Gas filling bottle welding rotating device and working method thereof

A technology for rotating devices and filling bottles, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of restricting production efficiency and production quality, increasing labor costs for skilled workers, increasing factory production costs, etc., and achieve simple and convenient control , reduce the requirements for input and proficiency, and achieve high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

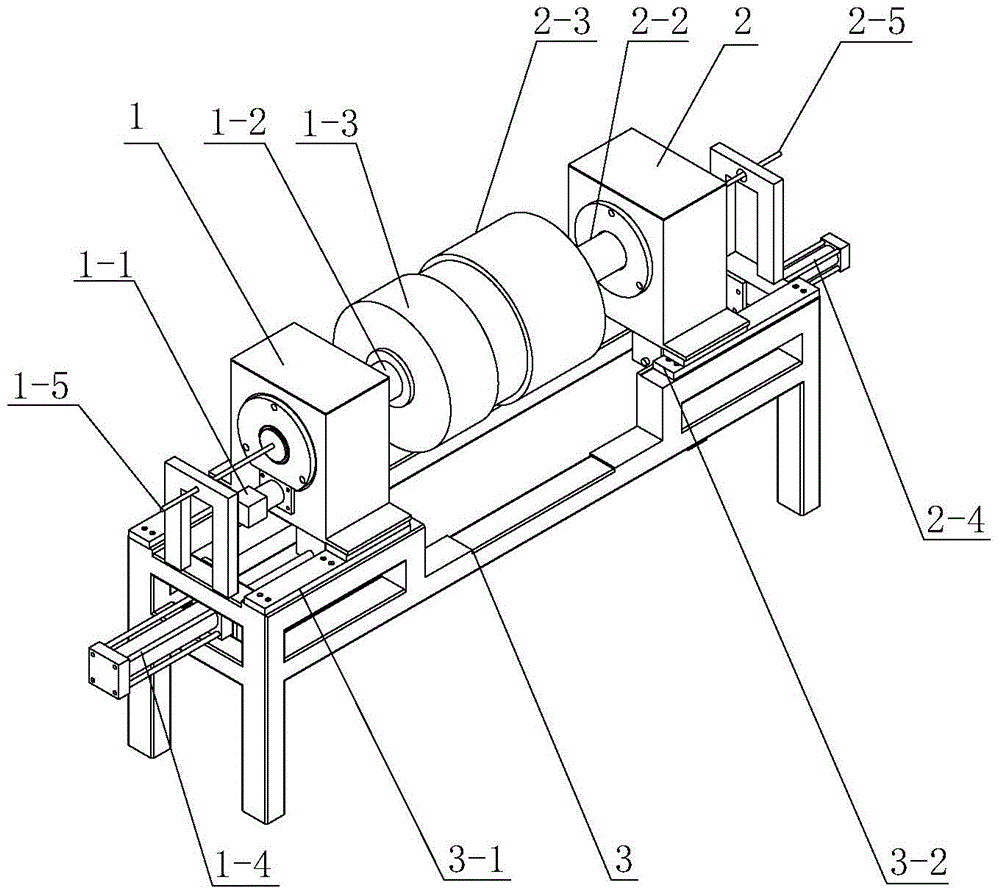

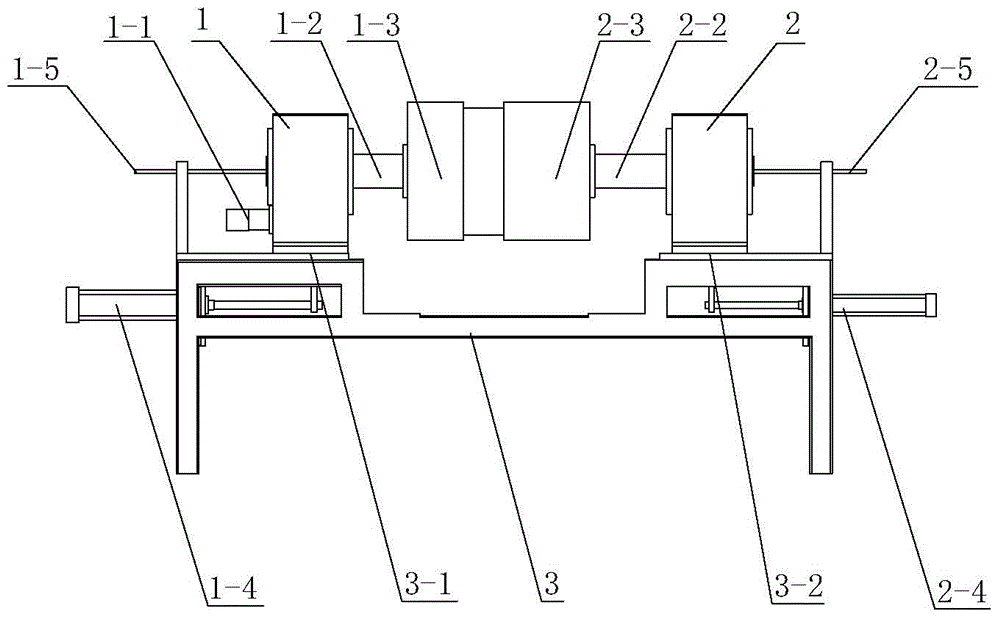

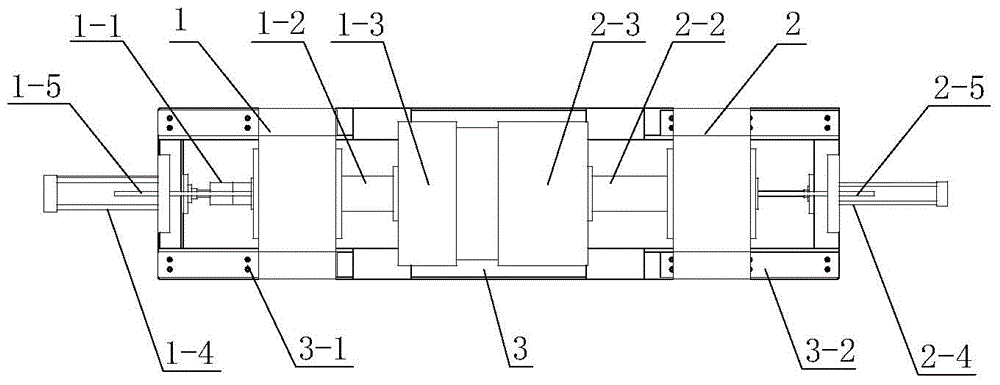

[0024] Embodiment: The gas filling bottle welding rotary device of this embodiment is used for clamping the gas filling bottle when it is automatically welded, and its overall structure is as follows figure 1 , figure 2 and image 3 As shown, it includes a driving rotating body 1 and a driven rotating body 2 symmetrically arranged on a frame 3 . The active rotating body 1 has an active motor 1-1 and an active rotating shaft 1-2 meshing with each other, and the end of the active rotating shaft 1-2 is equipped with a first jacket 1-3 that matches the outer contour of one end of the gas filling bottle . The driven rotating body 2 has a driven rotating shaft 2-2 on the same straight line as the driving rotating shaft 1-2, and a second clamp for clamping the other end of the gas filling bottle is installed at the end of the driven rotating shaft 2-2. Cover 2-3, the inner wall of the second jacket 2-3 coincides with the outer contour of the other end of the gas filling bottle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com