A composite shut-off door

A composite material and buoy technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of paralysis of sewage plants, inability to discharge in time, diversion, and overwhelmed sewage treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

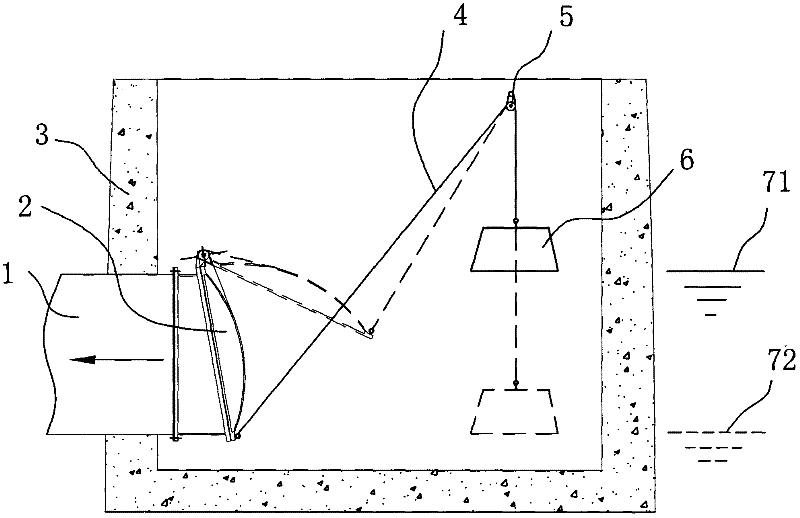

[0013] The present invention as figure 1 As shown: it includes a well body 3 located below the ground and connected to the sewage pipe 1, and also includes a flap door 2, a cable 4, a suspension pulley 5 and a counterweight buoy 6; the flap door 2 is movably connected to the sewage pipe 1 The suspension pulley 5 is located at the upper part of the wellhead in the well body 3; the drag cable 4 is wound around the suspension pulley 5, and one end of the drag cable 4 is connected to the lower edge of the flap door 2, and The other end of the cable 4 is connected to the counterweight buoy 6 .

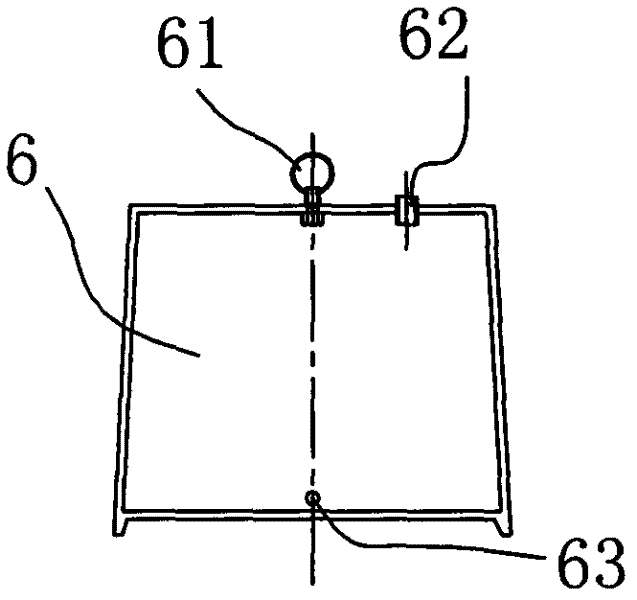

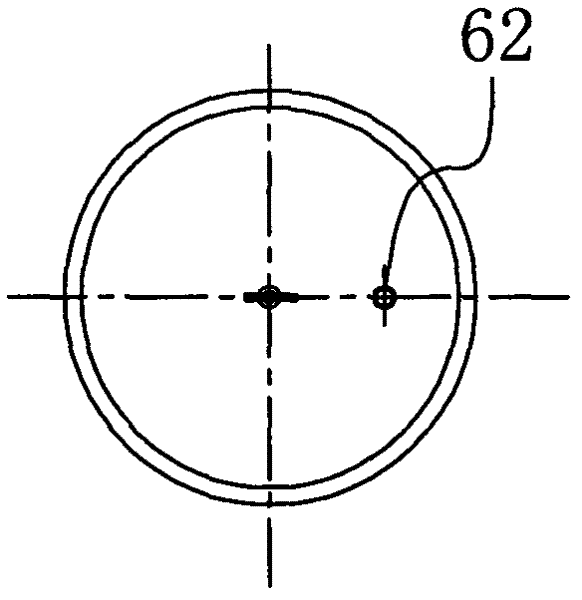

[0014] Such as figure 2 , 3 As shown, the counterweight buoy 6 is hollow, and the top surface of the counterweight buoy 6 is provided with a water inlet 62 . And the lug 61 that is used to connect dragline.

[0015] The bottom of the counterweight buoy 6 is provided with a water outlet 63 for adjusting the amount of water in the buoy.

[0016] The shut-off door of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com