Conduit flow energy harvester

A technology of energy harvester and pipeline flow, which is applied in the direction of electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, etc., which can solve electromagnetic interference, cut-off, and unsuitable pipe diameters of power generation devices. Small occasions and other problems, to achieve the effects of strong fluid adaptability, improved reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

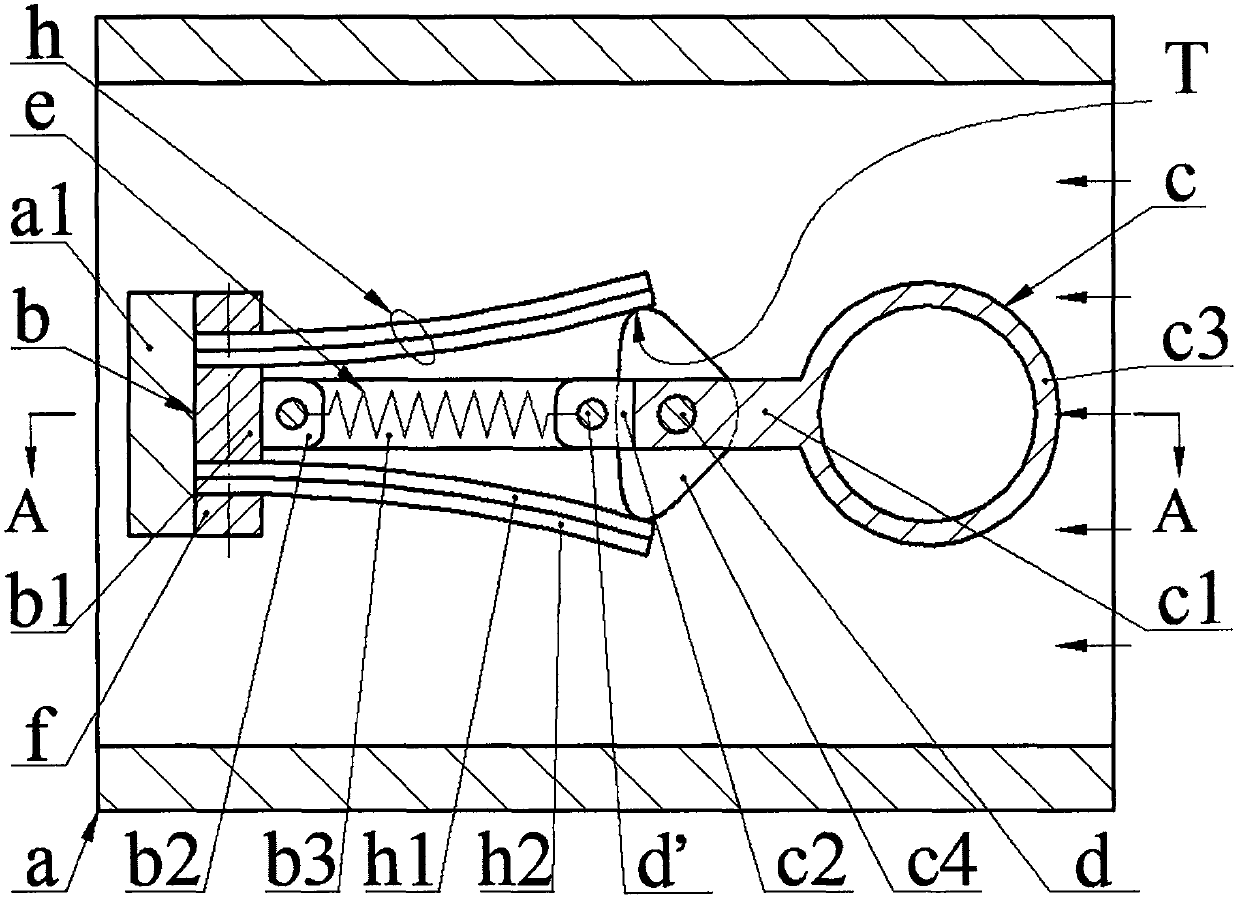

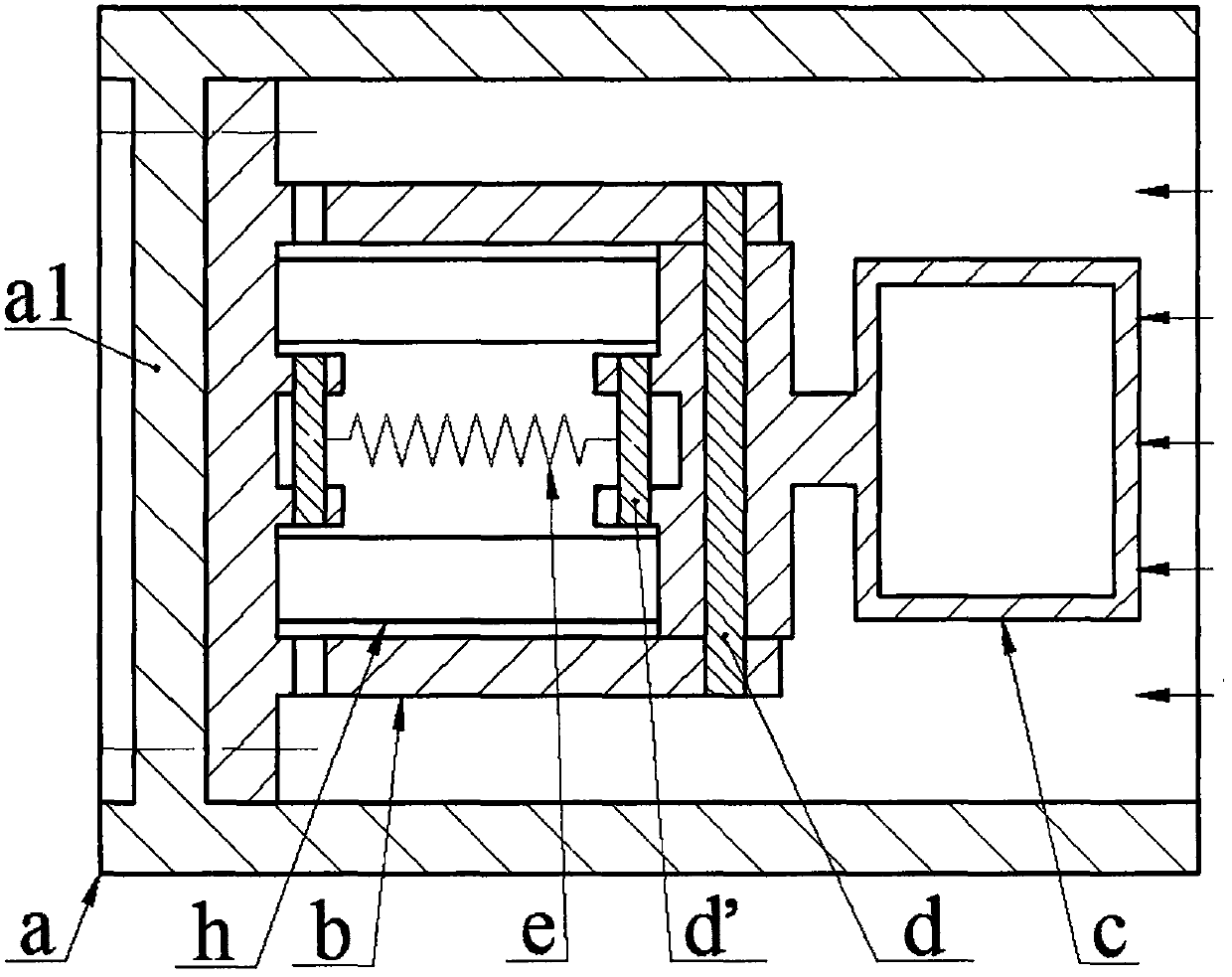

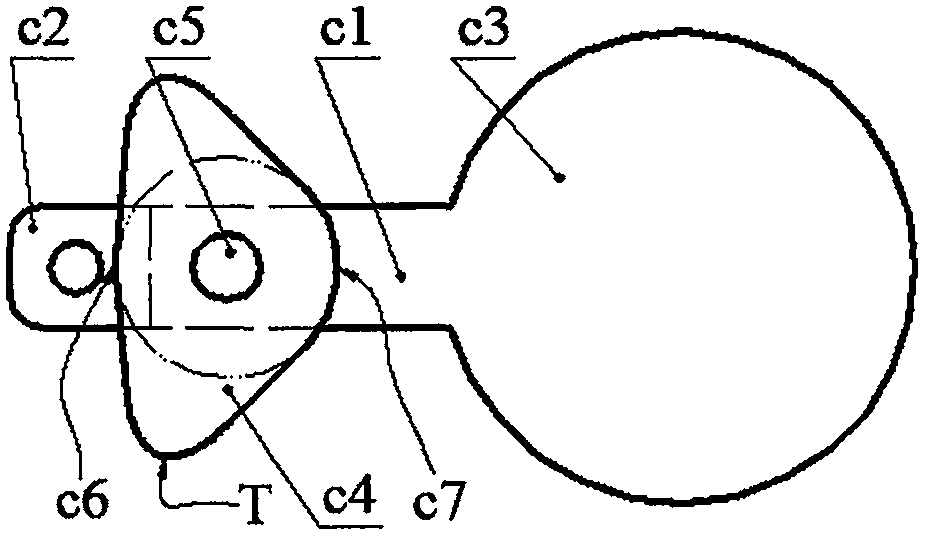

[0012] There is a crossbeam a1 inside the pipe a, a frame bottom b1, two inner ear plates b2 and two outer ear plates b3 on the frame b, the frame bottom b1 is installed on the cross beam a1 by screws; the left end of the rocker c1 of the exciter c is provided with Two rocker arm lugs c2, a hollow blunt body c3 on the right end, and cams c4 on the front and rear sides, the shaft hole c5 of the rocker arm c1 is set on the rotating shaft d, and the two ends of the rotating shaft d are respectively fixed on the two outer ear plates On b3; the pin shaft d' is installed on the inner ear plate b2 and the rocker arm ear plate c2, and the two ends of the spring e are respectively connected to the two pin shafts d'; the upper and lower sides of the frame bottom plate b1 are connected by screws and pressure plates A transducer h is installed. The transducer h is bonded by the substrate h1 and the piezoelectric film h2. The substrate h1 is installed close to the frame bottom plate b1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com