Fireproof dry-mixed mortar for exterior wall

A dry powder mortar and exterior wall technology, applied in the field of building materials, can solve the problems of poor high temperature resistance of polystyrene boards, rising overall project costs, unsatisfactory fire protection effects, etc., and achieves environmental protection requirements, economical and practical materials, and good adhesion. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

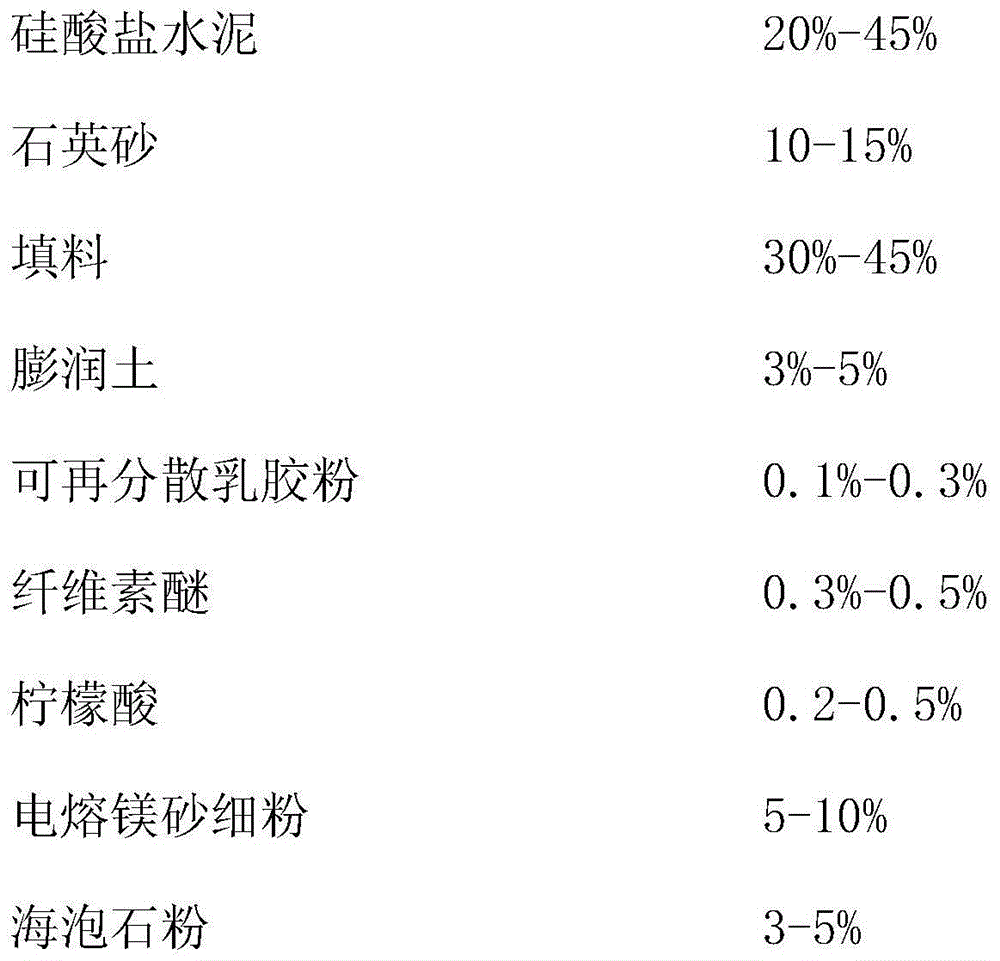

[0032] A dry powder mortar for a fireproof exterior wall, consisting of the following components by weight percentage:

[0033]

[0034]

[0035] Described portland cement is 42.5R cement;

[0036] The particle size of the quartz sand is 200 mesh;

[0037] The yellow sand is river sand with a mud content of 1% and a density of 2500kg / m 3 ;

[0038] The particle diameter of described gangue powder is 600 mesh;

[0039] Described bentonite is organic bentonite;

[0040] Described redispersible latex powder is the rubber powder that polyvinyl acetate and polyvinyl alcohol generate through copolymerization reaction;

[0041] The cellulose ether is methyl hydroxyethyl cellulose ether;

[0042] The particle diameter of described fused magnesia fine powder is 600 orders;

[0043] The particle diameter of described sepiolite powder is 200 orders;

[0044] The used raw material of embodiment 2-6 is identical with embodiment 1, and the proportioning ratio of each raw materi...

Embodiment 7

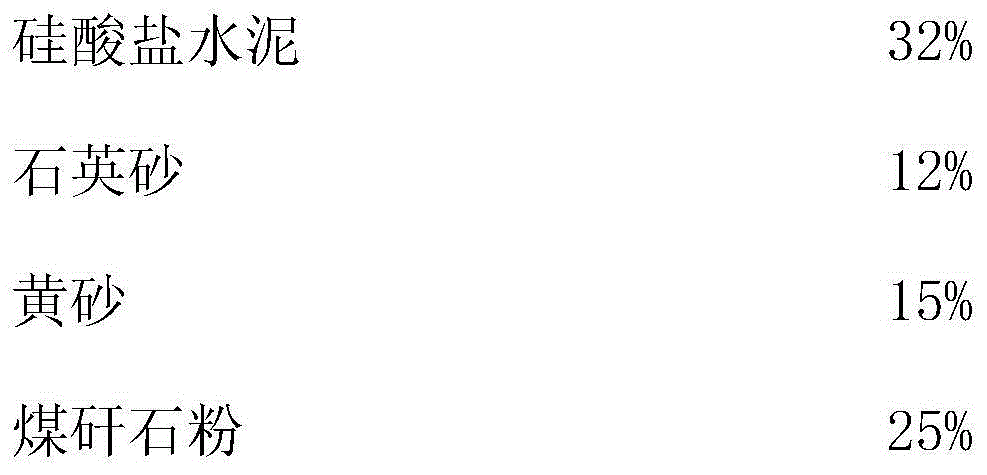

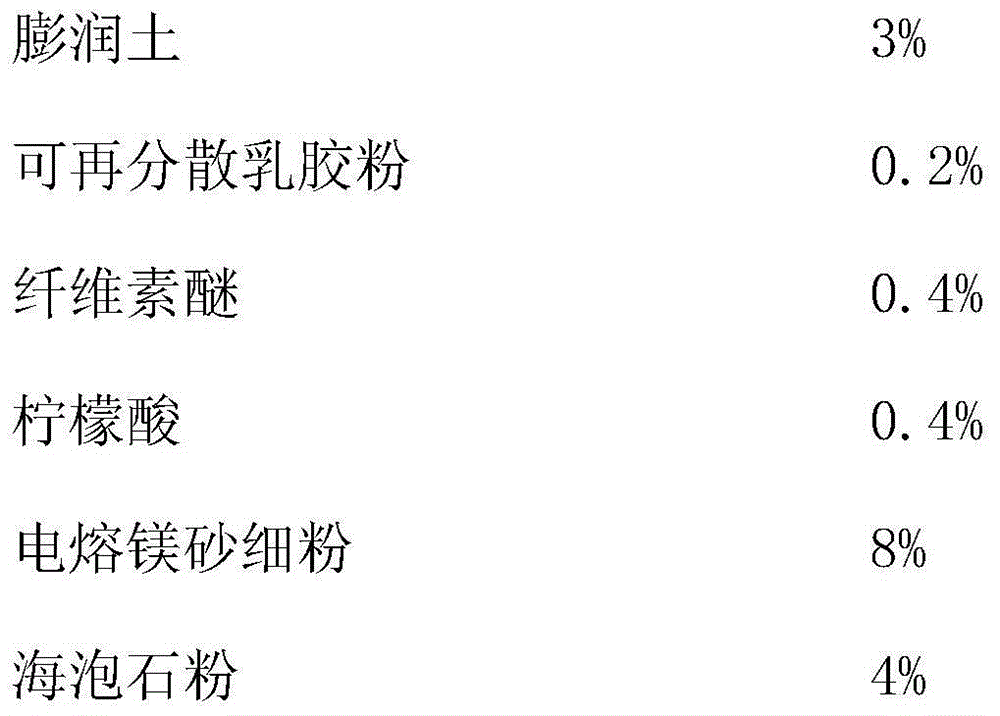

[0052] A dry powder mortar for a fireproof exterior wall, consisting of the following components by weight percentage:

[0053]

[0054]

[0055] Described portland cement is 32.5R cement;

[0056] The particle size of the quartz sand is 200 mesh;

[0057] The yellow sand is river sand with a mud content of 1% and a density of 2500kg / m 3 ;

[0058] The particle diameter of described gangue powder is 600 mesh;

[0059] Described bentonite is organic bentonite;

[0060] Described redispersible latex powder is the rubber powder that polyvinyl acetate and polyvinyl alcohol generate through copolymerization reaction;

[0061] The cellulose ether is methyl hydroxypropyl cellulose ether;

[0062] The particle diameter of described fused magnesia fine powder is 600 orders;

[0063] The particle diameter of described sepiolite powder is 200 orders;

[0064] The used raw material of embodiment 8-12 is identical with embodiment 7, and the proportioning ratio of each raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com