Layering continuous well testing system and use method thereof

A technology for testing oil and testing components, which is used in earth-moving drilling, production of fluids, measurement, etc., can solve problems such as inability to test operations, and achieve the effect of saving operation time, optimizing operation time, and saving oil testing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

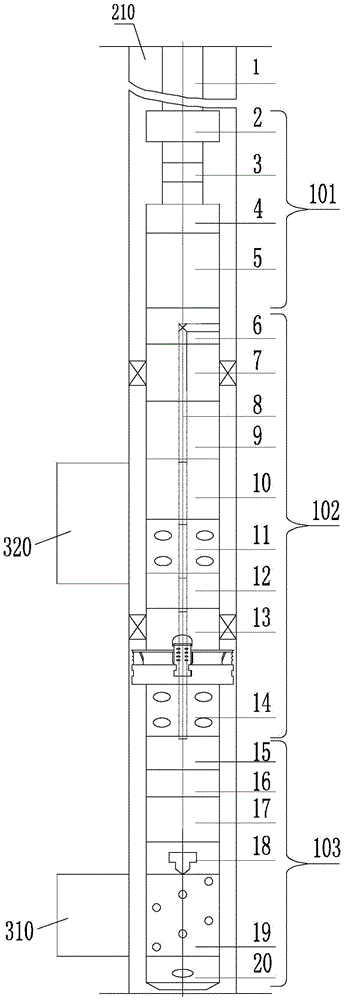

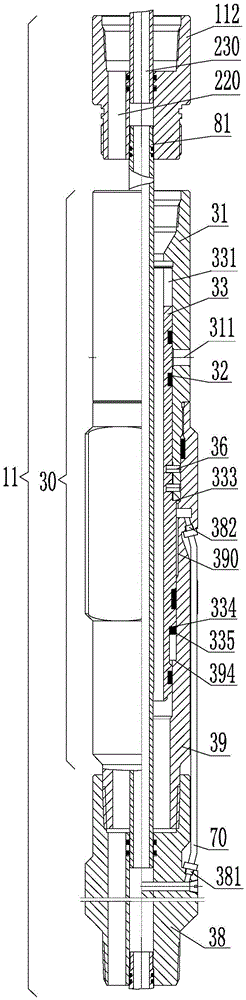

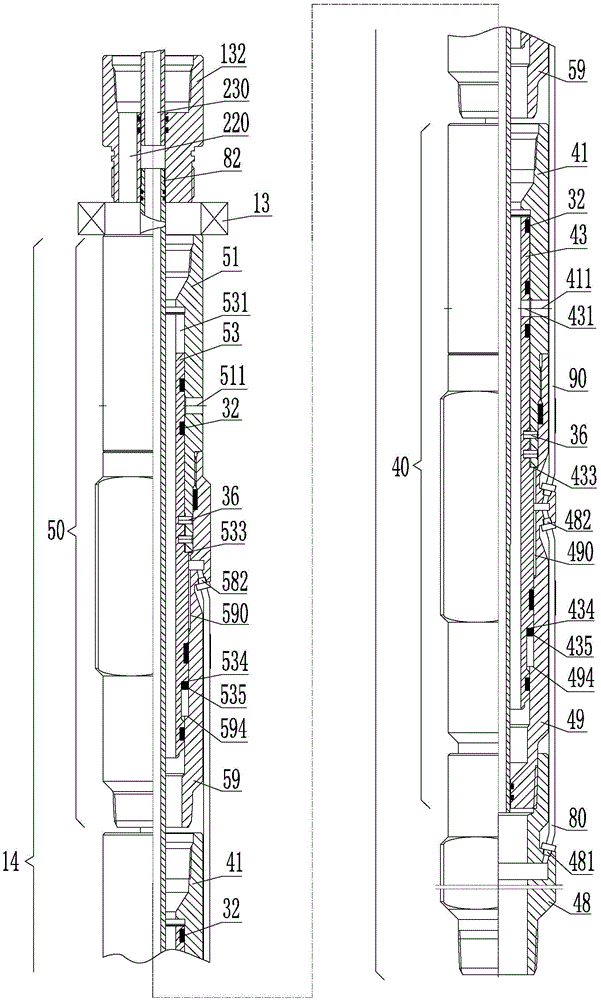

[0064] Please combine figure 1 with figure 2 As shown, a layered continuous oil testing system of the present invention is placed in the casing at intervals, and an oil jacket annulus 210 is formed between the layered continuous oil testing system and the casing. The layered continuous oil testing system includes top to bottom The drainage test assembly 101 , the straddle assembly 102 and the perforation assembly 103 are connected in sequence, and the through chamber provided in the drainage test assembly 101 communicates with the through chamber provided in the span assembly 102 to form a production channel 220 .

[0065] The straddle assembly 102 includes a pressure transmission joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com