Stacking system and stacking method for steel plate

A steel plate and stacking technology, applied in the steel plate stacking system and the field of stacking, can solve the problems of inability to meet the requirements of precise positioning of steel plate stacking, complicated equipment maintenance, and large system investment, so as to reduce potential safety hazards and surface scratches on steel plates. damage, improved stability and safety, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

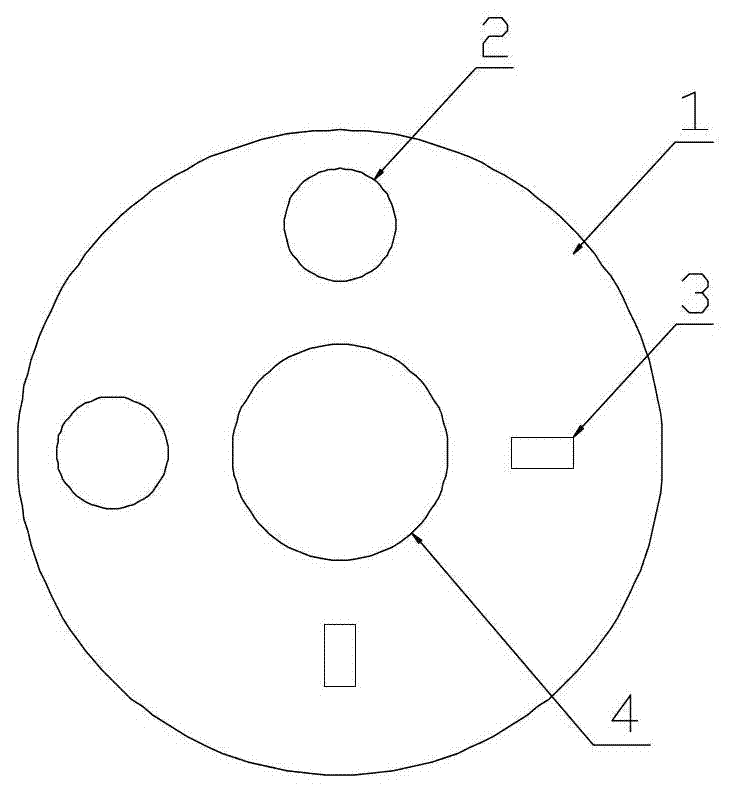

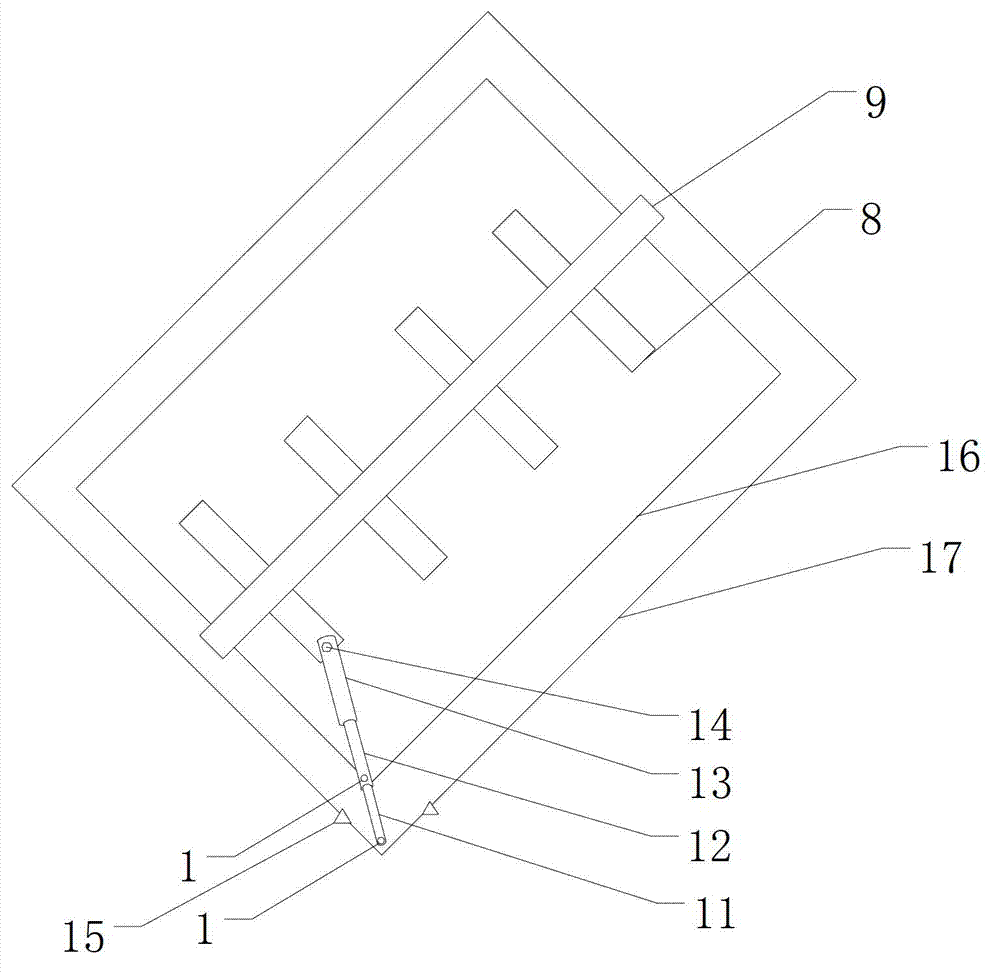

[0046]A steel plate stacking system, including a lighting subsystem 2 , an aiming and sighting subsystem 3 , a camera subsystem 4 , a display subsystem 5 , a position indication point 15 and a telescopic rod 10 .

[0047] Such as figure 1 As shown, the lighting subsystem 2 composed of two high-beam lighting lamps distributed at right angles, the camera subsystem 4 and the viewing and aiming indicator subsystem 3 composed of two red laser lights distributed at right angles are arranged in the integrated base 1. The indicator lines projected by the two red laser lights intersect perpendicularly to form a cross-shaped target aiming baseline.

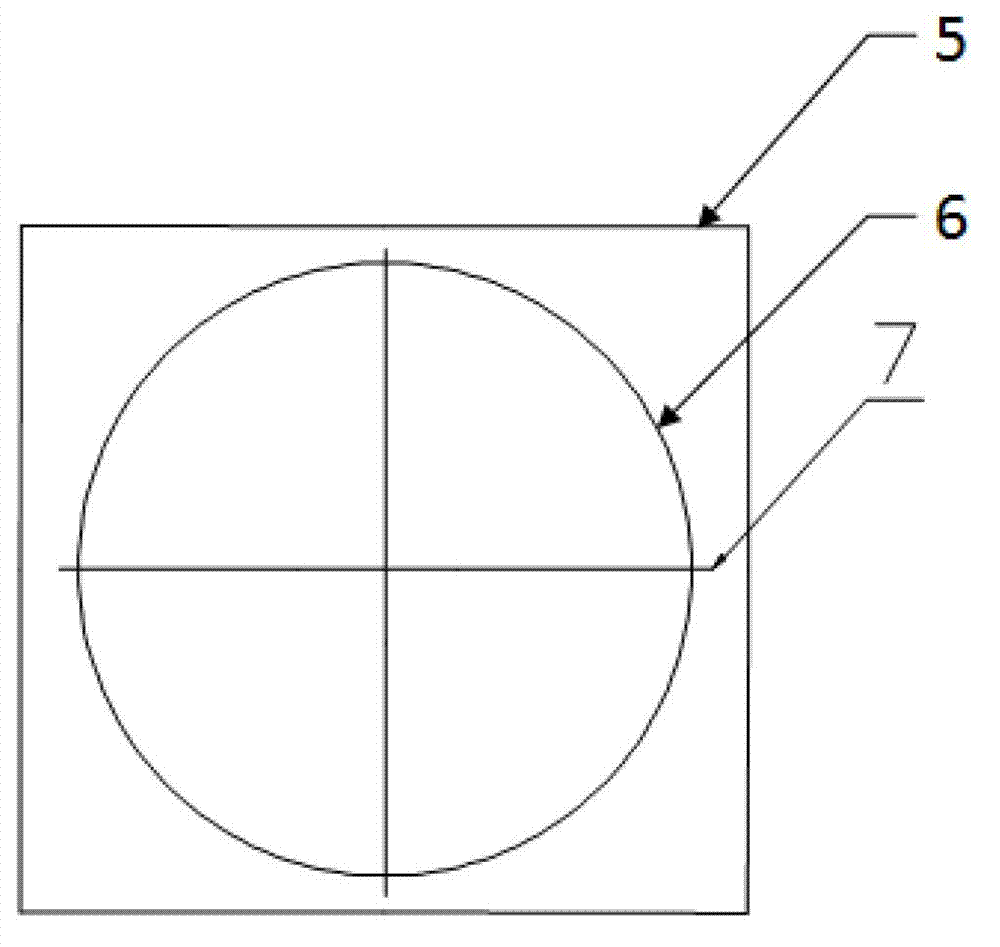

[0048] Such as figure 2 As shown, the display subsystem 5 displays the picture taken by the camera subsystem 4, and a field of view marking circle 6 is integrated on the display subsystem 5, and the cross-shaped target aiming baseline passes through the camera subsystem 4 The center of the field of view marking circle 6 imaged on the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com