Electrical control device and method for pressure oil pump

An electrical control device and pump control technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problems of pipeline oil shock, affecting the service life of the oil supply pump, not considering phase sequence protection measures, etc. The effect of reducing shock and noise, improving the quality of oil supply, and improving the quality of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

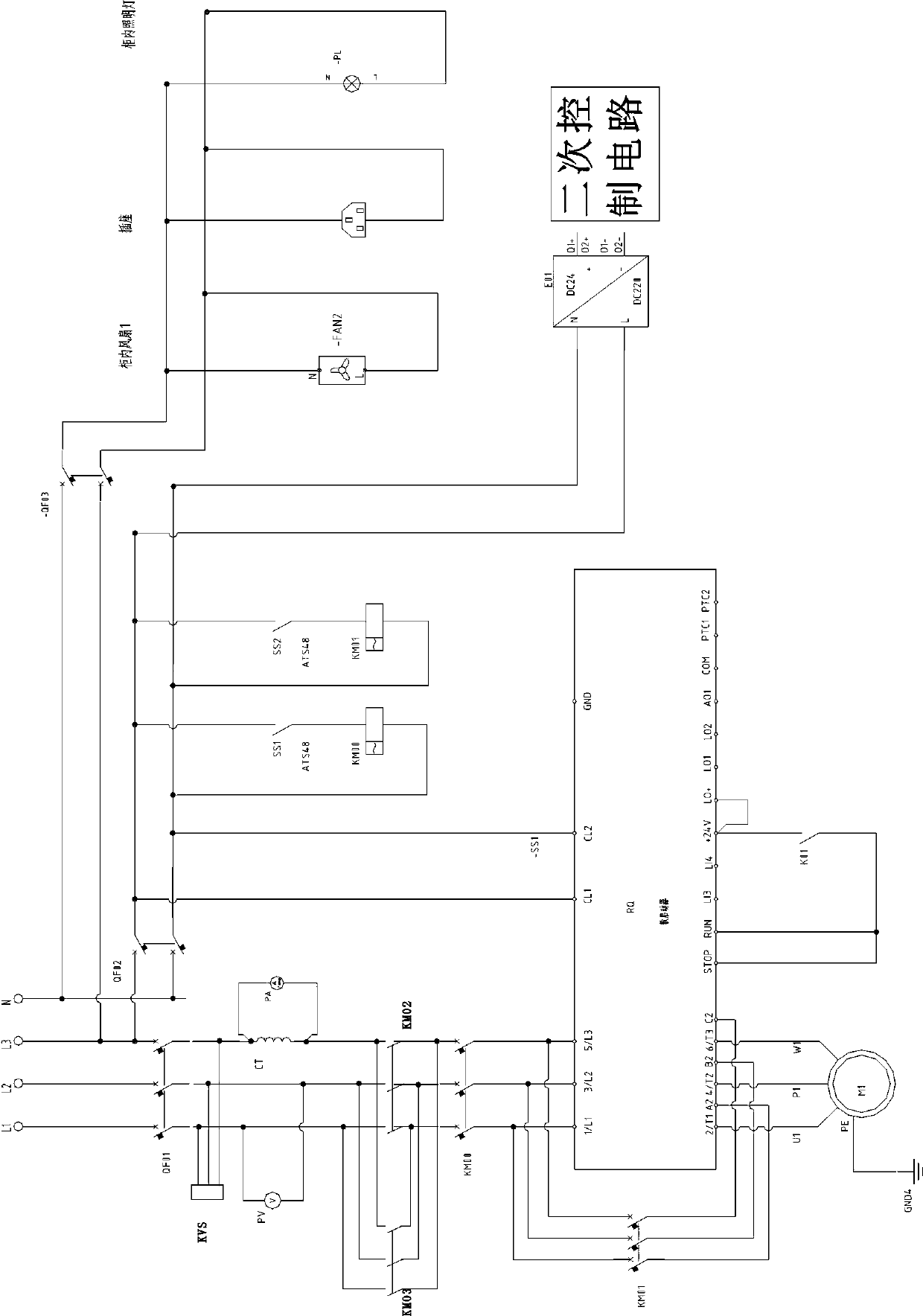

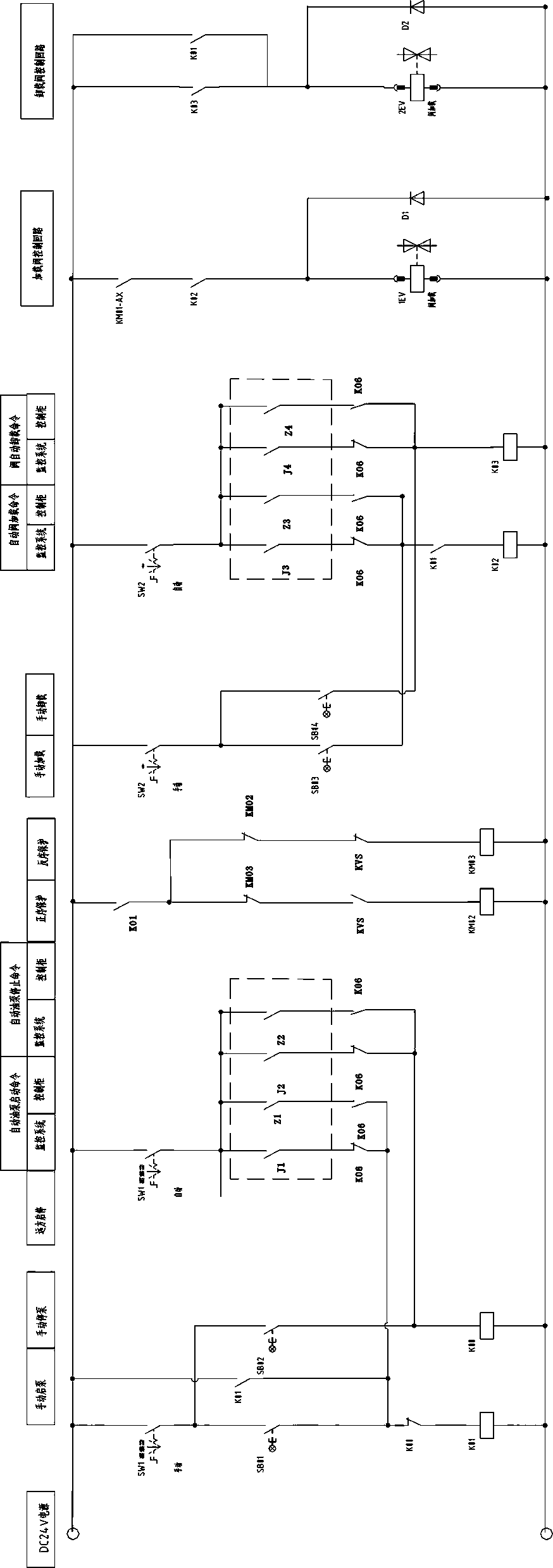

[0046] An electrical control device for a pressure oil pump, comprising a primary circuit, a secondary circuit and an auxiliary control circuit.

[0047] The primary circuit includes circuit breaker QF01, phase sequence protection device KVS, positive sequence contactor KM02, reverse sequence contactor KM03, main contactor KM00, bypass contactor KM01, soft starter RQ;

[0048] The secondary circuit includes start button SB01, stop button SB02, load button SB03, unload button SB04, pump start relay K01, pump stop relay K00, load relay K02, unload relay K03, positive sequence contactor KM02, reverse sequence contactor KM03, loading valve 1EV, unloading valve 2EV, start-stop switching handle SW1, loading and unloading switching handle SW2, control cabinet fault point relay K06;

[0049] The three phases L1, L2, and L3 are respectively connected to the phase sequence protection device KVS to detect whether the phase sequence is correct;

[0050] Any two phases are connected in pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com