Superhydrophobic inorganic organic nano composite polymeric coating material and preparation method thereof

A polymer coating and nano-composite technology, applied in coatings, polyester coatings, devices for coating liquid on the surface, etc., can solve problems such as poor mechanical properties and unstable super-hydrophobic properties, and achieve low cost and good performance. Industrial application prospect, good stain resistance and self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

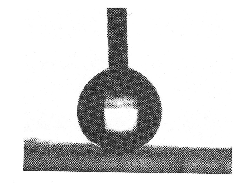

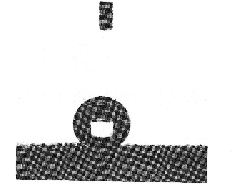

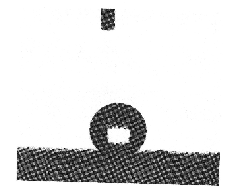

Image

Examples

Embodiment 1

[0044] The glass slides were ultrasonically cleaned in deionized water and dried. Then oxygen plasma cleaning, the treatment condition is that the oxygen flow rate is 200SCCM, the power is 300 watts, and the time is 600 seconds, to obtain a surface with active reflection centers. Take 10-20g of methacrylic acid glycidyl bisphenol A polycondensation resin and dissolve in 5.0-10g of styrene, then add 5-30g of 500nm amino-modified nano silicon dioxide into it, and mix uniformly by mechanical stirring. Add 2% methyl ethyl ketone peroxide and 0.5% cobalt naphthenate to the mixed nanocomposite, and then stir evenly. Spray it on the pre-treated glass sheet, and then put it in an oven at 40-70°C for curing. The measured contact angle of the cured coating material is 159°, and the rolling angle is 9°. After the coating is placed for several days, the contact angle is almost unchanged. After rubbing the coating 20 times with a cloth, the contact angle The angle was not significantly r...

Embodiment 2

[0046] Dry ordinary printing paper in an oven at 60°C. Dissolve 10-40 grams of glyceryl phthalate maleate copolymer in 10-20 grams of styrene, then add 5.0-30 grams of 200nm vinyltriethoxysilane-modified nano-titanium dioxide into it, and mix them by mechanical stirring uniform. Add 2% potassium carbonate and 0.1-1% benzoyl peroxide into the mixed mother liquor, and then stir evenly. Spray it on pre-treated ordinary printing paper, and then put it in an oven at 40-60°C for curing. The measured contact angle of the cured coating material is 157°, and the rolling angle is 14°. After the coating is placed for several days, the contact angle is almost unchanged. After rubbing the coating 20 times with a cloth, the contact angle is almost unchanged. The angle was not significantly reduced. It can be seen that the mechanical properties and wear resistance of the coating are very good, and the hydrophobicity is also very good.

Embodiment 3

[0048] The ceramic sheet was ultrasonically cleaned in deionized water, and then cleaned with oxygen plasma. The treatment conditions were that the oxygen flow rate was 200 SCCM, the power was 300 watts, and the time was 400 seconds. Take 10-20g of polypropylene oxide bisphenol A fumarate resin and dissolve it in 7-10g of styrene, and then add 10-50g of 10nm aminopropyltriethoxysilane-modified nano-iron ferric oxide into it , add 2-3% methyl ethyl ketone peroxide, 0.2-1% cobalt naphthenate, and mix uniformly by mechanical stirring. It is coated on the pre-treated ceramic sheet, and then placed in an oven at 40-70°C for curing. The measured contact angle of the cured coating material is 152°, and the rolling angle is 13°. After the coating is left for a few days, the contact angle is almost unchanged. After rubbing the coating 20 times with a cloth, the contact angle is almost unchanged. The angle was not significantly reduced. It can be seen that the mechanical properties an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com