Automatic fur-absorbing device of open-width airflow soft drying machine

A drying machine and airflow technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of air circulation obstruction, time-consuming and laborious, and reduce drying efficiency, so as to save manpower and improve drying efficiency , the effect of air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

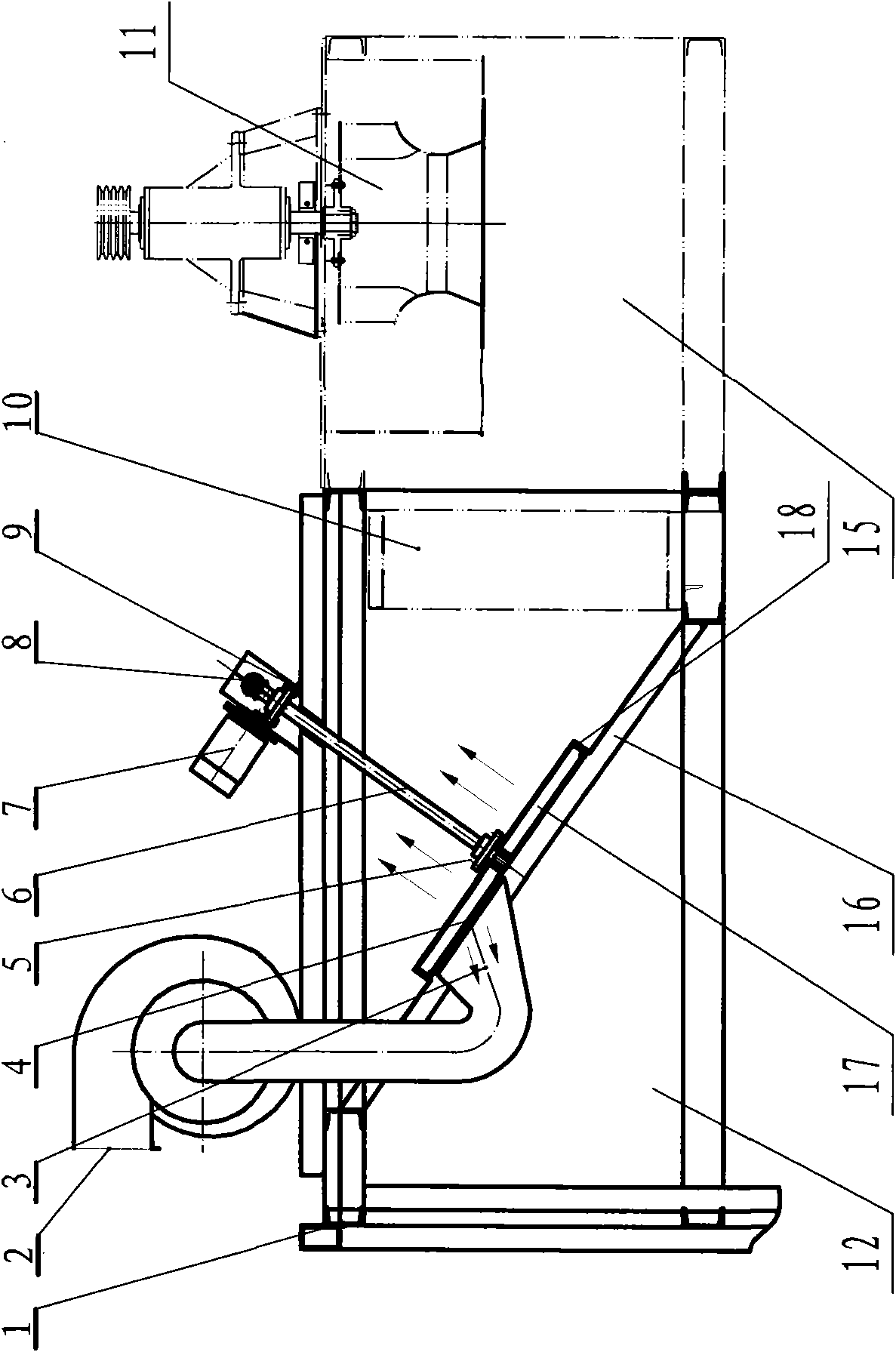

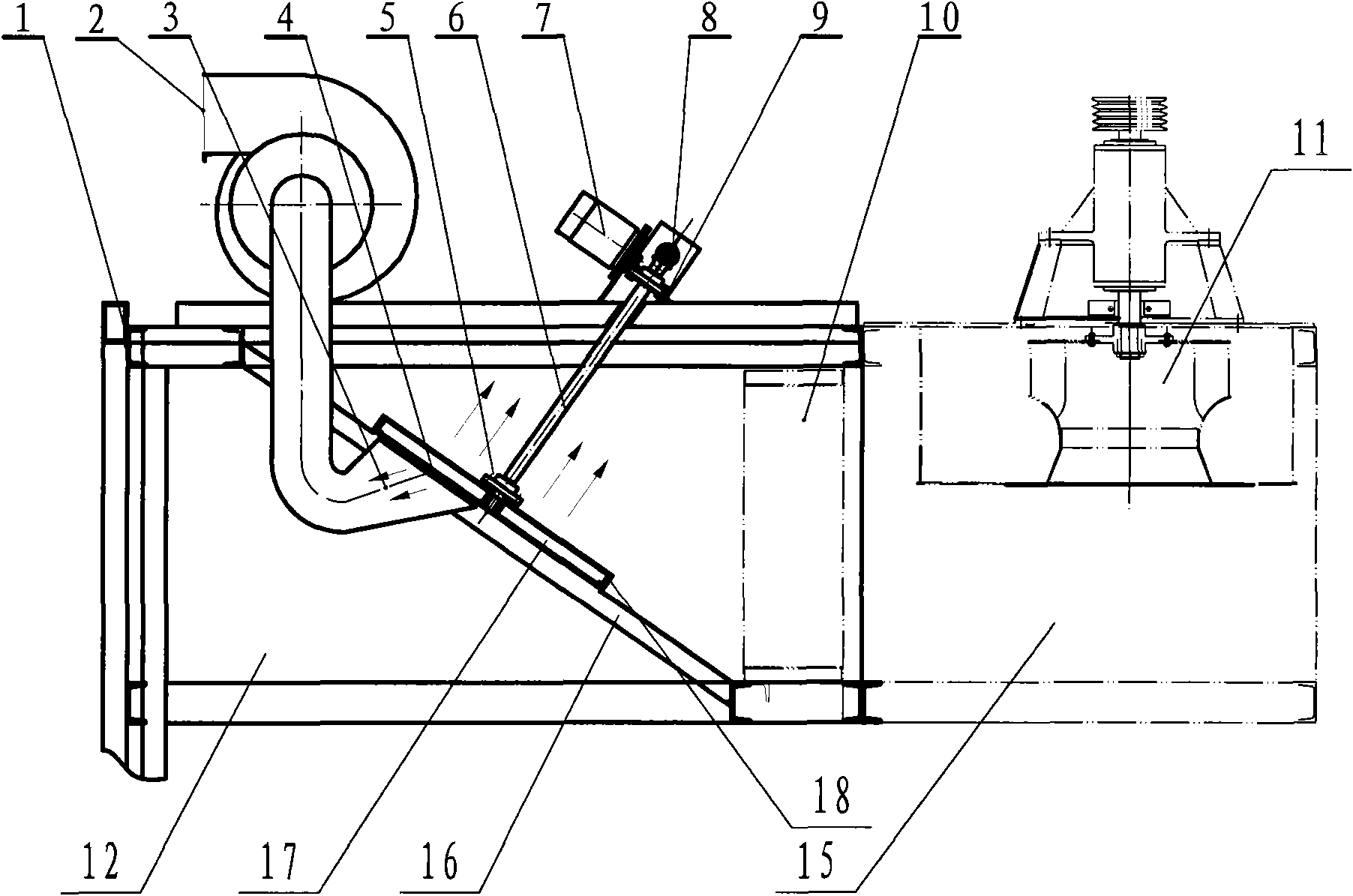

[0013] Describe the present invention in detail below in conjunction with accompanying drawing:

[0014] like figure 1 As shown, the automatic hair suction device of the open-width airflow soft dryer includes an electrical control system, a mechanical transmission system, a drying room skeleton 1, and the drying room is composed of 2-4 ovens. In order to remove the gray hairs produced by the machine during work, the inner cavity of the box is divided into two spaces by the inclined partition 16, half of which is the cavity 12 full of gray hairs during work, and the other half is connected with the heat exchanger 10, suction The air chamber 15 is connected, and a main blower fan 11 is arranged above the air suction chamber 15; an air suction port 17 is provided on the inclined partition 16, and a convex ring edge 18 is provided on the air suction port 17, and the filter screen 4 is dynamically matched by the convex ring In the air suction port 17 that side 18 constitutes. And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com