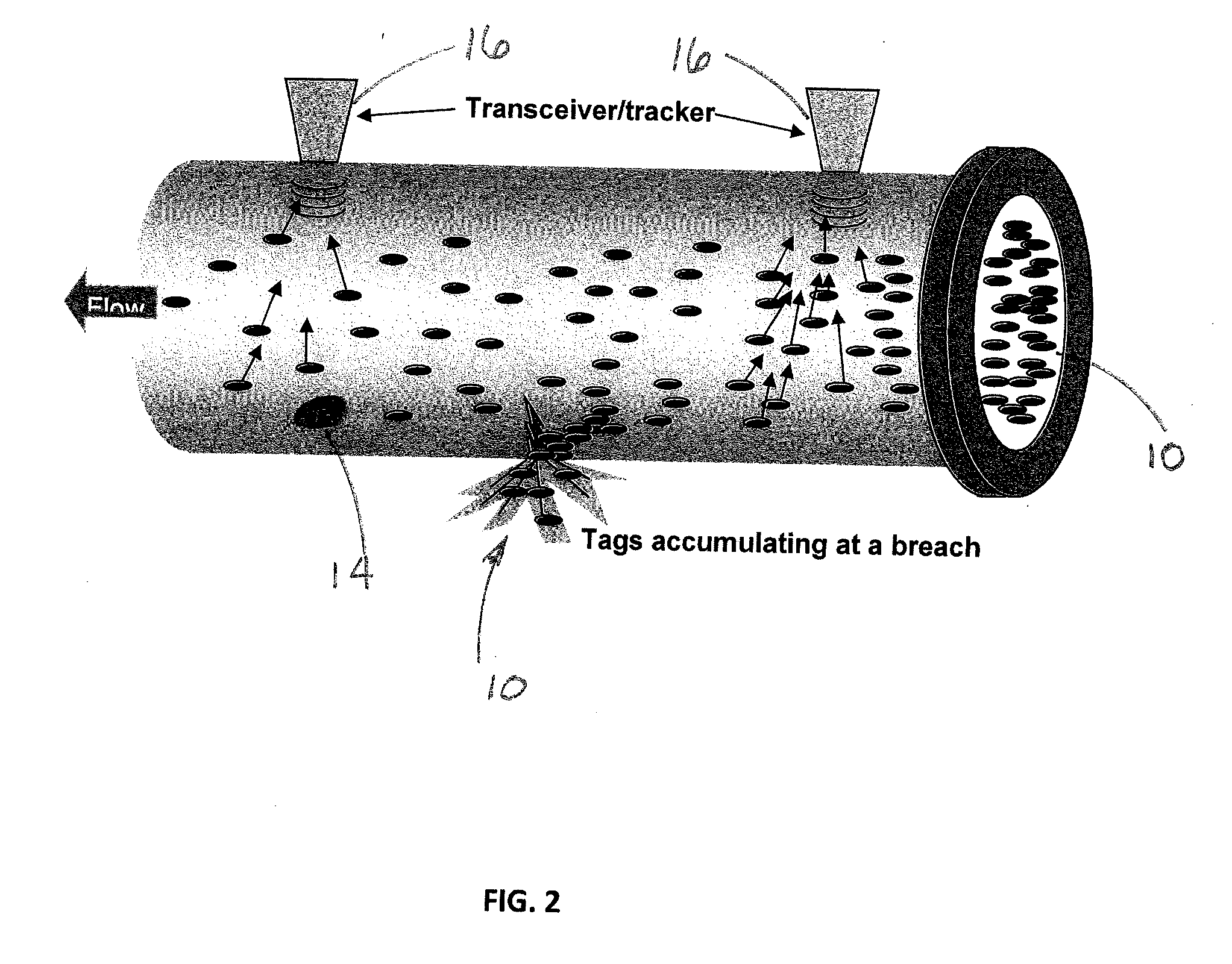

Fluid pipeline leak detection and location with miniature RF tags

ActiveUS9651445B2Measurement of fluid loss/gain rateSensing record carriersGeometric propertyTransceiver

Sensors locate troublesome leaks in pipes or conduits that carry a flowing medium. These sensors, through tailored physical and geometric properties, preferentially seek conduit leaks or breaches due to flow streaming. The sensors can be queried via transceivers outside the conduit or located and interrogated inside by submersible unmanned vehicle to identify and characterize the nature of a leak. The sensors can be functionalized with other capabilities for additional leak and pipeline characterization if needed. Sensors can be recovered from a conduit flow stream and reused for future leak detection activities.

Owner:UT BATTELLE LLC

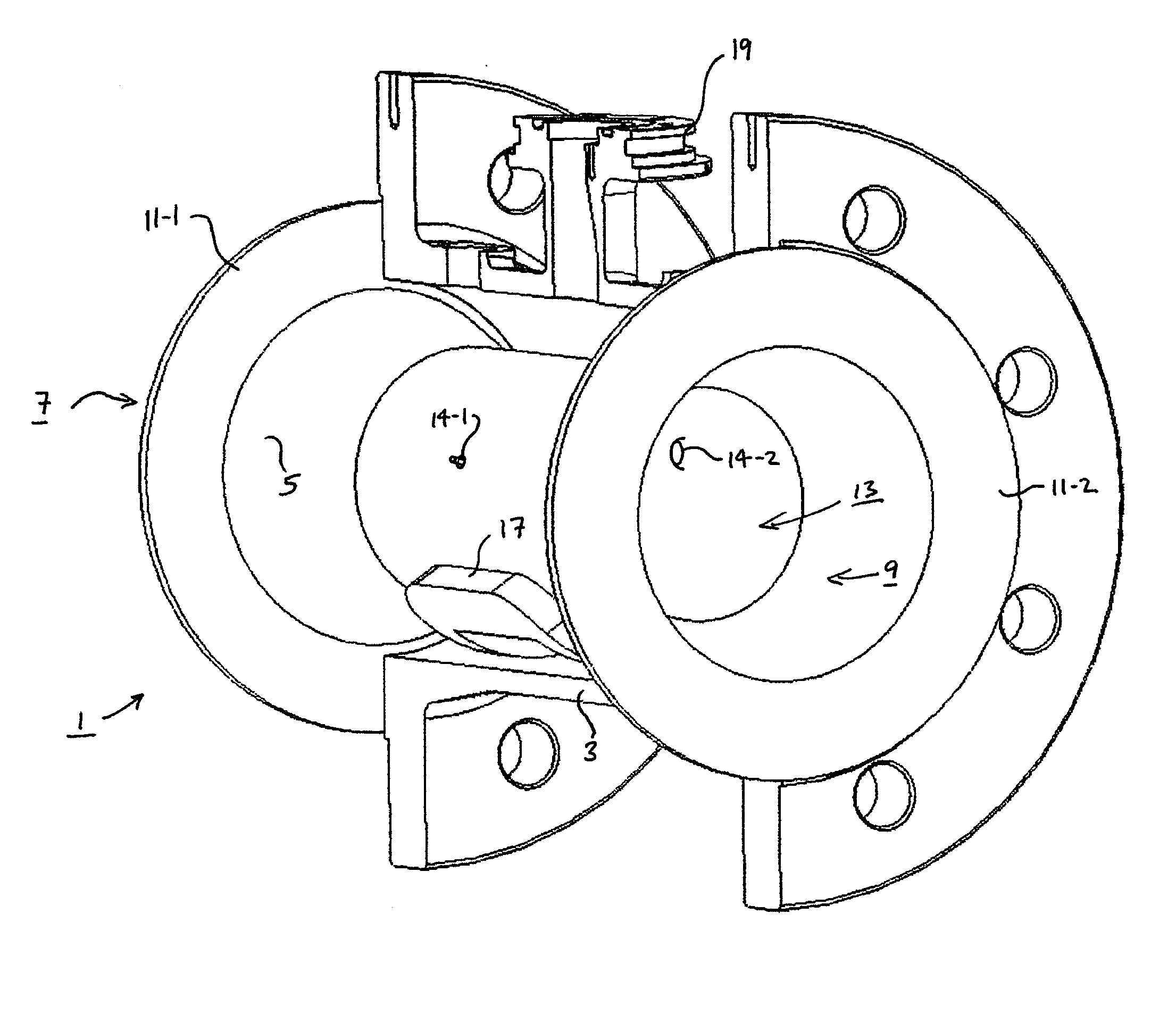

Flow meter

ActiveUS7665368B2Low costImprove the uniformity of the magnetic fieldVolume/mass flow by electromagnetic flowmetersElectromagnetsEngineeringAir flow meter

Owner:ABB LTD

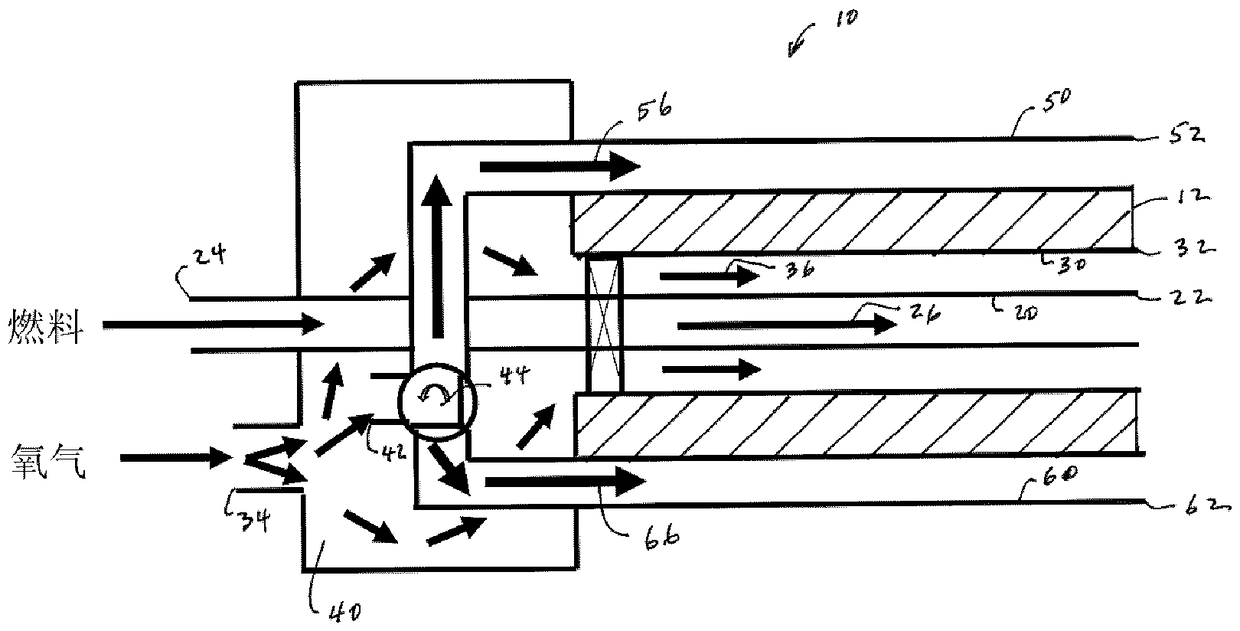

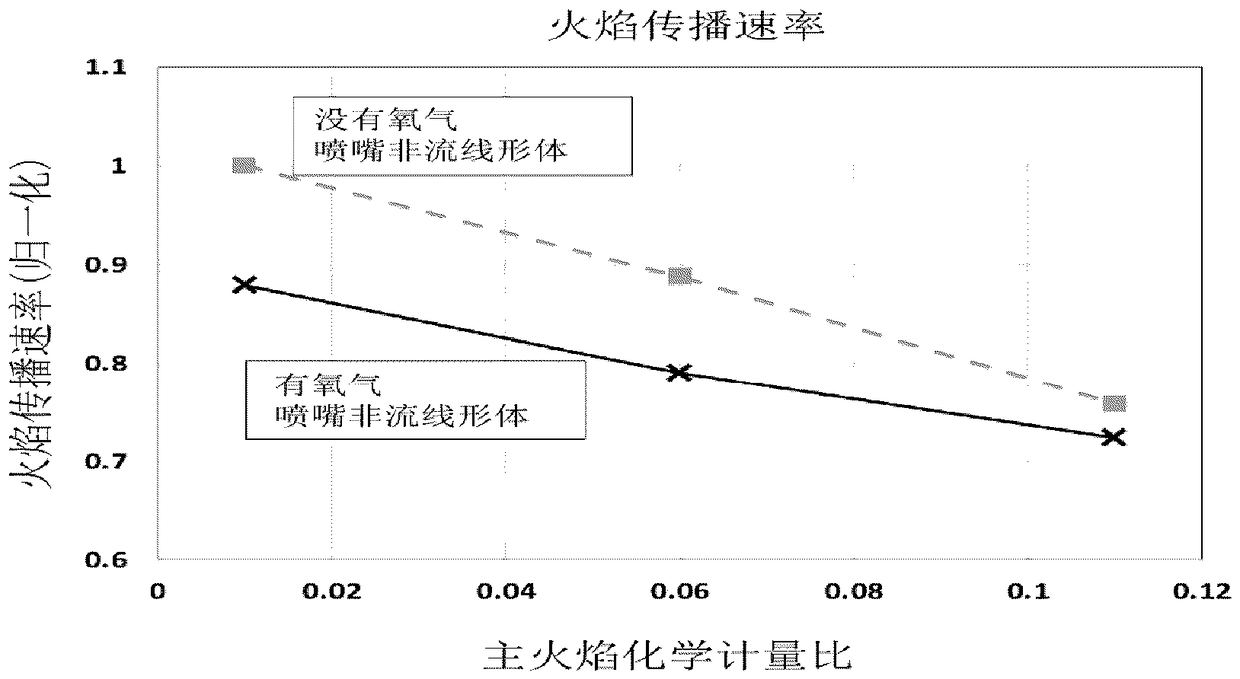

Double-staged oxy-fuel burner

An oxy-fuel burner includes a central burner element having a central conduit terminating in a central nozzle and an annular conduit terminating in an annular nozzle surrounding the central conduit, the central conduit flowing a first reactant and the annular conduit flowing a second reactant; a first staging conduit spaced apart from a side of the central burner element and terminating in a firststaging nozzle; a second staging conduit spaced apart from an opposite side the central burner element and terminating in a second staging nozzle; a first mechanism to apportion a flow of the secondreactant into a non-zero primary flow of the second reactant directed to the annular conduit and a non-zero secondary flow of the second reactant; and a second mechanism to selectively apportion the secondary flow of the second reactant between the staging conduits; wherein one reactant is fuel and the other reactant is oxygen.

Owner:AIR PROD & CHEM INC

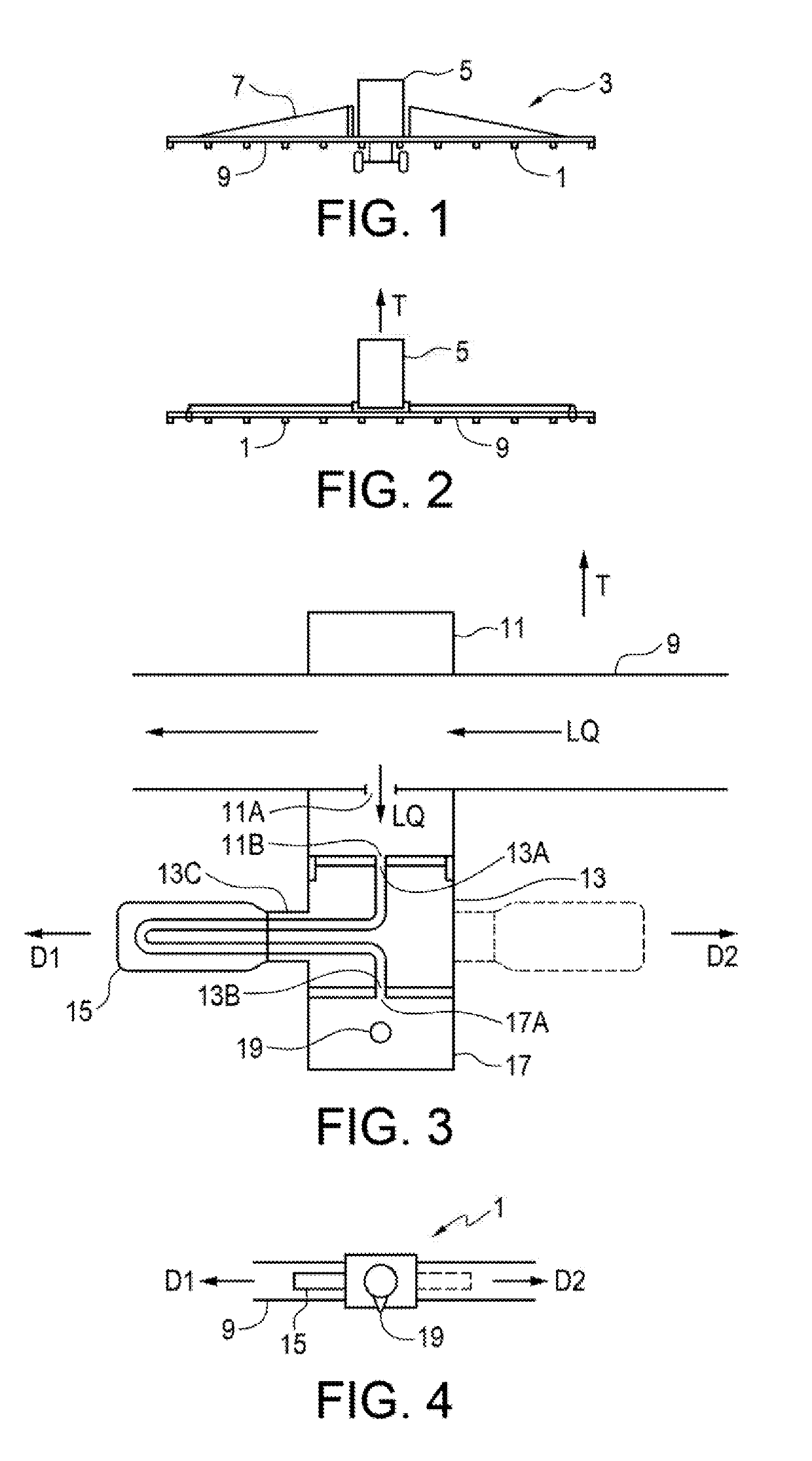

Debris filtering apparatus and method

InactiveUS20130105416A1Low and stable profileEasy to cleanSemi-permeable membranesWater/sewage treatmentBiomedical engineeringConduit flow

A debris filtering apparatus and method. The apparatus includes a first filter assembly. The first filter assembly includes an outer conduit and an inner conduit received within the outer conduit. An inner conduit flow-path is defined within the inner conduit and an outer conduit flowpath is defined between the inner conduit and the outer conduit. The inner conduit includes a filter. A fluid inlet is in communication with the inner conduit flowpath and a fluid outlet is in communication with the outer conduit flowpath. The filter permits a fluid to pass between the inner conduit flowpath and the outer conduit flowpath while retaining debris within the inner conduit. The method includes passing the fluid through the first filter assembly, removing the inner conduit from within the outer conduit, removing the debris from the inner conduit, and replacing the inner conduit within the outer conduit.

Owner:WESTERN ENERGY SERVICES PARTNERSHIP

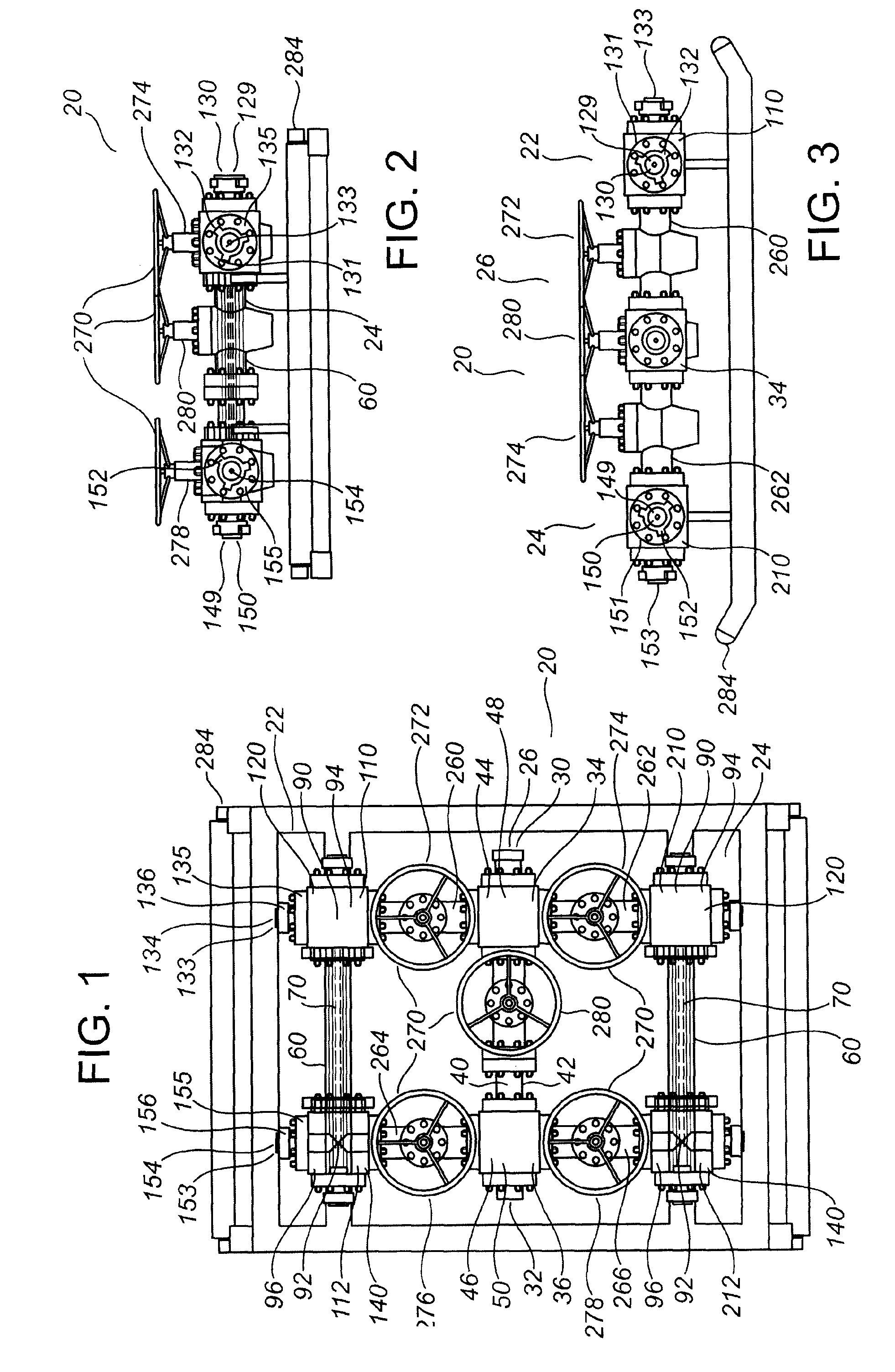

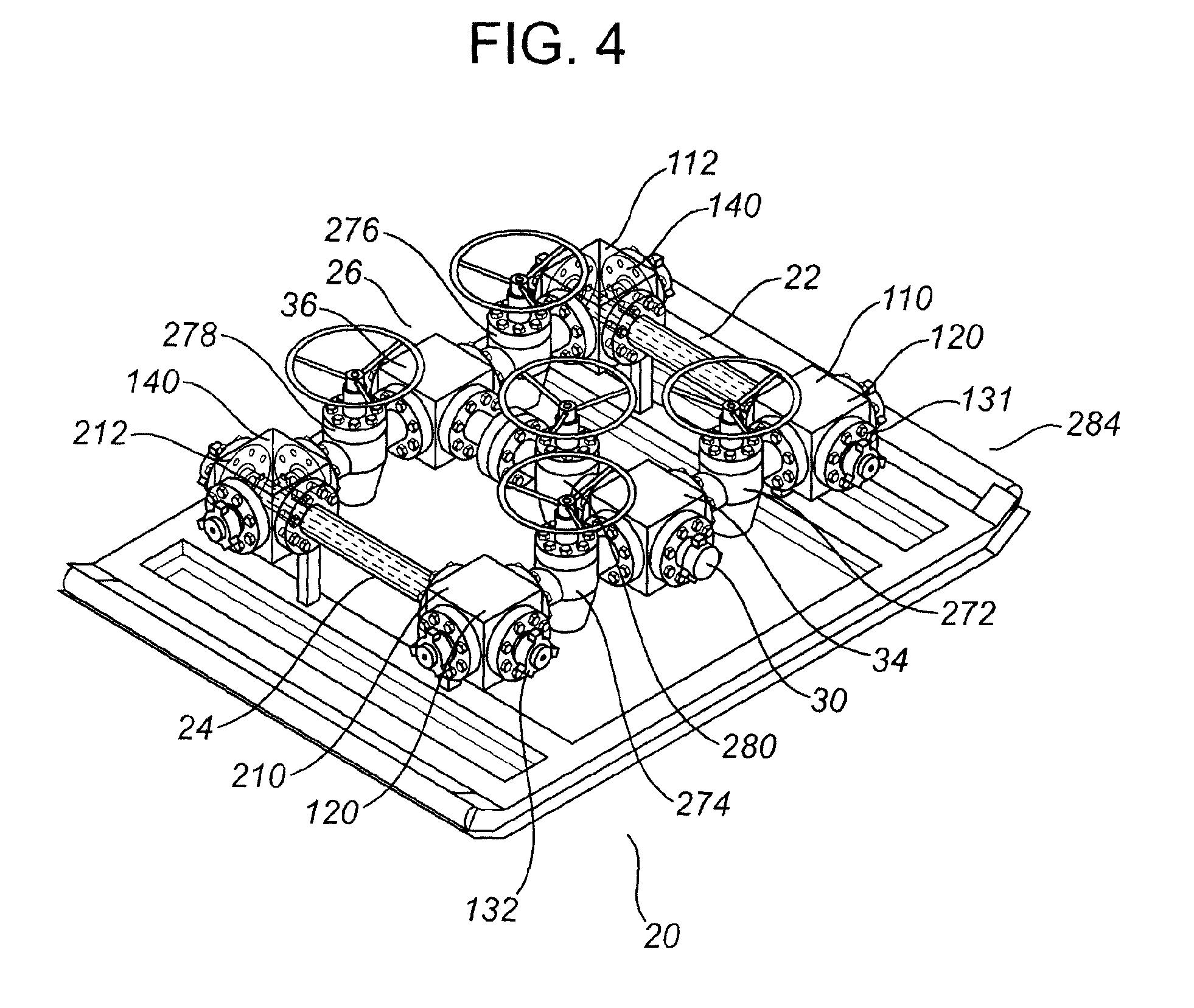

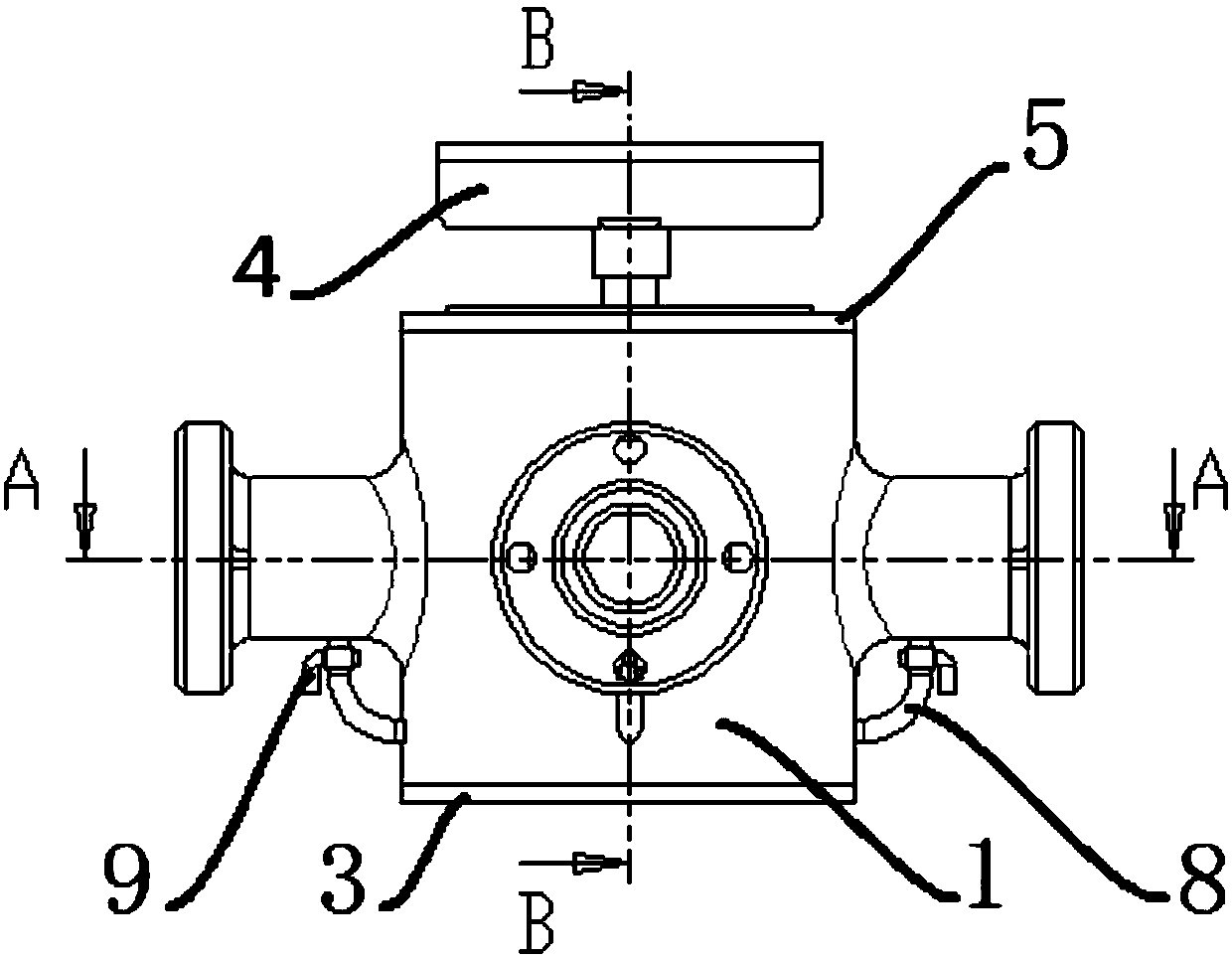

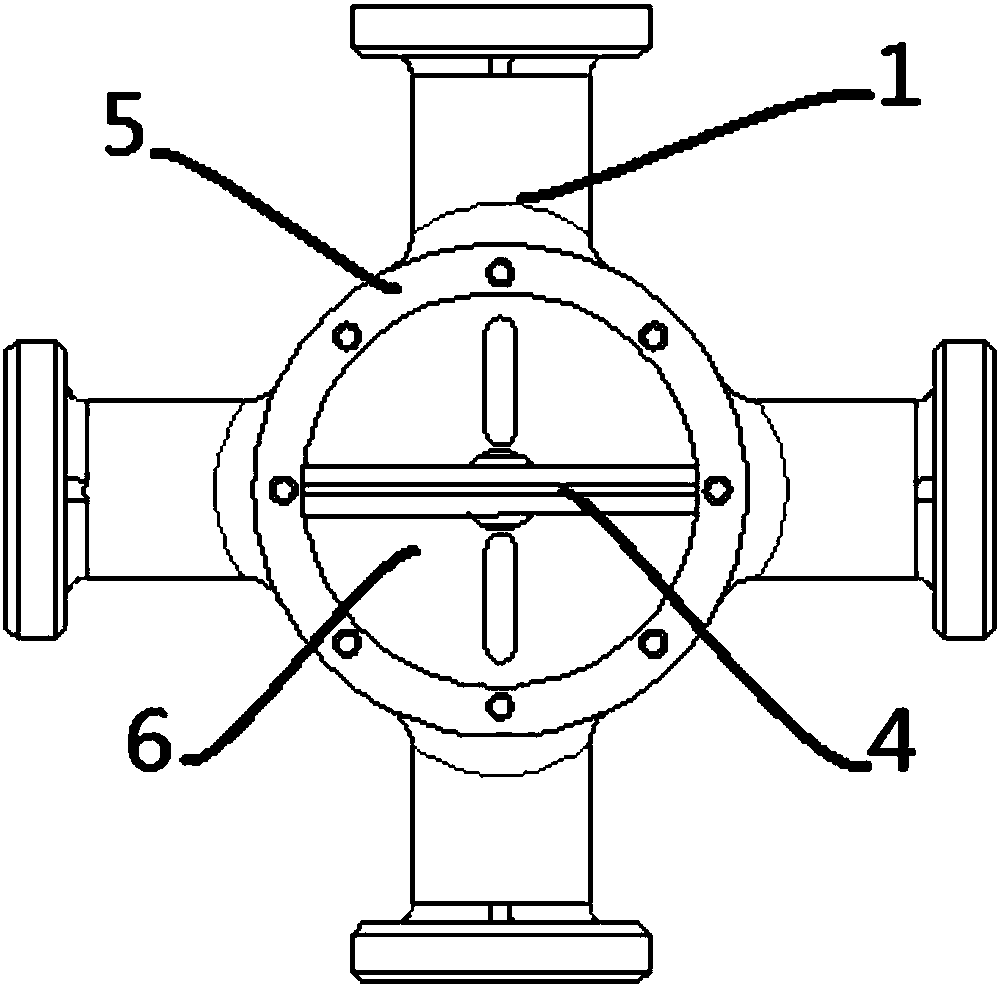

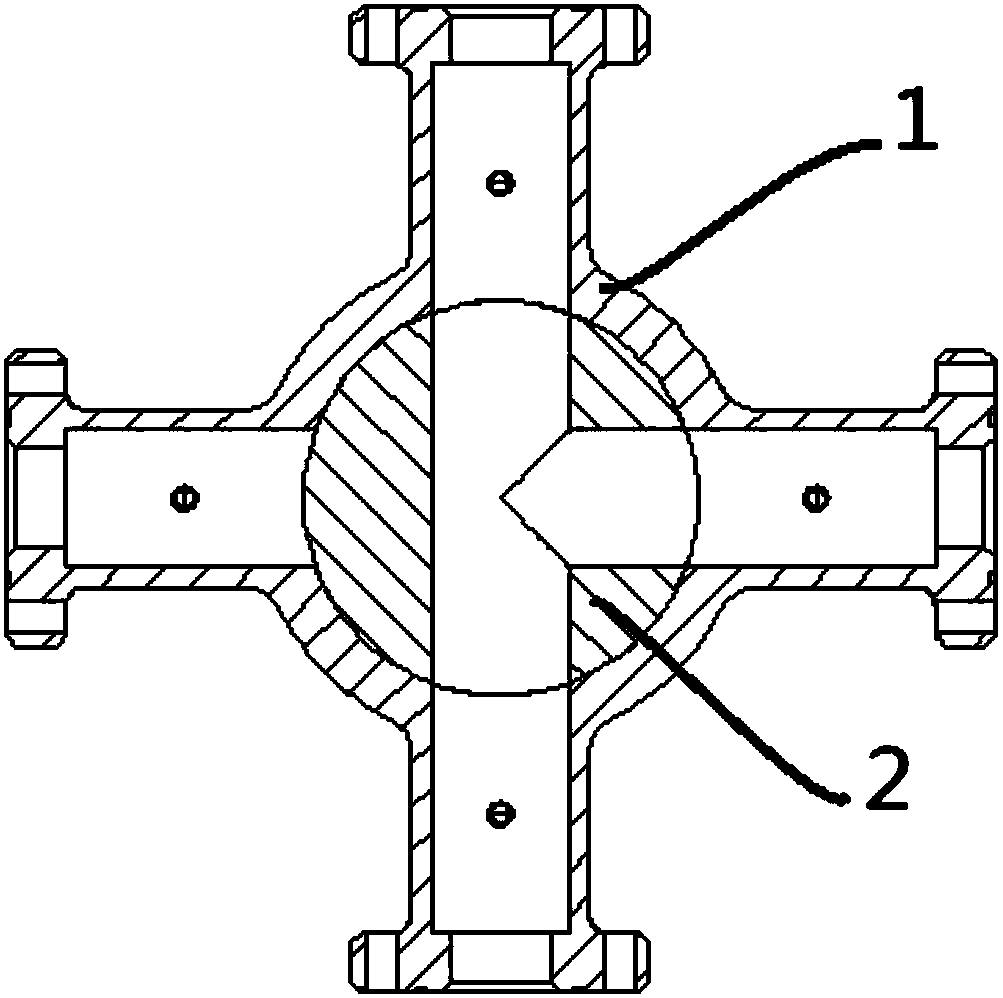

Four-channel and three-way reversing and automatic checking plunger valve

InactiveCN107725827AReach the function of non-returnOperating means/releasing devices for valvesMultiple way valvesFour-way valveEngineering

The invention discloses a four-channel three-way reversing and automatic return plunger valve, which comprises a valve body, a plunger body and a valve bottom plate. The valve body is a cross-shaped four-way structure. The second channel, the third channel, the fourth channel and the cylinder body are composed of a T-shaped channel in the radial direction of the plunger body. The plunger body is set in the cylinder body. An accommodation space is provided between the cylindrical guide sleeve, the plunger body and the valve bottom plate, and the valve passages communicate with the accommodation space through feedback pipelines. In the present invention, a feedback pipeline is provided on the valve body. The feedback pipeline can automatically adjust the flow rate and pressure of the valve according to the pressure and flow of the fluid at the valve inlet. The feedback pipeline can automatically close the valve when the fluid backflow is detected at the valve outlet, so as to achieve the function of backstop. .

Owner:成都市同展食品有限公司

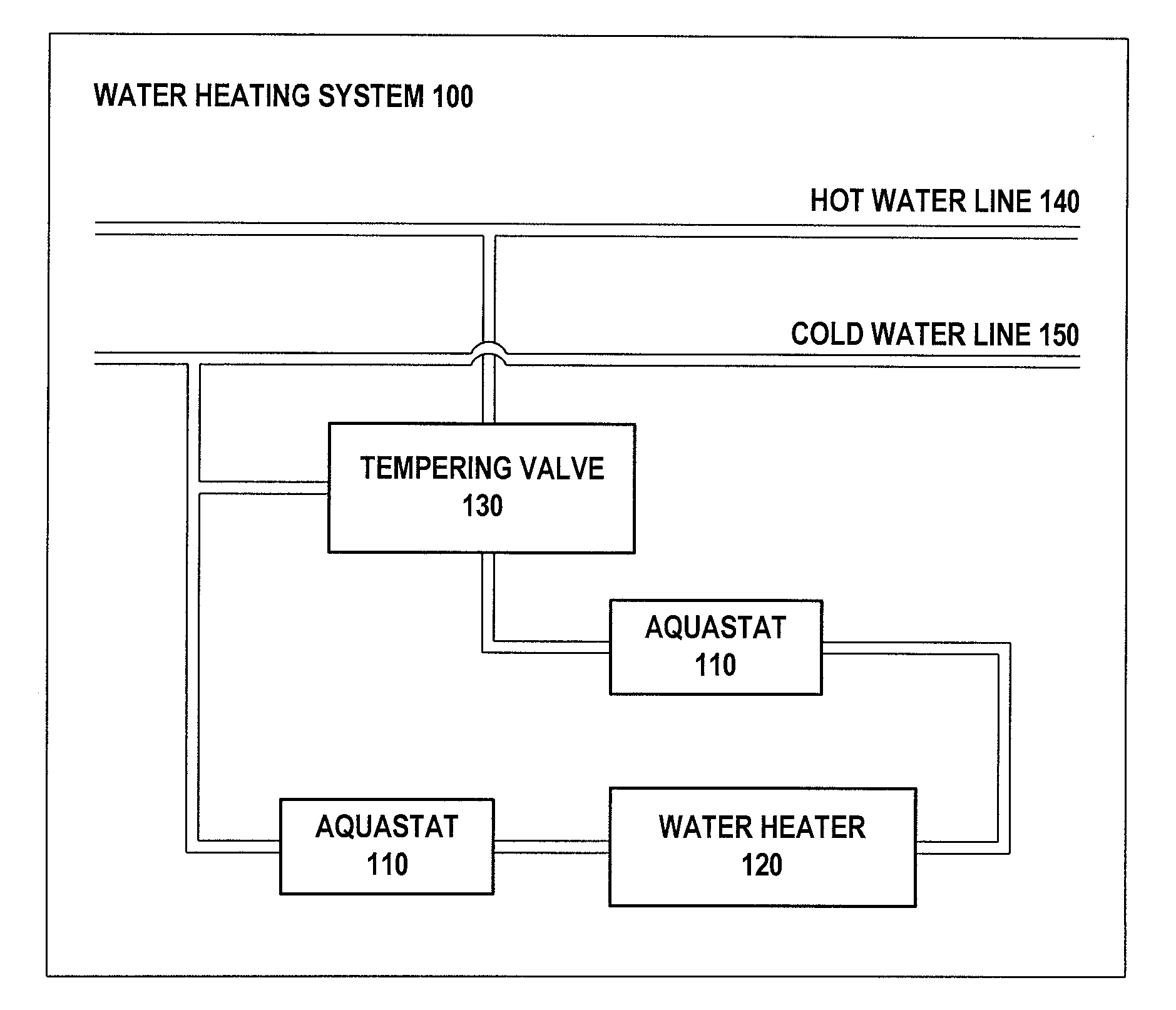

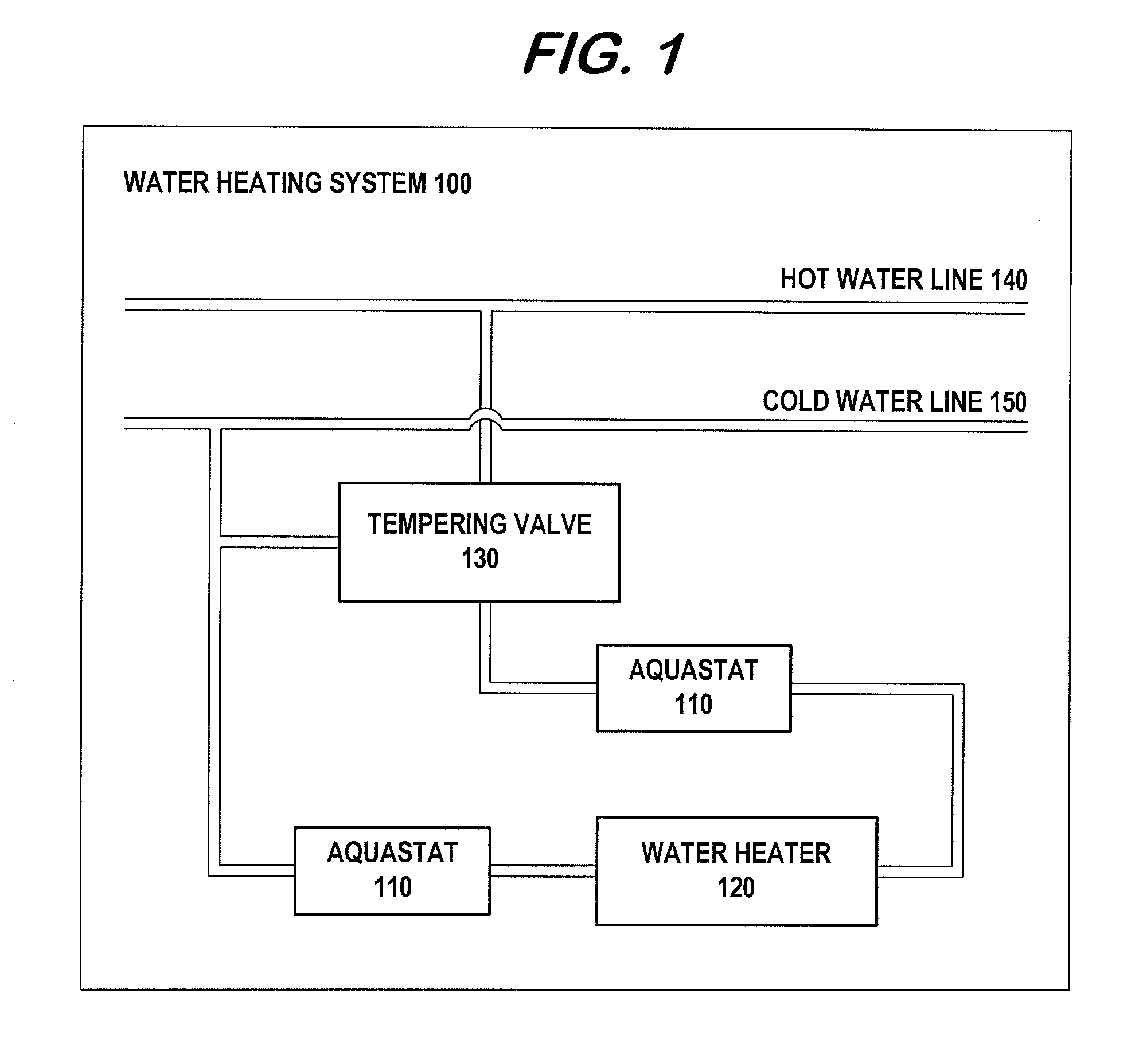

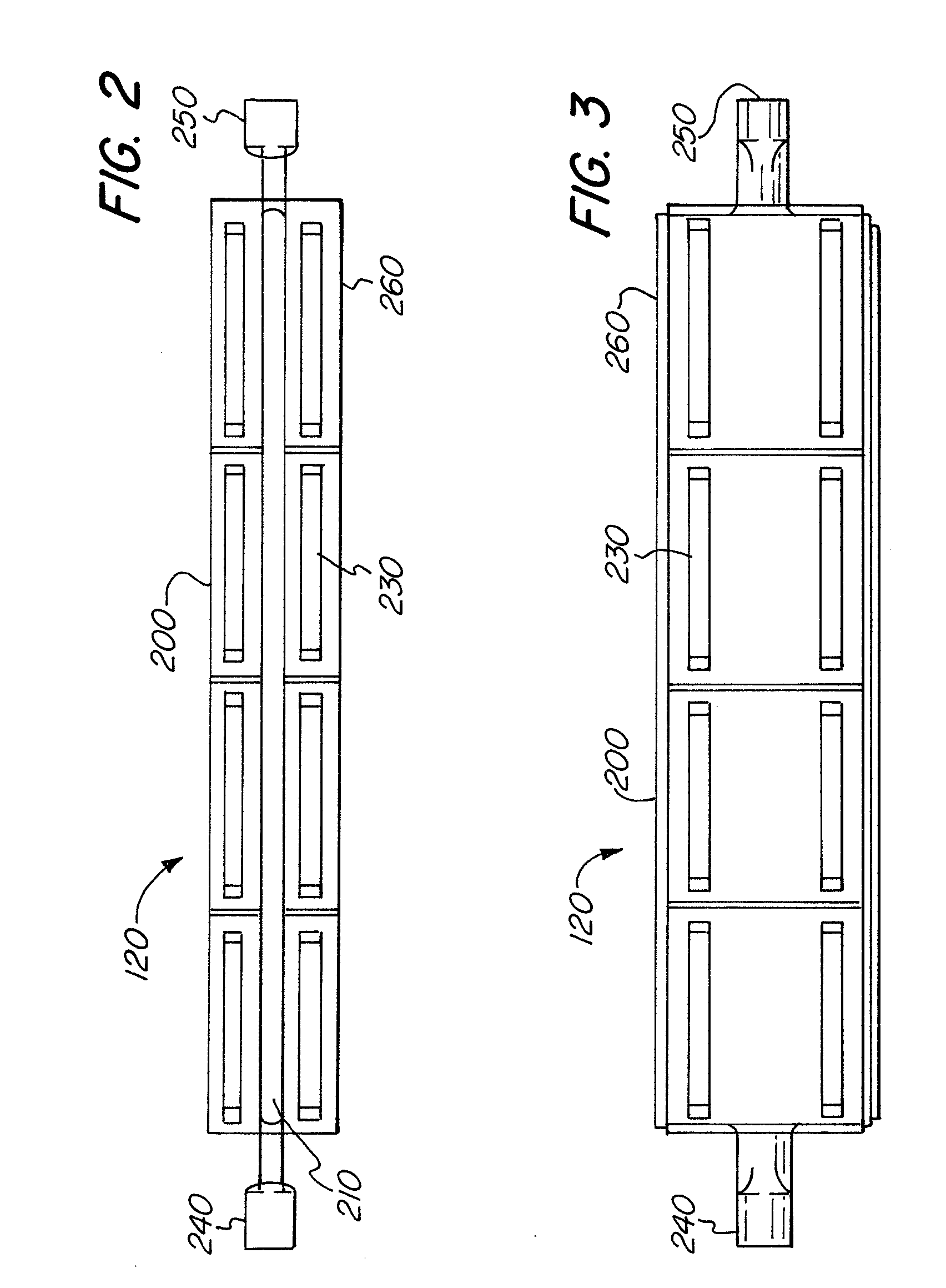

Halogen Water Heater

ActiveUS20110058797A1Drying solid materials with heatCentral heating with accumulated heatHalogenGuide tube

A fluid heating apparatus includes a housing containing a flattened tube and lamps. The apparatus further includes a first conduit flow-coupled to the flattened tube, the first conduit being adapted to provide fluid to the flattened tube. The apparatus further includes a second conduit flow-coupled to the flattened tube, the second conduit being adapted to channel fluid from the flattened tube. The lamps are arranged to irradiate the flattened tube, and the flattened tube is adapted to absorb radiation from the lamps and heat fluid contained therein.

Owner:SERVIDIO PATRICK F

Inline electric generator with magnetically suspended axial flow open center impeller

An electric power generator for placement inline with a conduit comprises a substantially cylindrical housing defining a non-magnetic elongated chamber configured to be coupled to the conduit so that a fluid flowing in the conduit flows through the elongated chamber, an impeller defining a central channel disposed in the elongated chamber and an inner surface of the central channel having a plurality of blade members shaping fluid flow in the central channel, where the impeller further including a matrix of permanent magnets secured to an exterior surface wall. The generator further comprises a copper coil assembly coupled to the substantially cylindrical housing and comprising a plurality of copper coils arranged circumferentially about the cylindrical housing, and configured to interact with the matrix of permanent magnets to generate electricity when the impeller rotates due to fluid flowing in the central channel and acting on the blade members.

Owner:MAGNETAR ELECTRIC TECH

Flow meter

ActiveUS20080060446A1Low costVolume/mass flow by electromagnetic flowmetersElectromagnetsEngineeringSingle coil

An electromagnetic flow meter for measuring flow rate of a fluid passing therethrough includes a conduit defining a fluid inlet, a fluid outlet and a measuring section positioned between the inlet and the outlet. The flow meter also includes a single coil for generating a magnetic field across the measuring section and electrodes for detecting induced electrical potential due to the fluid passage. The coil may be arranged to surround a section of the measuring section over a segment angle of between 140 and 180 degrees. The electrodes may be positioned so that they are offset from being opposite each other on the centerline of the measuring section, by an offset angle of between 5 degrees and 45 degrees.

Owner:ABB LTD

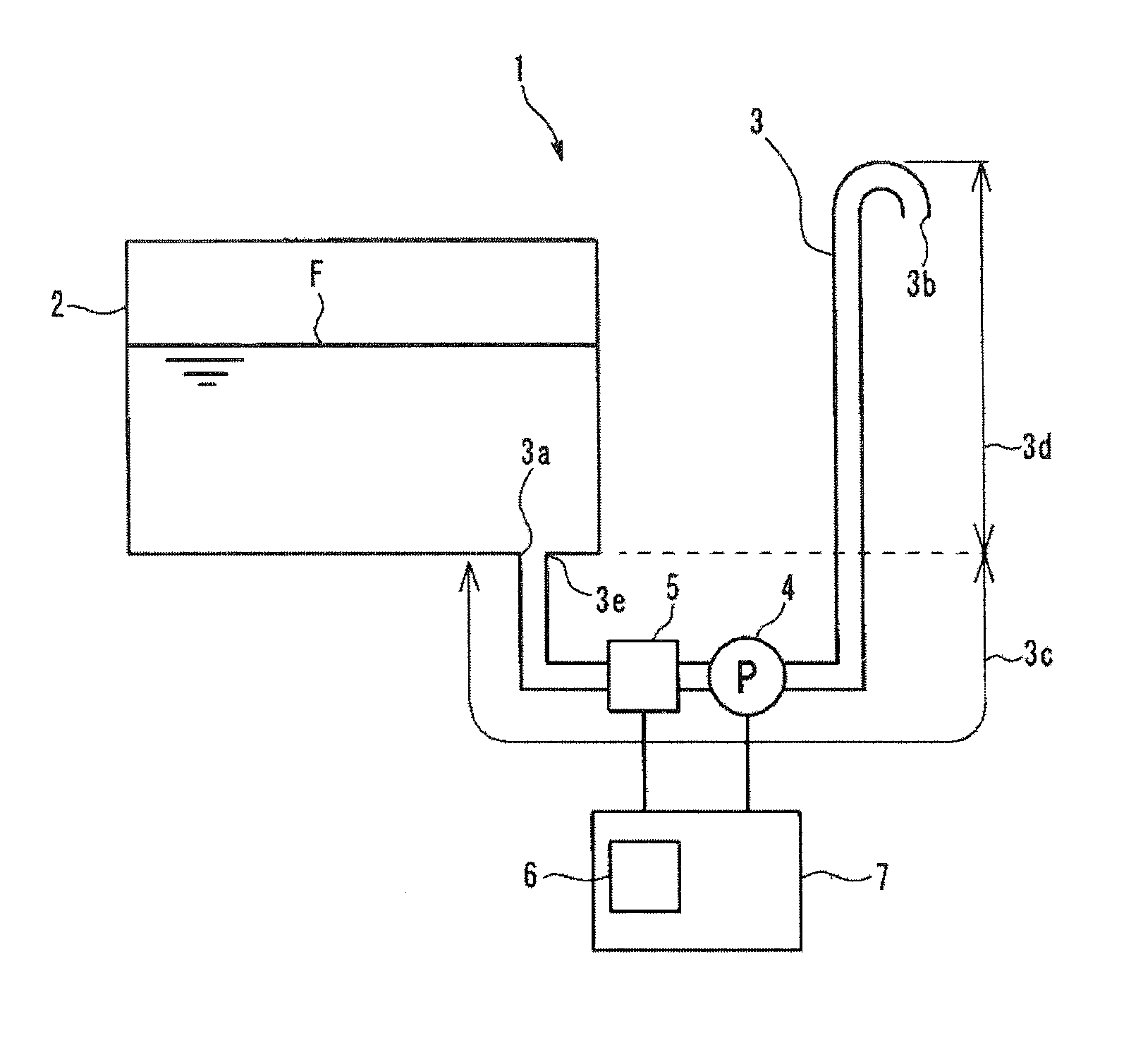

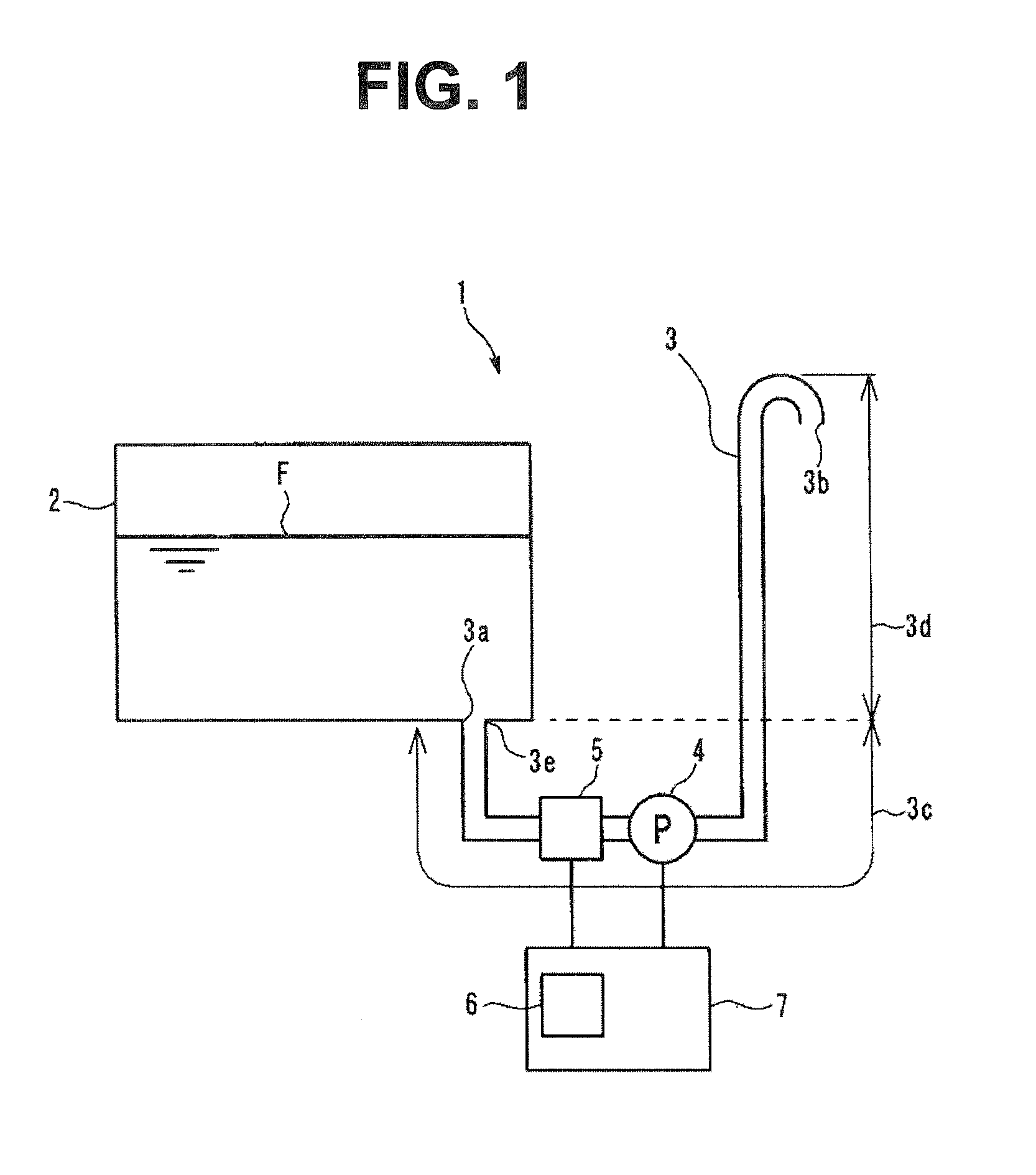

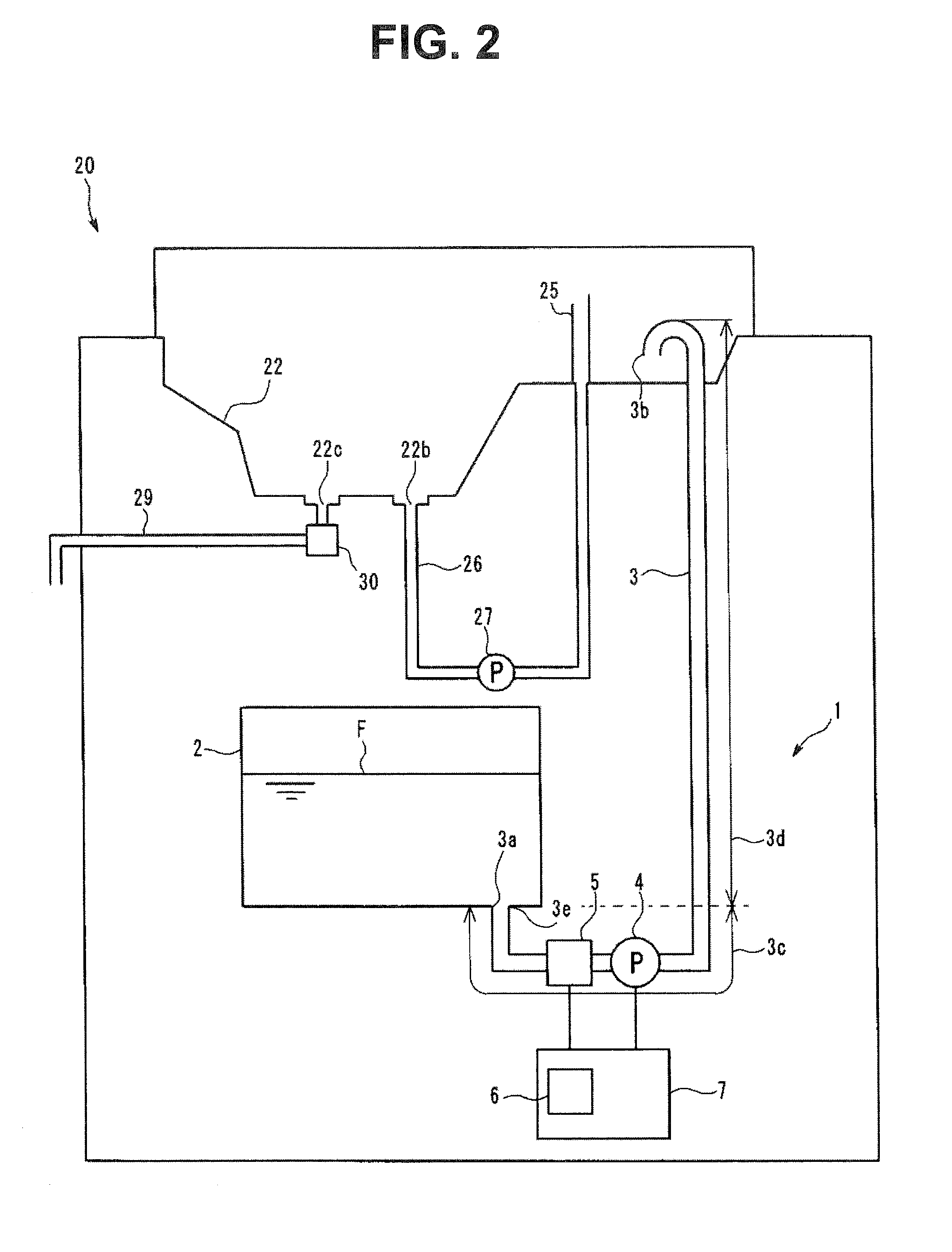

Liquid supplying apparatus and endoscope reprocessing apparatus

A liquid supply apparatus includes: a storing tank configured to store a liquid; a supply conduit through which the liquid remained inside the supply conduit flows reversely into the storing tank by a predetermined amount over time, the supply conduit having a first end portion connected to the storing tank; a liquid feeding section which is arranged at the storing tank or the supply conduit, and which is configured to feed the liquid from the storing tank to a second end portion of the supply conduit; a time measuring section which measures an elapsed time from stop of the liquid feeding by the liquid feeding section; and a control section which is connected to the liquid feeding section and the time measuring section and which is configured to drive the liquid feeding section for a predetermined time based on a length of the elapsed time.

Owner:OLYMPUS CORP

Fluid Pipeline Leak Detection and Location with Miniature RF Tags

ActiveUS20140306809A1Fluid-tightness measurementSensing record carriersGeometric propertyTransceiver

Sensors locate troublesome leaks in pipes or conduits that carry a flowing medium. These sensors, through tailored physical and geometric properties, preferentially seek conduit leaks or breaches due to flow streaming. The sensors can be queried via transceivers outside the conduit or located and interrogated inside by submersible unmanned vehicle to identify and characterize the nature of a leak. The sensors can be functionalized with other capabilities for additional leak and pipeline characterization if needed. Sensors can be recovered from a conduit flow stream and reused for future leak detection activities.

Owner:UT BATTELLE LLC

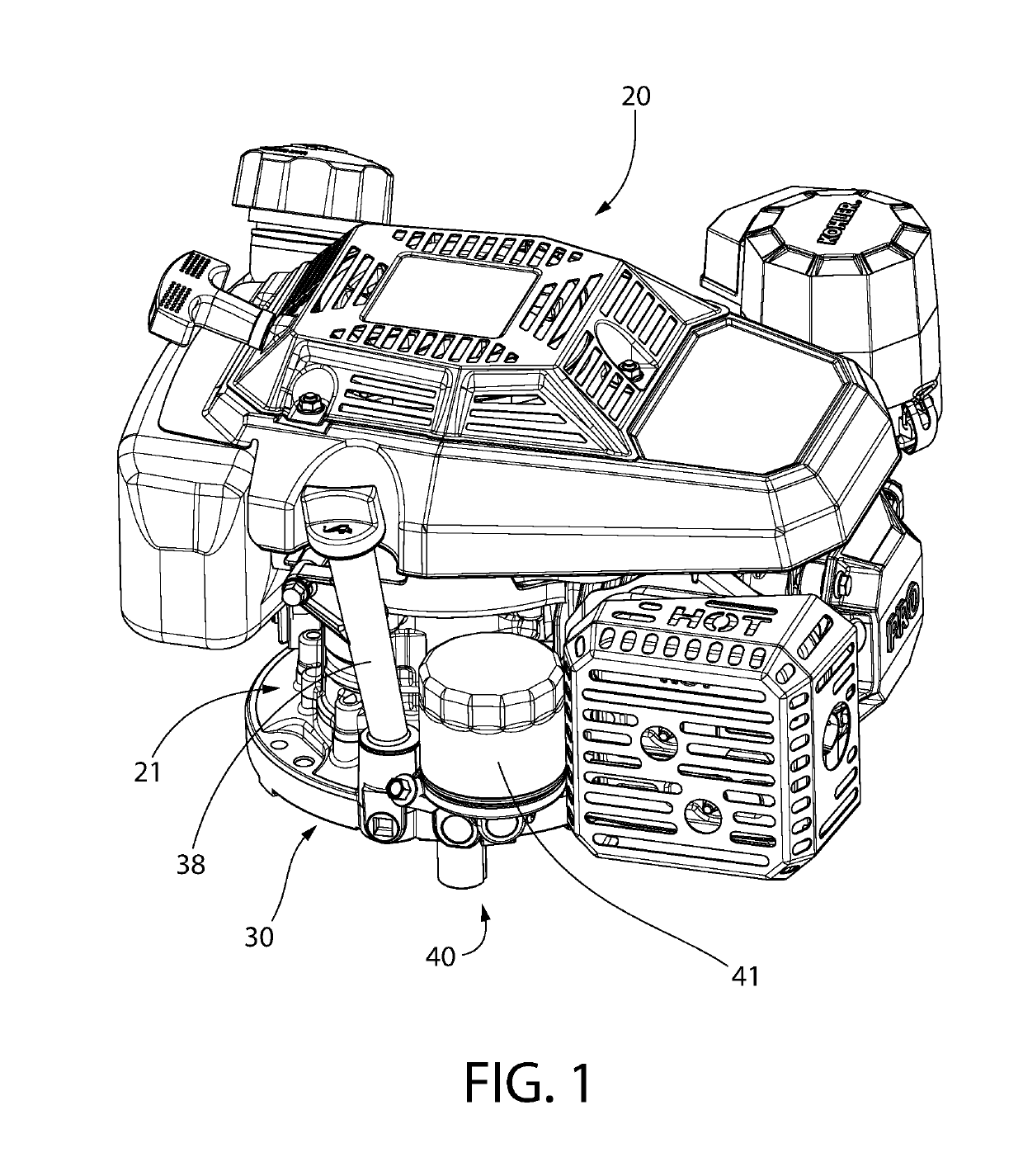

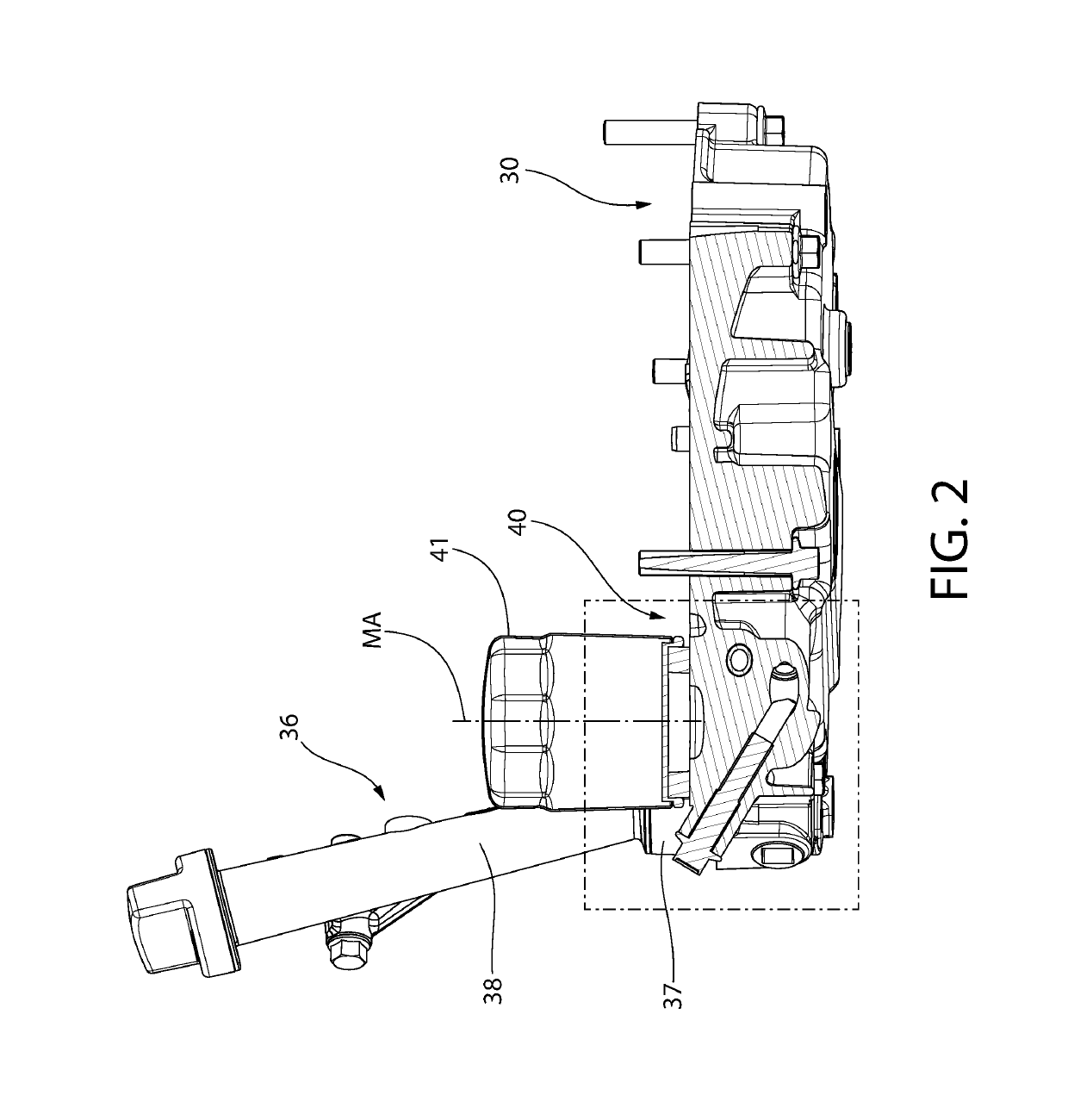

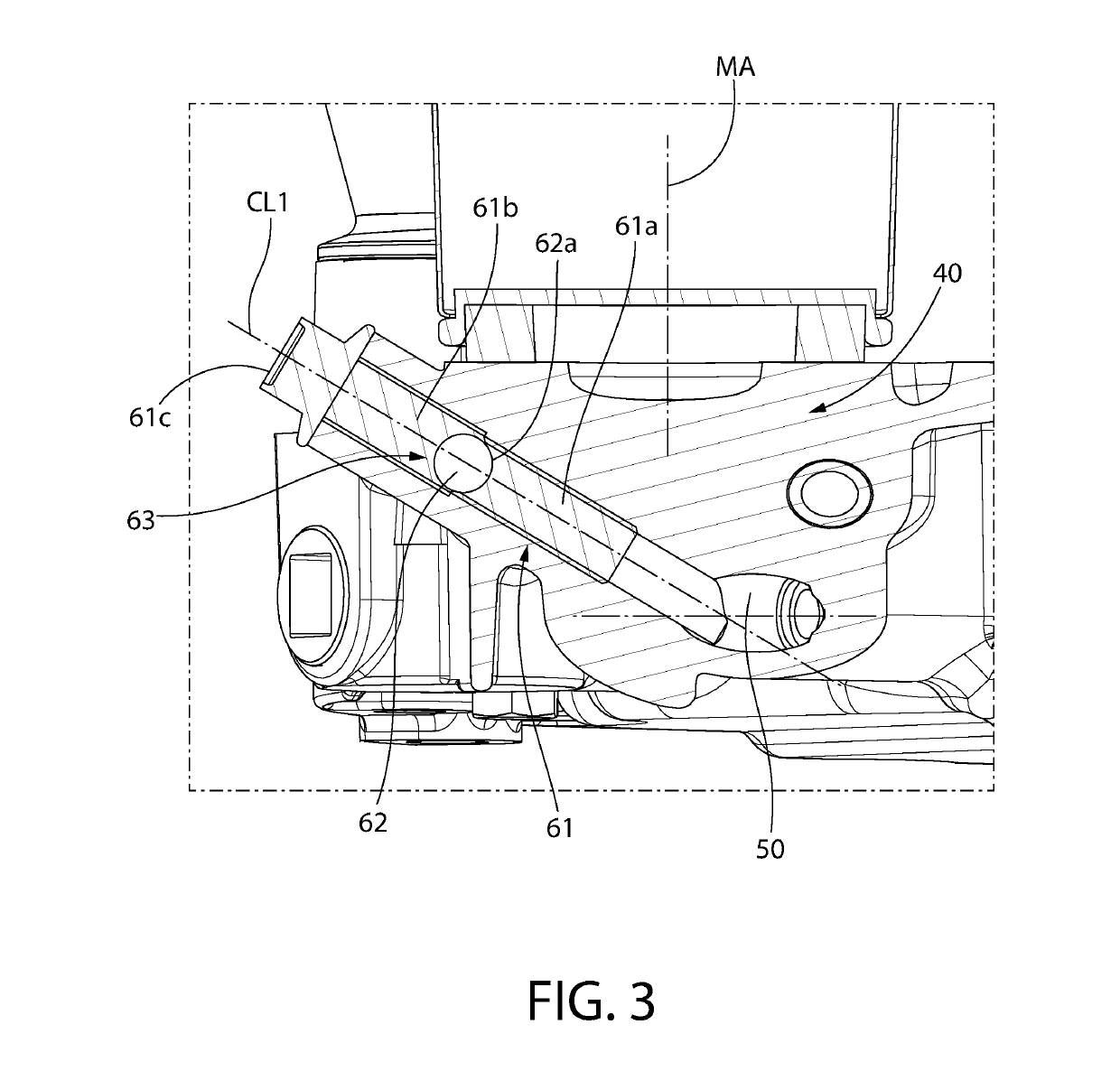

Residual oil drainage system and related method for replacing an oil filter of an engine

ActiveUS20190234260A1Reduce and eliminate spillageReduce and eliminate and leakageLubricant conduit arrangementsMachines/enginesResidual oilInternal combustion engine

A residual oil drainage system for use in replacement of the oil filter of an internal combustion engine is disclosed. The drainage system may include first and second drainage conduits disposed in the oil pan of the engine. The drainage conduits may be fluidly interconnected and coupled to portions of the oil inlet and outlet flow conduits which normally convey oil to and from the oil filter. A flow control device is movable to either open or close the drainage flowpath in the system. In use with an open flowpath and engine off, residual oil captured by the first and second drainage conduits flows through the drainage system and is returned to the oil reservoir in the oil pan via gravity. In one configuration, the drainage conduits are formed internally and directly within the body of the structure of the oil pan.

Owner:KOHLER CO

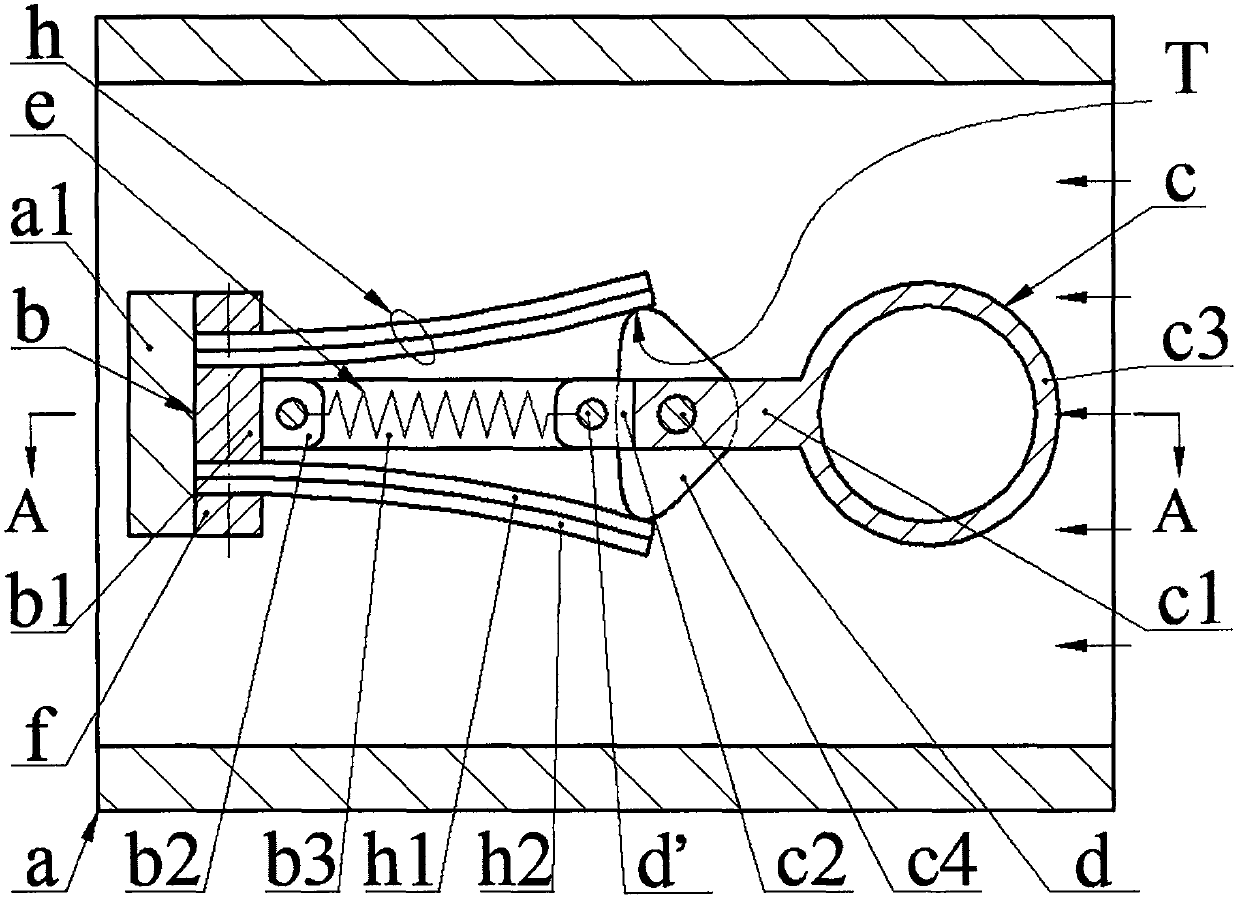

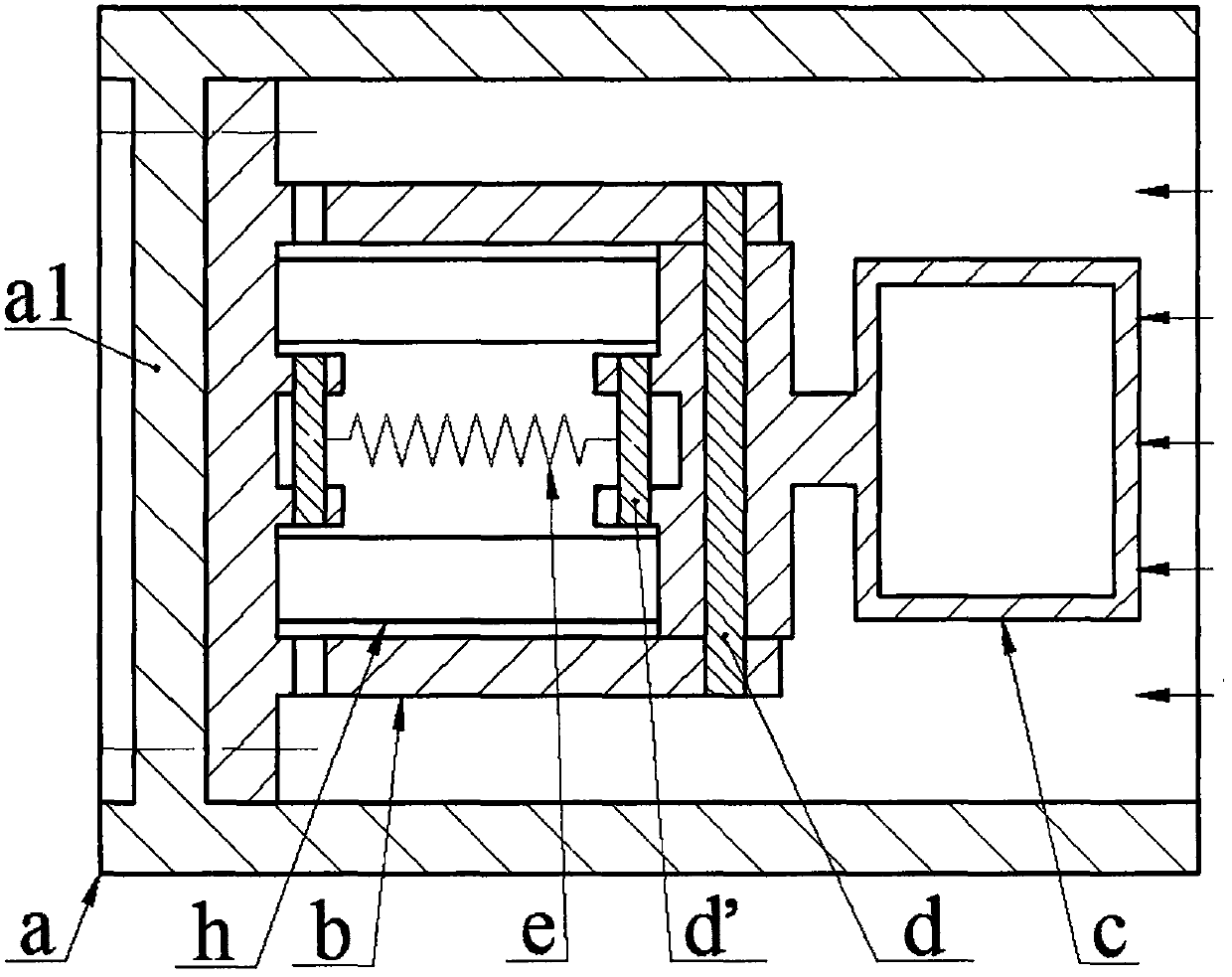

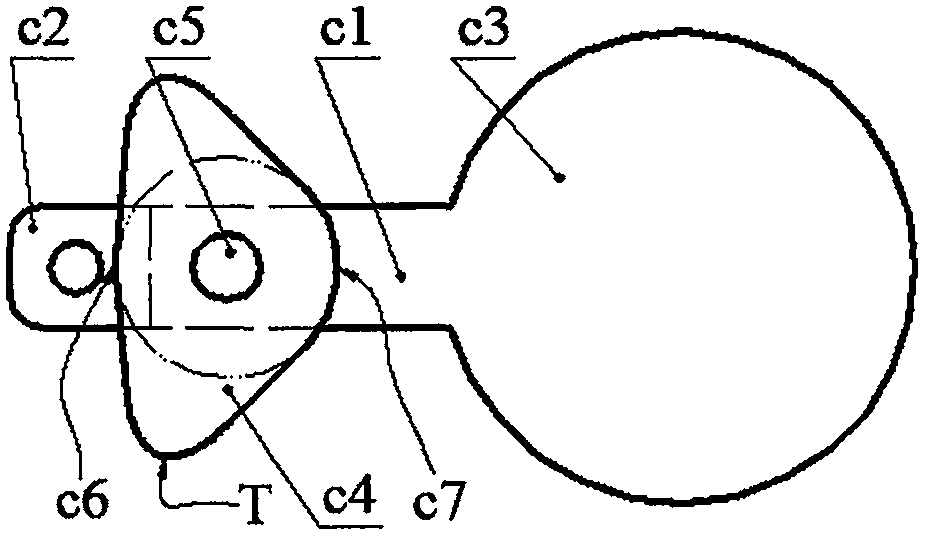

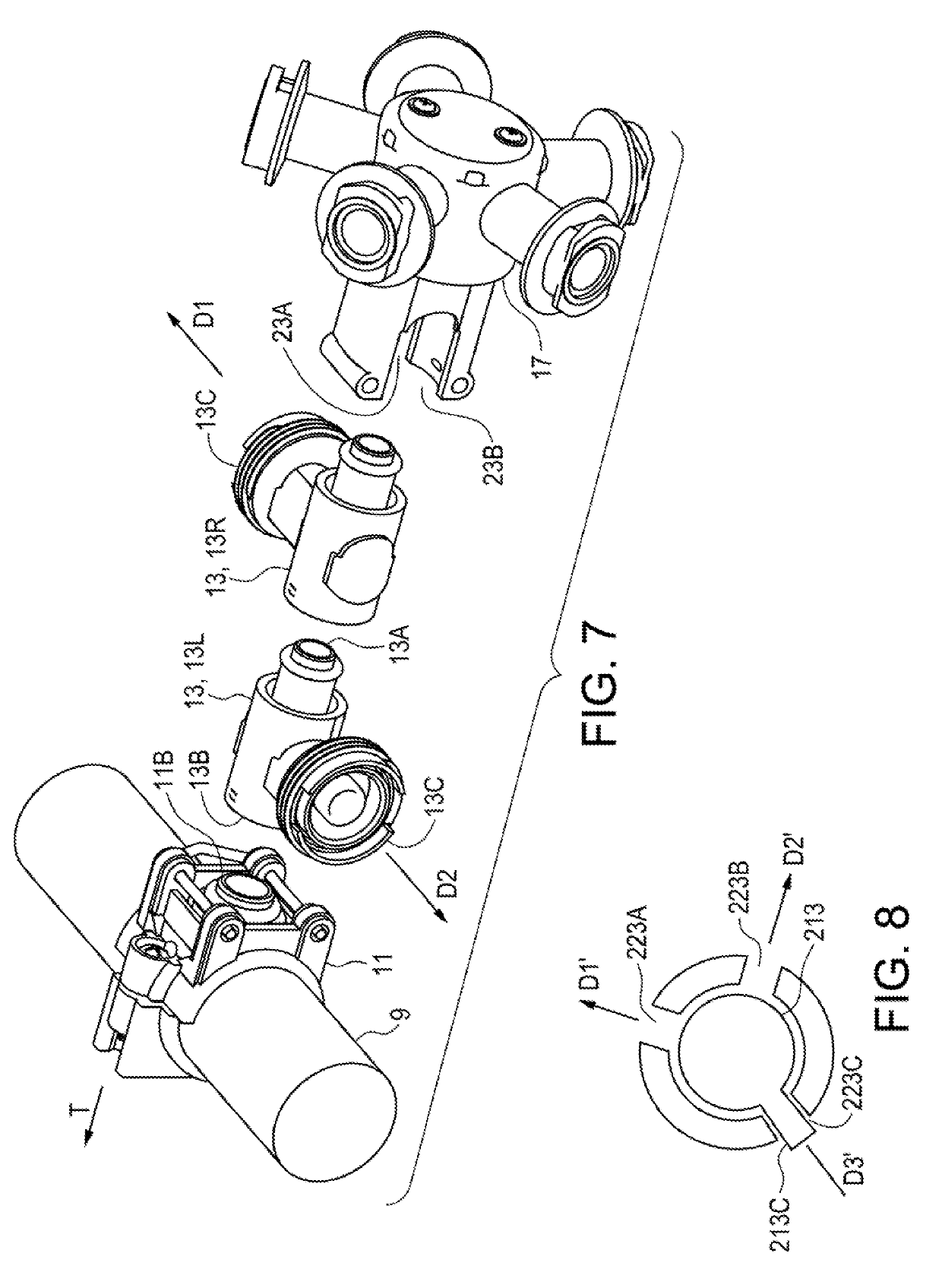

Conduit flow energy harvester

ActiveCN107359819ASimple structureImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesEnergy harvesterTransducer

The present invention relates to a conduit flow energy harvester and belongs to the field of fluid power generation. A framework bottom plate, provided with inner and outer anchorage plates, is installed on the cross beam of a pipeline. The left end of a rocking arm of an exciter is provided with a rocking arm anchorage plate, and the right end of the rocking arm of the exciter is provided with a blunt body. The front and back sides of the exciter are provided with cams. The shaft hole of the rocking arm is sleeved on a rotating shaft. The rotating shaft is fixed onto the outer anchorage plate. The inner anchorage plate and the rocking arm anchorage plate are provided with pin shafts. The two ends of a spring are connected with the pin shafts. The upper and lower sides of the framework bottom plate are provided with energy transducers and the substrates of the energy transducers are arranged closer to the framework bottom plate. The free ends of the energy transducers are pressed against the cams. The contour curve of each cam is composed of two sections of arc profiles concentric with the shaft hole. In the contour curve of each cam, the distance between each arc profile and the center of the shaft hole is the shortest. Before the installation of energy transducers, the energy transducers are of a flat and straight structure. After the installation of energy transducers, the energy transducers are of a bent structure. Meanwhile, the free ends of the energy transducers and the vertex of the profile of each cam are in contact with each other. In the contour curve of each cam, the vertex of the profile is the largest in distance from the center of the shaft hole. The deformation amount of the energy transducers is the largest when the energy transducers are in contact with the vertex of the profile.

Owner:ZHEJIANG NORMAL UNIVERSITY

Multi-position sprayer component for spraying implements

ActiveUS20190166775A1Increase flexibilityFacilitates componentWatering devicesSpray nozzlesSprayerSpray nozzle

A nozzle body apparatus having a conduit mounting member with a conduit input adapted to be connected such that liquid passing through a liquid conduit flows into the conduit input and out through a conduit output. A component mounting member has a component input releasably connected to the conduit output, a component attachment element, and a component output. Liquid passing out the conduit output flows into the component input then through a sprayer component connected to the component attachment element to the component output and then to a nozzle. The component mounting member is connectable to the conduit output in a first orientation where the component attachment element extends from the conduit output in a first direction, and is connectable to the conduit output in a second orientation where the component attachment element extends from the conduit output in a second different direction that is different from the first direction.

Owner:WILGER INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com