Patents

Literature

50results about How to "Long anti-fog time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing vehicle glass antifogging agent

The invention relates to a method for preparing an automobile glass antifoggant, wherein deionized water is added into a reaction kettle, and 0.1-0.6 percent of high molecular filmogen is added, heated to 40 DEG C, and agitated until dissolved, then 0.6-4.0 percent of fatty alcohol polyethenoxy ether or nonyl phenol polyethenoxy ether nonionics, 0.1-0.6 percent of coconut fatty alkyl trimethyl chloride or lauryl amphoteric propyl juanacidate cationic surfactant, and 0.2-1.0 percent mono ethanol amine or trolamine acidity modifier are added orderly; finally, 5.0-30 percent of isopropyl alcohol, ethanol, propanediol, and propanetriol are added, evenly agitated until the temperature lowers to the room temperature, and then the glass antifoggant is obtained. The invention has the advantages that the use is simple; the glass atomizing effect is good; dust can not be absorbed on the surface of the glass after the drying process, and no trace is left on the surface; the product is colorless and flavorless, safe and reliable.

Owner:QINGDAO UNIV

Glass detergent

InactiveCN103952123AEasy to makeLong anti-fog timeNon-ionic surface-active compoundsOther chemical processesAlcoholSodium silicate

The invention discloses a glass detergent. The glass detergent is prepared from the following raw materials in parts by mass: 1-1.3 parts of absolute ethyl alcohol, 0.2-0.3 part of sodium lauryl sulfate, 0.1-0.3 part of ethanol, 0.2-0.3 part of saponin, 0.8-1 part of sodium silicate, 1.5-2 parts of saponin, 2-6 parts of alkanolamide and 90-95 parts of deionized water. The antifogging agent disclosed by the invention is simple in preparation, has two functions of cleaning and fog prevention, and is long in antifogging time, wide in usable range, free of explosion risk and convenient to carry.

Owner:江苏紫石化工科技有限公司

Agent for dirt-removing and antifogging

InactiveCN1418787ANo pollution in the processNo pollutionOther chemical processesVehicle cleaningSolventSURFACTANT BLEND

The detersive antifogging agent for glass is made of (wt%) 10-20% of anhydrous ethanol as solvent, 5-15% of propylene glycol 5-15% of isopropanol as dispersing agent, 5-20% of cocoanut oil fatty acid diethanol acylamide as non-ionic surfactant, 1-1.5% of essence and 40-60% of pure clean water as raw material through the processes of uniformly stirring them and filling. It is simple in productionprocess and is obvious in detersive antifogging effect, and has extensive application.

Owner:崔长安

Cleaning and antifogging agent for glass

InactiveCN103409110AEasy to makeLong anti-fog timeNon-ionic surface-active compoundsOther chemical processesPolyvinyl alcoholDual effect

The invention discloses a cleaning and antifogging agent for glass, which is prepared from the following raw materials in parts by mass: 7-10 parts of anhydrous ethanol, 1-2 parts of alkanolamide, 0.2-0.3 part of sodium lauryl sulfate, 0.2-0.4 part of sodium dodecyl benzene sulfonate, 0.1-0.3 part of propanol / ethanol, 0.2-0.3 part of essence, 0.8-1 part of sodium silicate, 1.5-2 parts of polyvinyl alcohol and 90-95 parts of deionized water. The antifogging agent disclosed by the invention is simple to manufacture, has the dual effects of cleaning and fog inhibition, has the advantages of long antifogging time, wide application range and no explosion hazard, and is convenient to carry.

Owner:南通市通州区益君劳务有限公司

A kind of polymer type optical lens antifogging agent and preparation method thereof

InactiveCN102260482ADoes not affect light transmissionNot corrosiveOther chemical processesAnhydrous ethanolDistilled water

The invention relates to the field of material chemistry and mainly provides a polymer type antifogging agent for an optical lens and a preparation method thereof. The technical scheme in the invention comprises the following steps: mixing 1-2 parts by weight of colorless transparent secoctylphenol polyoxyethylene ether liquid which is abbreviated to TX-10, 8-12 parts by weight of isopropanol, 28-32 parts by weight of anhydrous ethanol and 45-50 parts by weight of double distilled water so as to form 100mL of basic liquid; and then adding about 100 parts by weight of double distilled water in 2-6 parts by weight of weighed white sodium dodecyl benzene sulfonate solid powder which is abbreviated to SDBS so as to prepare a 4.0% aqueous solution serving as an additive, and evenly mixing the additive with the basic liquid in a volume ratio of 1:1 (100mL:100mL), so that the antifogging agent is obtained.

Owner:中南大学肝胆肠外科研究中心 +1

Wiping-resistance glass antifogging agent and preparing method thereof

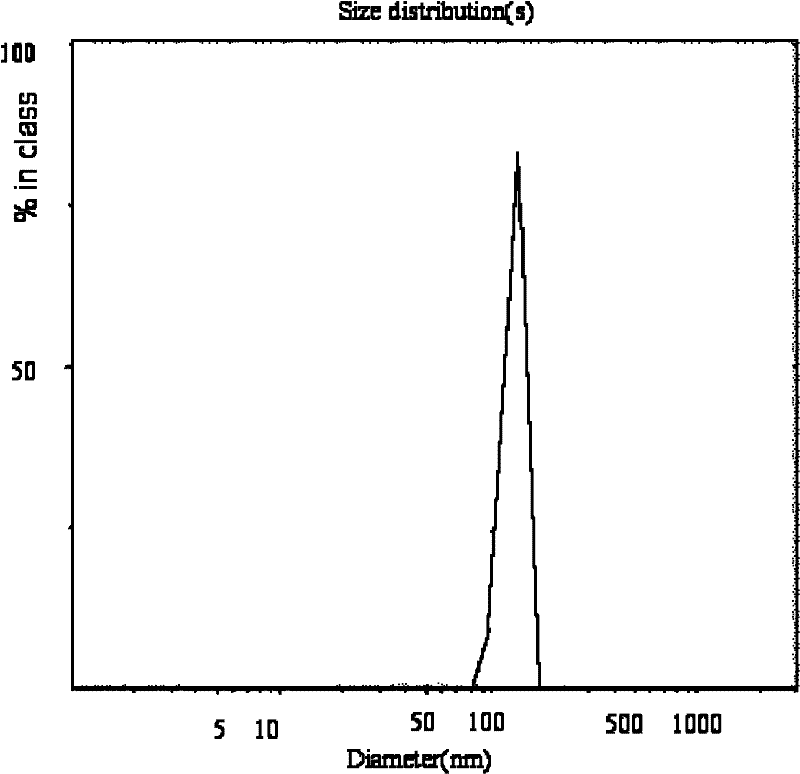

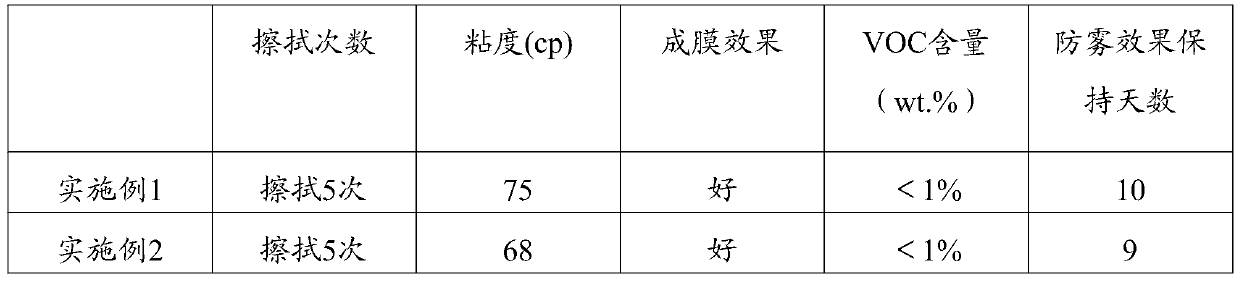

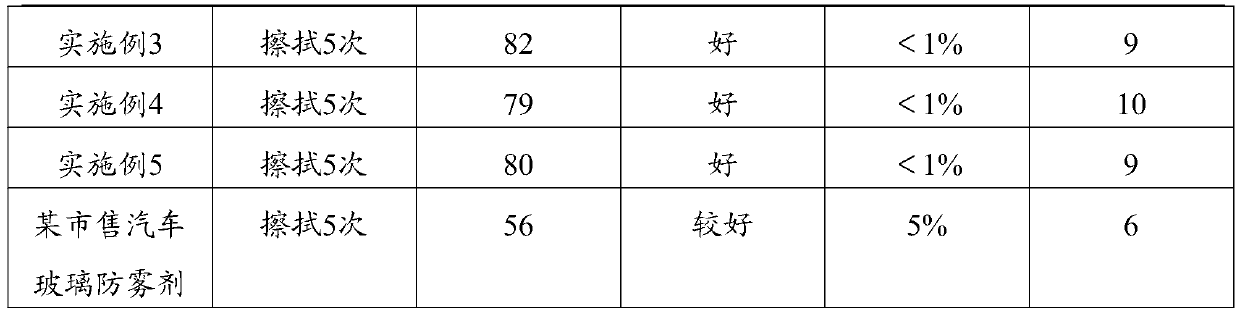

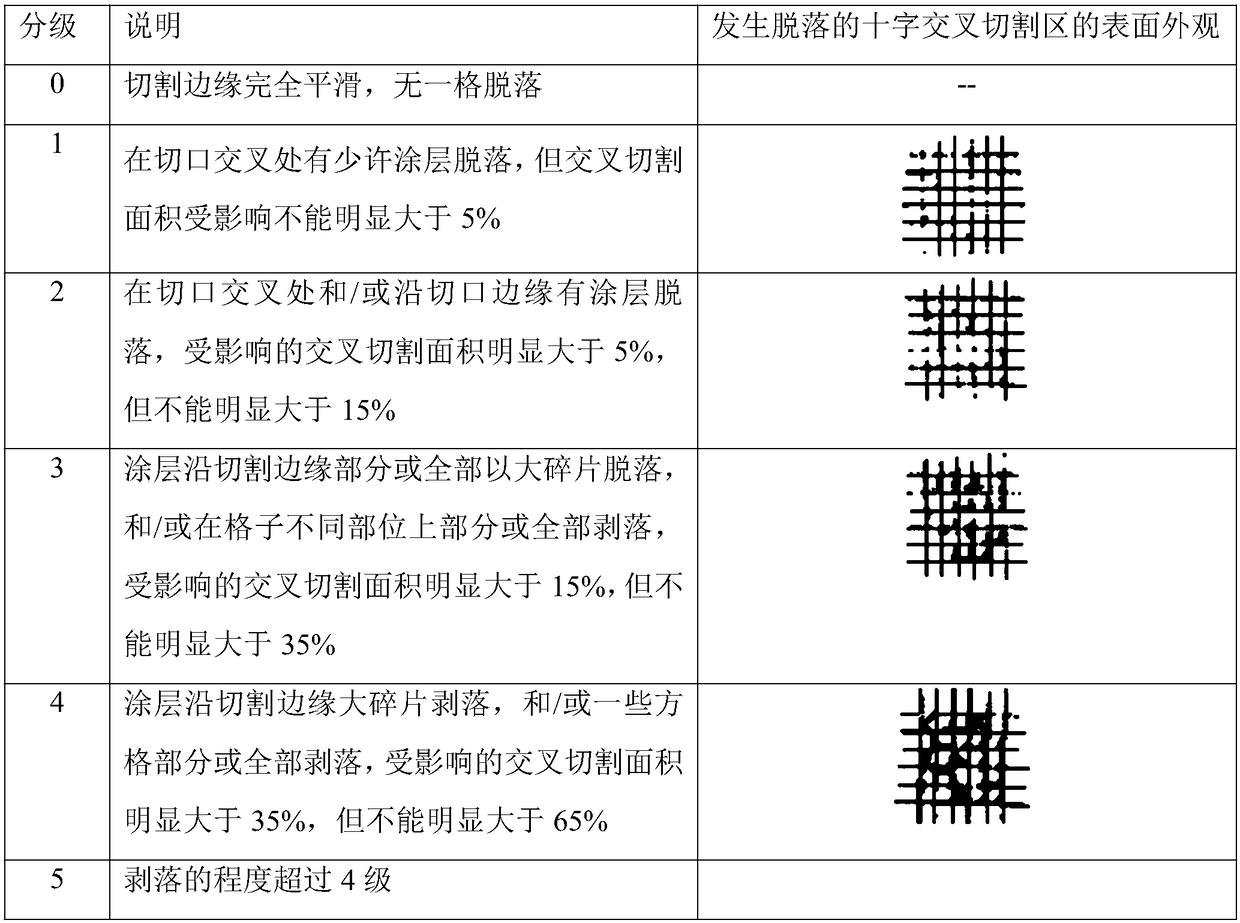

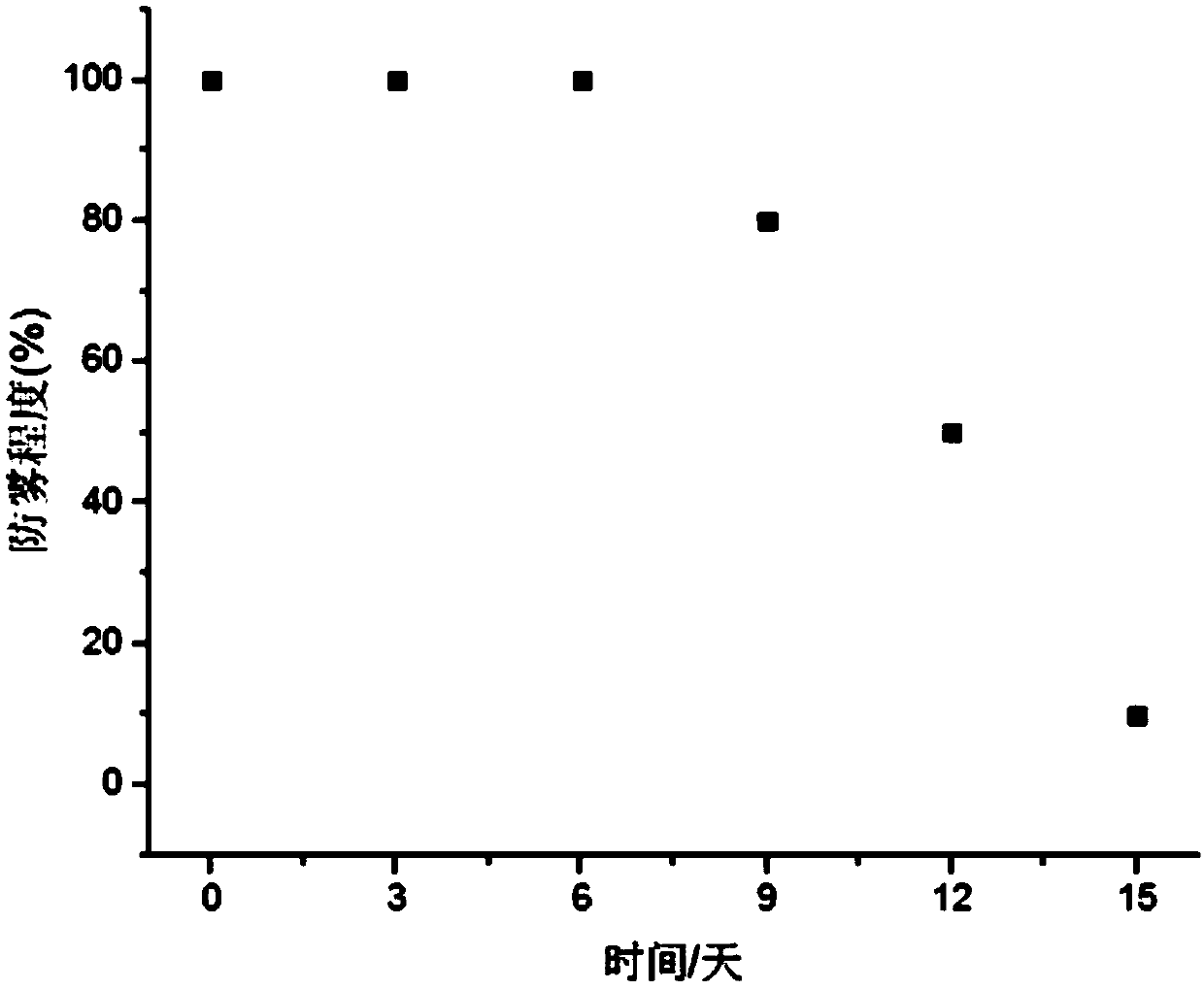

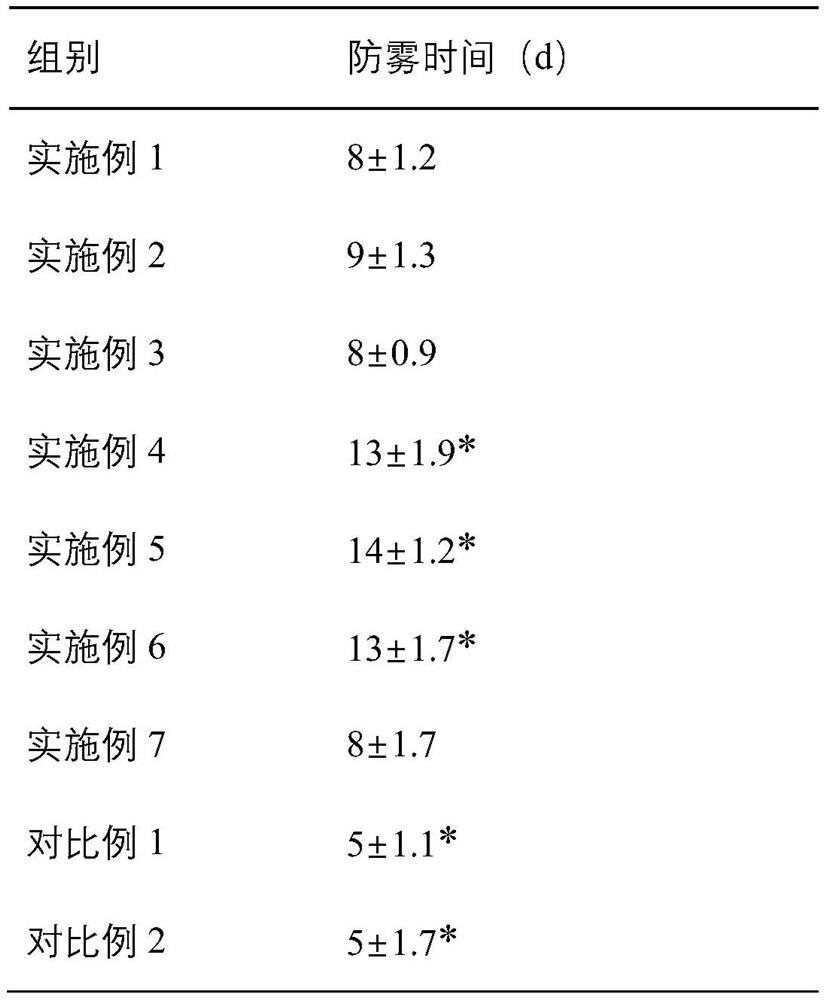

The invention provides a wiping-resistance glass antifogging agent and a preparing method thereof, and belongs to the technical field of preparation of antifogging agents. The wiping-resistance glassantifogging agent is prepared from linear-chain alkyl alcohol polyether, a hydrophile high-molecular polymer, a chelating agent, an acidity regulator and deionized water. According to the wiping-resistance glass antifogging agent, by optimizing the raw material composition and component quantity, a layer of hydrophile thin film with high adsorbability can be formed on the surface of glass so thatwater drops cannot be condensed into droplets, thus the glass is prevented from fogging, the wiping-resistance glass antifogging agent has the advantages of wiping resistance, good film forming performance and long antifogging time, and the VOC content is lower. As is shown by the results of the embodiment, the prepared wiping-resistance glass antifogging agent is wiped and uniformly smeared, theglass can be effectively prevented from fogging, the antifogging effect can be maintained for 10 days or longer after the agent is sprayed at a time and wiped 5 times, and the VOC content is smaller than 1 wt.%; the antifogging effect of an antifogging agent sold on the market as a contrast can only be maintained for 1-2 days after multiple times of wiping.

Owner:SHANGHAI BAIMAO

Automobile glass anti-fog detergent and preparation method thereof

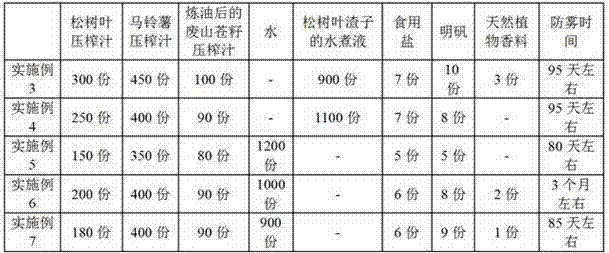

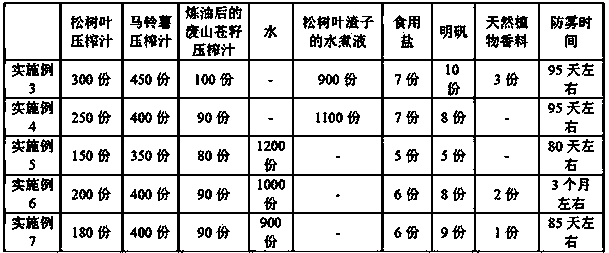

ActiveCN103045169AExcellent anti-fog and decontamination effectLong anti-fog timeOther chemical processesNon-surface-active detergent compositionsHuman healthAlum

The invention discloses an automobile glass anti-fog detergent and a preparation method thereof. The anti-fog detergent comprises the following components in parts by weight: 150 to 300 parts of pine leaf squeezed juice, 350 to 450 parts of potato squeezed juice, 80 to 100 parts of waste litsea cubeba squeezed juice after oil refining, 900 to 1,200 parts of water, 5 to 7 parts of common salt, and 5 to 10 parts of alum. During preparation, the raw materials are treated, mixed, and then uniformly stirred. The components of the automobile glass anti-fog detergent do not contain any component which can pollute the environment and is not favorable for human health, and the automobile glass anti-fog detergent has a significant anti-fog decontamination effect, is long in anti-fog time, and can prevent fog for about 3 months when being sprayed on front glass or door glass.

Owner:海宁市袁花镇工业投资有限公司

Anti-fogging cleaning cloth

ActiveCN105544197AGood dispersion and adhesionLong anti-fog timeOther chemical processesFibre treatmentSolventTriethanolamine

The present invention discloses an anti-fogging cleaning cloth, comprising a cleaning cloth body made form ultrafine fibers and an anti-fogging agent. The anti-fogging agent is dipped on the cleaning cloth body. The anti-fogging agent consists of the following raw materials by weight: 2-5 parts of a slow-release agent, 3-7 parts of nano-rare earth oxide particles, 40-50 parts of a polyalcohol nonionic surfactant, 5-10 parts of triethanolamine monolaurate, 15-25 parts of a solvent, 5-10 parts of a hydrophilic finishing agent and 50-60 parts of distilled water. The anti-fogging cleaning cloth has the characteristics of good dispersion and adhesion, long anti-fogging time, no toxicity, low cost, easy usage and long shelf life.

Owner:WUXI HAOYA MICROFIBER TECH CO LTD

Glass antifogging agent

InactiveCN103897660AEasy to makeLong anti-fog timeOther chemical processesAnionic-cationic-non-ionic surface-active compoundsPolyvinyl alcoholPhenyl Ethers

The invention discloses a glass antifogging agent. The glass antifogging agent comprises, by mass, 1-3 parts of polyethylene glycol phenyl ether, 1-2 parts of alkanolamide, 0.2-0.3 parts of sodium lauryl sulfate, 0.2-0.4 parts of sodium dodecyl benzene sulfonate, 0.1-0.3 parts of glycerol, 0.2-0.3 parts of an essence, 0.8-1 part of diglycol, 1.5-2 parts of polyvinyl alcohol and 90-95 parts of deionized water. The antifogging agent is simple to prepare, has dual efficacies of cleaning and antifogging, and has the advantages of long antifogging time, wide application range, no explosion danger, and portability.

Owner:南通优尼科化工有限公司

Preparation method of glass antifogging agent moist towel

InactiveCN102934964AImprove sexual functionGood anti-fog functionOther chemical processesDomestic applicationsSodium phosphatesPolyethylene glycol

The invention relates to a preparation method of an antifogging agent moist towel, in particular relates to a preparation method of a glass antifogging agent moist towel, and belongs to the field of moist towels. A cotton spunlace is used as the base material cloth, so that no paper scrap is generated; and the spunlace is soaked into a mixed liquid prepared with sodium phosphate and sodium tripolyphosphate as dispersants, lauryl alcohol polyethenoxy ether and fatty acid amine as emulsifying agents, as well as polyethylene glycol and dipropylene glycol, so that the moist towel has excellent hydrophilicity and antifogging function, so that the antifogging time is prolonged, and the antifogging effect is improved; and the moist towel is simple and convenient to use and does no harm to a human body.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

UV photocuring anti-fogging agent and preparation method thereof

ActiveCN108504146ADoes not affect light transmittanceLong anti-fog timeCoatingsPolymer scienceNanoparticle

The invention relates to a UV photocuring anti-fogging agent and a preparation method thereof, belongs to the chemical technical field, and provides the UV photocuring anti-fogging agent and the preparation method. The UV photocuring anti-fogging agent is prepared from nano particles, a solvent, a modifier, hydrophilic photocuring resin, hydrophilic photocuring monomer, a photoinitiator, a flattening agent and a dispersing agent. The anti-fogging agent prepared by the preparation method does not affect characteristics of a base material, is good in effect of inhibiting fog forming, has relatively high hardness and wear resistance, and provides powerful protection the transparent substrate. Meanwhile, the anti-fogging agent is simple and convenient in operation.

Owner:HUARONG COUNTY HENGXING BUILDING MATERIALS CO LTD

Preparation method of persistent antifogging agent

InactiveCN103709999ACause harmImprove sexual functionOther chemical processesSodium phosphatesAmmonia

The invention relates to a coat capable of reducing adhesion of water mist to a smooth object, and in particular relates to a preparation method of a persistent antifogging agent, wherein the raw materials of the persistent antifogging agent include sodium phosphate, sodium tripolyphosphate, sodium alginate, fatty acid ammonia, titanium dioxide, chitosan and deionized water; the sodium phosphate and the sodium tripolyphosphate are taken as the dispersant, while the fatty acid ammonia is taken as the emulsifier, and the sodium alginate and the chitosan are added so that the persistent antifogging agent has excellent hydrophily and antifogging function; in the meantime, the hydrophilic nanoscale titanium dioxide is added to prolong the antifogging time and improve the antifogging effect; no substance harmful on the human body is added so that the persistent antifogging agent is harmless to the human body.

Owner:栾晓健

Anti-fogging self-cleaning weakening ultraviolet glass coating and preparation method thereof

ActiveCN107841206AGood anti-fog performanceLong anti-fog timeAntifouling/underwater paintsPaints with biocidesSodium silicateChemistry

The invention provides an anti-fogging self-cleaning weakening ultraviolet glass coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 0.1-1.5 parts of an emulsifier, 0.1-1.5 parts of polyving akohol, 0.2-1.3 parts of an anionic surfactant, 0.1-1.3 parts of a photocatalyst, 0.1-1 parts of sodium metasilicate, 1-15 parts of isopropanol, 3-8 parts of glycerin, 0.05-0.3 parts of essence, 30-50 parts of ethanol, and the balance of deionized water, wherein the emulsifier is octylphenol polyoxyethylene ether and octylphenyl polyoxyethylene ether; while preparing, the raw materials are mixed, and then a mixture is uniformly stirred. Compared with the prior art, the glass coating disclosed by the invention has strong photocatalytic activity and lasting fogging resistance, is capable of weakening ultraviolet light and has excellent self-cleaning ability and sterilization ability, and is easily prepared.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Glasses fogging-preventing and cleaning solution and preparation method thereof

InactiveCN107937165AGood anti-fog performanceImprove hydrophilic abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsVinyltriethoxysilaneSURFACTANT BLEND

The invention discloses a glasses fogging-preventing and cleaning solution and a preparation method thereof. Raw materials for preparing the glasses fogging-preventing and cleaning solution include, by weight, 10-15 parts of tetraethyl orthosilicate, 10-15 parts of vinyltriethoxysilane, 0.5-2 parts of nanometer titanium dioxide, 40-50 parts of anhydrous ethanol, 1-5 parts of potassium sorbate, 0.5-3 parts of a surfactant and 5-10 parts of deionized water. The glasses fogging-preventing and cleaning solution prepared in the invention has the advantages of good antifogging effect, long antifogging time, obvious glasses cleaning effect, simple use method, no damages to the glasses, and cheap and easily-available raw materials, and the preparation method is simple and is suitable for large-scale production.

Owner:永嘉姜君科技有限公司

Automobile glass antifogging agent

InactiveCN104650810AImprove sexual functionImprove stain resistanceOther chemical processesPalmitatesStearic acid

The invention relates to an antifogging agent and especially relates to an automobile glass antifogging agent. The automobile glass antifogging agent comprises, by weight, 16-20% of sorbitan monstearate (S-60), 2-5% of methyltrifluoropropyl silicone oil, 14-18% of sorbitan monopalmitate (S-40), 2-5% of volatile perfluoro-oil, 2-5% of 1, 5-pentanediol, 0.5-2.5% of sodium benzoate, and 45-65% of deionized water. The automobile glass antifogging agent has excellent hydrophobicity and antifogging function, can prevent a high temperature, can improve dirt resistance, can prolong antifogging time, can improve antifogging effects, and has a wide use range, a low cost and no side effects on the human body. Through coating automobile outer glass and rearview mirrors, the automobile glass antifogging agent has effects of preventing rain, cleaning glass and protecting a wiper. The automobile glass antifogging agent can be dissolved in water, has no easy combustion and blast risk and is portable.

Owner:王沛强

Preparation technology of high-weather-resistance anti-fogging heat insulation membrane

InactiveCN109627870AImprove wear resistanceGood weather resistanceReflecting/signal paintsSilanesAcrylic resin

The invention provides a preparation technology of a high-weather-resistance anti-fogging heat insulation membrane. The technology comprises the steps that silicon nitride whiskers are mixed with a sodium lauryl benzene sulfonate solution and then mixed with ethanol; ethyl silicate and the ethanol are mixed, and the ethanol is cooled down to a room temperature after stirring reaction is conducted;silica alcosol is sequentially added to methacryloxypropyl trimethoxy silane and methacrylic acid, stirring reaction is conducted, and modified silica alcosol is mixed with a suspension; hydrophilicthermal curing solvent acrylic resin, propylene glycol monomethyl ether, dimethylformamide, a catalyst triethylenediamine, a flatting agent, isopropyl alcohol and the ethanol are stirred and mixed; the surface of a glass plate is sequentially coated with coating liquid and tape casting liquid. The anti-fogging heat insulation membrane has the advantages of excellent wear resistance, weather resistance and stability, ageing is not easily caused, so that the service life of the anti-fogging heat insulation membrane is effectively prolonged, better heat insulation and air permeable performance are achieved, an anti-fogging effect is enhanced, and the anti-fogging time is prolonged.

Owner:TIANJIN ZHONGYA HUITONG SCI & TECH CO LTD

Vehicle glass antifogging agent

InactiveCN104497978AReasonable formulaImprove antifreeze effectOther chemical processesBetaineSodium phosphates

A disclosed vehicle glass antifogging agent is prepared from the following raw materials in parts by weight: 33-53 parts of portion, 6-10 parts of propylene glycol, 6-10 parts of sodium phosphate, 3-5 parts of magnesium silicate, 9-12 parts of betaine, 3-8 parts of sodium tripolyphosphate, 4-8 parts of polyethylene wax, 5-10 parts of alum, 5-15 parts of sodium alginate, 3-7 parts of silicone, 7-14 parts of olive oil, 7-14 parts of fatty acid amide, 5-10 parts of titanium dioxide, 6-9 parts of chitosan, 8-10 parts of glycerin, 4-8 parts of sodium chloride, and 3-7 parts of tween. The provided vehicle glass antifogging agent is reasonable in formula, good in antifreezing effect, good in antifogging effect and long in antifogging time.

Owner:QINGDAO LAOXIANG TEA PROD

Novel rare earth nano-composite cleaning antibacterial antifogging agent as well as preparation method and application thereof

PendingCN111875995AImprove antibacterial propertiesSmall particlesAntifouling/underwater paintsOther chemical processesActive agentOxide composite

The invention provides a novel rare earth nano composite cleaning antibacterial antifogging agent and a preparation method and application thereof. The novel rare earth nano composite cleaning antibacterial antifogging agent is prepared from, by weight, 0.2-30% of nano rare earth oxide composite dispersion liquid, 0.05-6% of surfactant, 10-25% of solvent, 0.2-5% of lubricant and 0.05-2% of chelating agent, and the balance is a diluent; wherein the nano rare earth oxide composite dispersion liquid is a composite dispersion liquid of nano rare earth oxide and rare earth supported nano titanium dioxide. The novel rare earth nano-composite cleaning antibacterial antifogging agent is remarkable in demisting effect, stable in performance, low in cost, green and non-toxic, and has cleaning and antibacterial functions.

Owner:TIANJIN BAOGANG RES INST OF RARE EARTHS

Preparation method of automotive glass antifogging agent

InactiveCN102936487ACause harmImprove sexual functionOther chemical processesPolypropylenePropylene glycol

The invention relates to a glass antifogging agent, in particular relates to an automotive glass antifogging agent, and belongs to the field of antifogging agents. Tea oil, polypropylene and propylene glycol are used as dispersants, and volatile perfluor oil is added, so that the automotive glass antifogging agent has excellent hydrophilicity and antifogging functions, the antifogging time can be prolonged, and the antifogging effect can be improved; and the automotive glass antifogging agent has no harm to a human body as the substance harmful to the human body is not added.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Preparation method of glass antifogging agent

The invention relates to a preparation method of an antifogging agent, particularly a preparation method of a glass antifogging agent. Sodium phosphate and sodium tripolyphosphate are used as dispersants, laurinol polyethenoxy ether and fatty acid amine are used as emulsifiers, and polyethyleneglycol and isopropanediol are matched, so that the glass antifogging agent has favorable hydrophilicity and antifogging function, and can prolong the antifogging time and enhance the antifogging effect; and no substance harmful to the human body is added, so the glass antifogging agent can not hurt the human body.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

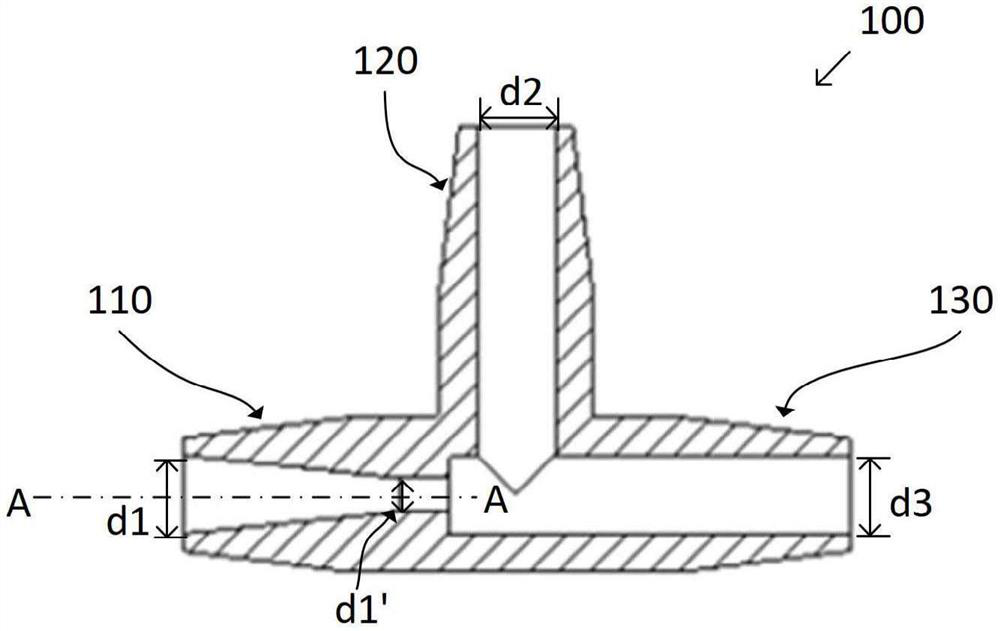

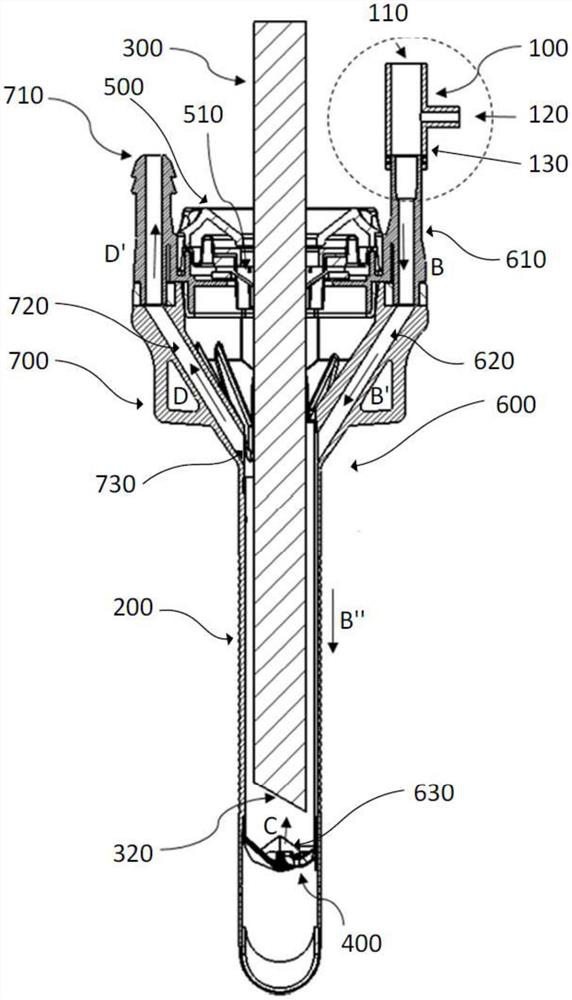

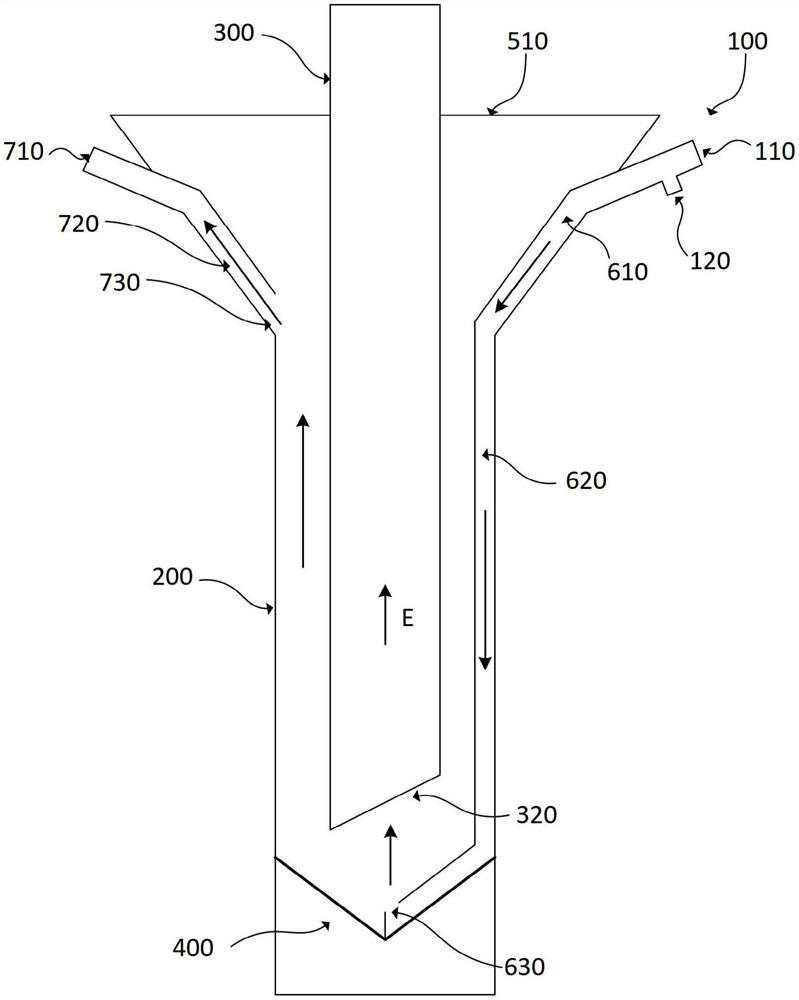

Access assembly for endoscope and using method of access access assembly

The application discloses an access assembly for an endoscope. The access assembly comprises a tubular body for receiving the endoscope, a far-end piece, a near-end piece, a fluid supply passage, a vacuum suction part and a three-way pipe; the far-end piece is connected with the far end of the tubular body; the near-end piece is connected with the near end of the tubular body, wherein the inner wall of the tubular body, the far-direction surface of the near-end piece and the near-direction surface of the far-end piece jointly define a cavity of the access assembly; the fluid supply passage comprises a fluid input port, a fluid discharge port and a fluid pipeline; the fluid input port and the fluid discharge port are in fluid communication through the fluid pipeline, and the fluid discharge port is arranged in the cavity of the access assembly; and the vacuum suction part is configured to be connected with a vacuum suction source. The invention also relates to a using method of the access assembly.

Owner:NINGBO HITCM MEDICAL DEVICES CO LTD

Antibacterial anti-fogging wet tissue and preparation method thereof

ActiveCN102618217BAvoid Shedding Residue ProblemsLong anti-fog timeCarpet cleanersOther chemical processesEthyleneglycol dimethacrylateSilicon dioxide

The invention relates to the field of anti-fogging products and provides an antibacterial anti-fogging wet tissue and a preparation method of the antibacterial anti-fogging wet tissue. The antibacterial anti-fogging wet tissue has strong antibacterial property and long anti-fogging time. The antibacterial anti-fogging product is prepared by uniformly spraying an antibacterial anti-fogging liquid on a non-woven fabric; the antibacterial anti-fogging liquid comprises the following components in percentage by weight: 30-50% of polyacrylic acid modified nanoparticle liquid, 0.05-0.1% of kathan and the rest of water; the polyacrylic acid modified nanoparticle liquid comprises the following components in percentage by weight: 1-20% of silica nanoparticles, 0.01-2% of KH-560, 0.01-5% of AEO-23 (Fatty Alcohol-polyoxyethylene Ether), 0.1-10% of acrylic acid, 0.001-1% of EGDMA (Ethyleneglycol Dimethacrylate), 0.01-2% of ammonium persulfate and the rest of water.

Owner:FUSTIN XIAMEN COMMODITY

Automotive glass antifogging agent

InactiveCN104194724AImprove sexual functionImprove stain resistanceOther chemical processesSorbitan monostearateSide effect

The invention relates to an antifogging agent and in particular relates to an automotive glass antifogging agent. The automotive glass antifogging agent comprises the following components in percentage by weight: 16-20 percent of sorbitan monostearate (S-60), 2-5 percent of methyl trifluoropropyl silicone oil, 14-18 percent of sorbitan monopalmitate (S-40), 2-5 percent of volatile perfluorinated oil, 2-5 percent of 1,5-pentanediol, 0.5-2.5 percent of sodium benzoate and 45-65 percent of deionized water. The automotive glass antifogging agent disclosed by the invention has excellent hydrophobicity and antifogging function and has high-temperature resistance and enhanced stain resistance; the antifogging time can be prolonged and the antifogging effect is improved; the automotive glass antifogging agent is wide in application range and low in cost and does not have a side effect on the human body; the antifogging effect has the effects of protecting glass from rain, cleaning the glass and protecting the windscreen wiper after applied to the automobile outside glass and a rearview mirror; and the antifogging agent takes water as a solvent, eliminates inflammable and explosive hazards and is convenient to carry.

Owner:QINGDAO RUNXIN WEIYE TECH & TRADE

Durable antifogging agent

InactiveCN103709997AGood anti-fog functionExtend the time of anti-fogOther chemical processesChemistrySmooth surface

The invention relates to a liniment for reducing adhesion of water mist on a smooth surface, particularly a durable antifogging agent which is prepared from sodium phosphate, sodium tripolyphosphate, sodium alginate, fatty acid amine, titanium dioxide, chitosan and deionized water. By using the sodium phosphate and sodium tripolyphosphate as the dispersant and fatty acid amine as the emulsifier and adding the sodium alginate and chitosan, the durable antifogging agent has favorable hydrophilicity and antifogging function; meanwhile, the nano titanium dioxide with hydrophilicity is added to prolong the antifogging time and enhance the antifogging effect; and no substances harmful to the human body are added, so the antifogging agent can not jeopardize the human body.

Owner:栾晓健

Anti-fog type automobile front windshield glass

InactiveCN109133658ACause harmImprove sexual functionWindowsWindscreensIrritationPolyethylene glycol

An anti-fog type automobile front windshield glass belongs to the technical field of glass materials. The glass comprises, by weight, the following components: 3-13 parts of borax, 2-10 parts of sodium hydroxide, 1-7 parts of limestone, 2-8 parts of glass fiber, 15-25 parts of silicon dioxide, 2-8 parts of zinc oxide, 3-13 parts of sodium carbonate, 2-12 parts of curing agent, 2-5 parts of dispersing agent, 1-5 parts of emulsifier, 1-3 parts of polyethylene glycol and 2-3 parts of propylene glycol. The automobile glass has the advantages of high structural strength, long service life and the like, a problem of breakage does not occur in the use process, the structural strength of the glass material is strengthened, and the service life is prolonged; the strength is high, the glass is capable of resisting strong impact, effectively blocking sun irritation, protecting skin from being injured, effectively preventing fog, and adding safety to driving.

Owner:景有超

Automotive glass antifogging agent and preparation method thereof and automotive glass antifogging cloth

InactiveCN106147712ASolve the defect of easy foggingImprove sexual functionOther chemical processesCleaning apparatus for vehicle exteriorsNonylphenol ethoxylateCoconut diethanolamide

The invention relates to an automotive glass antifogging agent and a preparation method thereof and automotive glass antifogging cloth. The automotive glass antifogging agent is mainly prepared from, by weight, 3-5 parts of polyoxyethylene polyoxypropylene monobutyl ether, 5-10 parts of coconut diethanolamide, 10-20 parts of polyoxyethylene lauryl ether, 5-15 parts of nonylphenol ethoxylates, 10-20 parts of sodium hydroxide, 10-20 parts of sodium hydroxide, 15-25 parts of dimethyl formamide, 5-25 parts of alkylphenol ethoxylates, 50-100 parts of ethanol and 100-200 parts of deionized water. The automotive glass antifogging agent has advantages of low cost and less proneness to deterioration, and the defect of proneness to fogging of automotive glass is overcome.

Owner:蒋兆财

A kind of anti-fogging agent for new energy vehicles

Owner:东阳市医药卫生用品有限公司

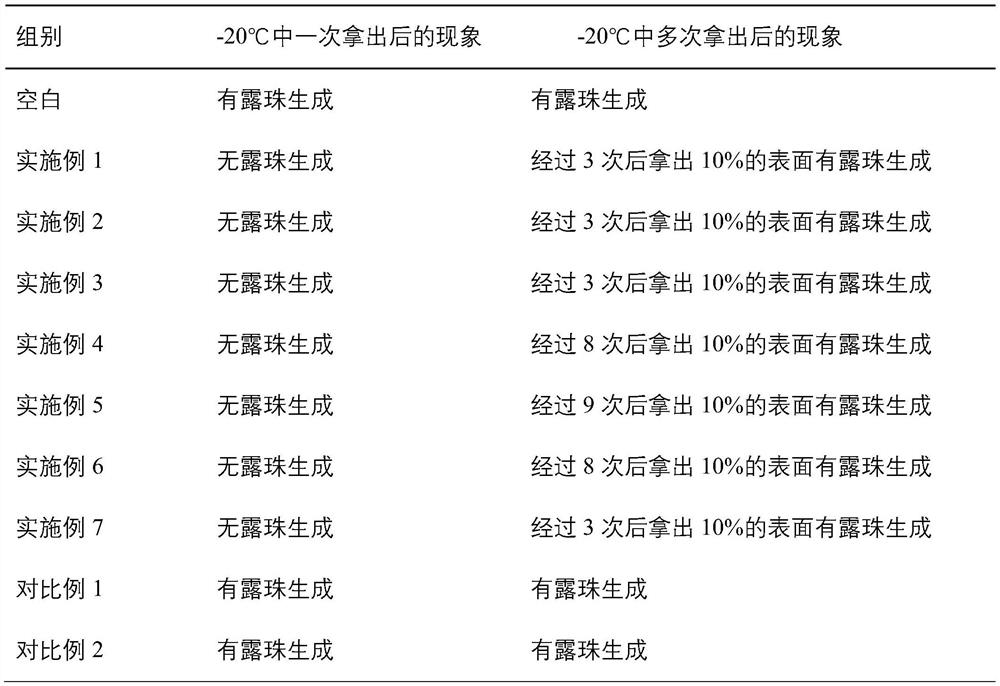

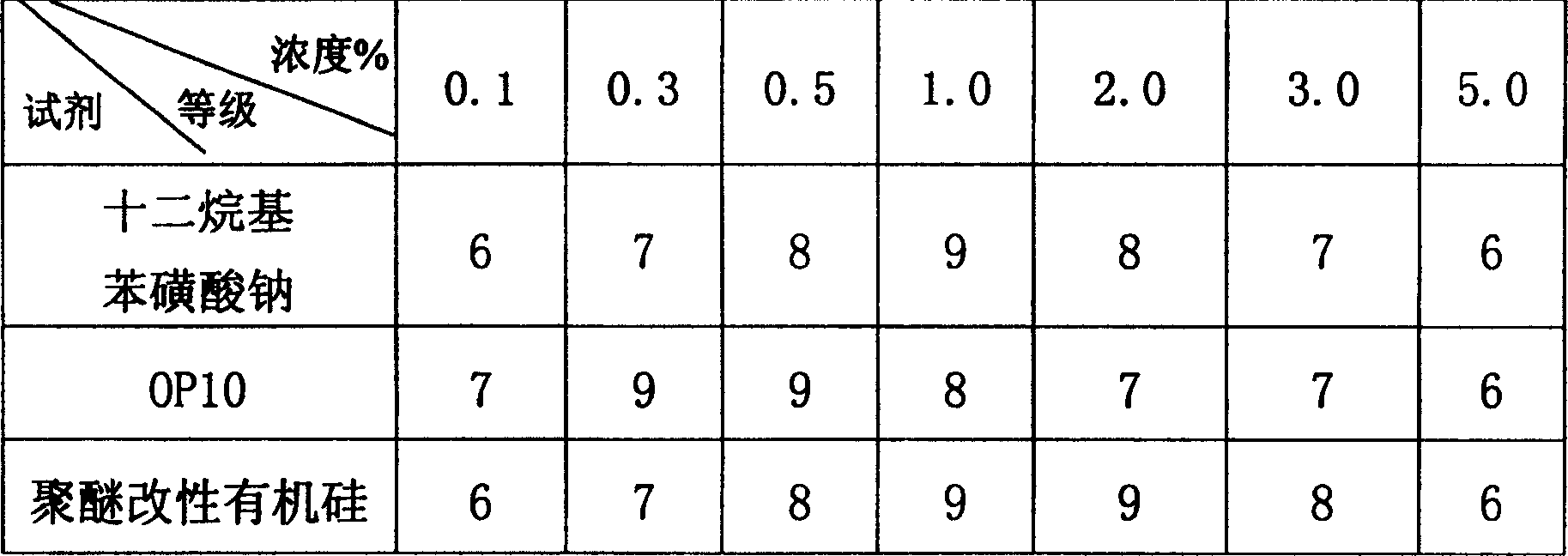

Glass fog-proof agent and its preparing method

The present invention relates to surfactant, and provides one kind of glass antifogging agent and its preparation process. The glass antifogging agent consists of surfactant 0.2-1.5wt%, polyether modified organic silicon surfactant 1.5-3.0wt%, and alcohol 9-20wt% except water. The glass antifogging agent is re-compounded with several kinds of surfactant, and has long antifogging period and wide application range and may be used also as glass cleaning agent. In addition, it has water as solvent and has no danger of explosion and is easy to carry about.

Owner:ZHEJIANG UNIV

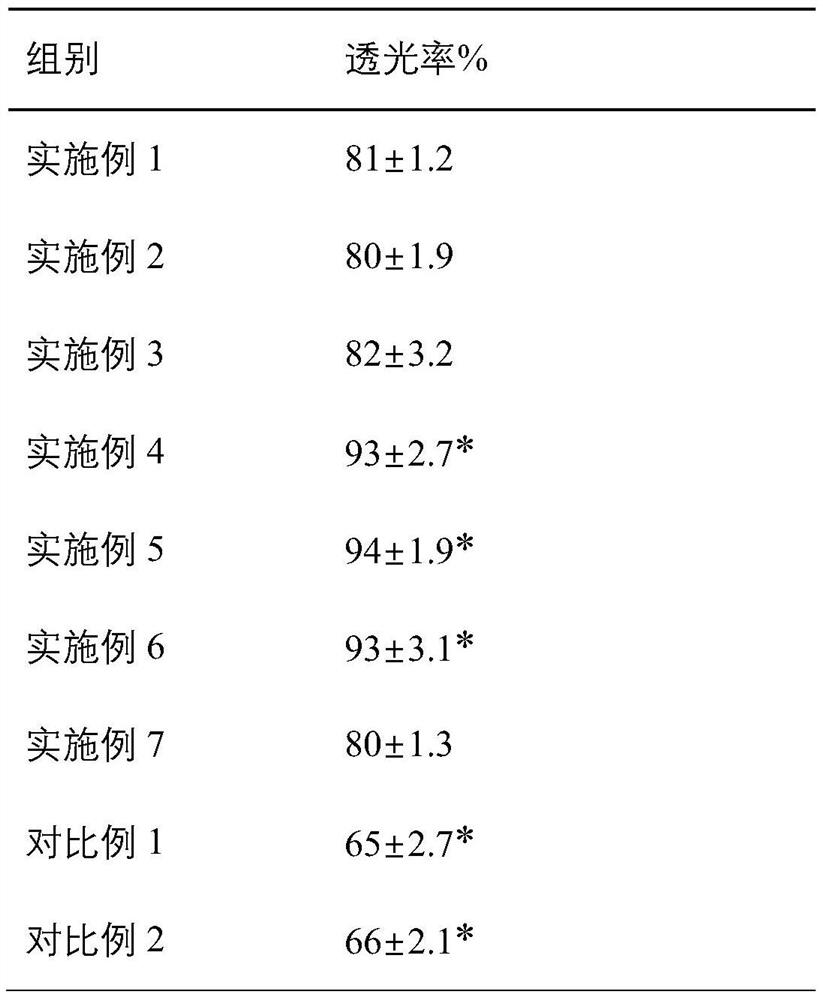

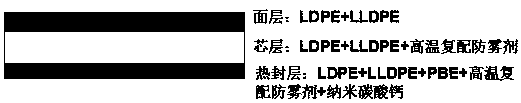

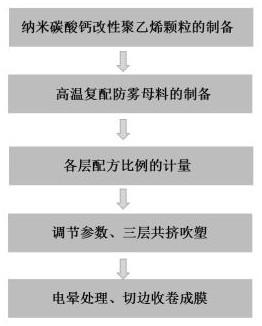

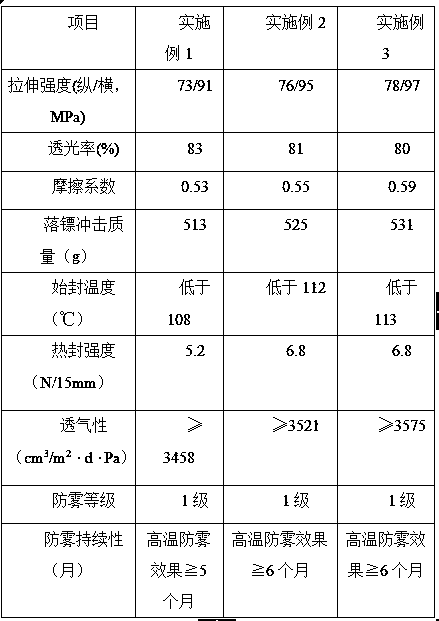

High-temperature anti-fog breathable polyethylene heat-seal film and preparation method thereof

InactiveCN111070834AReduce precipitationImprove hydrophilicityFlexible coversWrappersPolymer scienceNano carbon

The invention belongs to the field of preparation of anti-fog heat-sealing films, and particularly relates to a high-temperature anti-fog breathable polyethylene heat-sealing film and a preparation method thereof. The heat-sealing film comprises a surface layer, a core layer and a heat sealing layer from top to bottom, a three-layer co-extrusion layer ratio structure is as follows: LDPE + LLDPE / (LDPE + LLDPE + an initial high-temperature antifogging agent + a long-acting high-temperature antifogging agent) / (LDPE + LLDPE + PBE + an initial high-temperature antifogging agent + a long-acting high-temperature antifogging agent + nano calcium carbonate); wherein the surface layer accounts for 10-30 wt%, the core layer accounts for 40-75 wt%, and the heat sealing layer accounts for 15-30 wt%. The anti-fog heat-sealing film prepared by the invention has the characteristics of better anti-fog durability, better air permeability, high heat-sealing strength and good comprehensive performance, isparticularly suitable for packaging of fruit and vegetable products, is particularly beneficial to market development, and promotes the progress of packaging materials.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV +1

Automobile glass anti-fog detergent and preparation method thereof

ActiveCN103045169BExcellent anti-fog and decontamination effectLong anti-fog timeOther chemical processesNon-surface-active detergent compositionsHuman healthAlum

Owner:海宁市袁花镇工业投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com