Well control project monitoring system

An engineering monitoring and circulation system technology, which is applied to the automatic control system of drilling, measurement, drilling equipment, etc., can solve the problems of dangerous well control, blowout out of control, low precision, etc., to prevent diffusion, prevent falling objects, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

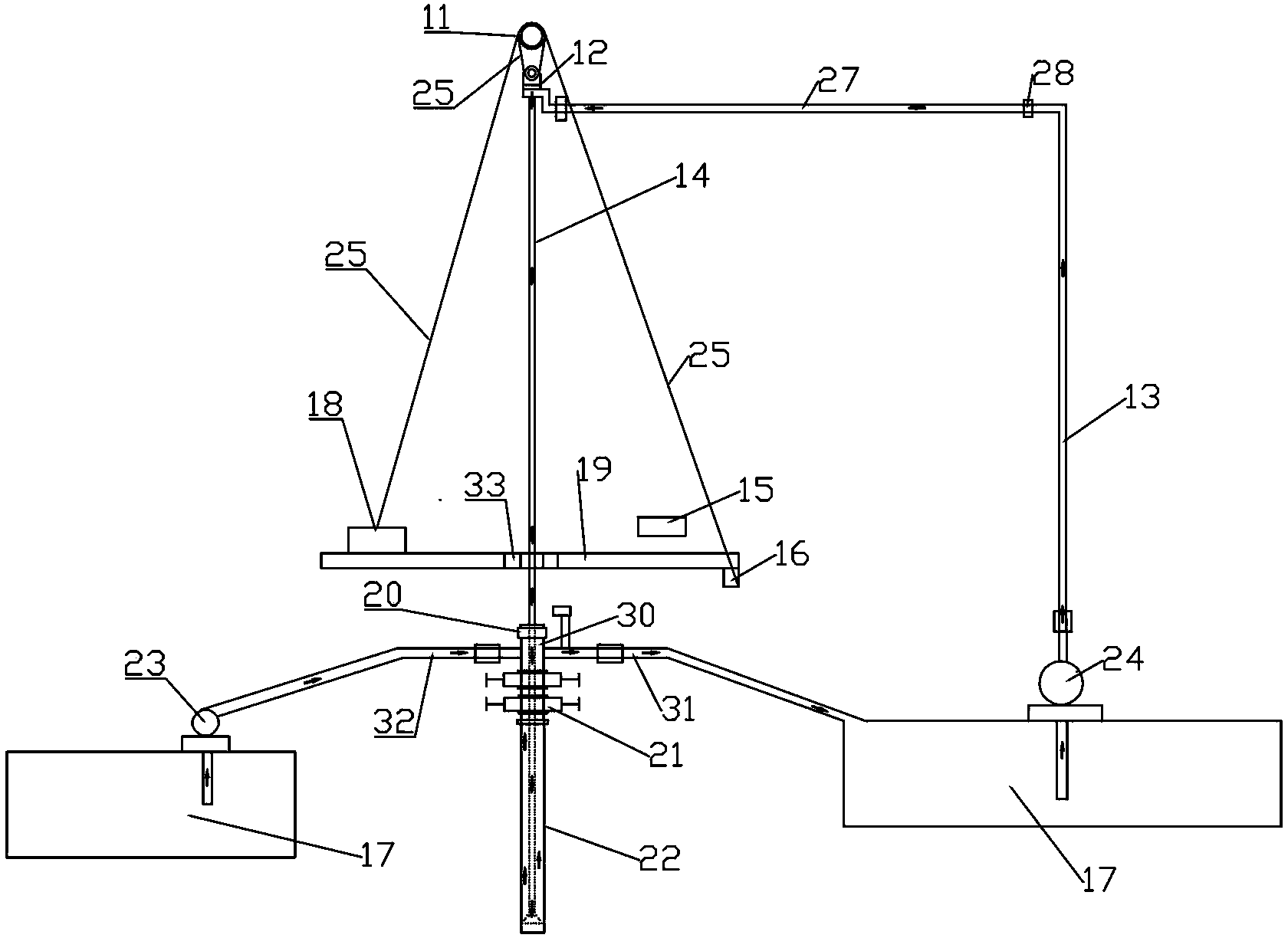

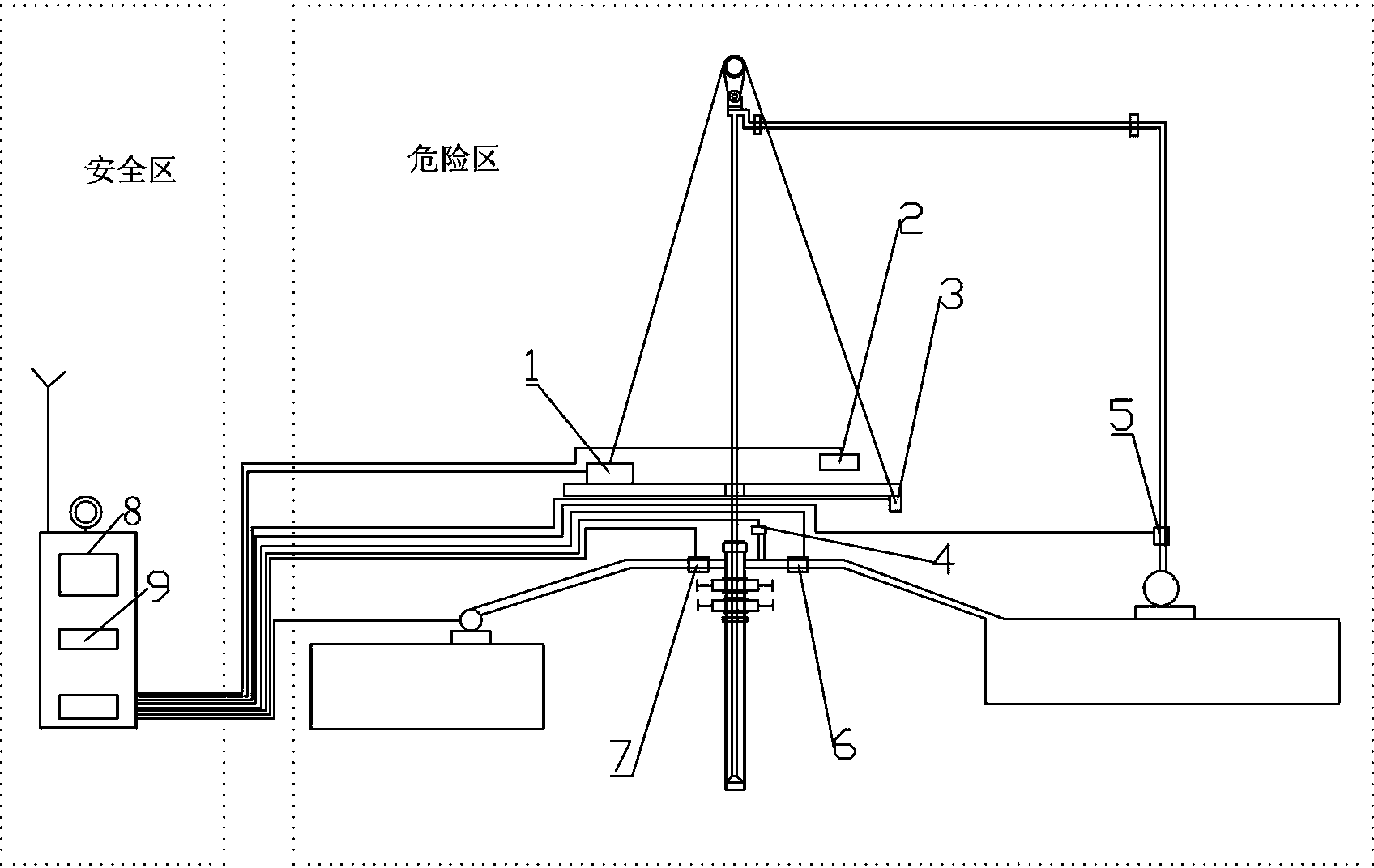

[0023] Such as figure 1 and figure 2 As shown, a well control engineering monitoring system includes a drill floor adjustment device. The drilling tool 14 is inserted into the wellbore 22 through the drill floor adjustment device. Circulation, connecting the overflow prevention pipe 30 above the wellbore 22, the upper end of the overflow prevention pipe 30 is provided with a wellhead sealer 20, and the lower part of the overflow prevention pipe is provided with a blowout preventer 21, between the wellhead sealer 20 and the blowout preventer 21 After passing through the grouting pipe 32 and the grouting pump 23 in sequence, it is connected with the mud tank 17. The grouting pipe 32 is provided with a grouting pipe flow sensor 7, and the grouting pipe flow sensor 7 is used to monitor the flow of grouting in the grouting pipe 32 to the wellbore 22; At the conduit of the outlet of the overflow prevention pipe 30 in the mud circulation system, a conduit flow sensor 6 is provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com