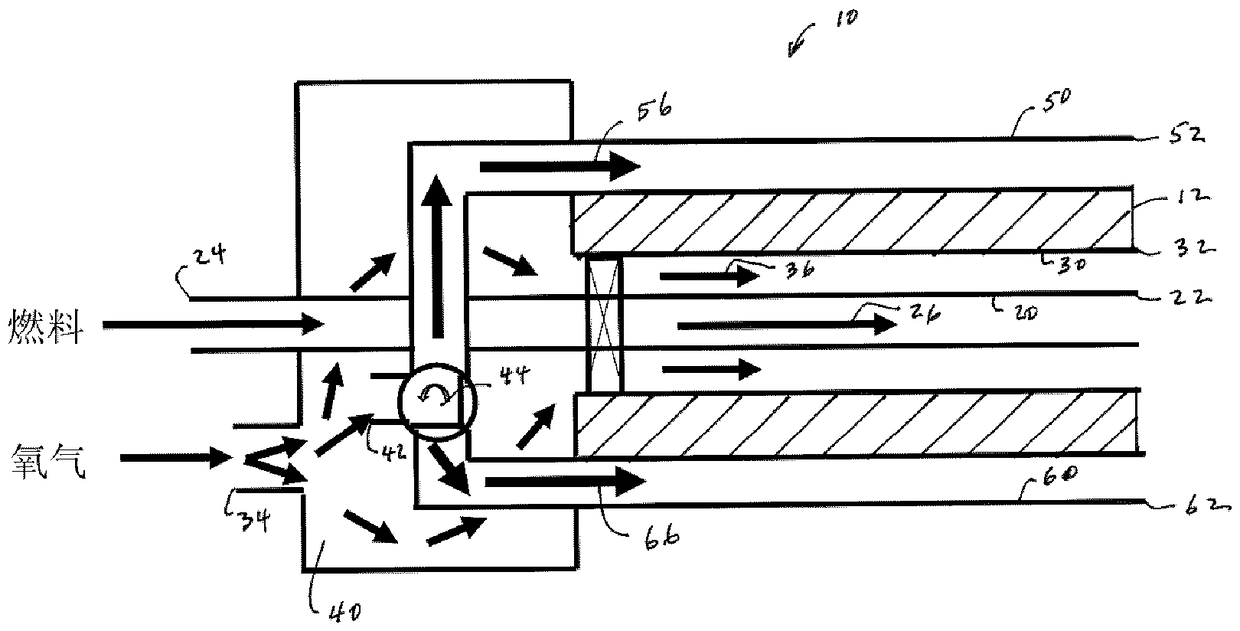

Double-staged oxy-fuel burner

A burner and oxygen technology, applied in the direction of gas fuel burner, burner, staged combustion, etc., can solve the problems of weakening the convection of the melt to drive the secondary flow, interrupting the clarification process, and reducing the glass temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059]As used herein, the term "oxygen" refers to molecular oxygen (O 2 ) concentration is greater than the oxygen in the air (O 2 ) concentration (i.e., greater than 20.9 mol%), and in some embodiments, the oxygen has at least 23 mol% O 2 , at least 30mol% O 2 , at least 70mol%O 2 or at least 90mol%O 2 .

[0060] As used herein, the term "oxy-fuel burner" means a burner as defined herein combusting fuel and oxygen.

[0061] As used herein, the term "fuel" includes any mixture of hydrocarbons capable of burning, including specifically gaseous, liquid, and powdered solid fuels. All data presented here are for natural gas as the fuel, but the results are considered generally applicable to other fuels, especially other gaseous fuels.

[0062] As used herein, the term "staged" means supplying a portion of a staged reactant through a nozzle spaced from a burner element through which another reactant is supplied. For example, when discussing burner elements, if the oxygen is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com