Anti-clogging device for filter screen of textile vacuum equipment

A filter and equipment technology, which is applied in the field of anti-clogging devices for textile vacuum equipment filters, can solve problems such as burning out motors, falling, and large motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

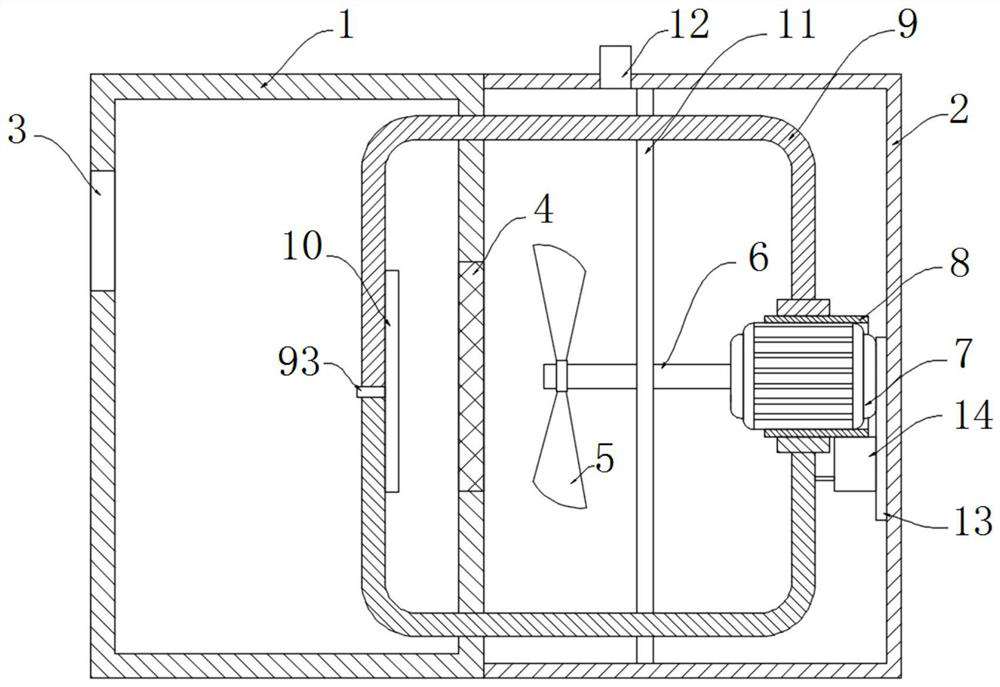

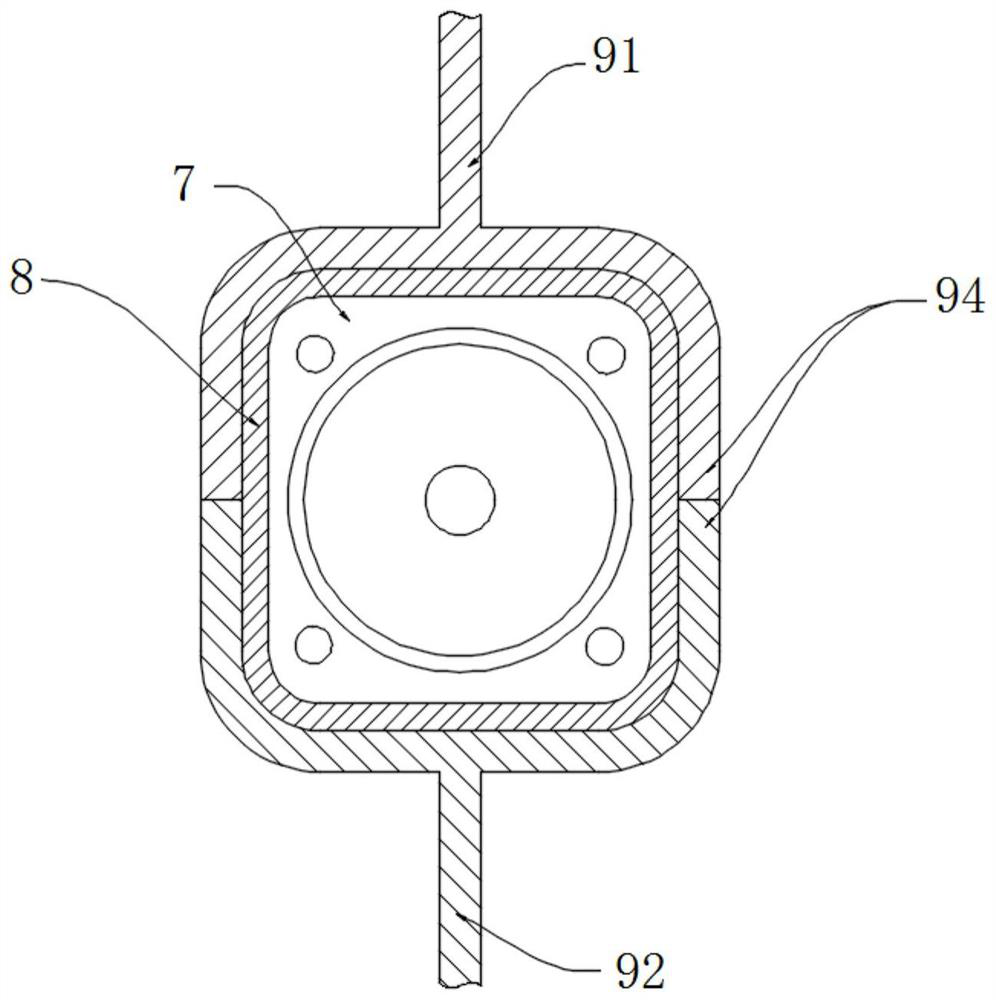

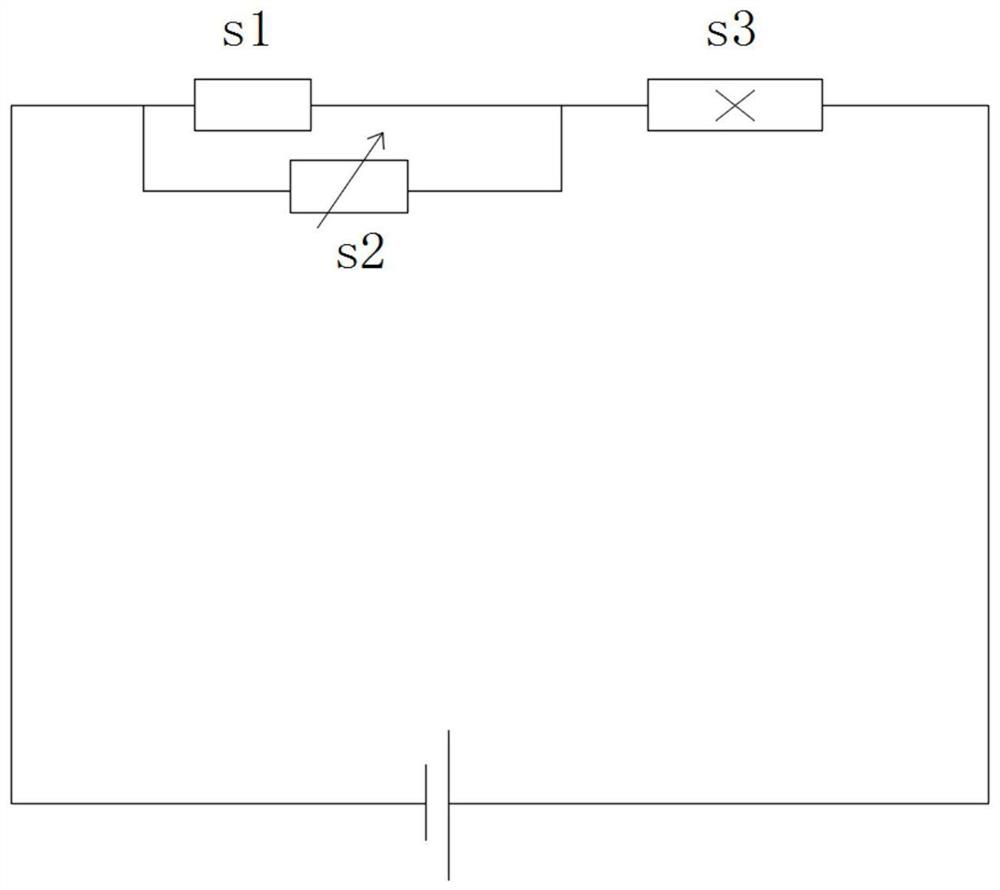

[0022] refer to Figure 1-3 , an anti-blocking device for a filter screen of a dust collection device for textiles, comprising an ash collection box 1, a feed inlet 3 is provided on one side of the ash collection box 1, and a filter screen 4 is provided on the other side of the ash collection box 1, and the ash collection box 1 is provided with a filter screen 4. The side of the box 1 near the filter screen 4 is fixedly connected with an air chamber 2, the air chamber 2 is sealed and connected with a baffle plate 11 and the space in the air chamber 2 is divided into two parts, and the part of the air chamber 2 near the filter screen 4 is provided with There is an impeller 5, the center of rotation of the impeller 5 is fixedly connected with a rotating shaft 6, the rotating shaft 6 seals through the baffle plate 11 and the rotating shaft 6 is fixedly connected with a motor 7 in another part of the air chamber 2, and the motor 7 is connected with a conductive structure;

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com