Device and method for feeding wood support rod into linking rod

A technology of linkage rod and support rod, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unfavorable automation, low efficiency, easy generation of waste parts, etc., to improve production efficiency, low rejection rate, accurate counterpoint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below.

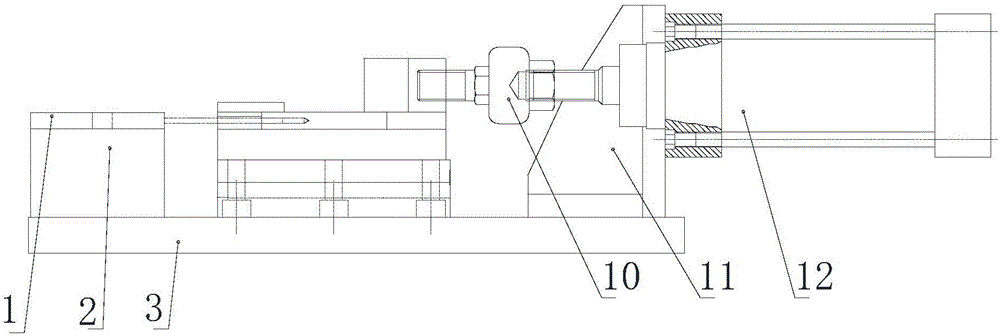

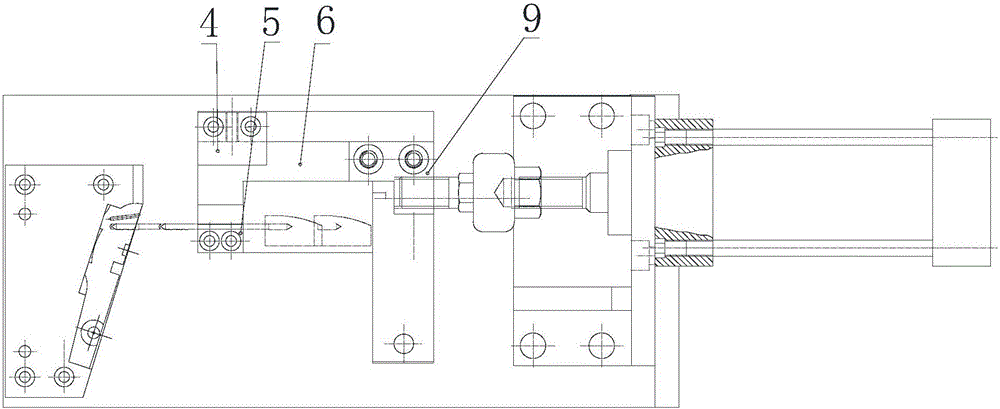

[0026] The device for loading the backing rod into the linkage rod includes a base, a linkage rod positioning mechanism, and a backing rod jacking mechanism. The linkage rod positioning mechanism and the backing rod jacking mechanism are all installed on the base.

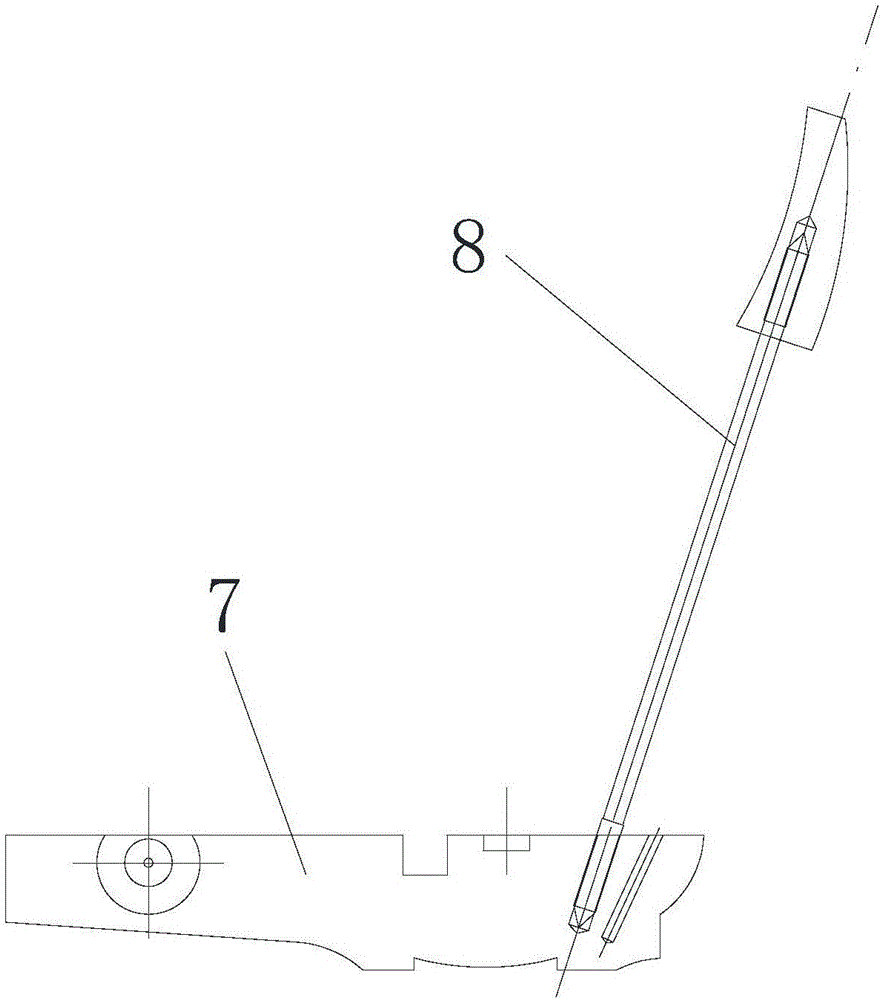

[0027] The linkage rod positioning mechanism includes a linkage rod positioning block and an adjustment pad, and the linkage rod positioning block is fixed on the base through the adjustment pad. The upper edge of the linkage rod positioning block is provided with a linkage rod slot with a shape corresponding to the linkage rod. Clip backing rod.

[0028] The backing rod jacking mechanism includes a translational driving mechanism, a translational guiding mechanism, a mounting plate, a movable pressing block, a clamping positioning block, and a back positioning block. Both the clamping positioning block and the back positioning block are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com