Method for synchronizing low-level mercaptan

A synthesis method and thiol technology, which are applied in thiol preparation, chemical recovery, organic chemistry, etc., can solve the problems of poor catalyst selectivity and activation, high production process safety, low product yield, etc., and achieve product yield. High, low energy consumption, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

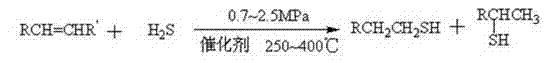

Method used

Image

Examples

Embodiment 1

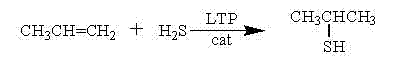

[0031] The dried and purified by-products of the petrochemical industry, propylene and hydrogen sulfide gas, adjust the molar ratio of the flow control material to be propylene: hydrogen sulfide = 1.0: 1.0, and enter the static pipeline mixer to fully mix and evenly adjust the temperature of the mixed gas to 20°C to 0.1min -1 The space velocity continuously enters the plasma reaction chamber filled with transition metal oxide catalysts that has been evacuated from the air. The system reaction temperature is 20°C, the reaction pressure is -0.08MPa, and the dielectric barrier plasma is used as the plasma power supply. The following chemical reactions take place in the plasma reaction chamber:

[0032]

[0033] The reactants pass through the condensation recovery device, and after condensation and separation, the liquid phase enters the crude product storage tank, and the gas phase is compressed and recovered for recycling. The crude product phase was distilled and the fracti...

Embodiment 2

[0036] The dried and purified by-products of the petrochemical industry, propylene and hydrogen sulfide gas, adjust the flow rate to control the material molar ratio to be propylene:hydrogen sulfide=1.0:2.0, and enter the static pipeline mixer to fully mix evenly, and at the same time adjust the temperature of the mixed gas to 30°C to 1min -1 The space velocity continuously enters the plasma reaction chamber filled with activated carbon-loaded ionic liquid that has been evacuated from the air, and the glow plasma is used as the plasma power supply. The following chemical reactions take place in the plasma reaction chamber:

[0037]

[0038] The reactants pass through the condensation recovery device, and after condensation and separation, the liquid phase enters the crude product storage tank, and the gas phase is recovered and compressed for recycling. The crude product phase is distilled and the fraction at 57-60°C is collected.

[0039] The product obtained by mass spe...

Embodiment 3

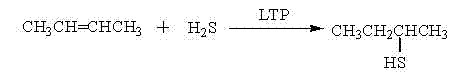

[0041] The dried and purified petrochemical industry by-products 2-butene and hydrogen sulfide gas, adjust the flow rate to control the molar ratio of the materials to be 2-butene: hydrogen sulfide = 1.0: 1.0, enter the static mixer to fully mix and evenly adjust the temperature of the mixed gas to 10℃, take 50min -1 The space velocity continuously enters the plasma reaction chamber filled with molecular sieve-loaded phosphotungstic heteropoly acid that has been evacuated, and the low-temperature plasma is used as the plasma power supply. The following chemical reactions take place in the plasma reaction chamber:

[0042]

[0043] The reactants pass through the condensation recovery device, and after condensation and separation, the liquid phase enters the crude product storage tank, and the gas phase is compressed and recovered for recycling. Distill the crude product phase, and collect fractions at 80-95°C.

[0044] The product obtained by mass spectrometry and infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com