Solar battery charging based wood material surface treatment equipment of botanic garden scenic spots

A wooden material and surface treatment technology, applied in metal processing equipment, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve the problems of low precision, uncleanness, time-consuming and laborious, etc., and achieve small grinding depth , The grinding process saves labor and time, and prevents wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The use steps and principle of the present invention are:

[0037] The present invention requires two people to operate, one person is the main control person, responsible for grinding control, and the other person is an auxiliary person, responsible for keeping the equipment parallel to the ground and preventing tilting.

[0038] After starting up, the main controller is initialized and self-inspected. The self-inspection process includes motor inspection and battery power check. After the self-inspection is completed, the indicator light on the casing will be lit. If the battery power is lower than 10%, the indicator light will flash to remind the operation or charge in time.

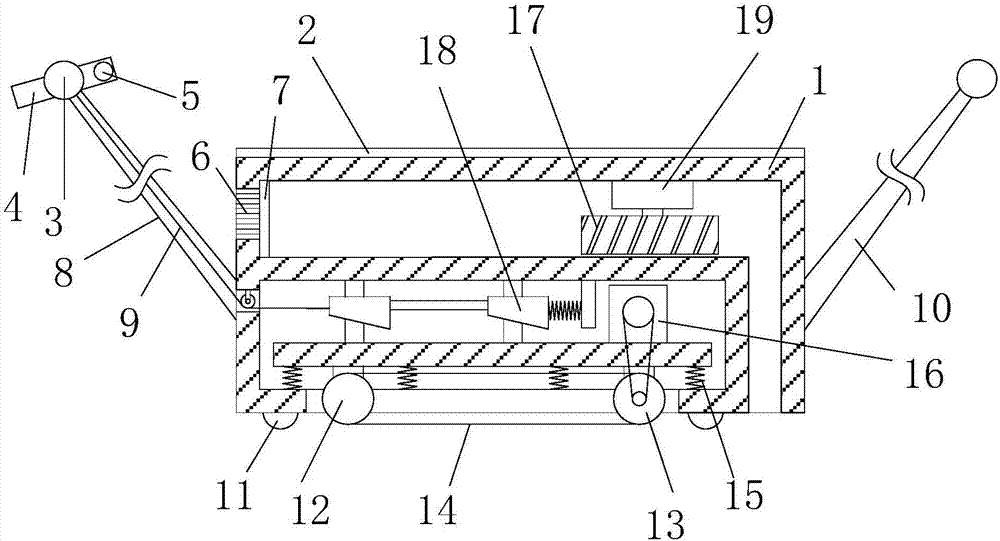

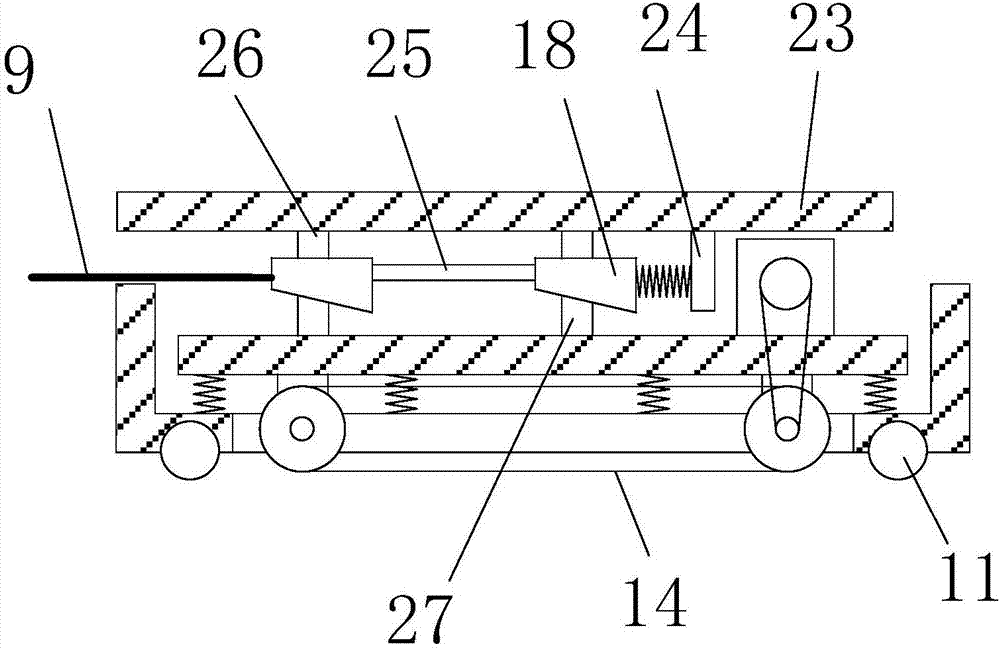

[0039] During operation, push the device to the vicinity of the ground that needs to be polished, the main controller presses the grinding button on the handle, the first motor 16 rotates, drives the second shaft roller 13 to rotate through the transmission belt 29, and the second shaft roller ...

Embodiment 2

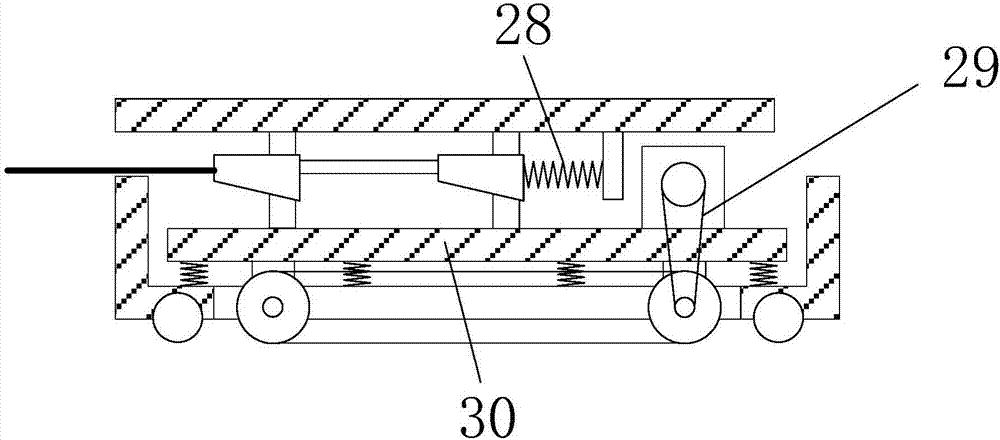

[0044] In actual use, the steel wire rope 9 is slightly stretched. Although the deformation is small, it is enough to affect the accuracy. Therefore, it is necessary to regularly debug the equipment to keep the steel wire rope 9 tight and reduce the influence of its deformation. Its method is to turn the screw 22 with a flat-head screwdriver, so that more steel wire ropes 9 are wound on the screw 22, as Figure 8 As shown, the screw 22 middle part is perforated, and the wire rope 9 ends pass therethrough and are fastened therewith.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com