Portable machine tool with striker capture device and/or striker damping device

A machine tool, portable technology, applied in the field of hammer drill or impact hammer, can solve the problems of low quality, damaged hammer drill or impact drill, etc., and achieve the effect of simple installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

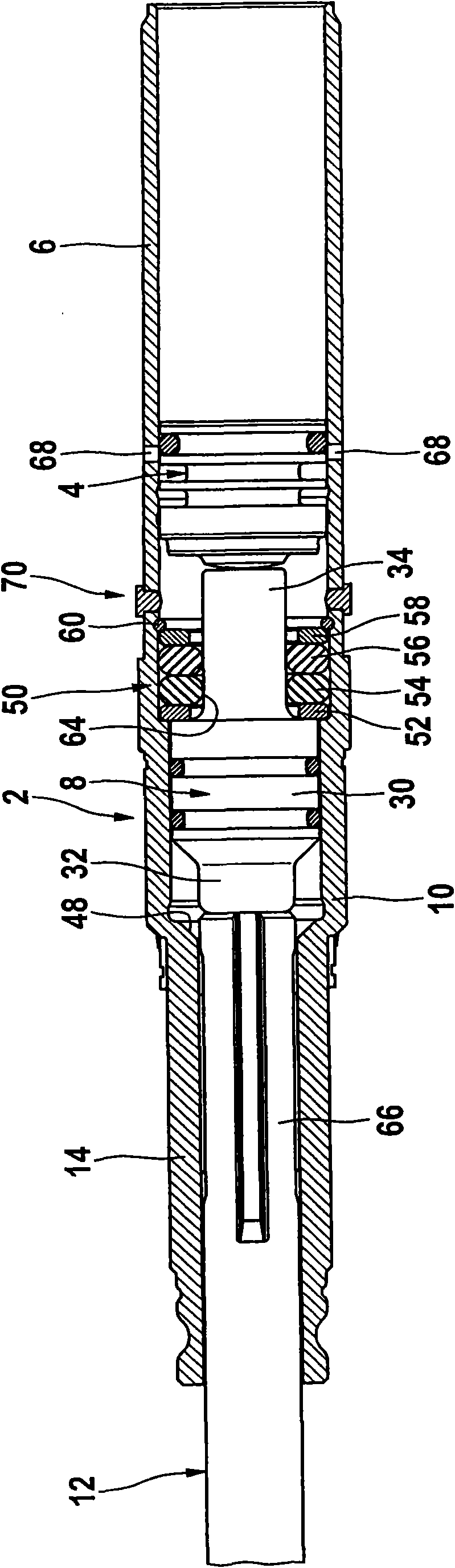

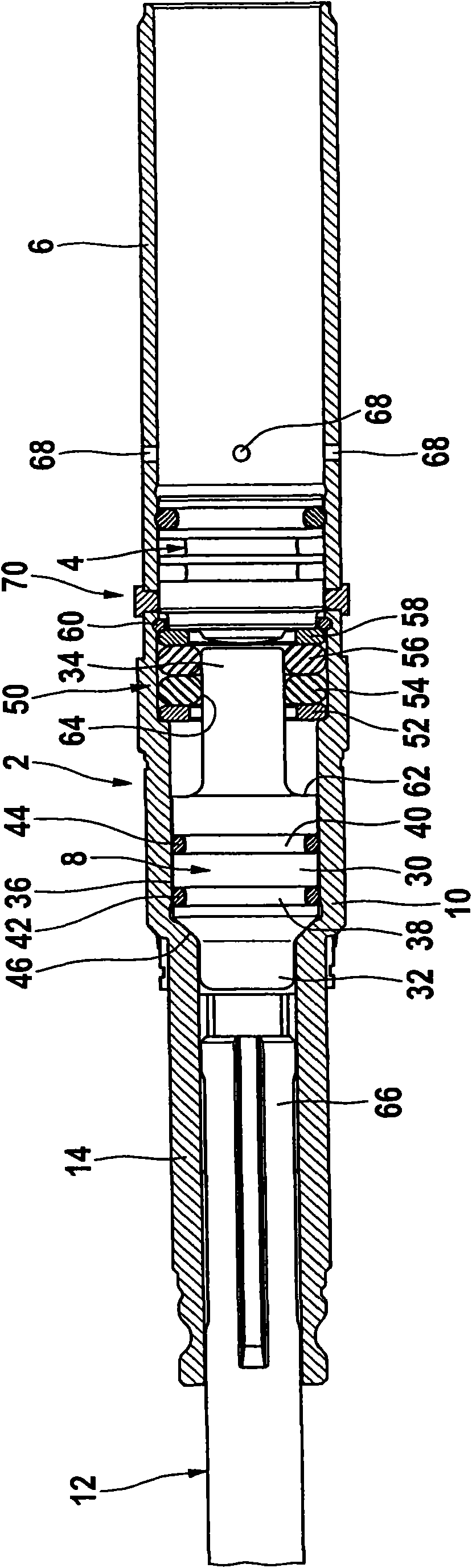

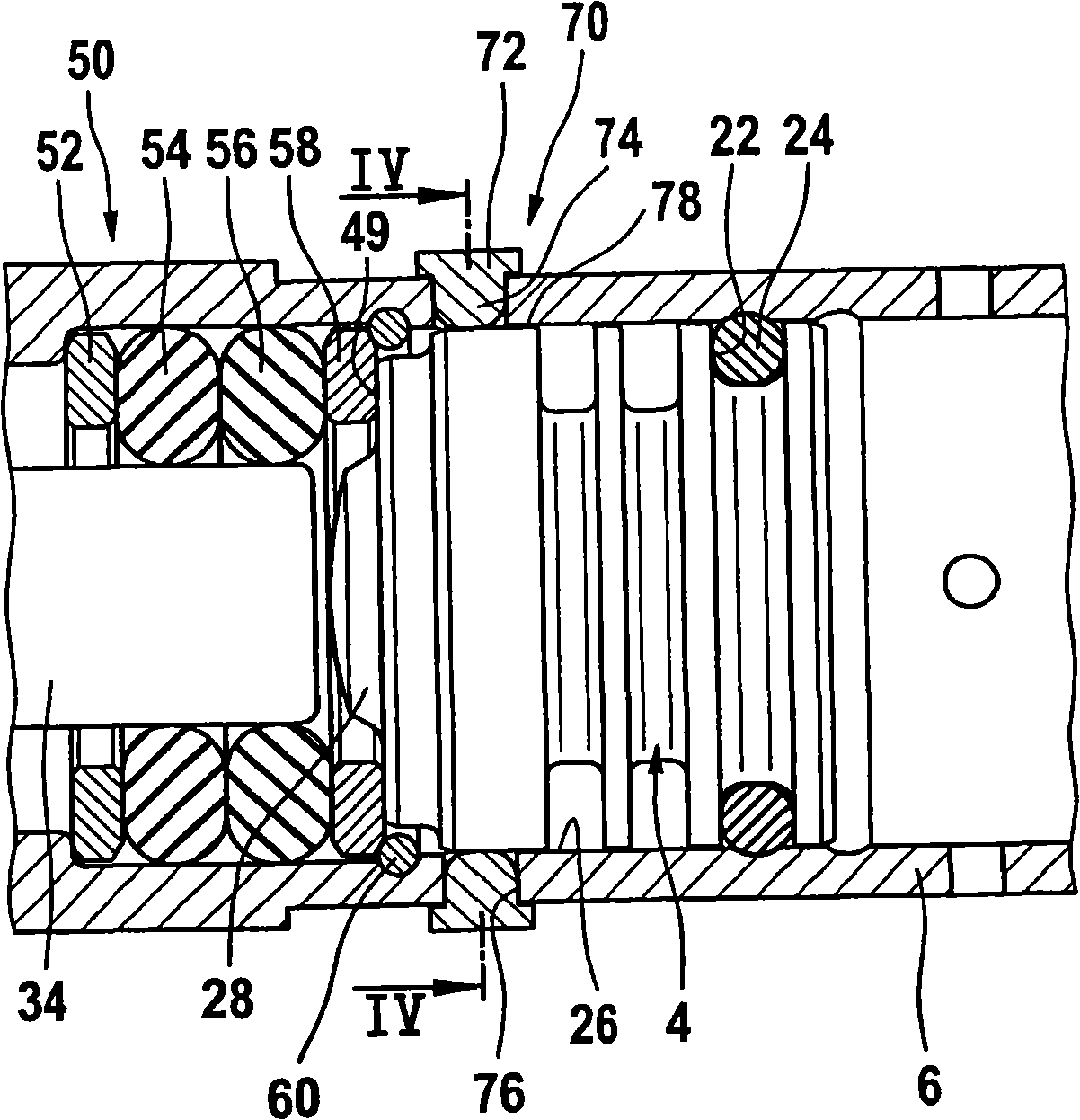

[0025] The hammer drill or percussion hammer, which is only partly shown in the figures, comprises an elongately extending hammer tube 2 with a hammering part 4 serving as the striking mechanism (not shown) of the hammer drill or percussion hammer Guided, rear section 6 with a large inner diameter; a middle section 10 with a slightly smaller inner diameter used as a guide for the impact pin 8 or punch of the impact mechanism and a middle section 10 used as a drilling tool or The front section of the tool receptacle of the chisel tool 12 has an even smaller inner diameter. The striker 4 , the striker bolt 8 and the drilling or chiseling tool 12 are each dimensioned such that they are guided axially movable within the associated section 6 , 10 or 14 of the hammer tube 2 .

[0026] Such as Figures 3 to 8 As shown most clearly in , the hammer 4 has a cylindrical outer peripheral surface 16 whose outer diameter is adapted to the inner diameter of the rear section 6 of the hammer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com