Intelligent remote parameter monitoring system for manned spacecraft manufacturing equipment production line

A manned spacecraft and monitoring system technology, applied in the field of industrial equipment parameter monitoring, can solve problems such as incomplete product quality and reliability data packets, large amounts of production information and quality information, and difficulty in synchronously viewing the operation of other equipment remotely. Achieve the effect of convenient unified processing and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

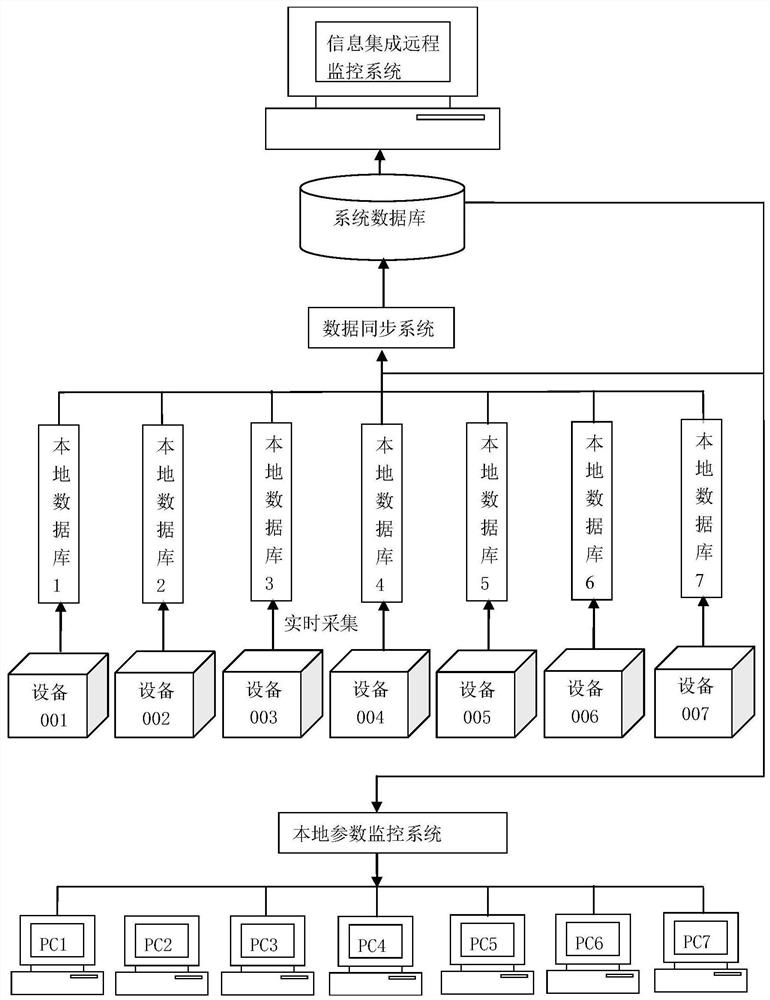

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] An intelligent remote parameter monitoring system for a manned spacecraft manufacturing equipment production line, including: several data acquisition systems, several local computers and a database server;

[0040] Several data acquisition systems are correspondingly connected to several local computers, and several local computers are connected to the database server,

[0041] Each data acquisition system includes: field controller, camera, card reader and scanning gun;

[0042] Each local computer is installed with OPC client, local database and local parameter monitoring system;

[0043] Data synchronization system, system database and information integration remote monitoring system are installed on the database server;

[0044] The on-site controller and the local computer form a local area network, the on-site controller is used as a local OPC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com