Radiation resistant fabric based on ferrite coating finishing and preparation method of fabric

A technology for coating finishing and radiation protection, applied in coating, fiber treatment, physical treatment, etc., can solve the problems of inconvenient and not very mature preparation methods, and achieve the effect of simple preparation methods and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

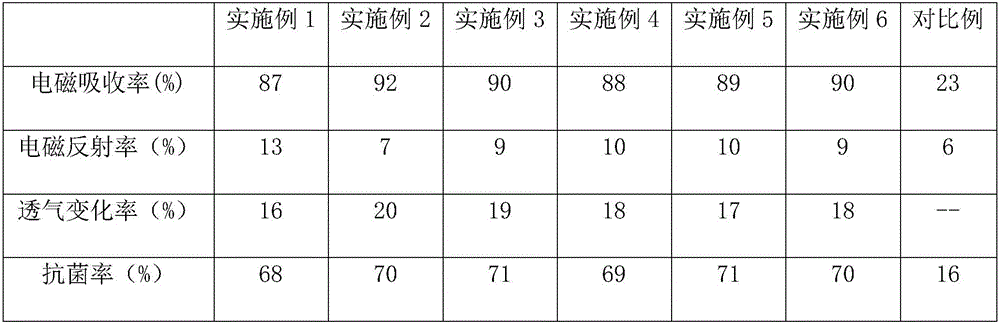

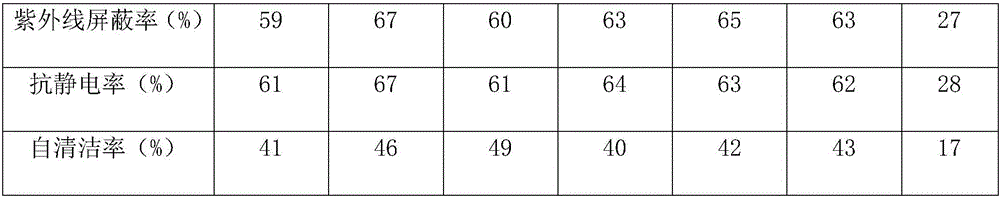

Examples

Embodiment 1

[0028] (1) After cleaning and drying the surface of the cellulose fiber fabric, place it in a low-temperature plasma device, and treat it with a low-temperature plasma at a power of 150 W for 60 seconds in an oxygen atmosphere to obtain a pretreated fabric.

[0029] (2) In parts by weight, 1 part of nano-ferrite is added to the aqueous solution containing 15 parts of chitosan, fully stirred evenly, to form the bottom finishing agent, with the bath ratio of 1:30, the pretreated fabric Immerse in the bottom finishing agent, one dipping and one padding, the padding temperature is 60°C, the excess rate is 80%, take it out, and dry it at 70°C to obtain a primary finishing fabric.

[0030] (3) Add carbon nanotubes and aniline monomers with a mass ratio of 1:5 into a strong acid solvent, mix ultrasonically for 30 minutes, add ammonium persulfate oxidant dropwise, and heat and stir at 100°C for 5 hours to form a carbon nanotube / polyaniline composite Finishing agent.

[0031] (4) The ...

Embodiment 2

[0033] (1) After cleaning and drying the surface of the cellulose fiber fabric, place it in a low-temperature plasma device, and treat it with a low-temperature plasma at a power of 250 W for 90 seconds in an oxygen atmosphere to obtain a pretreated fabric.

[0034] (2) In parts by weight, 1 part of nano-ferrite is added to the aqueous solution containing 20 parts of chitosan, fully stirred evenly, to form the bottom finishing agent, with the bath ratio of 1:30, the pretreated fabric Immerse in the bottom finishing agent, one dipping and one padding, the temperature of padding is 80°C, the excess rate is 85%, take it out, and dry it at 80°C to obtain a primary finishing fabric.

[0035] (3) Add carbon nanotubes and aniline monomers with a mass ratio of 1:10 into a strong acid solvent, mix ultrasonically for 30 minutes, add ammonium persulfate oxidant dropwise, and heat and stir at 120°C for 8 hours to form a carbon nanotube / polyaniline composite Finishing agent.

[0036](4) T...

Embodiment 3

[0038] (1) After cleaning and drying the surface of the cellulose fiber fabric, place it in a low-temperature plasma device, and treat it with a low-temperature plasma at a power of 200 W for 70 seconds in an oxygen atmosphere to obtain a pretreated fabric.

[0039] (2) In parts by weight, 1 part of nano-ferrite is added to the aqueous solution containing 17 parts of chitosan, fully stirred evenly, and the bottom finishing agent is formed. With a bath ratio of 1:30, the pretreated fabric Immerse in the bottom finishing agent, one dipping and one rolling, the temperature of the padding is 70°C, the excess rate is 82%, take it out, and dry it at 75°C to obtain a primary finishing fabric.

[0040] (3) Add carbon nanotubes and aniline monomers with a mass ratio of 1:8 into a strong acid solvent, mix ultrasonically for 30 minutes, add ammonium persulfate oxidant dropwise, and heat and stir at 110°C for 6 hours to form a carbon nanotube / polyaniline composite Finishing agent.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com