Method and device for measuring high polymer molten volume flow

A measuring device and volume flow technology, applied in the field of polymer rheological measurement, can solve the problems of accurate measurement error of polymer melt volume flow, the influence of difficulty in predicting and estimating reliability, etc., to improve accuracy and reliability. Accuracy, Elimination of Measurement Error Interference, Simple Calculation of Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mensuration of the volumetric flow rate of embodiment 1 single high polymer system rheology

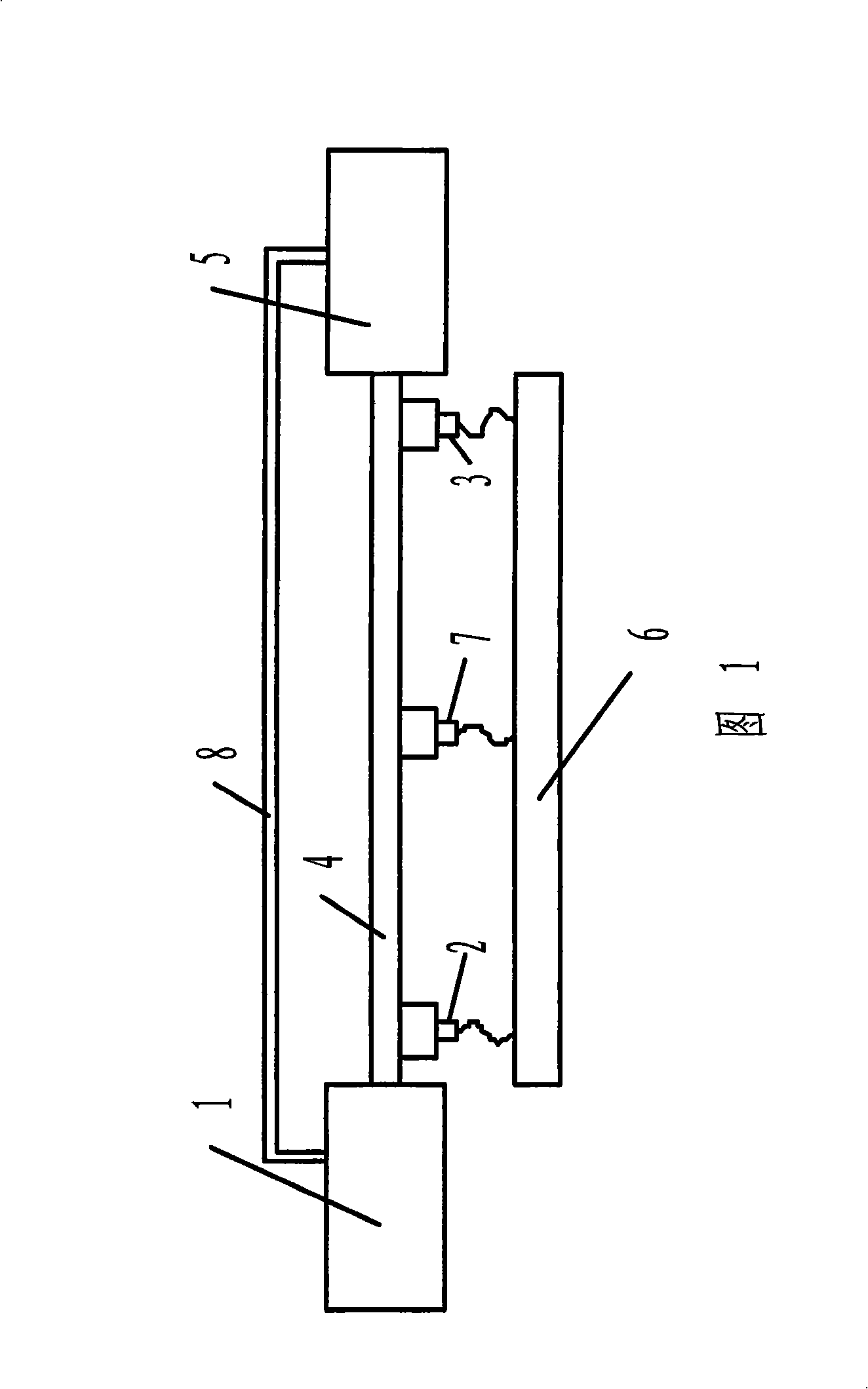

[0041] The high polymer melt volume flow measurement device is characterized in that the measurement device consists of a power mechanism 1 that pushes the high polymer melt into the flow channel, a slit flow channel or a conduit flow channel 4, two pressure sensors 2, 3, and a temperature sensor. Sensor 7, melt outer flow channel 5, loop flow channel 8, temperature and data collection and processing system 6, one end of the slit flow channel or conduit flow channel 4 is connected to the flow channel power mechanism 1, the slit flow channel or conduit flow channel The other end is connected with the melt outer flow channel 5, the outer flow channel is connected with the flow channel power mechanism through the loop flow channel 8, a temperature sensor 7 and a plurality of pressure sensors 2, 3 are set in the slit flow channel or the conduit flow channel, and the temperature ...

Embodiment 2

[0046] The mensuration of the rheological volume flow of multiple high polymer blend systems of embodiment 2

[0047] Adopt the polymer melt volume flow measuring device of embodiment 1, promote polypropylene (T30S) and linear low-density polyethylene (DFDA-7042) with conical twin-screw (screw diameter 5 / 14mm, screw length 109.5mm) The blend enters a slit channel to measure its volumetric flow rate

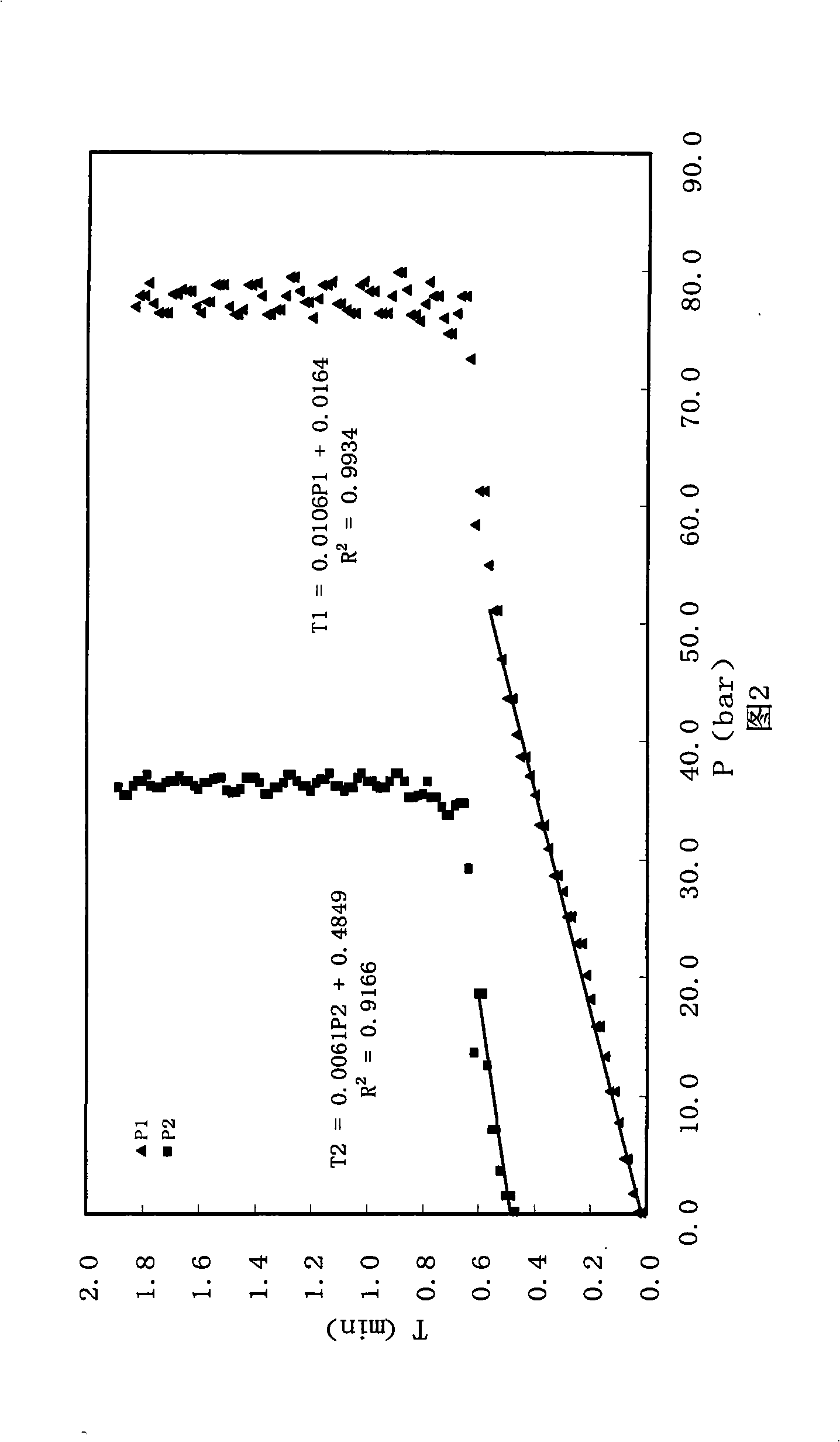

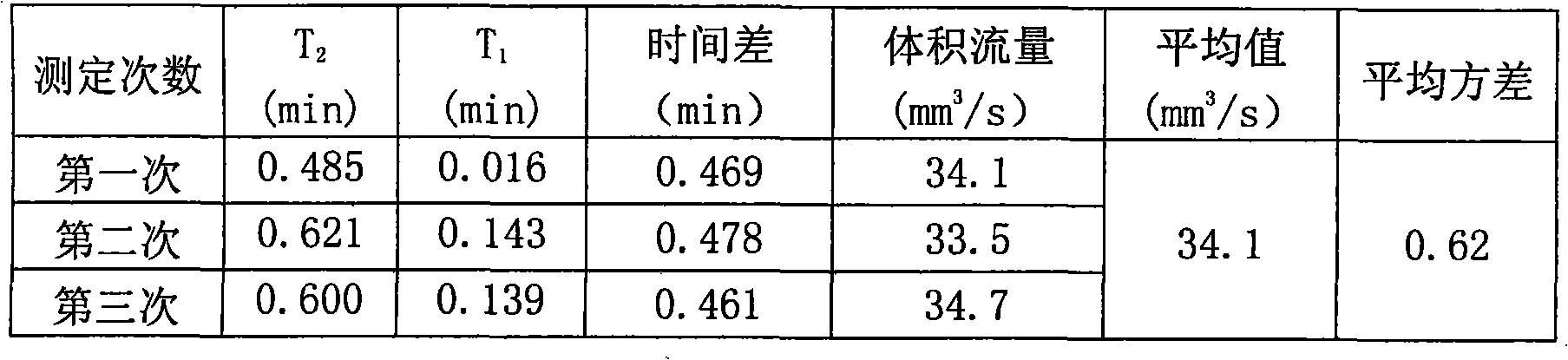

[0048] The mass ratio of polypropylene and linear low-density polyethylene is (90 / 10). At a temperature of 190°C, the conical twin-screws rotate in the same direction at a rotation speed of 30r / min, melt and plasticize for 5min, and then push the blended material into the Slit, record the readings of the two pressure sensors and their corresponding times. (The geometric dimensions of the slit flow channel are: width 10mm, height 1.5mm, length 64mm between the two sensors, and the volume of the slit between the two sensors is V=64*1.5*10=960(mm 3 )). The fluid volume flow rate i...

Embodiment 3

[0049] The mensuration of the volume flow of embodiment 3 high polymer and auxiliary agent (stabilizer, lubricant, filler)

[0050] Adopt the high polymer melt volume flow measuring device of embodiment 1, push the polypropylene (T30S), ethylene vinyl acetate copolymer and calcium carbonate with conical twin-screw (5 / 14mm in screw diameter, 109.5mm in length of screw) The mixture enters the slit flow channel to measure its volumetric flow rate

[0051] The mass ratio of polypropylene, ethylene vinyl acetate copolymer and calcium carbonate is (60 / 10 / 30) at 190°C, the conical twin-screws rotate in reverse, the number of revolutions is 40r / min, melt plasticization for 5min, and then The blended material is pushed into the slit, and the readings from the two pressure sensors and their corresponding times are recorded. (The geometric dimensions of the slit flow channel are: width 10mm, height 1.5mm, length 64mm between the two sensors, and the volume of the slit between the two se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com