Patents

Literature

292results about How to "Short installation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

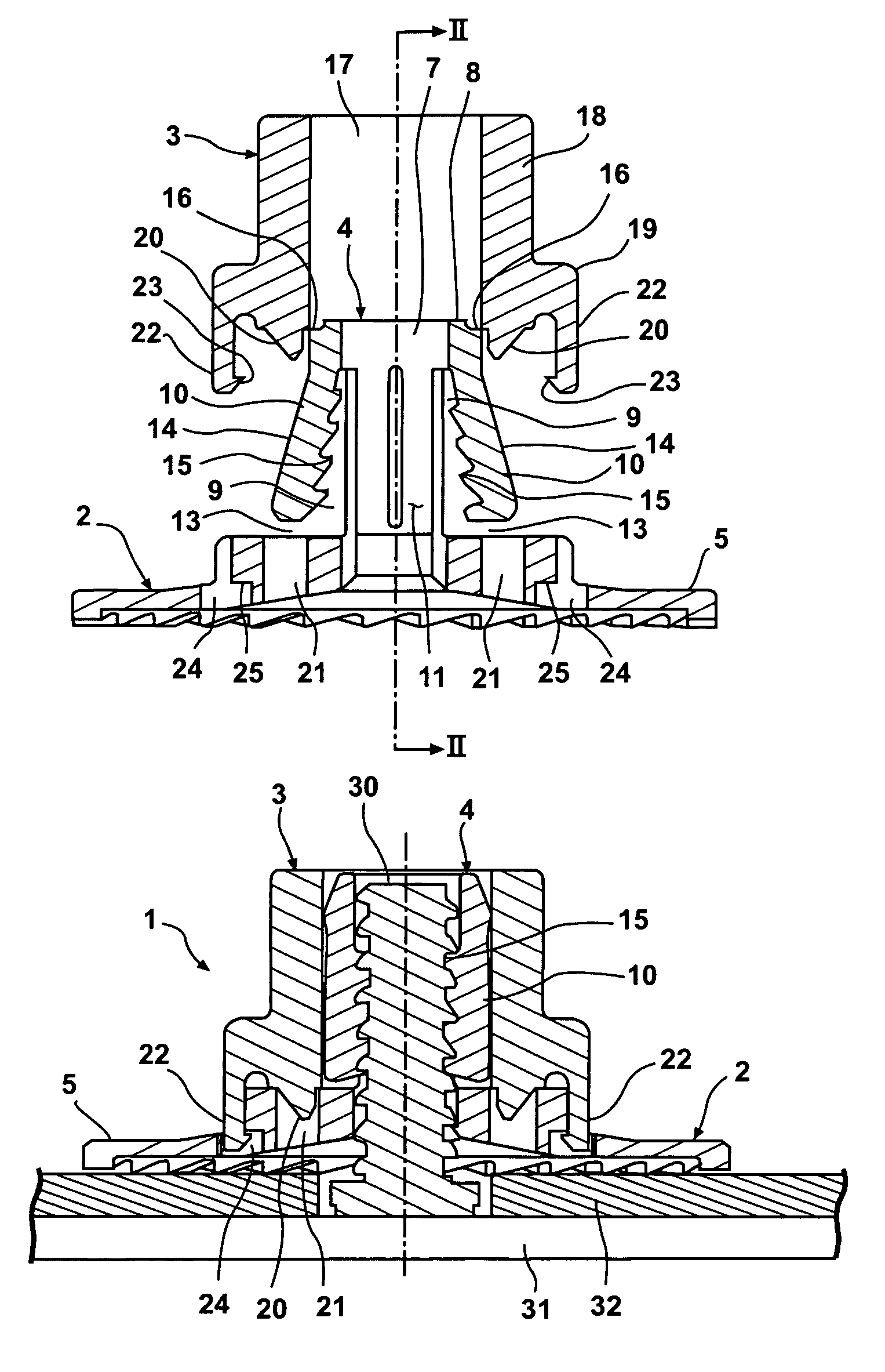

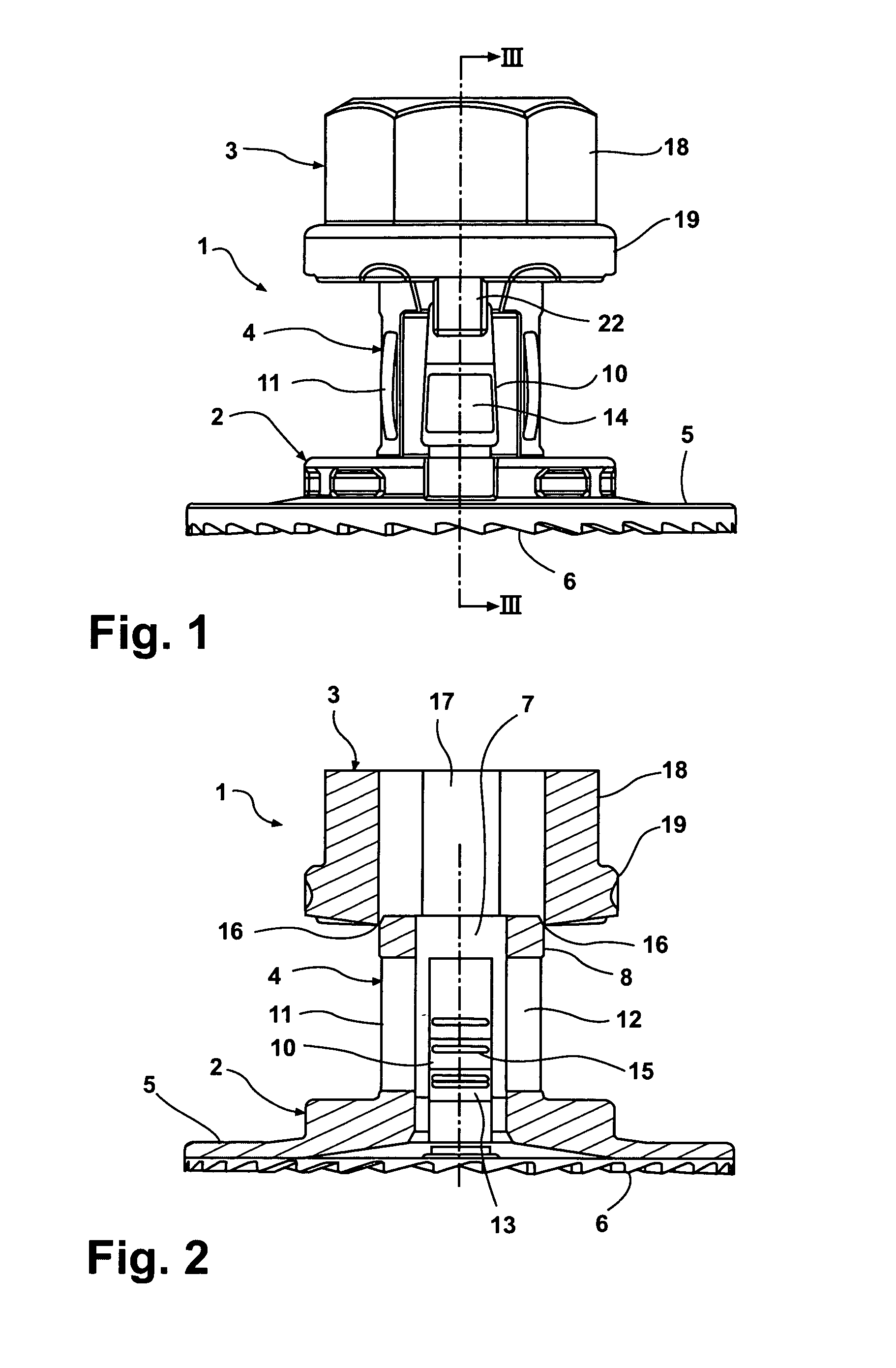

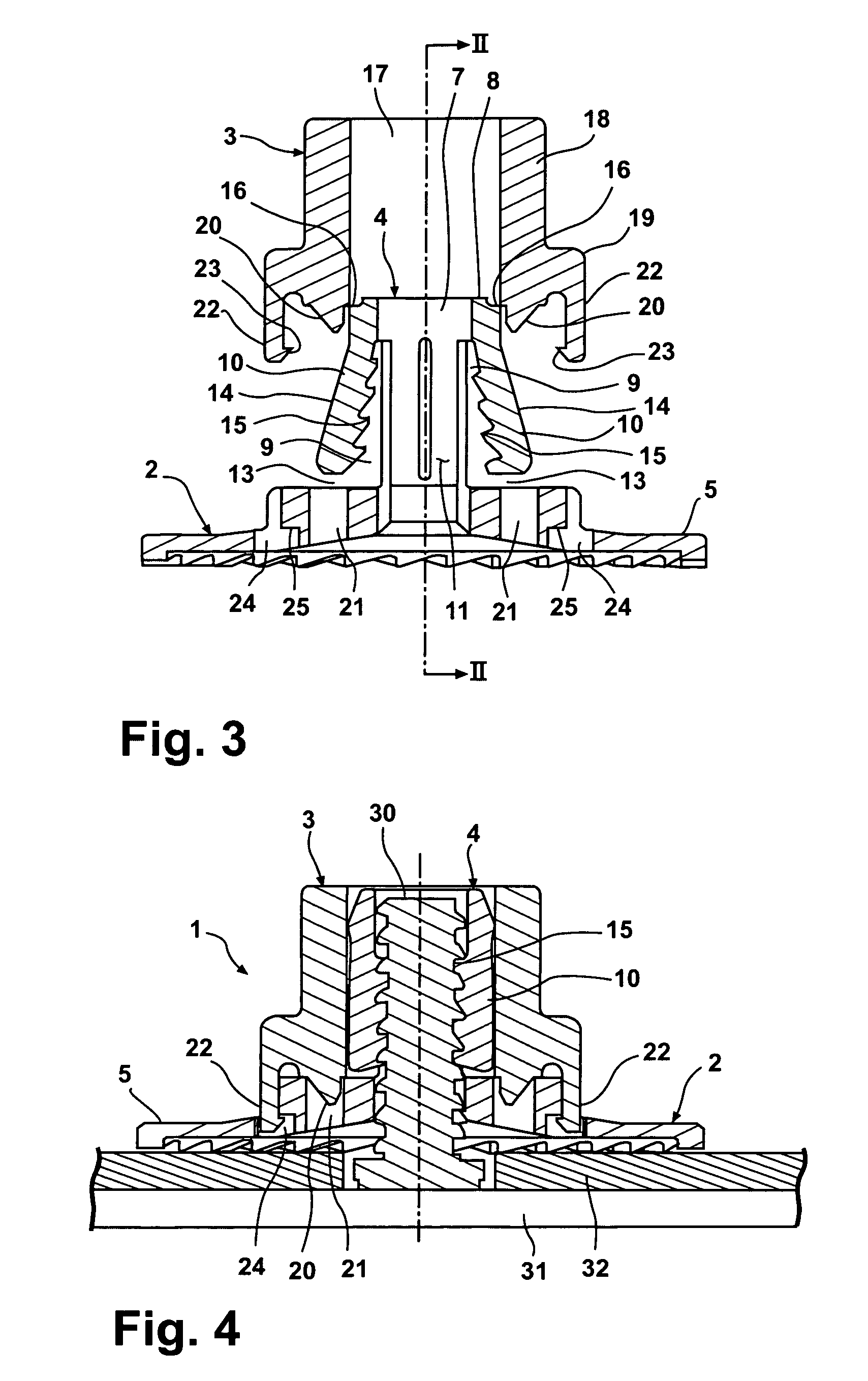

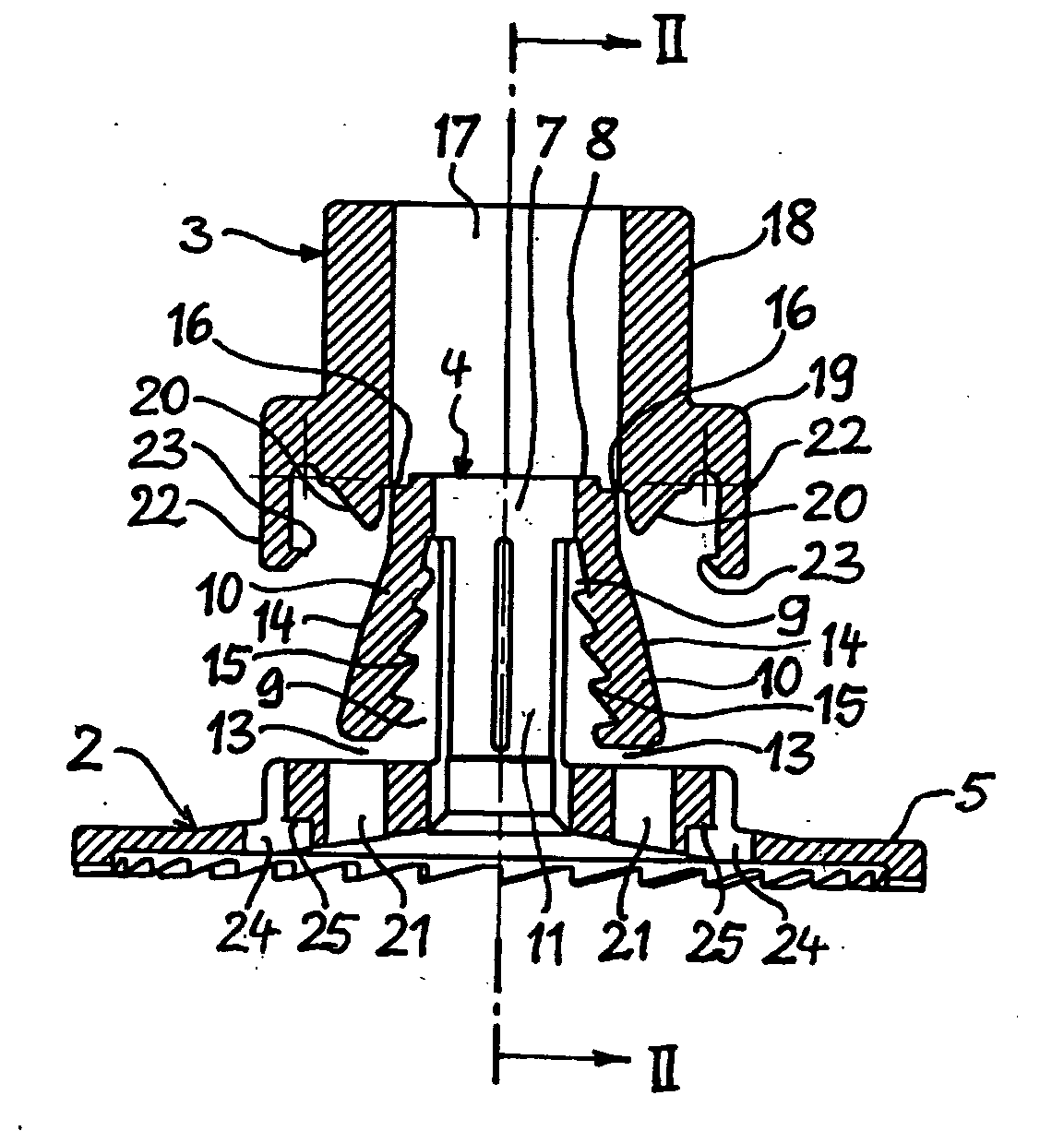

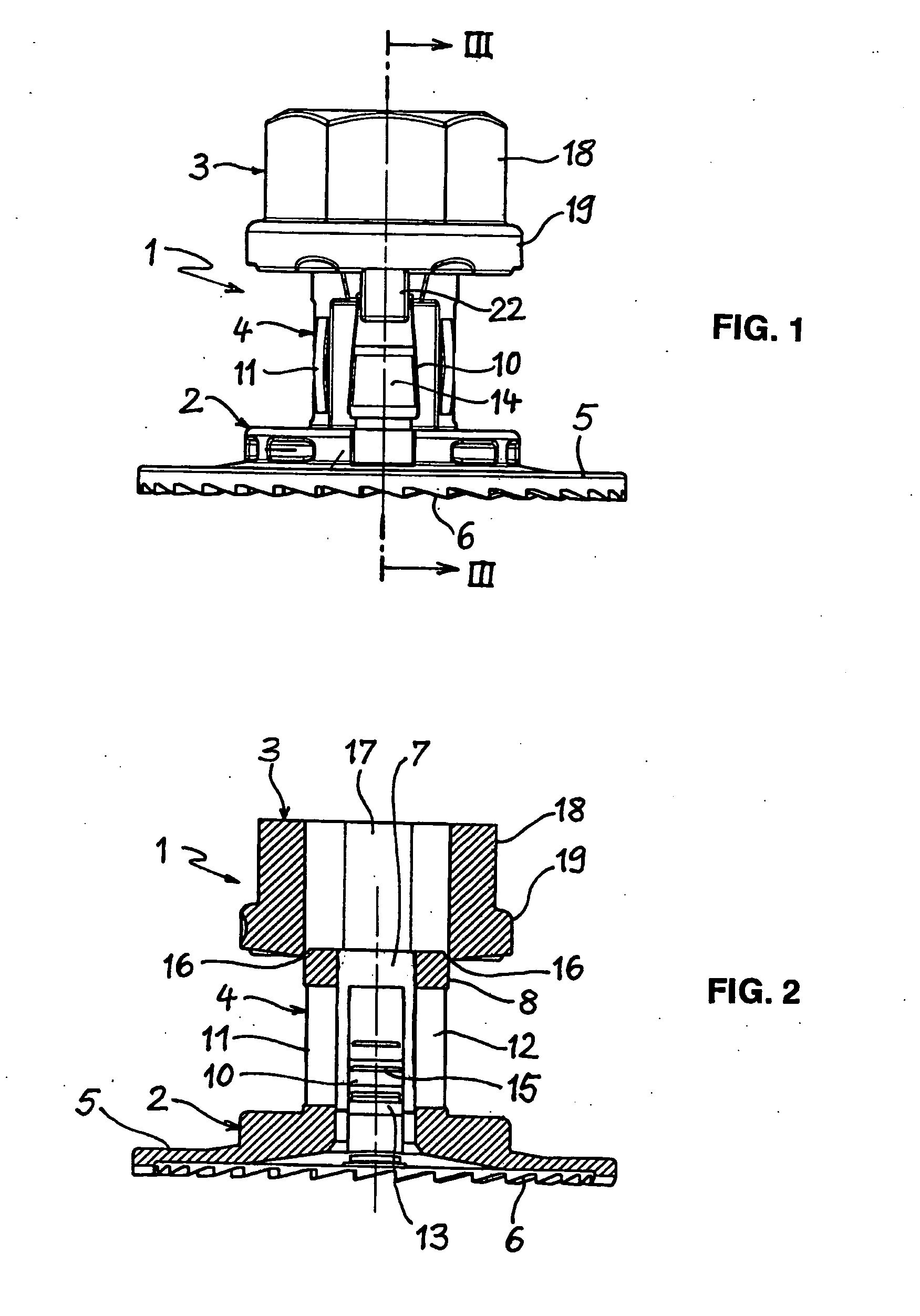

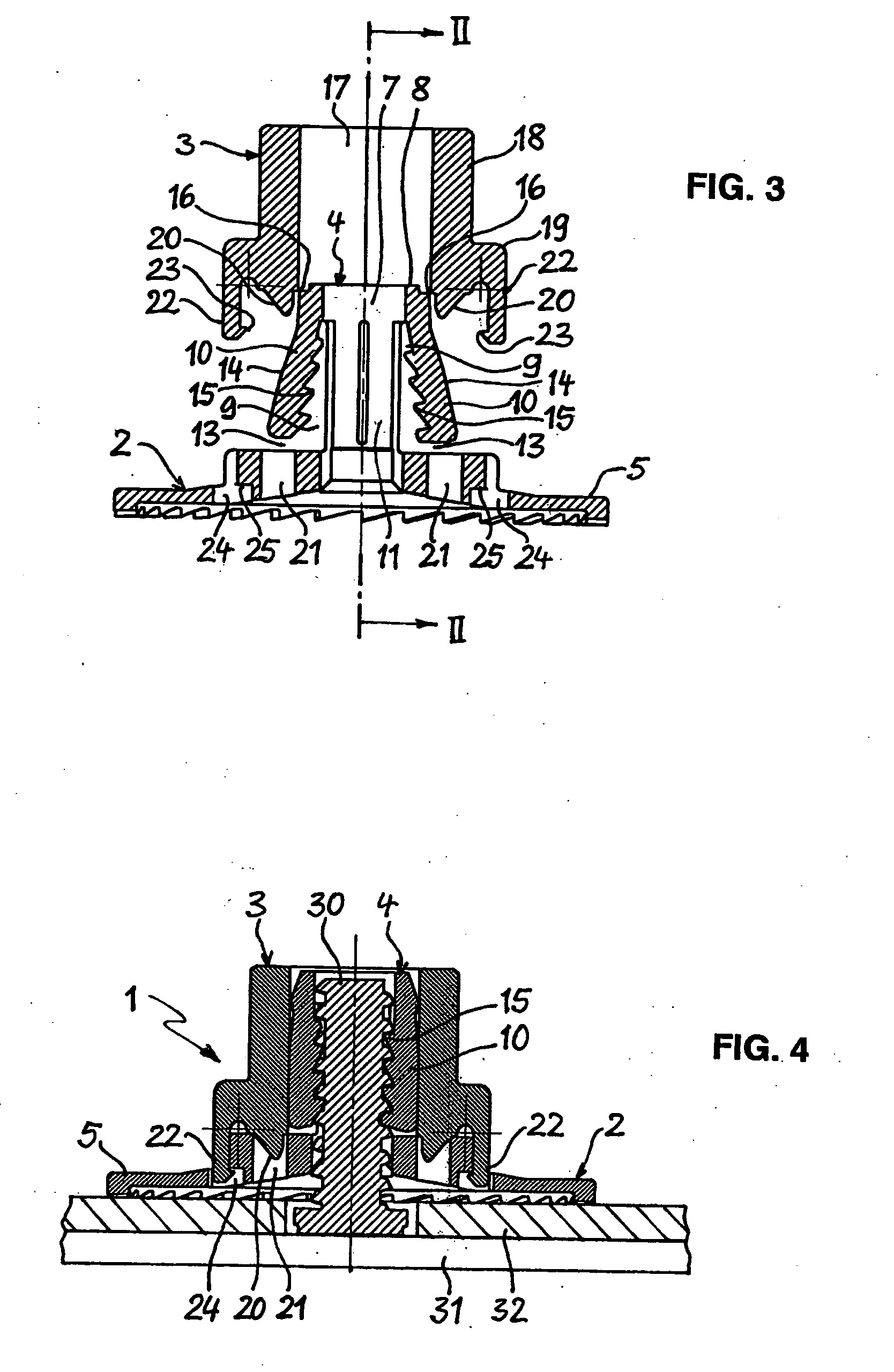

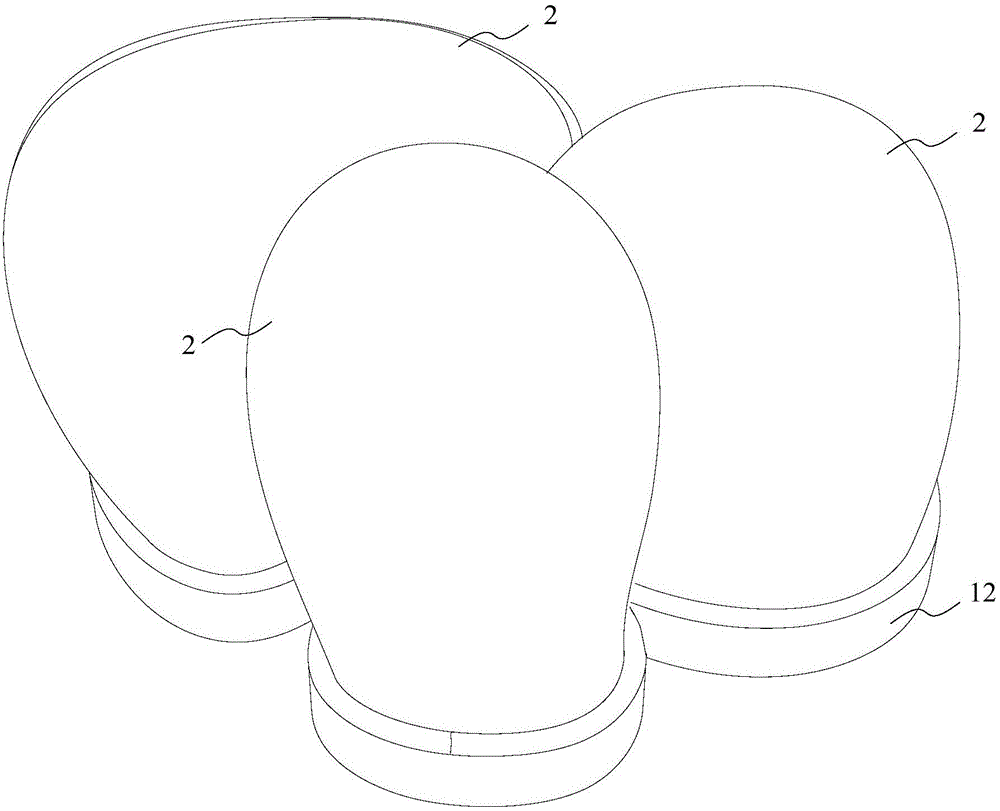

Fastener for application to a threaded stud

A fastener includes a sleeve-like clamping element having a cavity extending in the direction of its longitudinal axis which accommodates a threaded stud. At least one clamping region is deformable into the cavity forming at least one clamping ramp inclined toward the longitudinal axis on an outside of the clamping element. A clamping sleeve pushed onto the clamping element in an installed state grips around the clamping element. A clamping sleeve inner surface cooperates with the clamping ramp so the clamping region reaches a clamping position deformed into the cavity to hold the threaded stud. The clamping element has a forward end flange in an installation direction. Coupling elements and mating coupling elements arranged on the flange and a clamping sleeve end facing the flange interlock in the installed state, preventing rotation between the clamping sleeve and clamping element.

Owner:NEWFREY

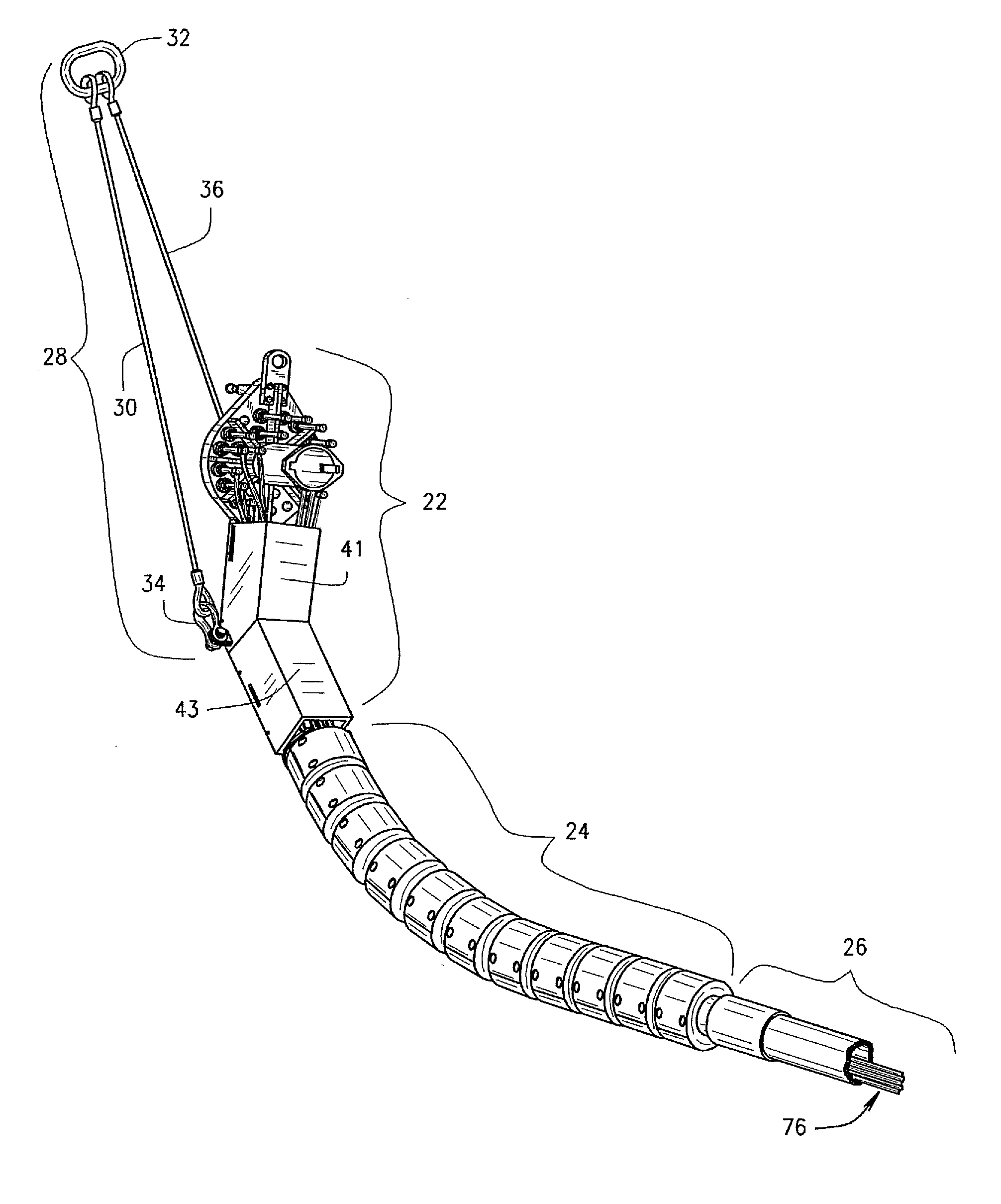

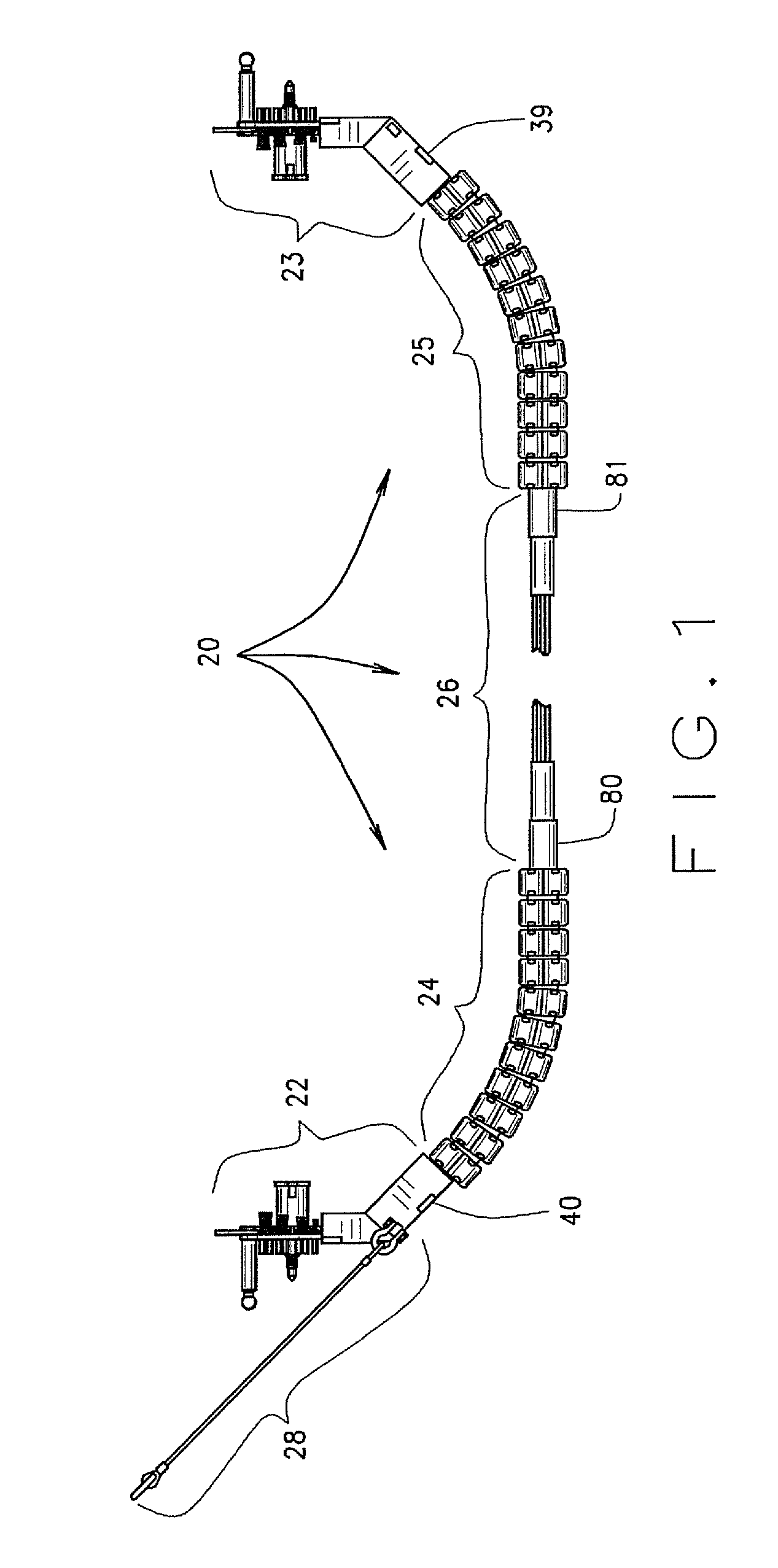

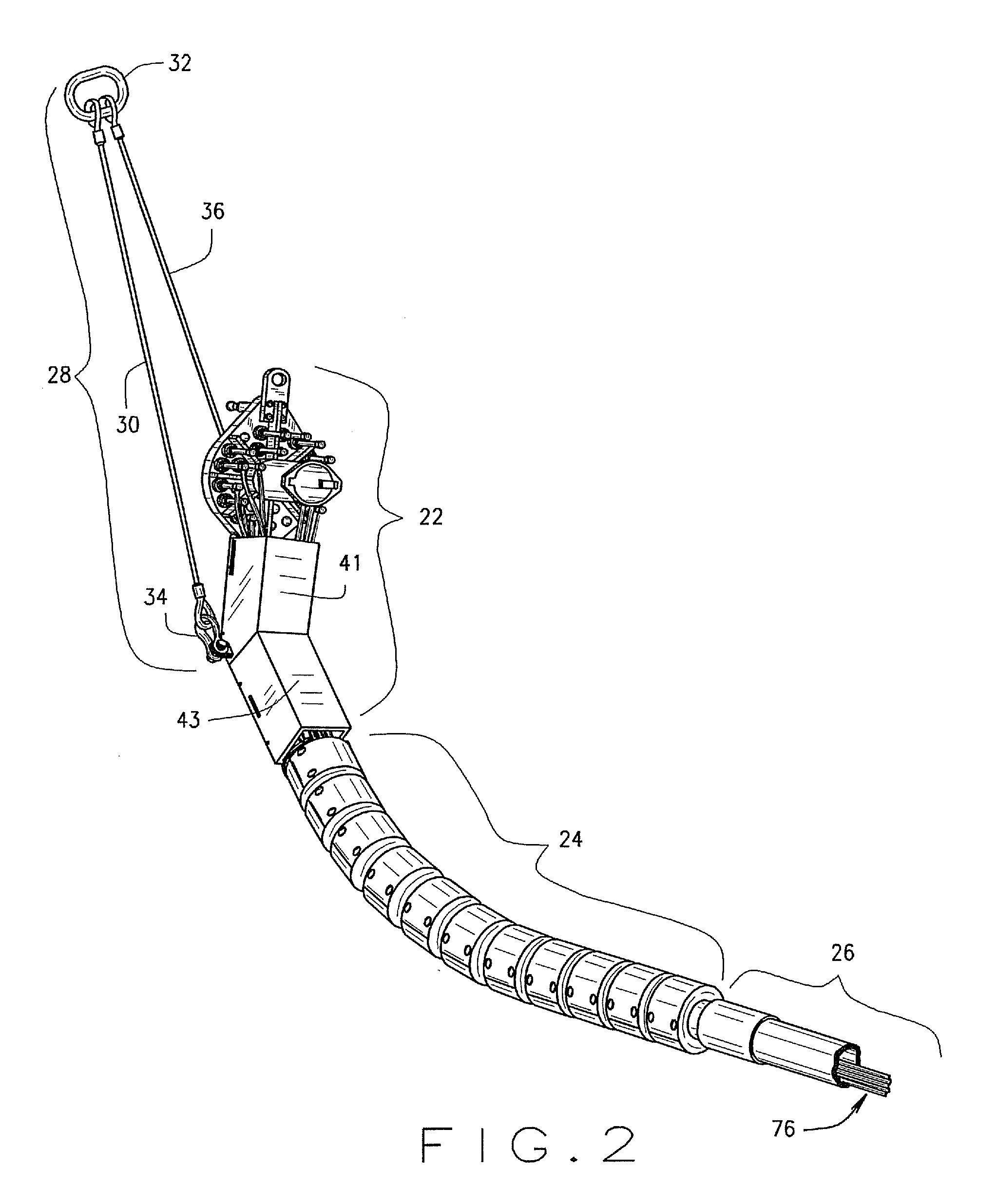

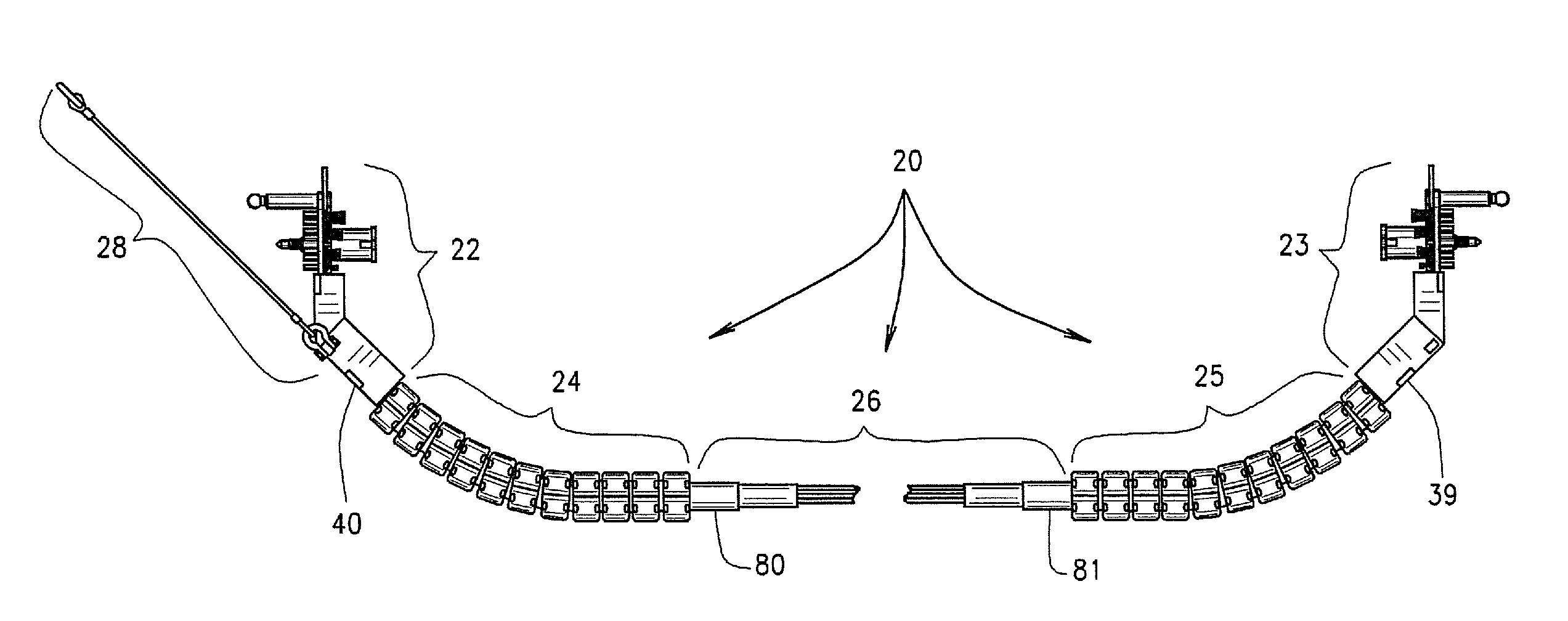

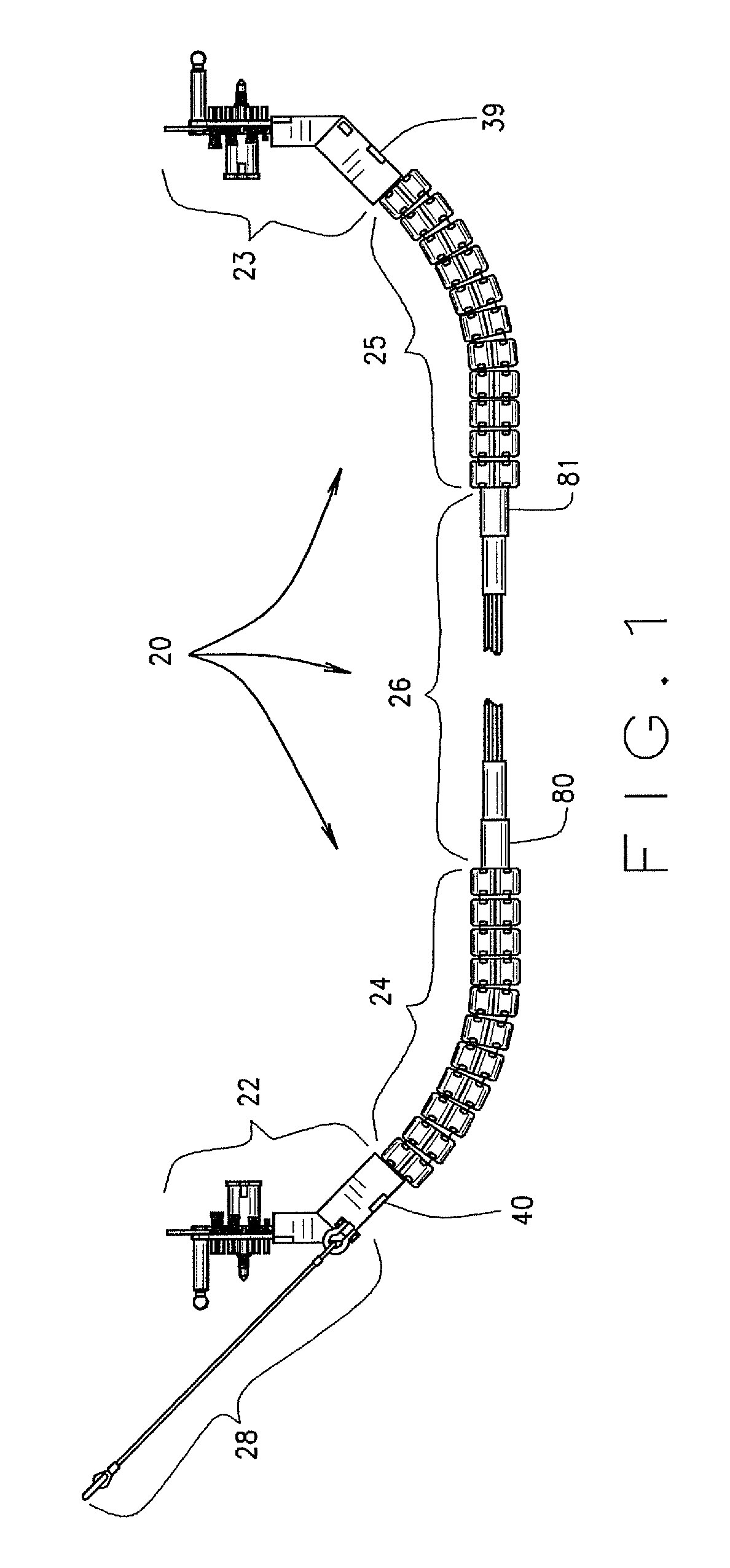

Loose tube flying lead assembly

InactiveUS20100059229A1Adequate movementPrevents unwanted exposureDrilling rodsFluid removalGuide tubeBiomedical engineering

In combination, the loose tube flying lead includes: a) a pair of improved cobra head assemblies, each being able to receive a variety of different stab-plates with minimal modification; b) a pair of bend limiters, one extending from each cobra head assembly and c) an elongate bundle of non-constrained interior conduits surrounded by an over-hose, the over-hose being connected to each bend limiter. The over-hose may rotate independently of the bend limiters and the cobra head assemblies.

Owner:DEEP DOWN INC

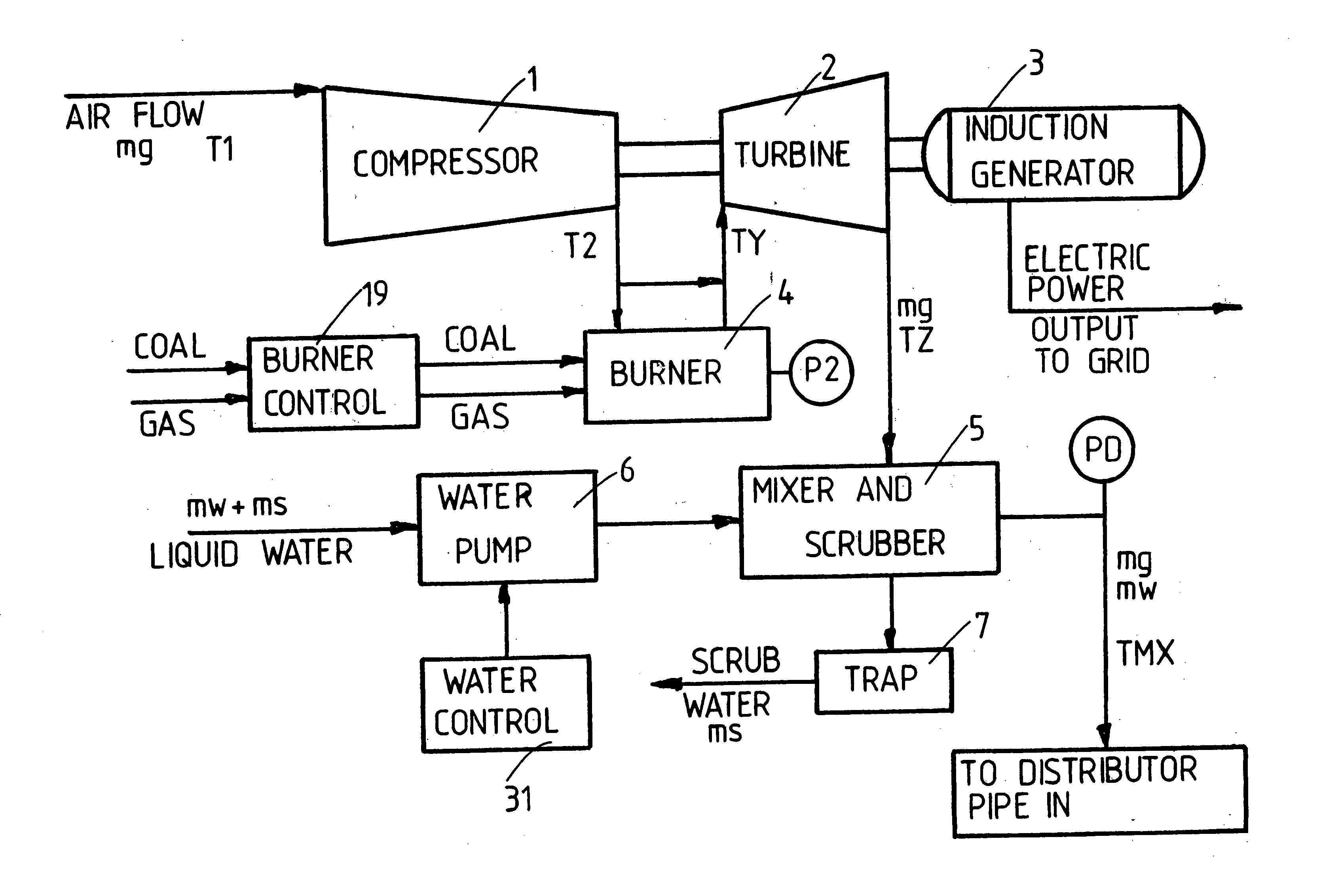

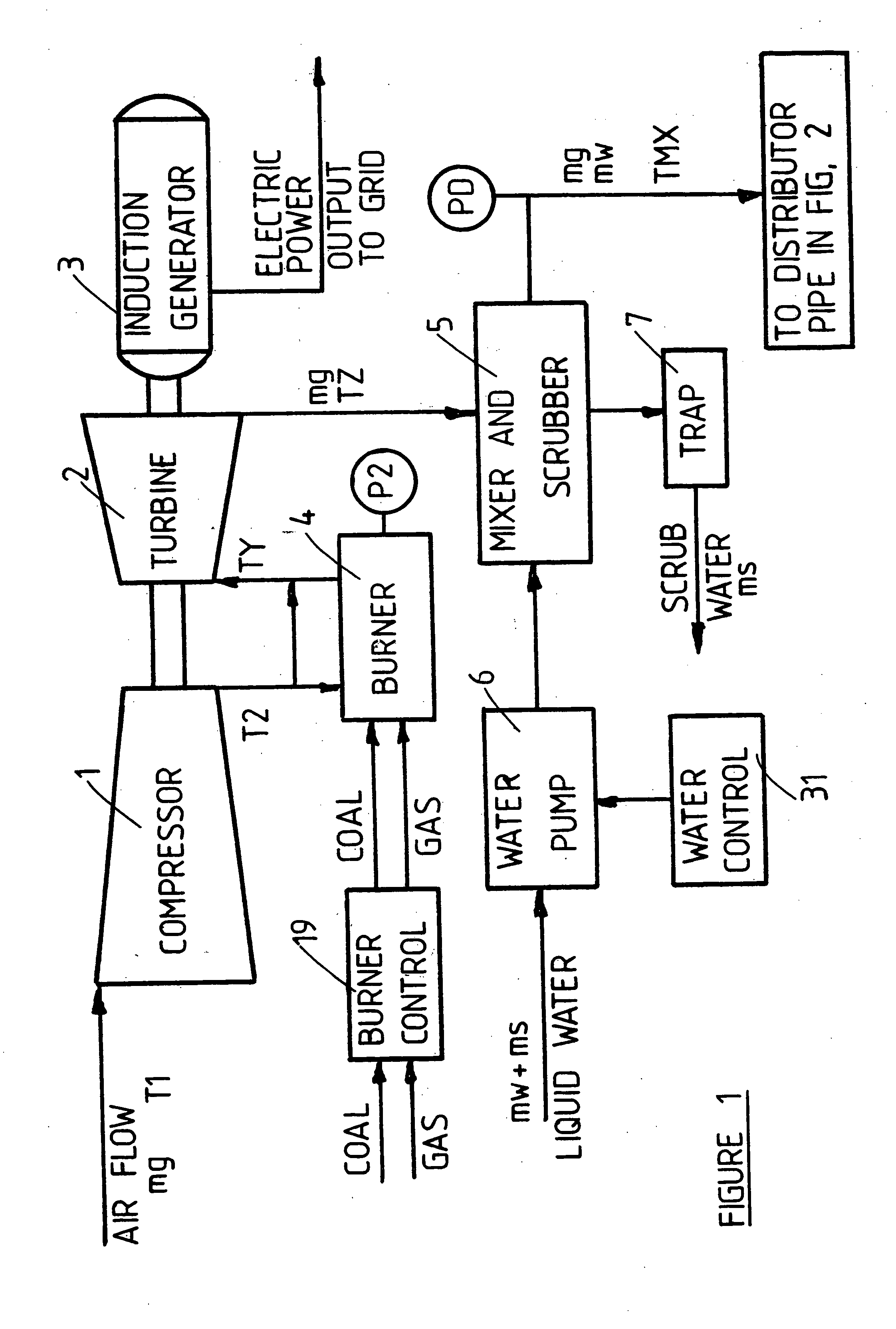

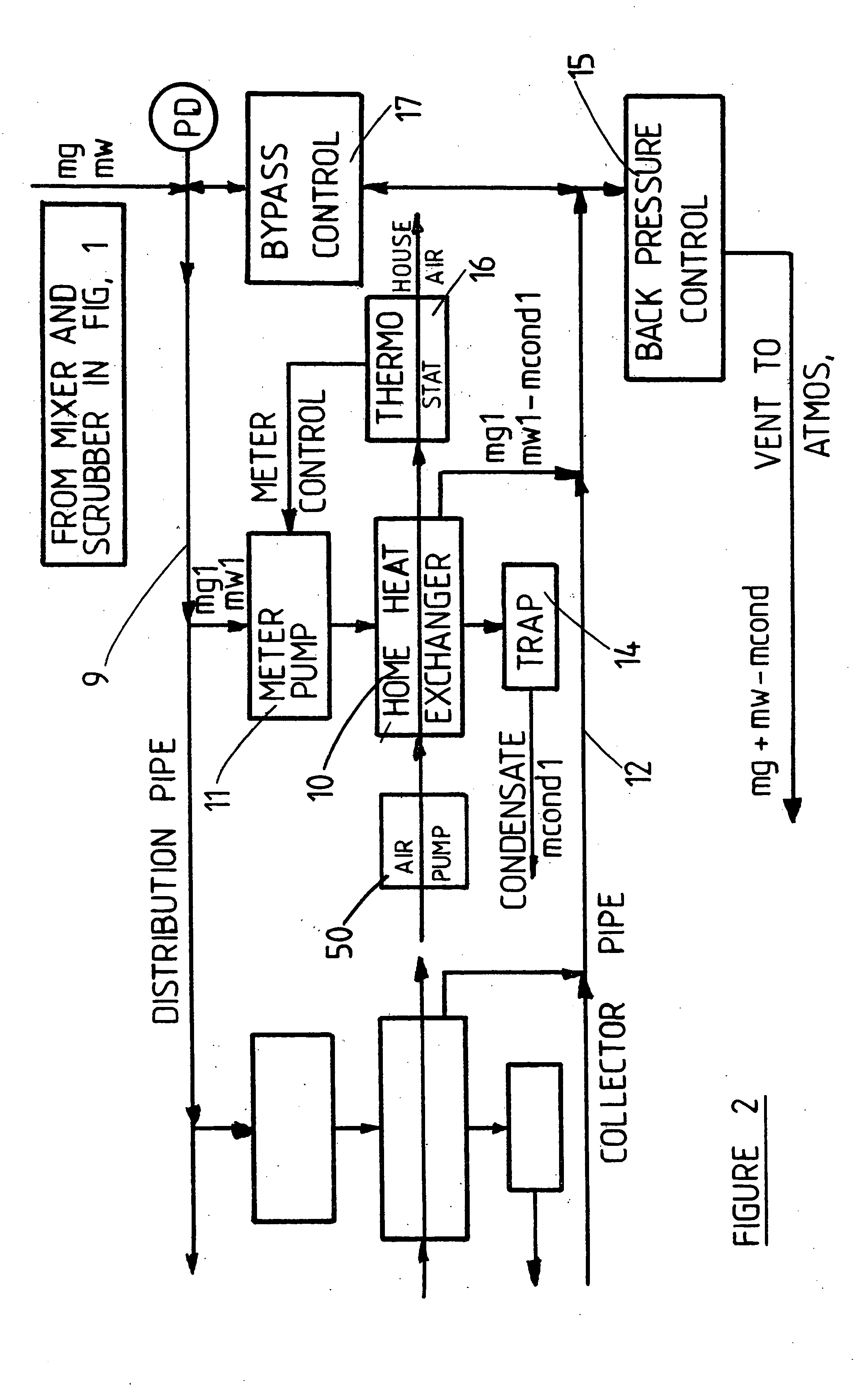

Coal fired gas turbine for district heating

InactiveUS20060207262A1Reduce personnel costsLower cost of capitalGas turbine plantsCombined combustion mitigationWater vaporEngineering

A district heating system is described, for heating several homes and businesses in a district. The hot exhaust gas, of a gas turbine engine, is saturated with water vapor, and then passed through each home heater, where condensation of the water vapor provides heat to each home. With low cost coal fuel, burned in the gas turbine engine burner, a large portion of the fuel energy is efficiently utilized for home heating and electric power generation. In this way, low cost domestic coal can replace expensive imported petroleum fuels for home heating and electric power generation.

Owner:FIREY JOSEPH CARL

Loose tube flying lead assembly

InactiveUS8100182B2Improve serviceabilityReduce manufacturing costDrilling rodsFluid removalGuide tubeBiomedical engineering

In combination, the loose tube flying lead includes: a) a pair of improved cobra head assemblies, each being able to receive a variety of different stab-plates with minimal modification; b) a pair of bend limiters, one extending from each cobra head assembly and c) an elongate bundle of non-constrained interior conduits surrounded by an over-hose, the over-hose being connected to each bend limiter. The over-hose may rotate independently of the bend limiters and the cobra head assemblies.

Owner:DEEP DOWN INC

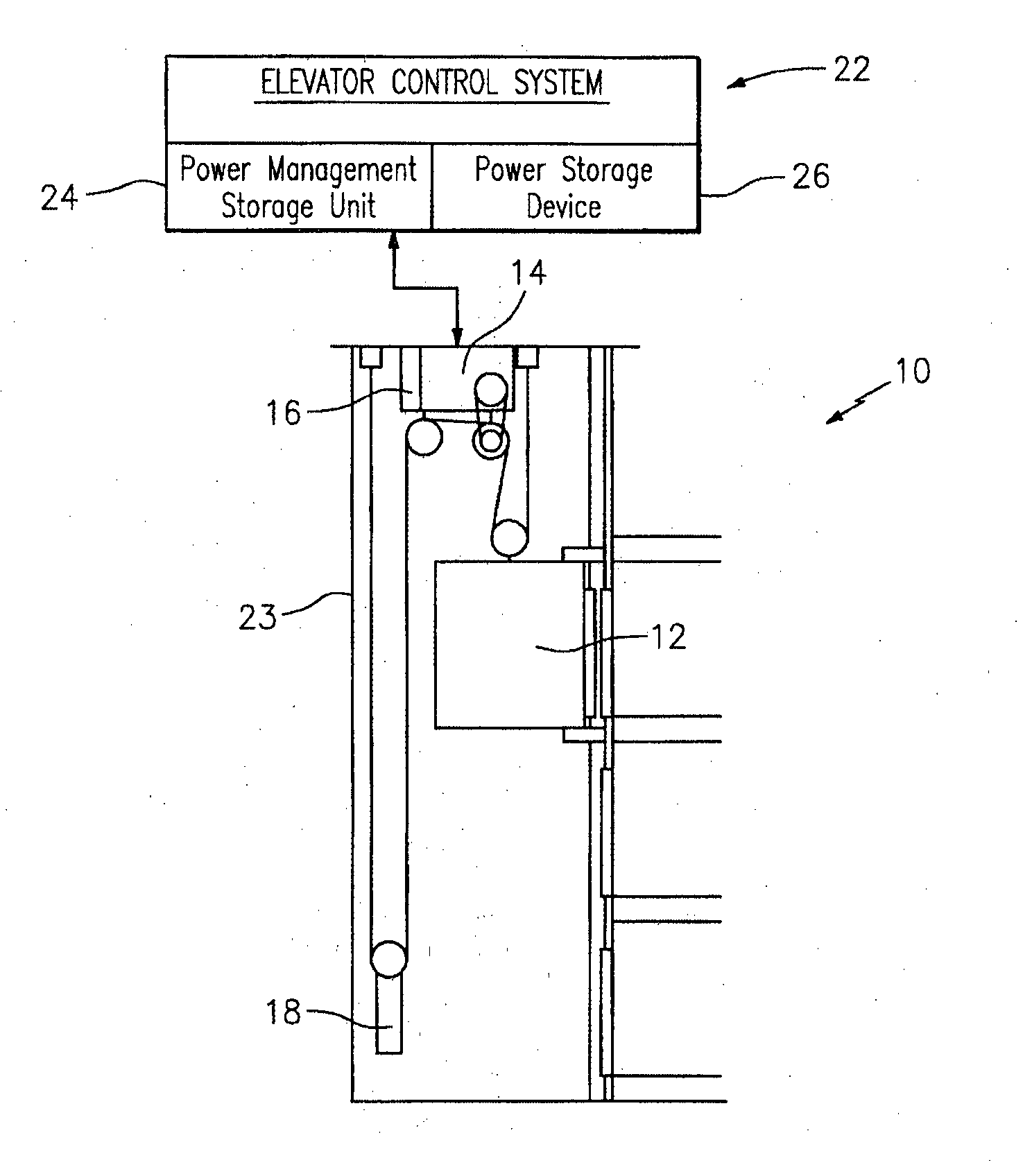

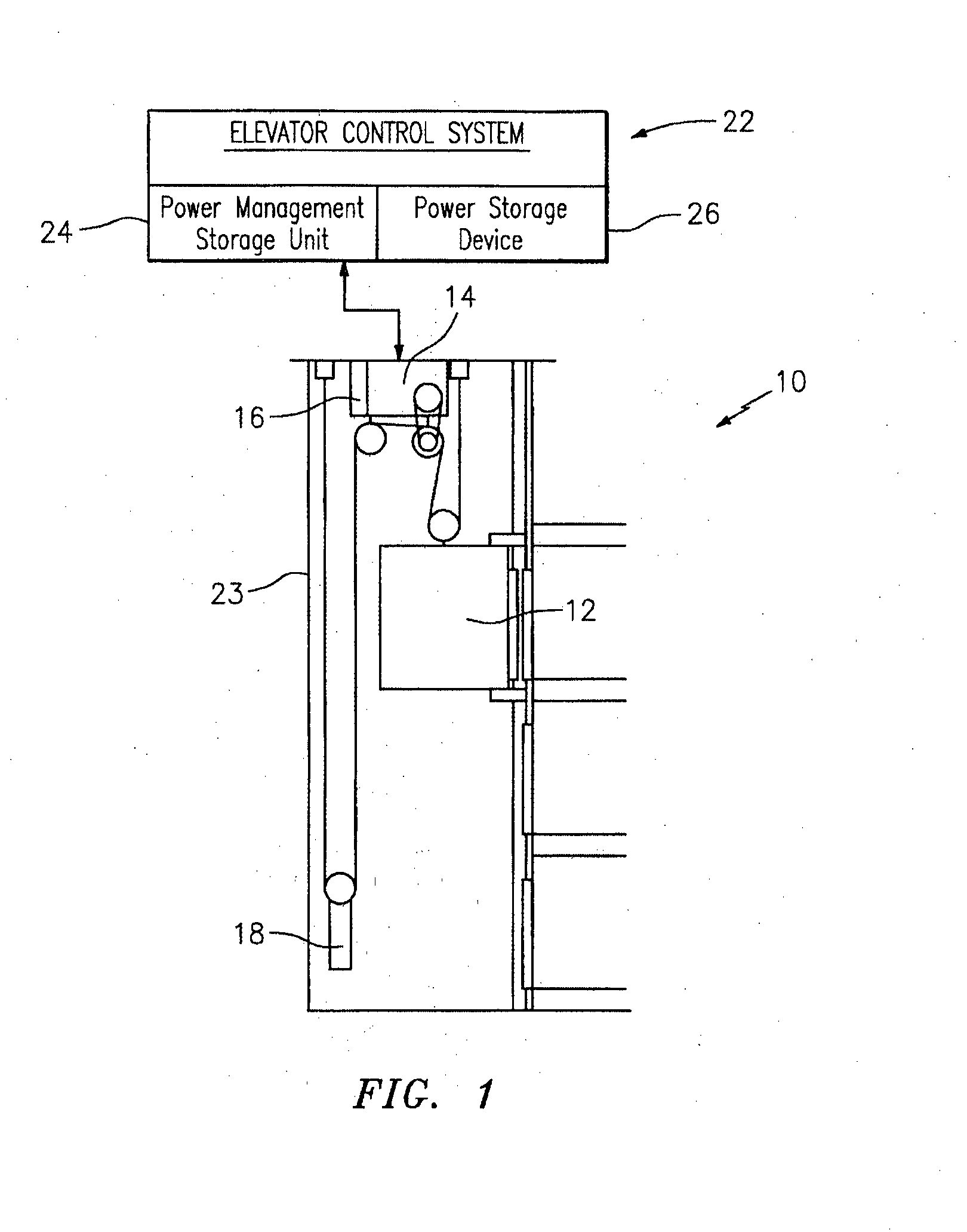

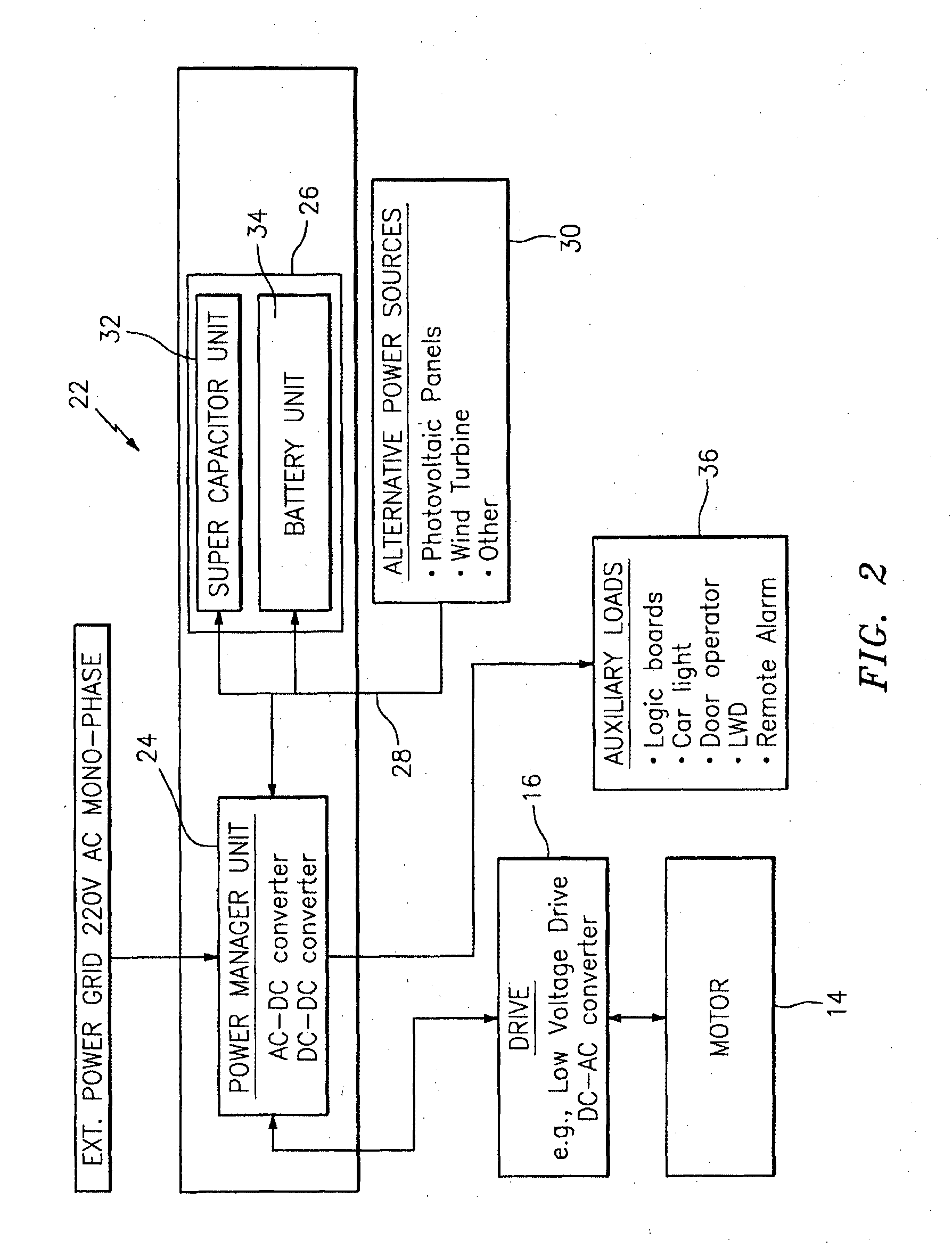

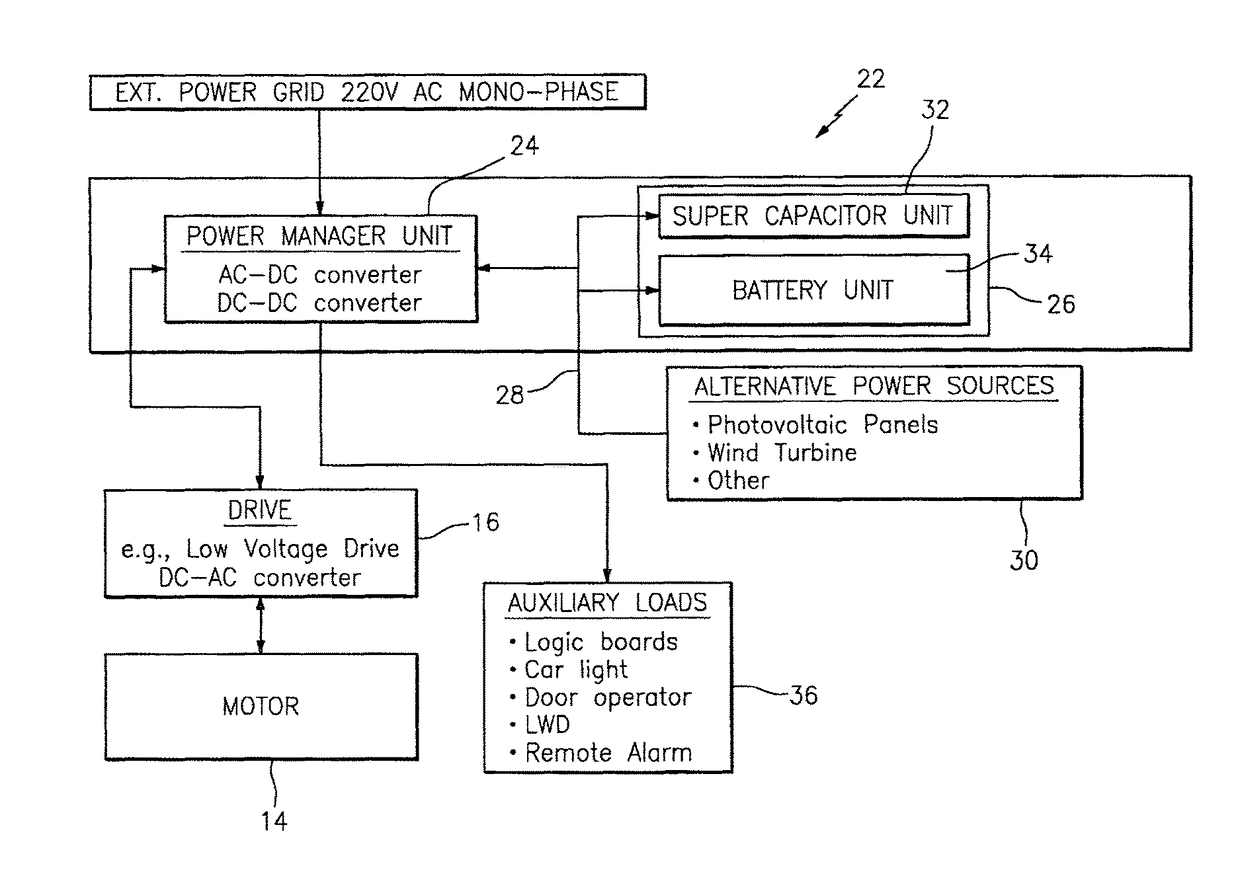

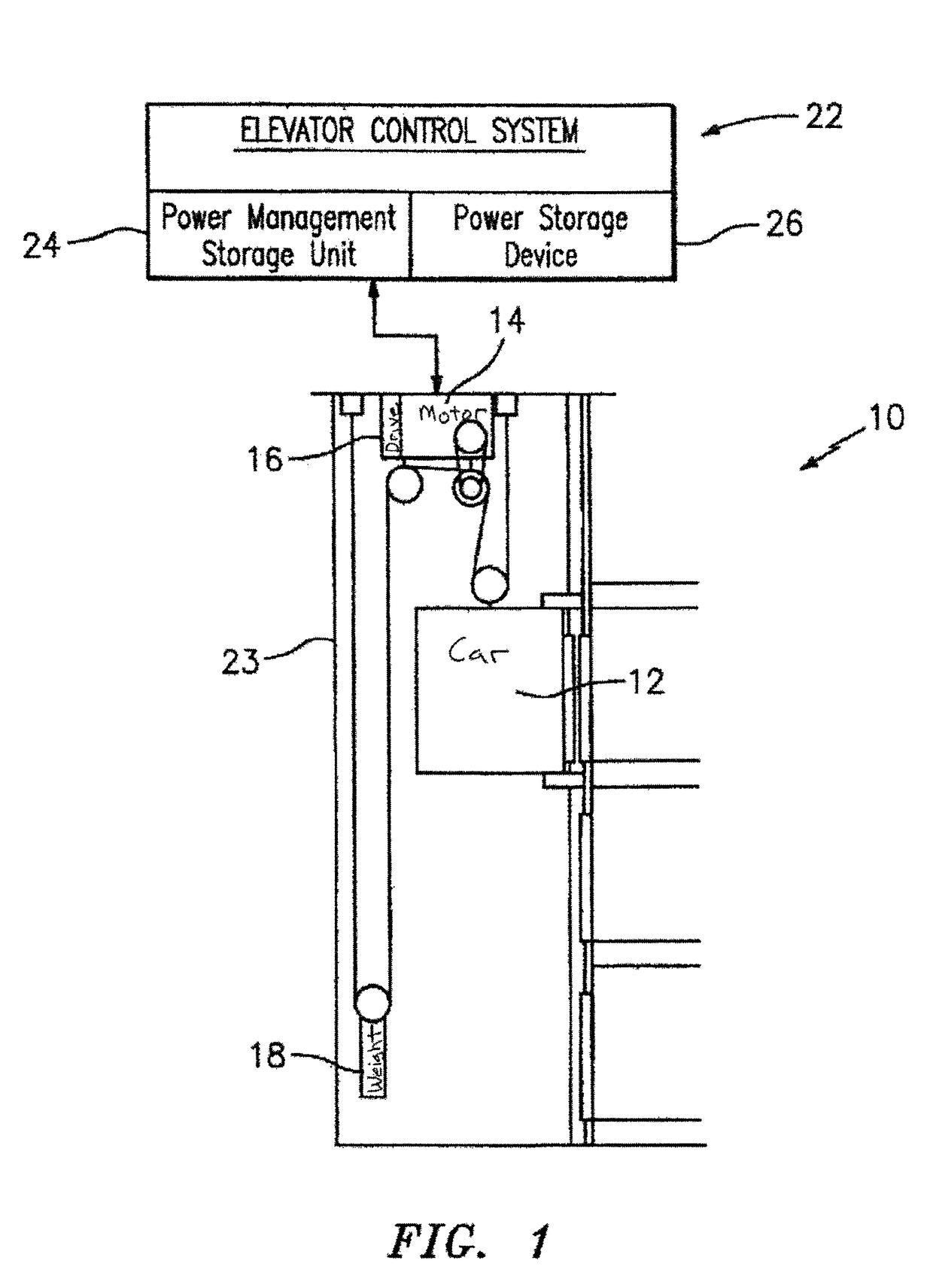

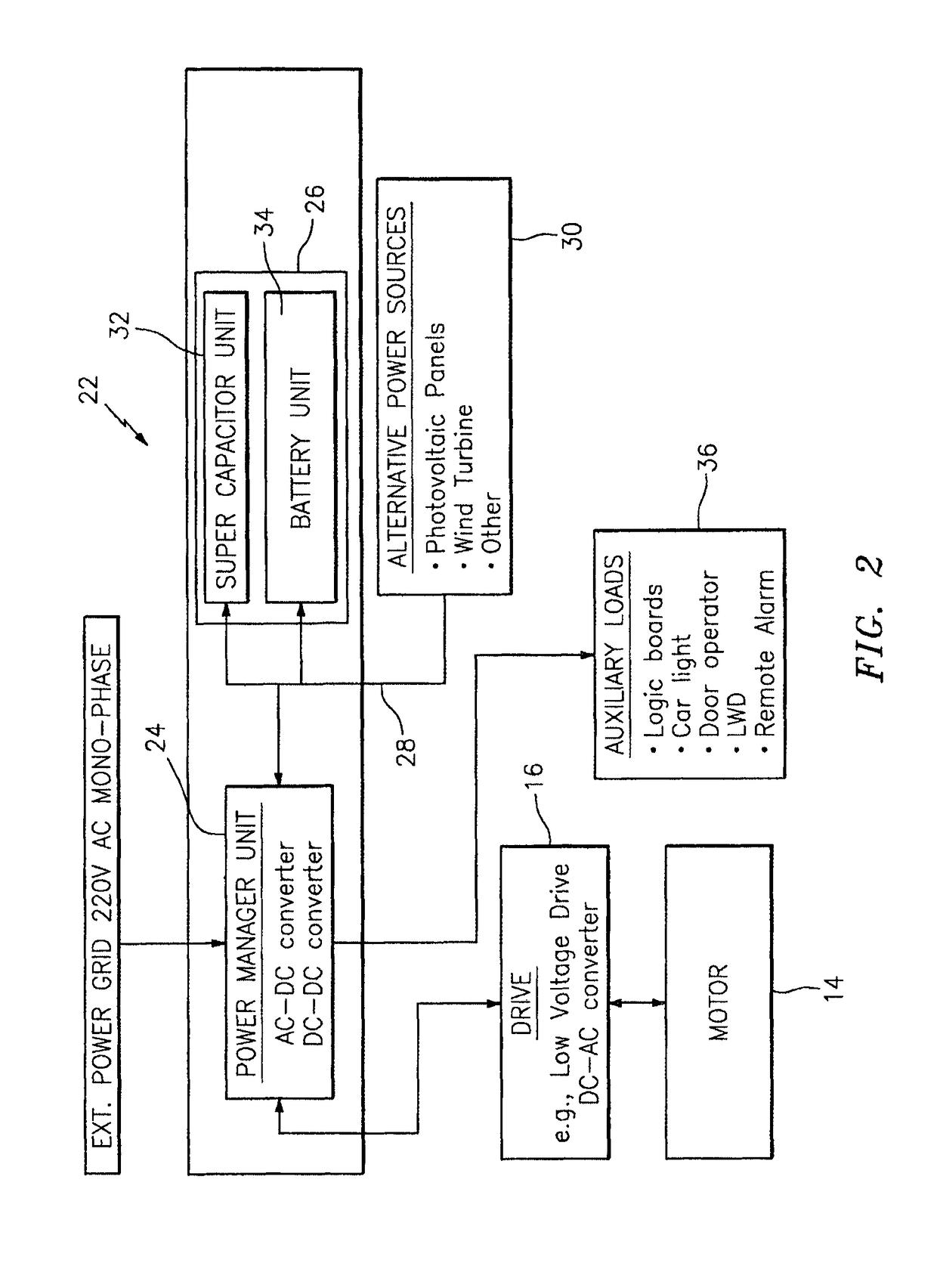

Elevator system with power storage device

ActiveUS20150122589A1Significant energy savingCompetitive costElevatorsMine liftsElectric powerElevator control system

An elevator system is provided that includes an elevator car (12), a counterweight (18), a load bearing flexible member, a motor have a drive, and an elevator control system (22). The car and counterweight are operable to be translated within a hoistway. The load bearing flexible member extends between the elevator car and the counterweight. The motor is operable to move the load bearing member and thereby drive the elevator car and counterweight within the hoistway. The elevator motor and drive are configured to selectively produce regenerative power. The elevator control system includes a power manager unit (24) and a power storage device (26). The power storage device includes a supercapacitor unit (32) and a battery unit (34). The power manager unit is operable to selectively manage the flow of power between the power storage device and the motor drive, and the flow of regenerative power from the motor drive to the power storage device (26).

Owner:OTIS ELEVATOR CO

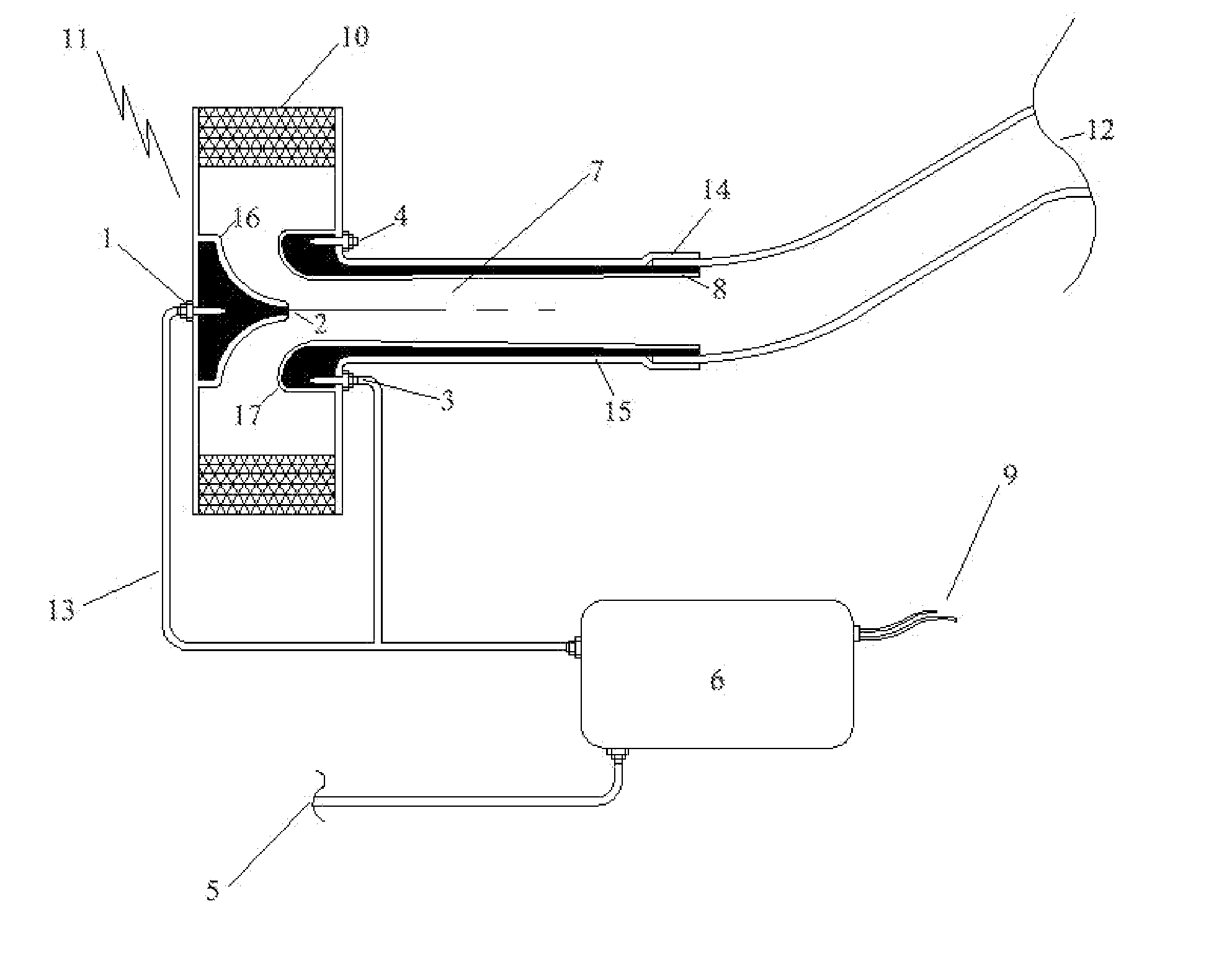

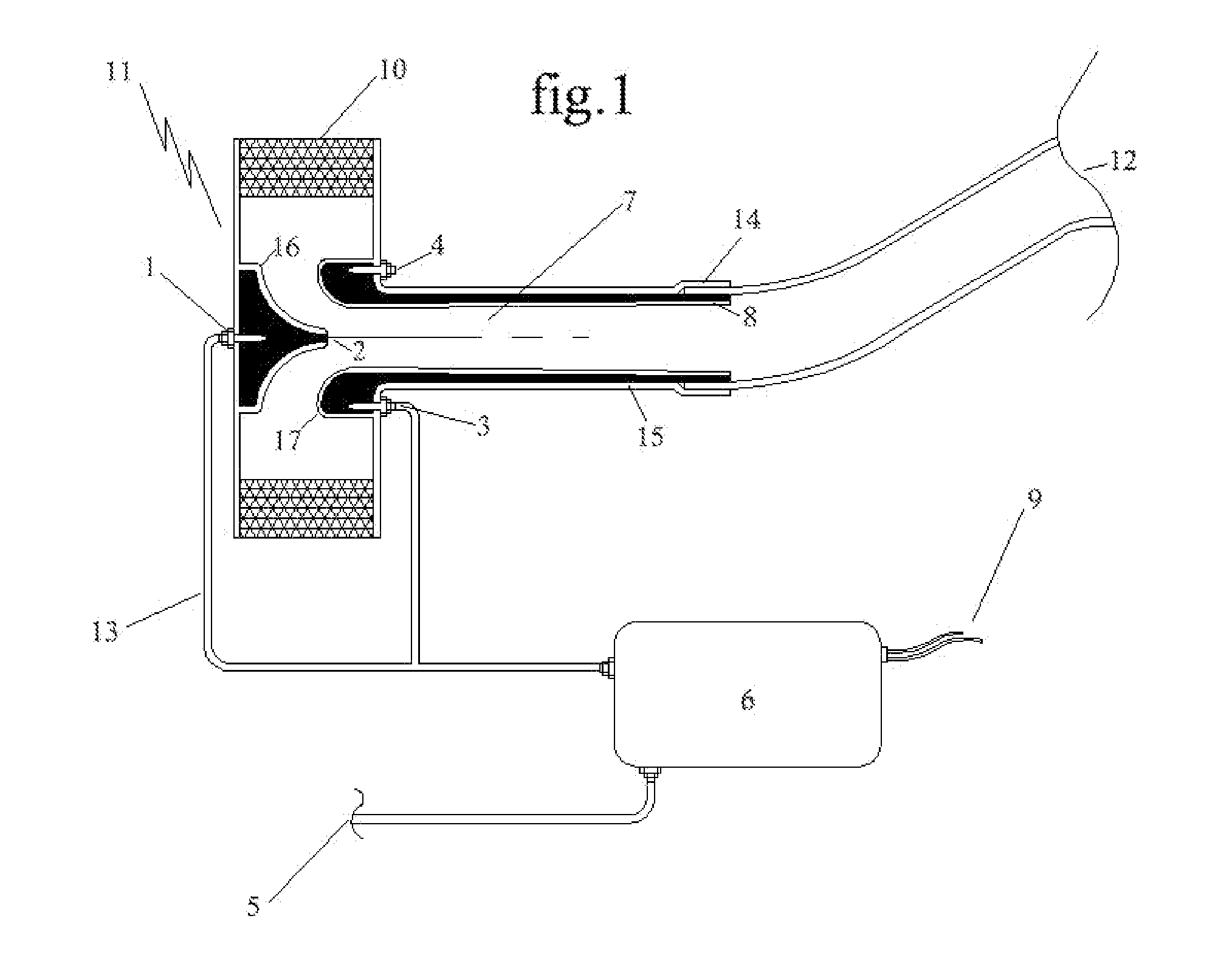

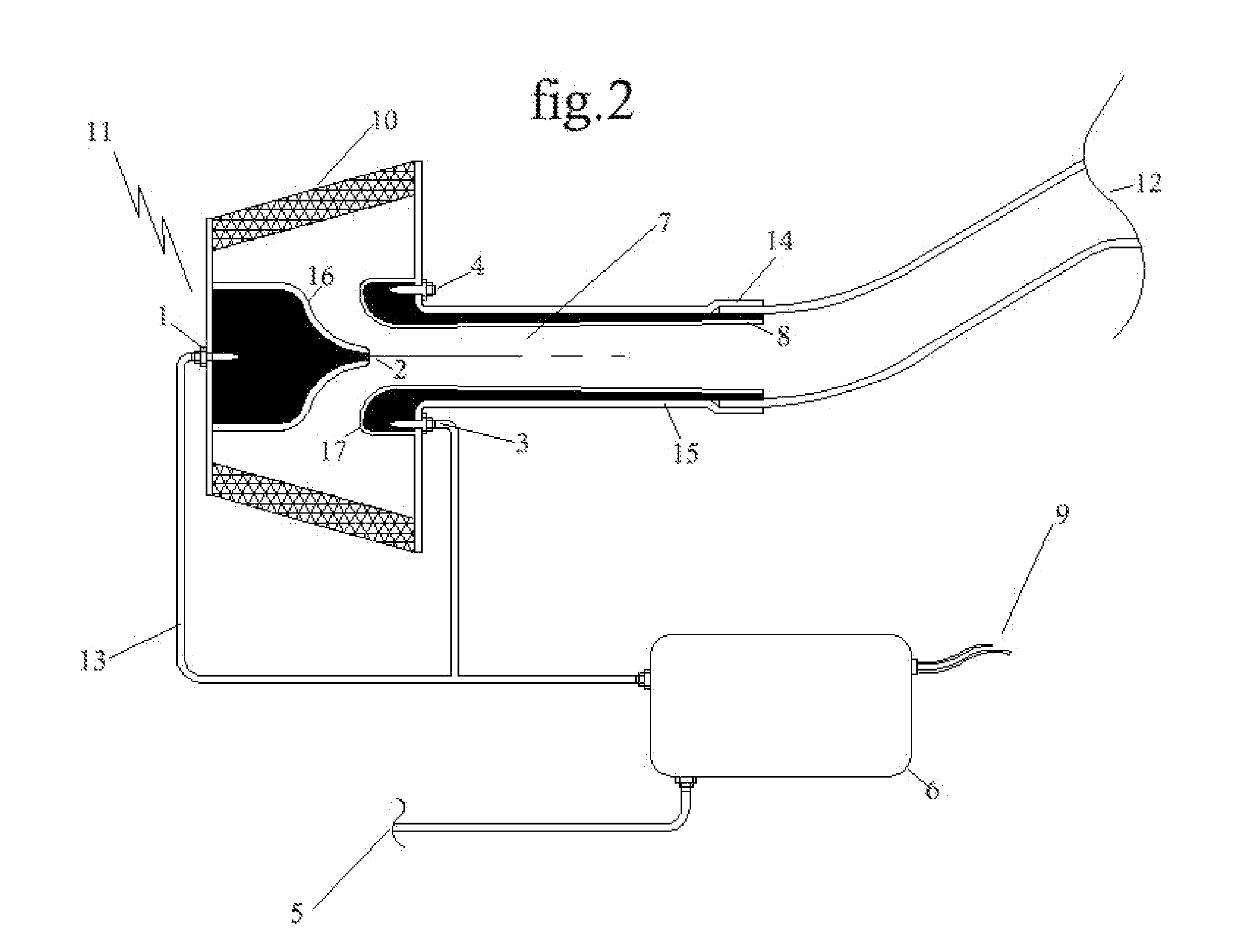

Apparatus for the multiplication of air flow in internal combustion engines increasing horsepower and torque, while reducing emissions

InactiveUS20070044779A1More versatilityIncrease airflowNon-fuel substance addition to fuelInternal combustion piston enginesAlternative fuelsPositive pressure

Compressed air is fed from a pressurized reservoir (5) thru a nozzle / vortex unit (1) simultaneously drawing ambient air through an air filter element (10). The air mixes in a merging plenum (7) where air-charge multiplication occurs resulting in boost or positive pressure conditions. The positive pressure introduced to the intake air of the engine results in a higher cylinder combustion compression ratio. The increase compression ratio with proper air to fuel ratio results in an increase in horsepower and torque. Air is controlled by a computer (6), regulators, solenoids, micro-switches, and nozzle configurations. Air is supplied via reservoir (5) and replenished from mechanical or electric air pumps (FIG. 3 18s, 18b, 18c, 18d). Alternative fuels / gases can be added such as nitrous oxide or propane (3, 4). In diesel engine applications (FIG. 3), the power and torque increases can also be experienced, but also reduce emission levels at low rpm or idle mode conditions.

Owner:GREEN CARL ANSON

Elevator system including a power storage device with a supercapacitor unit and a battery unit

ActiveUS9834406B2Significant energy savingCompetitive costElevatorsMine liftsElectrical batteryElectric power

An elevator system is provided that includes an elevator car, a counterweight, a load bearing flexible member, a motor having a drive, and an elevator control system. The car and counterweight are operable to be translated within a hoistway. The load bearing flexible member extends between the elevator car and the counterweight. The motor is operable to move the load bearing member and thereby drive the elevator car and counterweight within the hoistway. The elevator motor and drive are configured to selectively produce regenerative power. The elevator control system includes a power manager unit and a power storage device. The power storage device includes a supercapacitor unit and a battery unit. The power manager unit is operable to selectively manage the flow of power between the power storage device and the motor drive, and the flow of regenerative power from the motor drive to the power storage device.

Owner:OTIS ELEVATOR CO

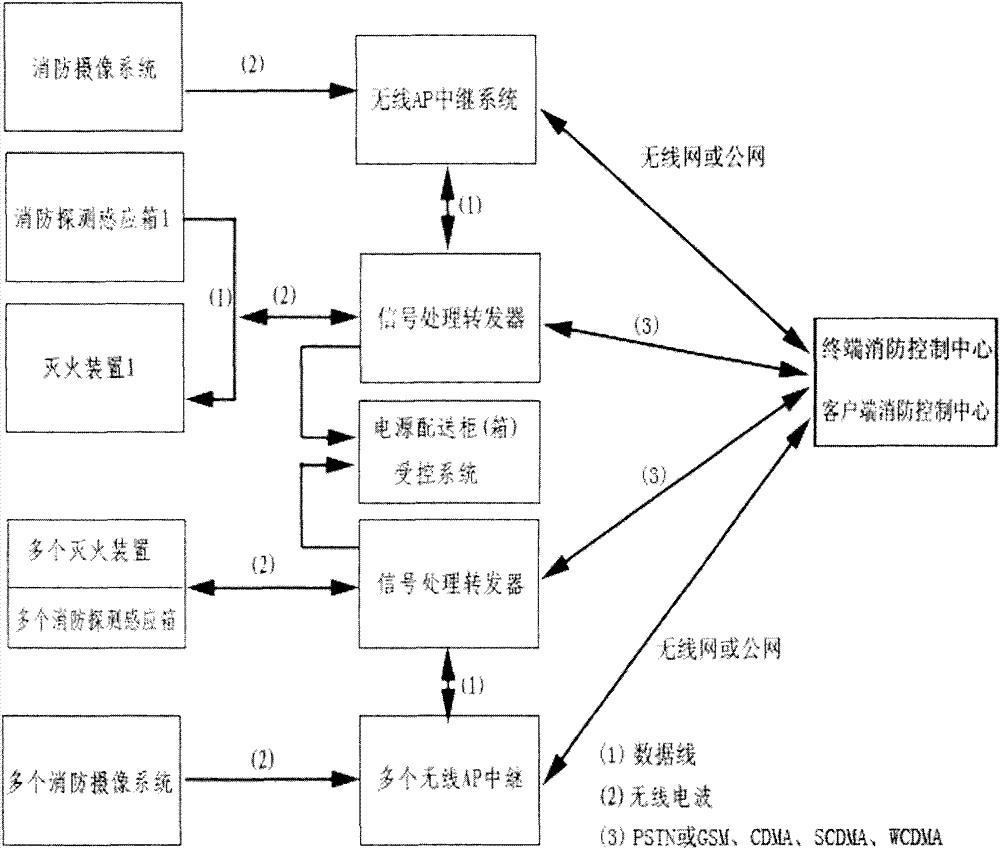

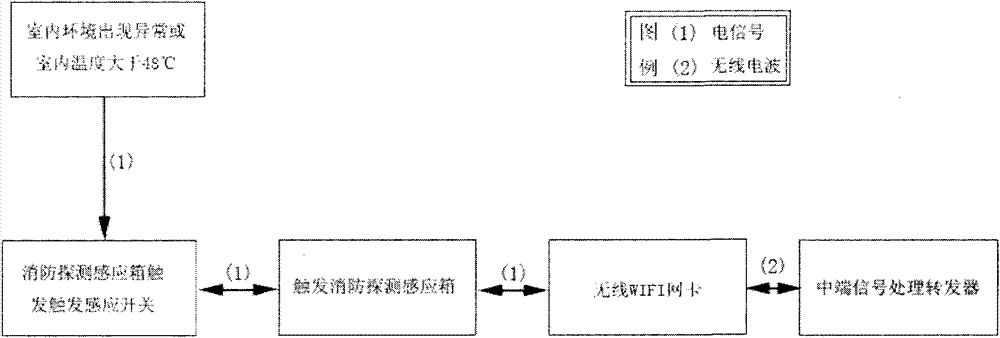

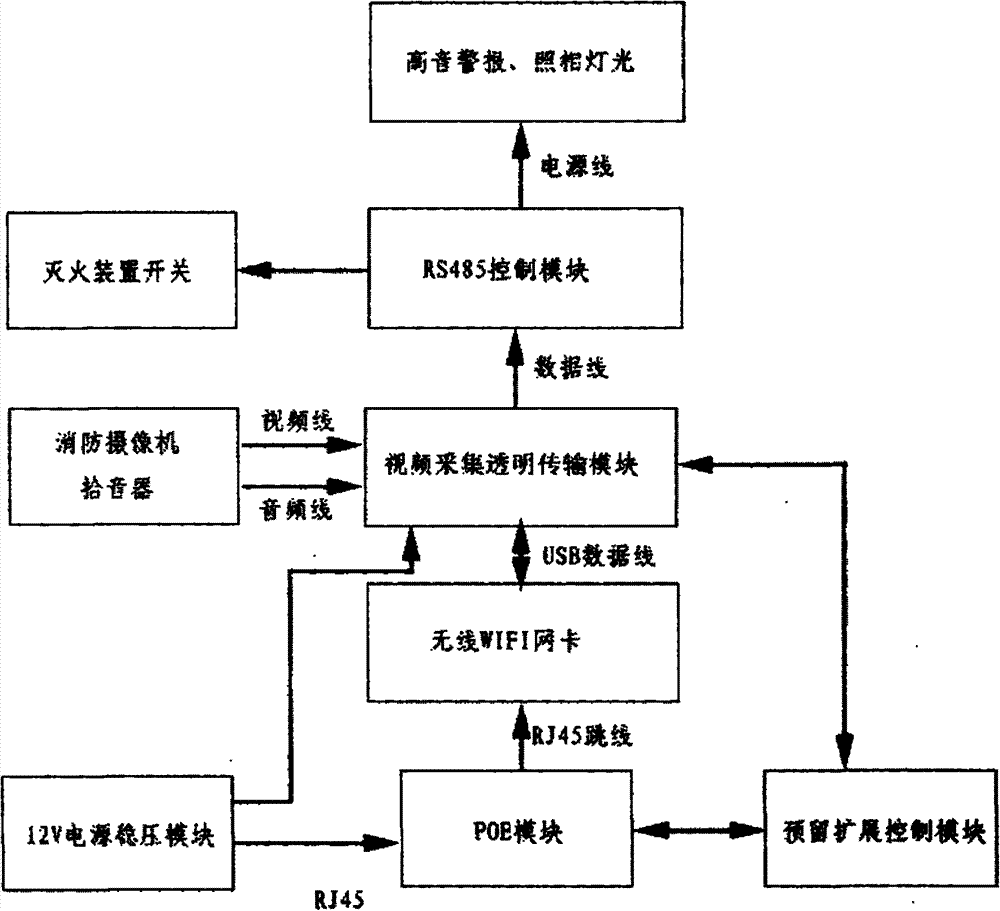

Fire-control remote visible alarming and remote control fire extinguishing system

ActiveCN103585736AReal-time field monitoring of fireQuick realization of the duty roomFire rescueClosed circuit television systemsEngineeringEmergency situations

The invention discloses a fire-control remote visible alarming and remote control fire extinguishing system which is composed of a front-end detecting and sensing system, a middle-end signal processing transponder and a terminal remote emergency command platform. A box body connecting socket of a fire-control detecting and sensing box is electrically connected with a temperature sensor and a temperature sensing trigger switch through signal wires, and the fire-control detecting and sensing box emits a wireless signal to be communicated with the intelligent control host of the middle-end signal processing transponder. The relay AP of the middle-end signal processing transponder receives and emits a wireless WIFI network card to be communicated with a terminal router and a network switch. The system is adopted for real-time field monitoring and in-time feedback so as to realize functions of remote visible alarming, remote visible control fire extinguishing, remote scheduling of nearby firefighters for rescue and remote emergency command for rescue and disaster relief at first time to furthest avoid or reduce the loss caused by fire.

Owner:上饶市广丰区金盾系统科技有限公司

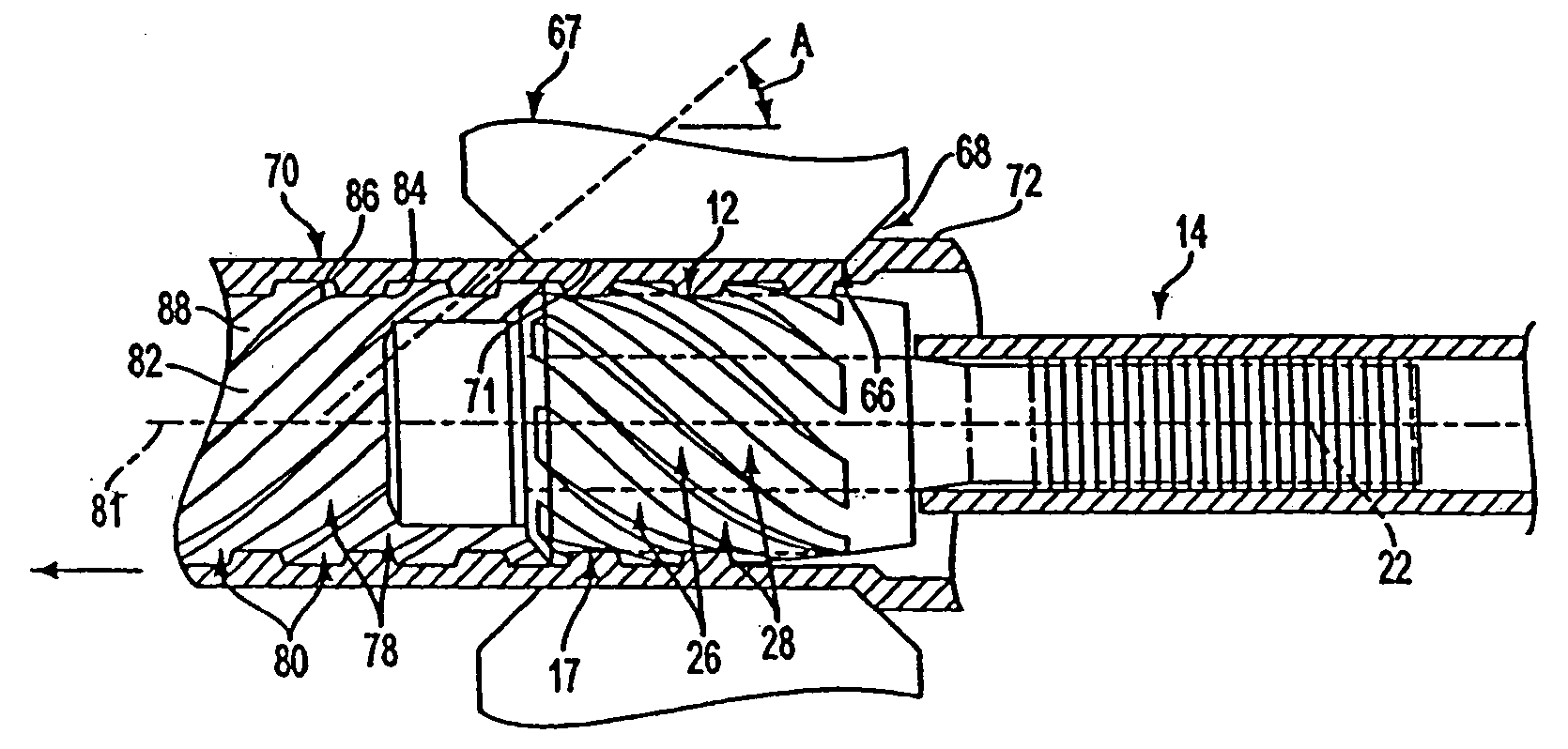

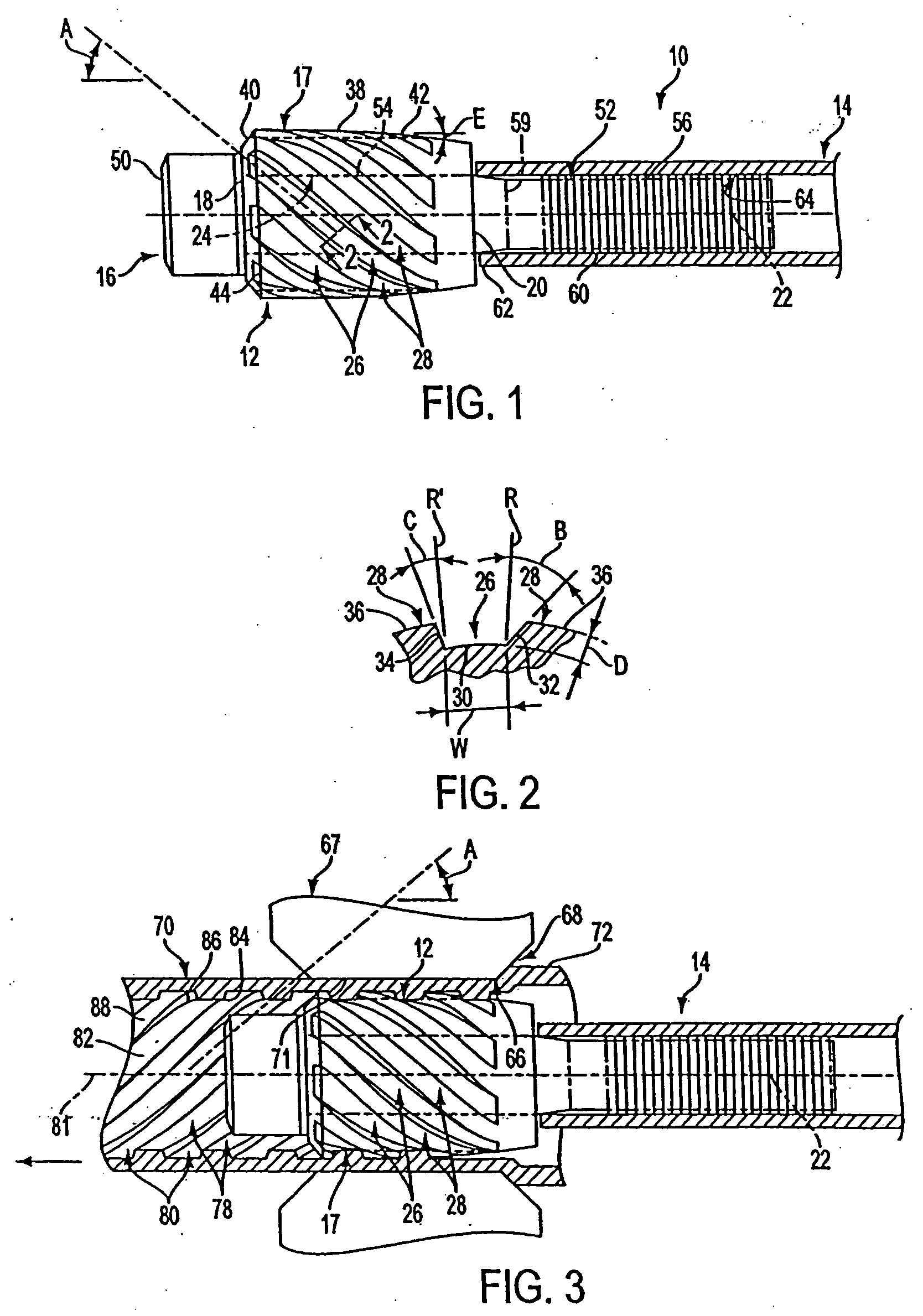

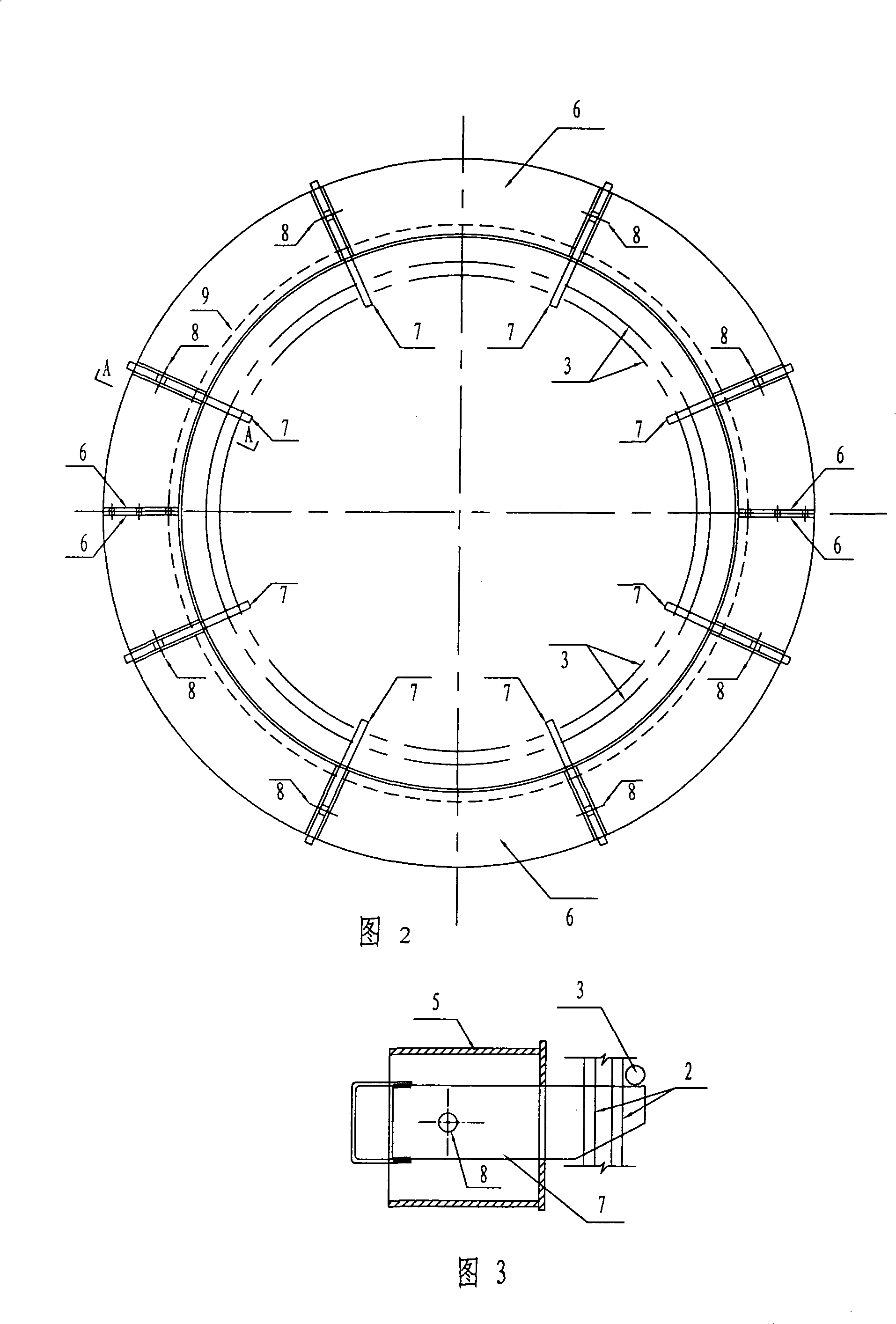

Apparatus and method for forming internally ribbed or rifled tubes

ActiveUS20050229667A1Improve productivityImprove tool lifeDrawing mandrelsMetal rolling stand detailsEngineeringHelix

A plug tool for forming internally helically ribbed tube comprises a plug body for being rotatably disposed in a die orifice of a drawing die. The plug body has a central longitudinal axis, a plurality of external grooves equally spaced about the axis and a plurality of external lands in alternating arrangement with the grooves. The grooves extend along the plug body at a helix angle to the axis. Each groove has a normal cross-section defined by a root surface and opposing flank surfaces extending angularly outwardly from the root surface to adjacent land surfaces. The flank surfaces extend angularly outwardly from the root surface in opposite directions at different angles from one another. A method for forming internally helically ribbed tube involves drawing a length of tubing over the plug body rotatably disposed in a die orifice of a drawing die and constricting the tubing in the drawing die to force the tubing into the grooves of the plug body to form a plurality of internal helical ribs in the tubing in correspondence to the grooves.

Owner:DOOSAN BABCOCK ENERGY AMERICA

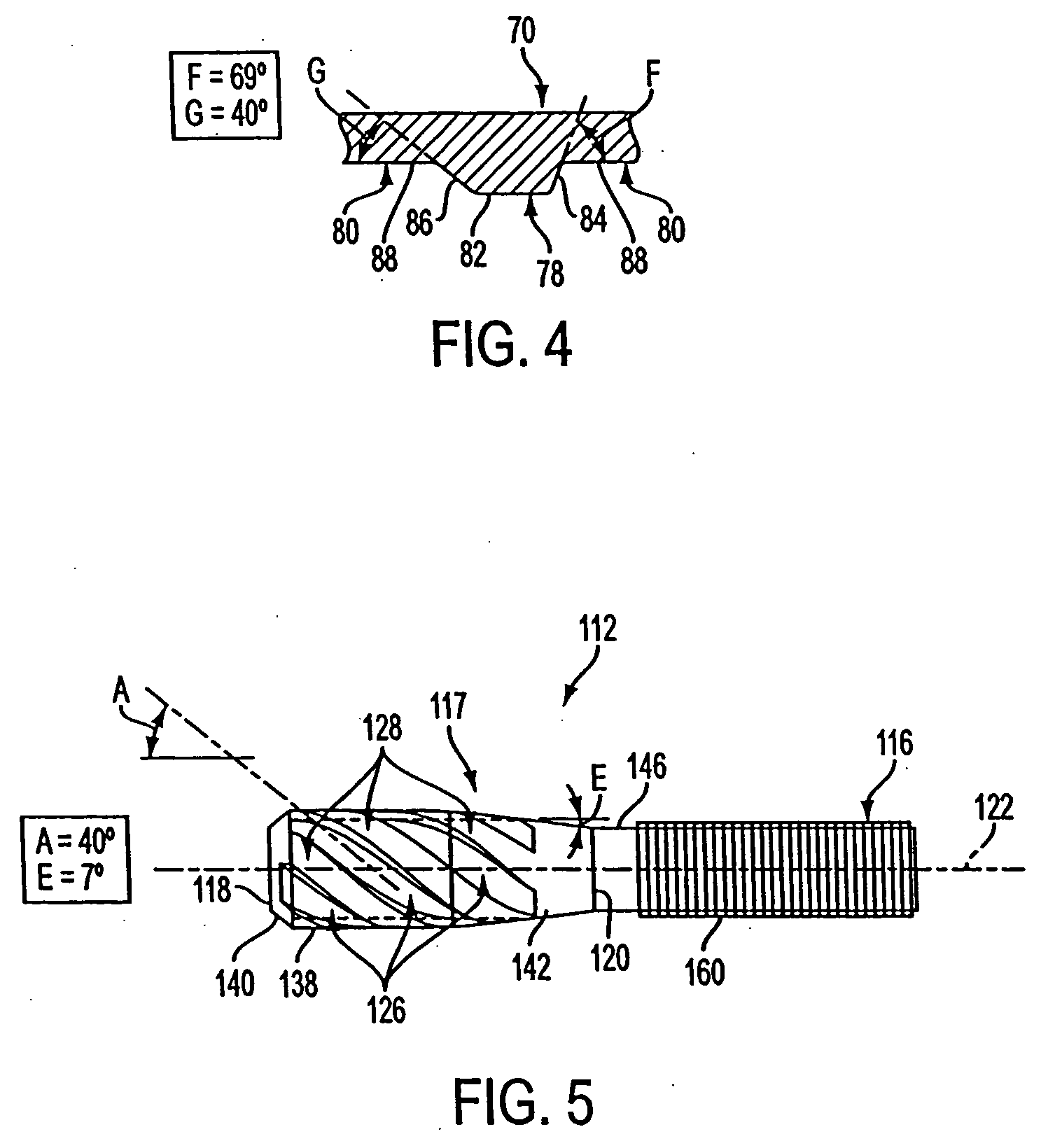

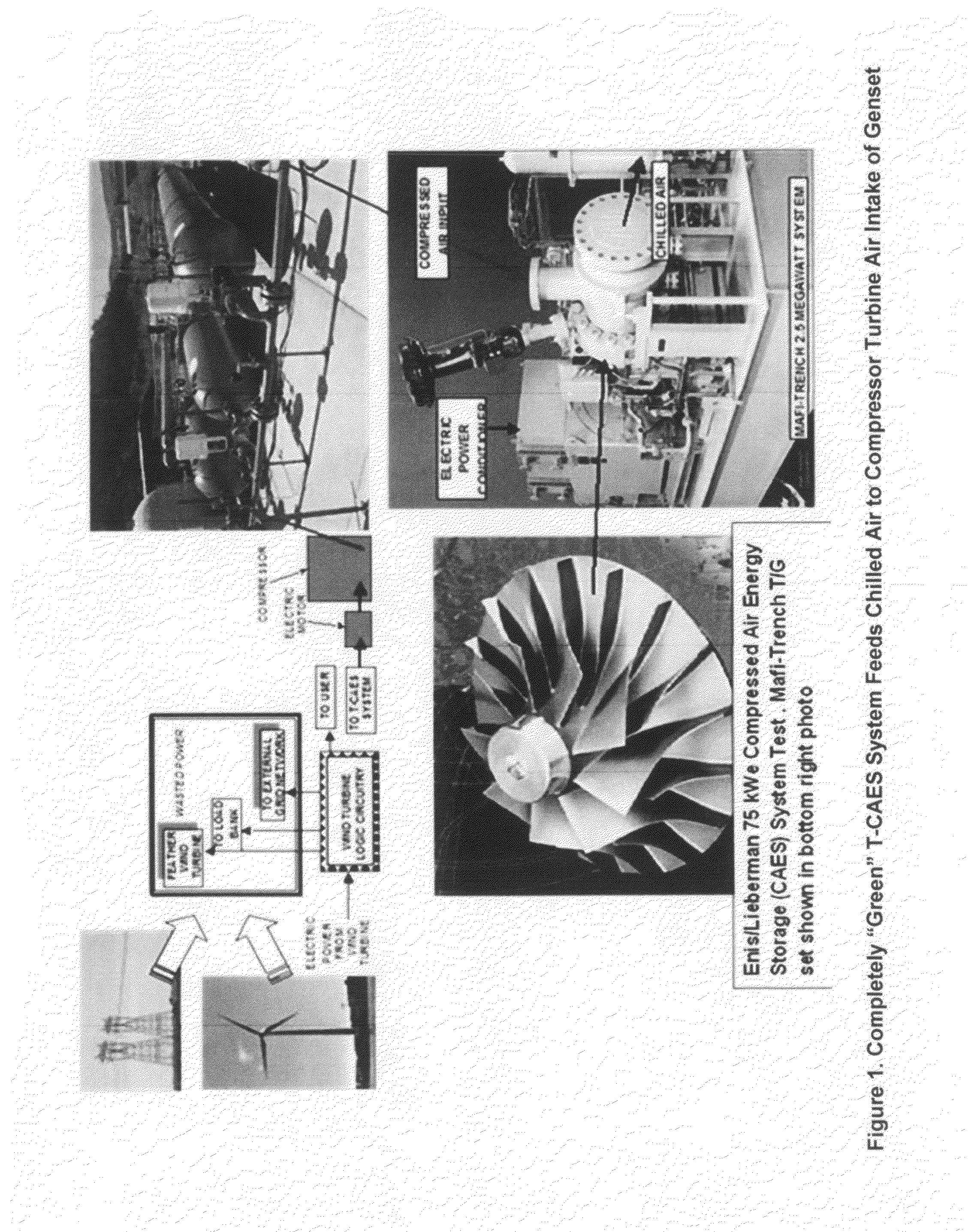

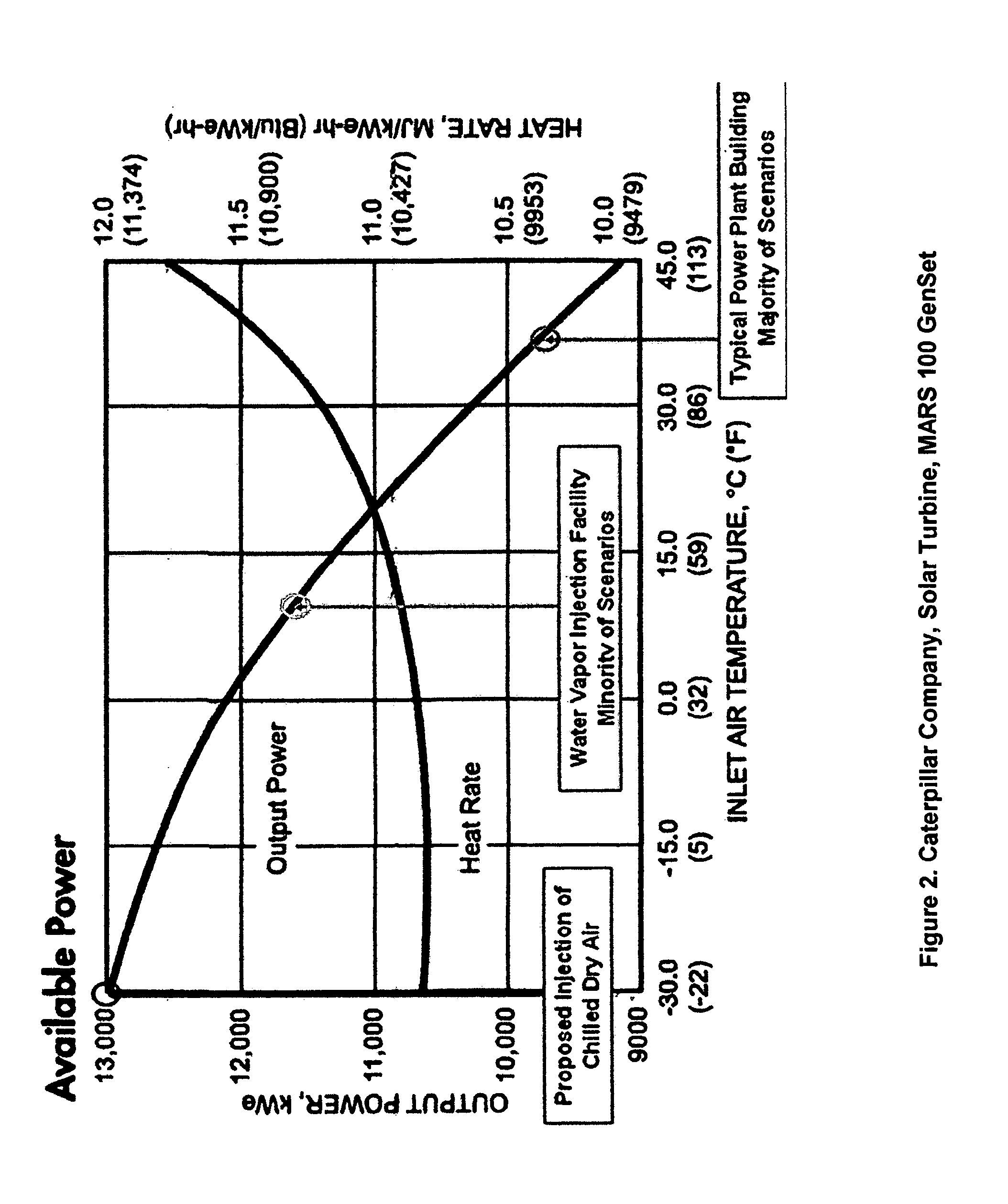

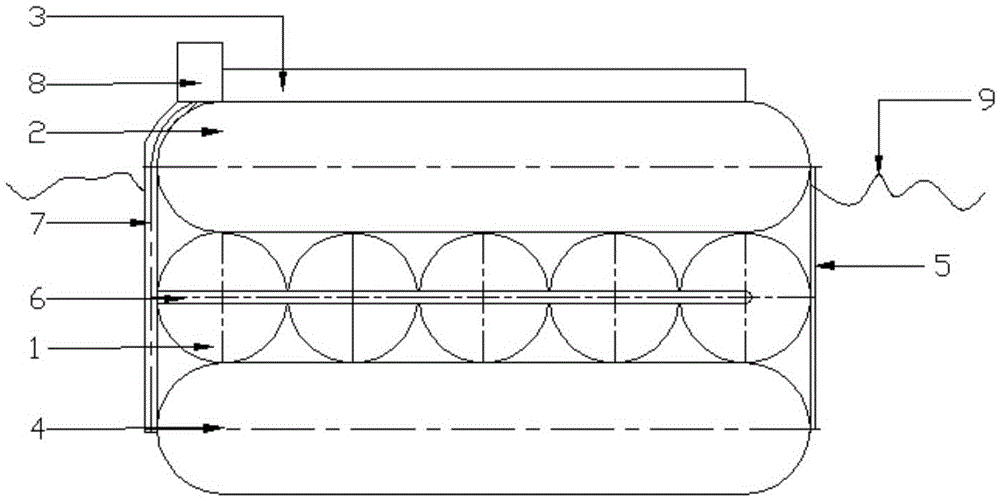

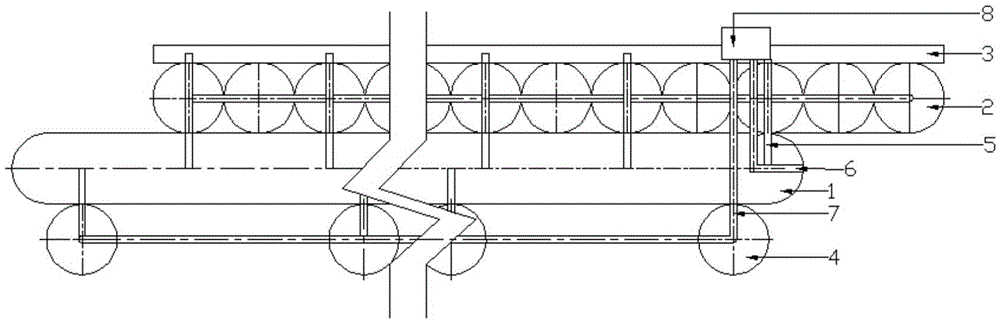

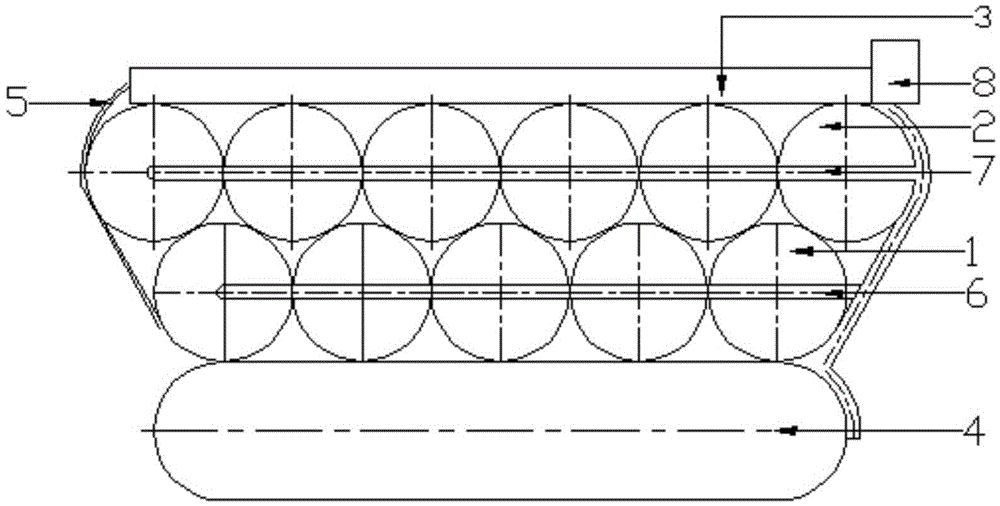

Method and apparatus for integrating on-shore green and other on-shore power sources with a compressed air energy storage system on a floating power plant.

InactiveUS20140333069A1Increase mass flowReduce fuel consumptionGeneral water supply conservationPV power plantsThermal energy storageHigh pressure

The invention relates to a method and apparatus that shares the cost and areal footprint of the barge floatation platform for a floating power platform (FPP) with the cost and aerial footprint of the high pressure vessels of the compressed air energy storage (CAES) system. The integration of these two systems provides cost savings and energy consumption savings with potential for desalination.

Owner:ENIS +1

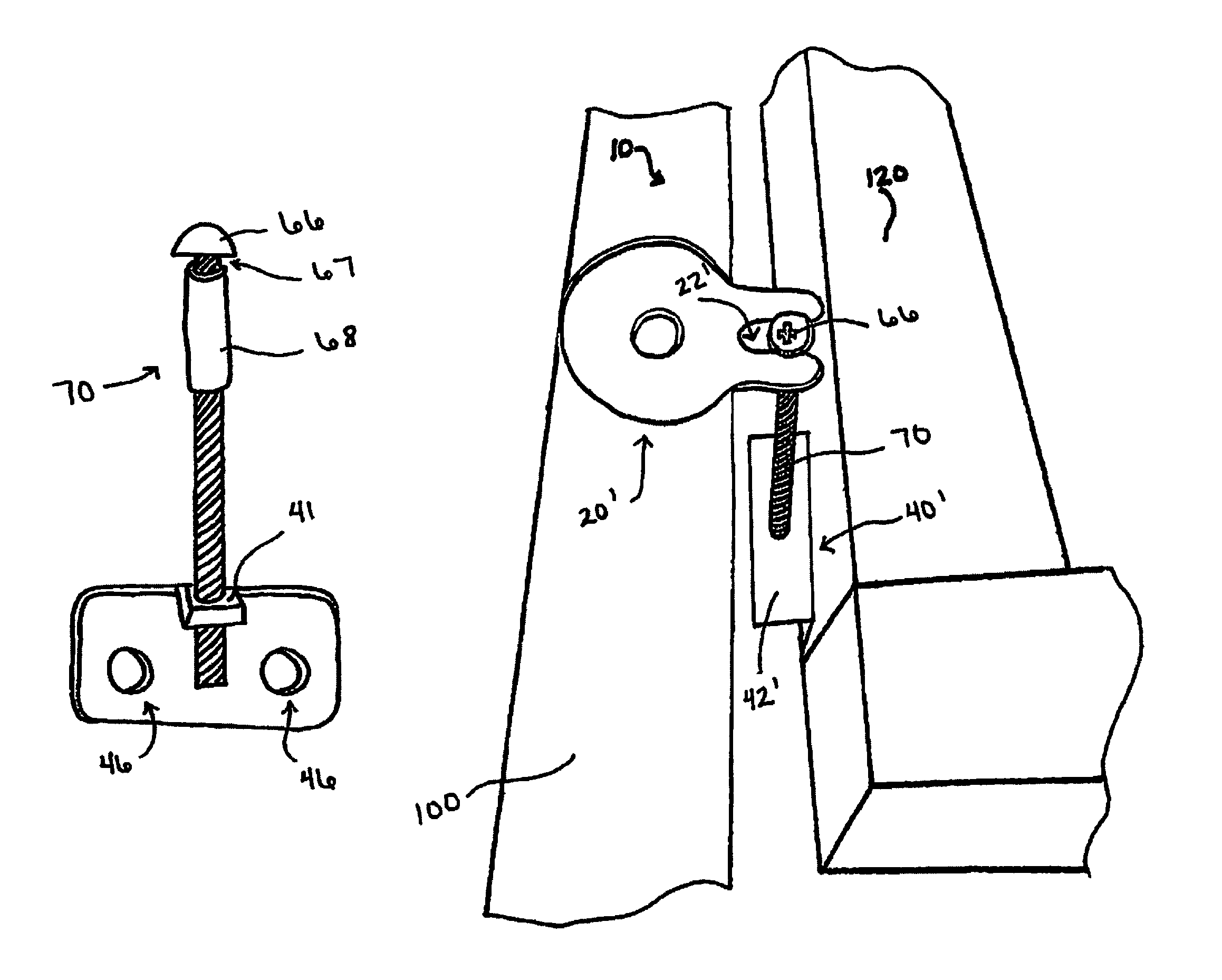

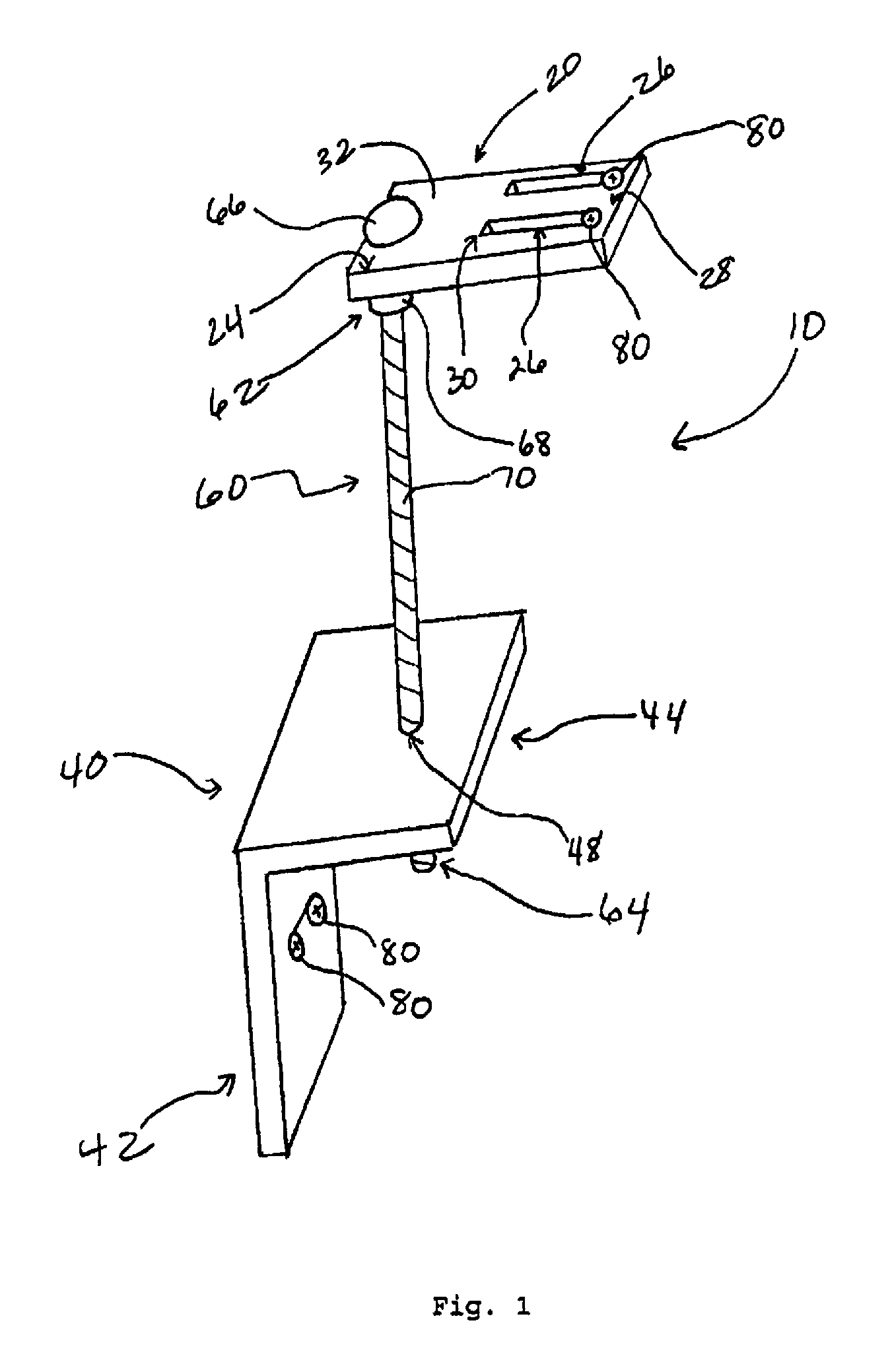

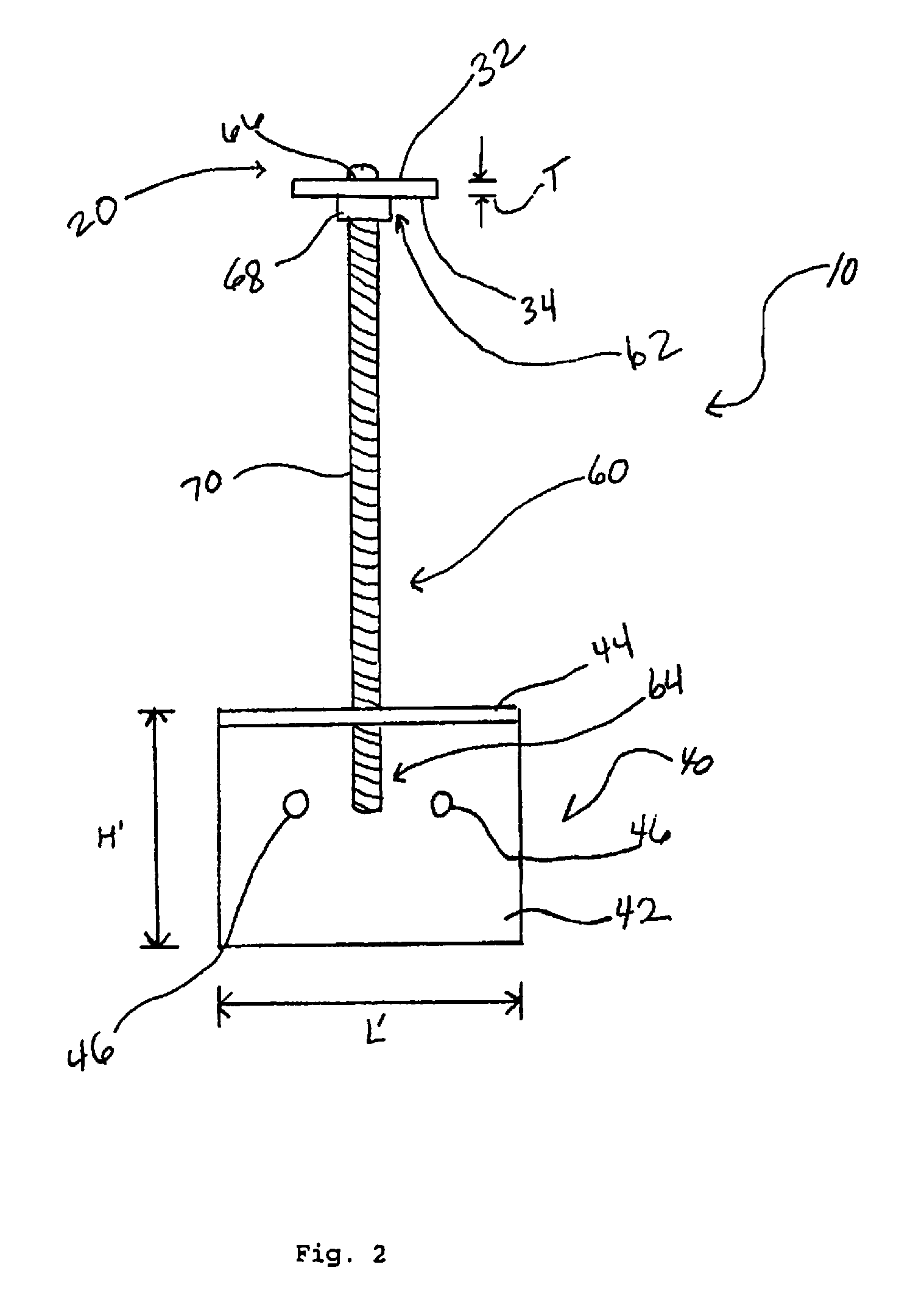

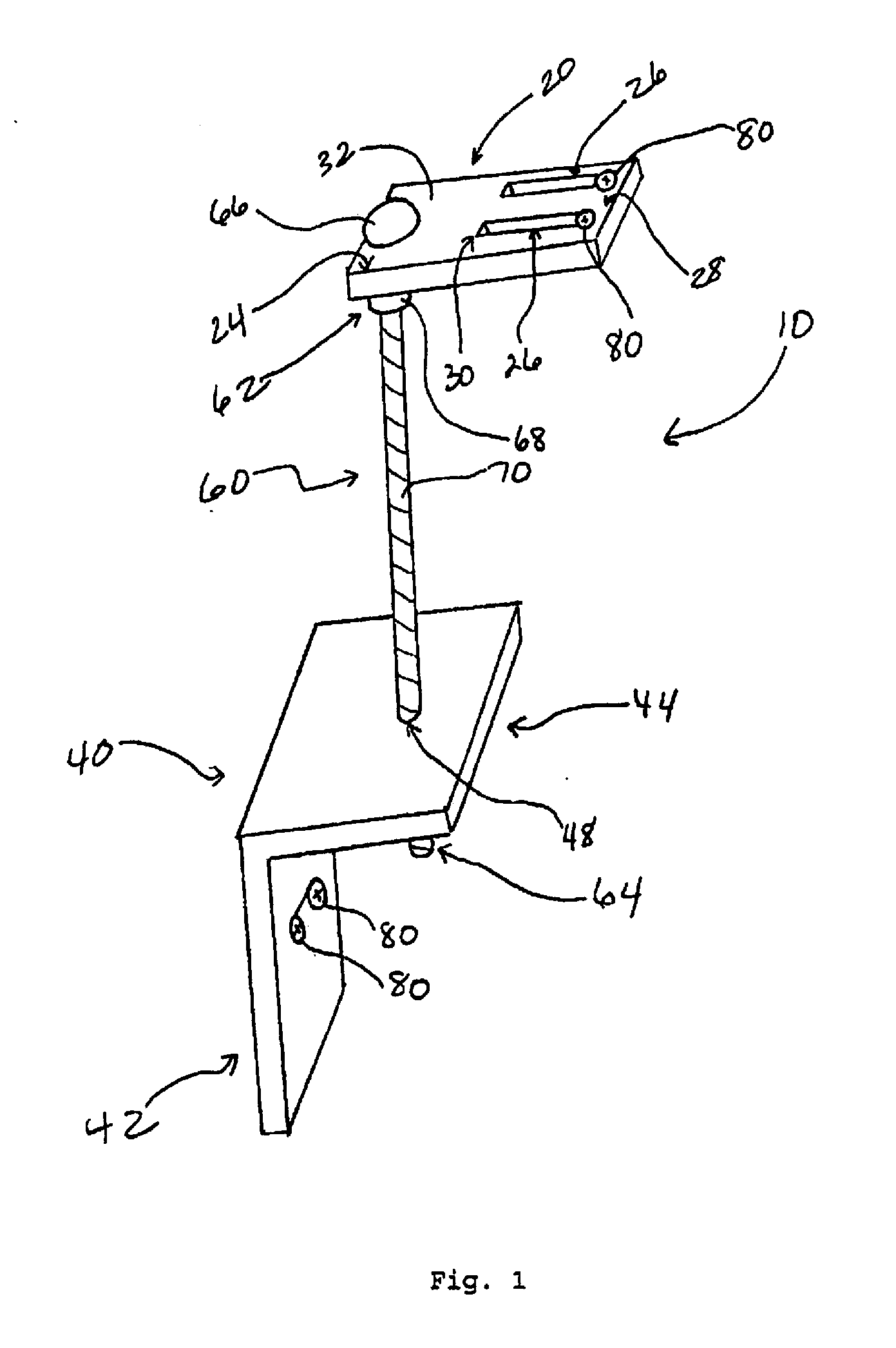

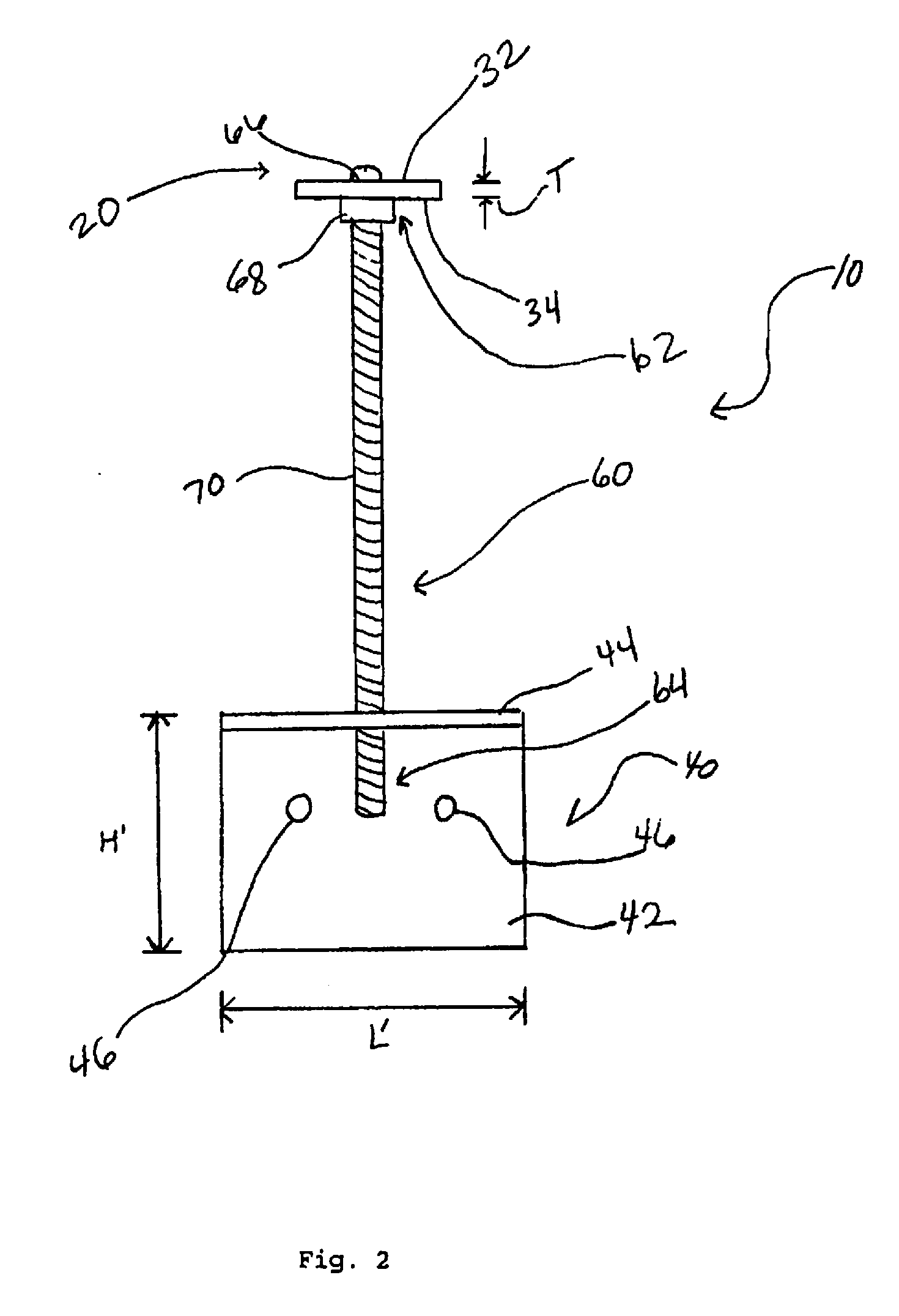

Adjustment device and system

InactiveUS9010704B2Short installation timeKeep for a long timeCandle holdersLighting support devicesLinear motionEngineering

The invention includes an alignment device and system having a guide member, a support member and a connector which engages the guide member and the support member. The guide member may be a relatively flat piece attachable to and edge of a frame. In one aspect the guide member includes a perimeter slot. The support member may have a first portion generally perpendicular with a second portion and the first portion may be attached to an object (or integral with an object such as a window or door casing) which is to be aligned with a frame. The second portion may have a connector portion or threaded hole for receiving a connector. The connector may also engage the slot of the guide member. The device allows for desired alignment of an object within a frame by transferring rotational movement to linear movement.

Owner:SIREK ANDREW +1

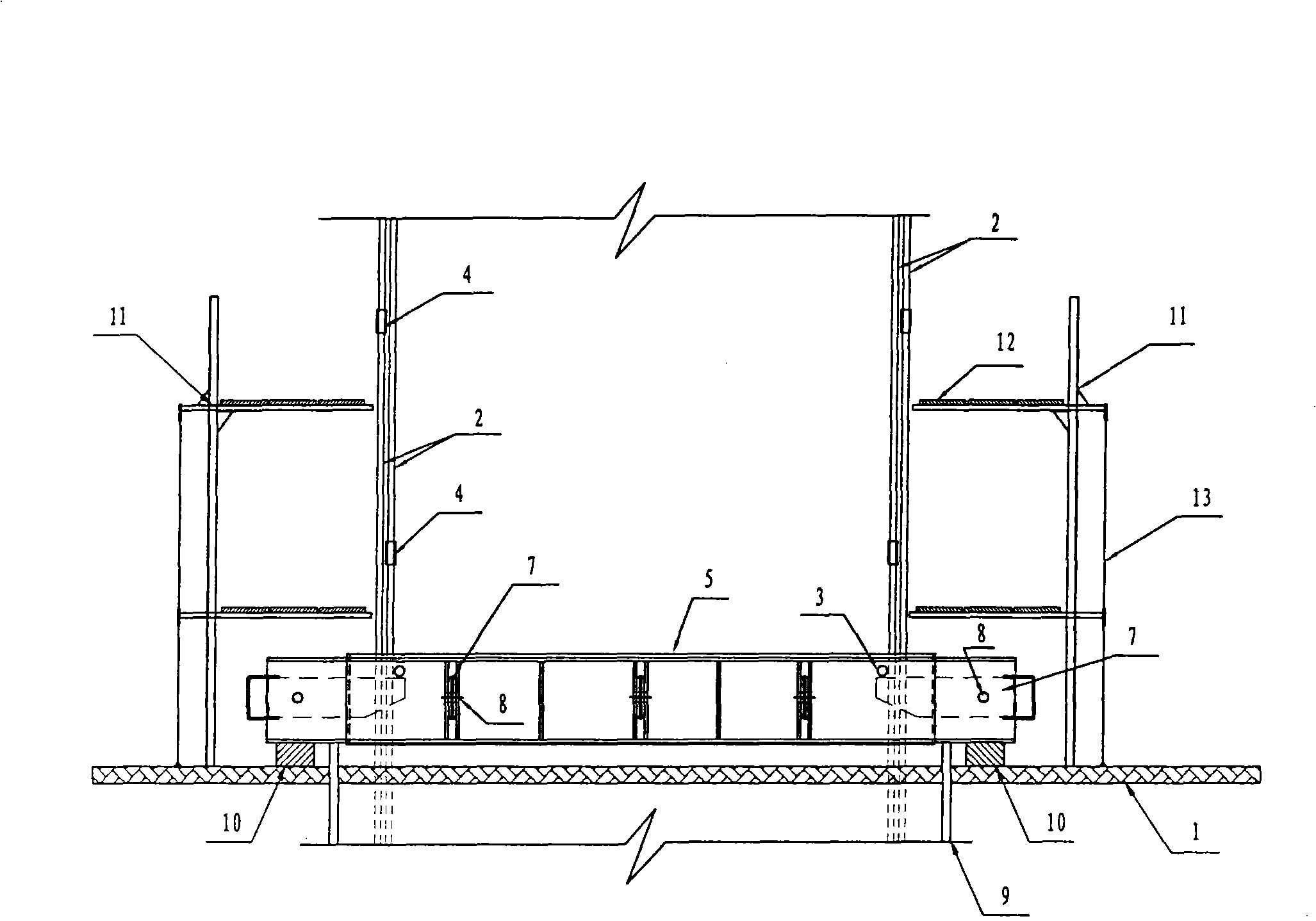

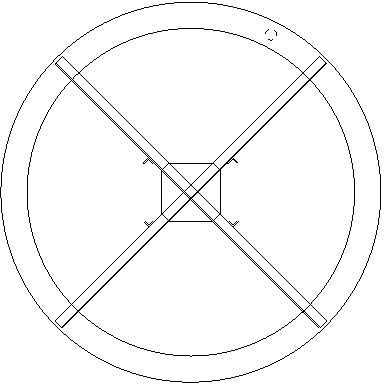

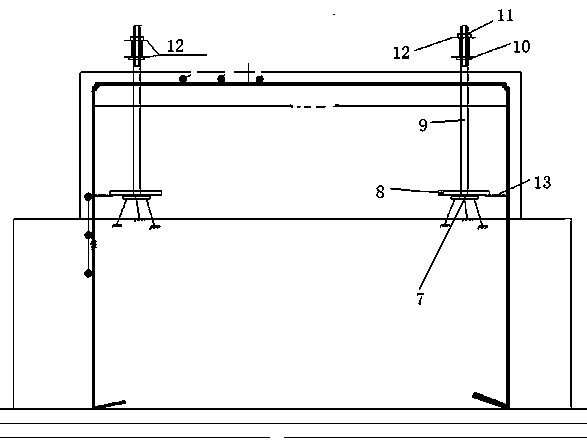

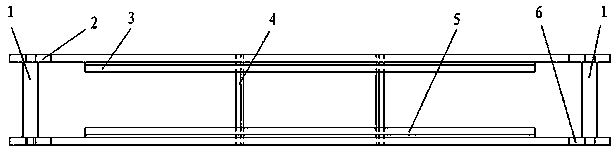

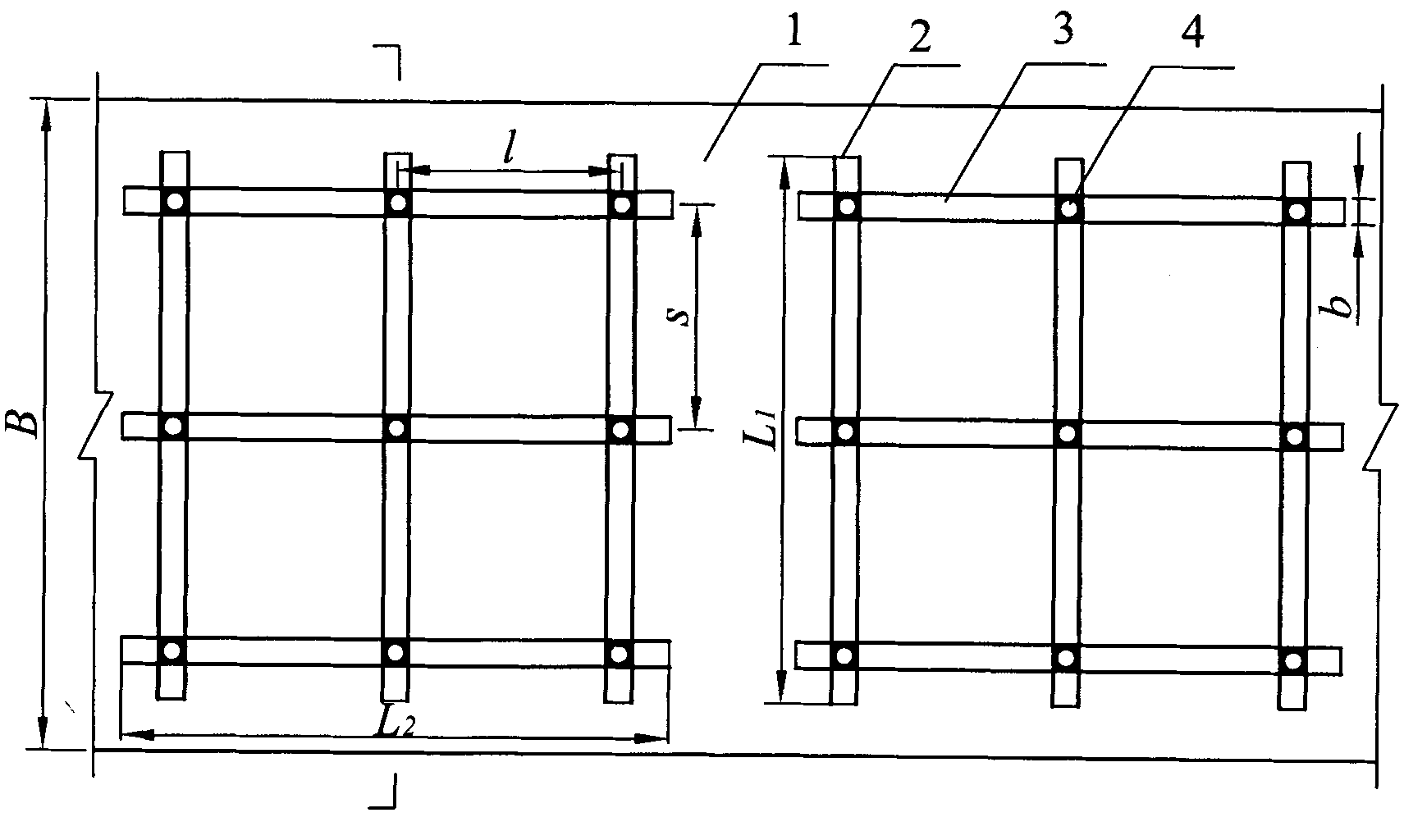

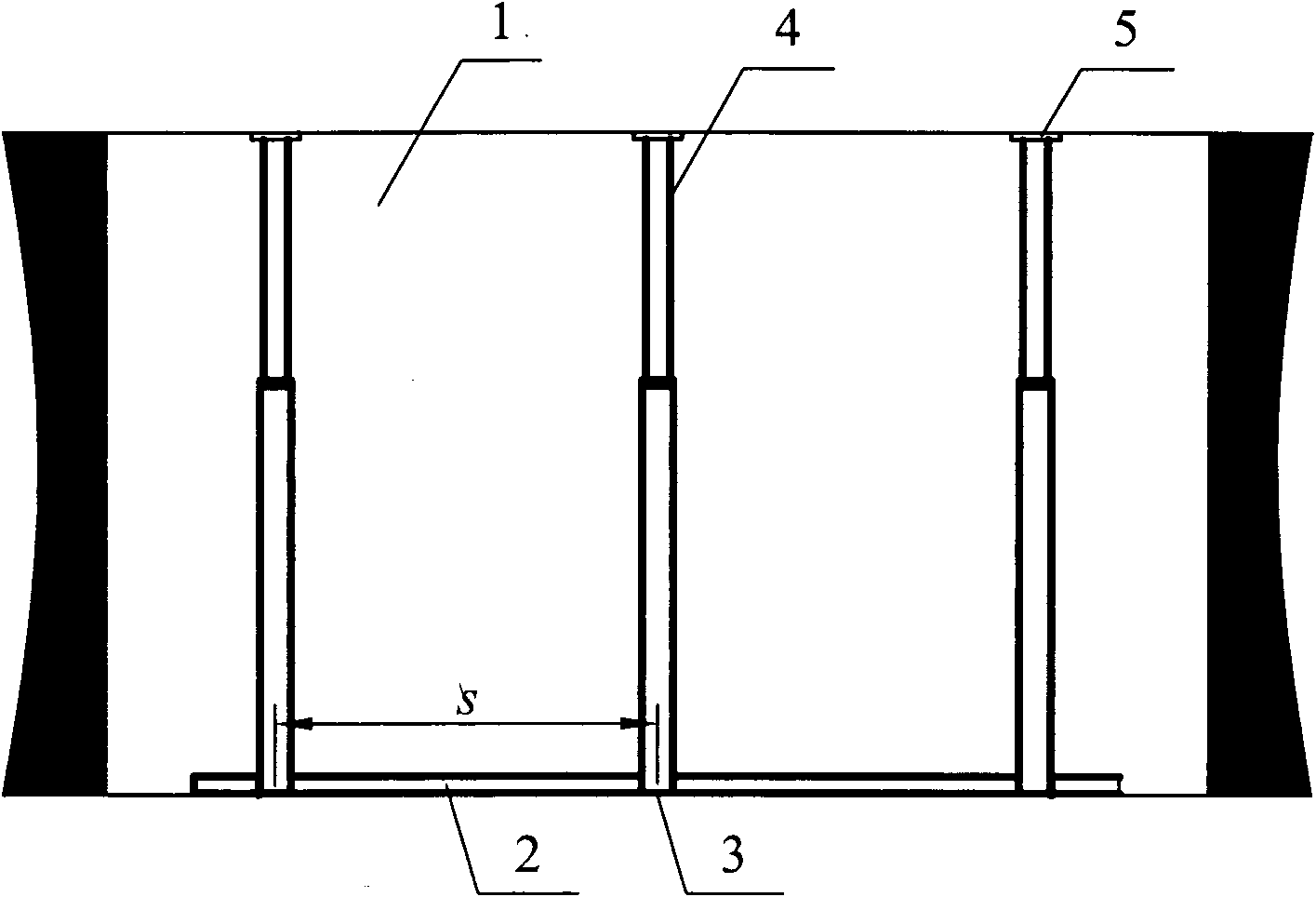

Reinforcement cage quick-assembling positioning system

InactiveCN101338561AShort installation timeLow usage feeBridge erection/assemblyBulkheads/pilesRebarUltimate tensile strength

The invention relates to a reinforcing cage rapid assembling and positioning system, which comprises a drilling platform, a reinforcing cage main reinforcement, a reinforcing cage hoop, reinforcing cage main reinforcement connectors, a end fixing ring, a end fixing ring splicing plate, end fixing ring movable inserting plates, a end fixing ring movable inserting plate pin, a drilling pile steel sleeve, a packing block, an operation platform, an operation platform scaffold board and an operation platform safety cable. The system has the advantages that two hemicyclic steel rings are spliced into the end fixing ring, and the assembling labor intensity of the end fixing ring is reduced; a reinforcing cage in the lower layer is hung by adopting eight movable inserting plates uniformly arranged on the end fixing ring, thereby the expansion of the tip beating ring is easily realized; the main reinforcement connectors in the upper and in the lower layers can be simultaneously spliced by adopting a double layered platform; the whole system has the advantages of reasonable loading, high connector quality, high construction efficiency, low labor intensity, short pile-forming period and low construction cost, and is particularly applied to the rapid assembling of the long pile reinforcing cage with double layered main reinforcement and large diameter.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

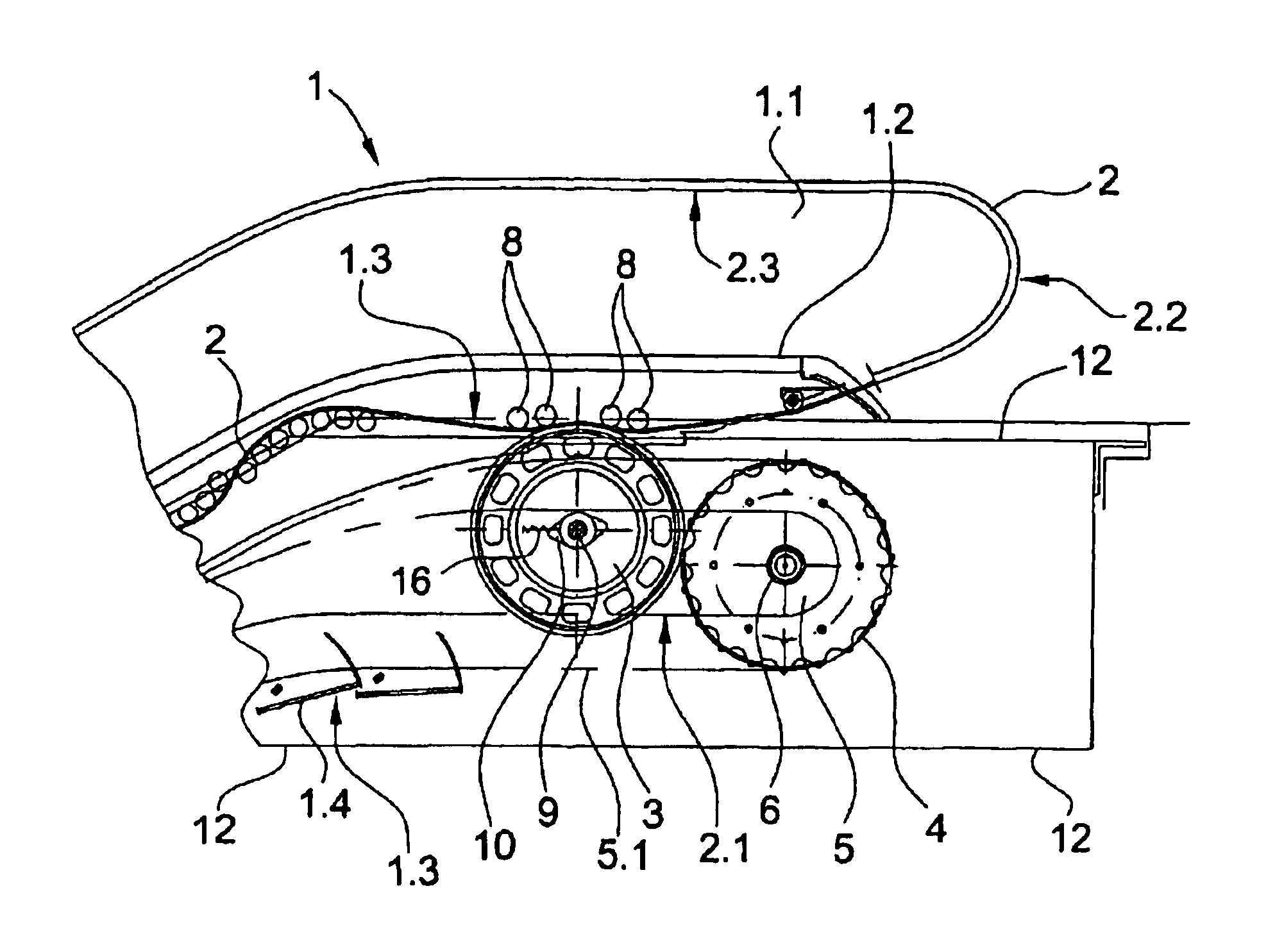

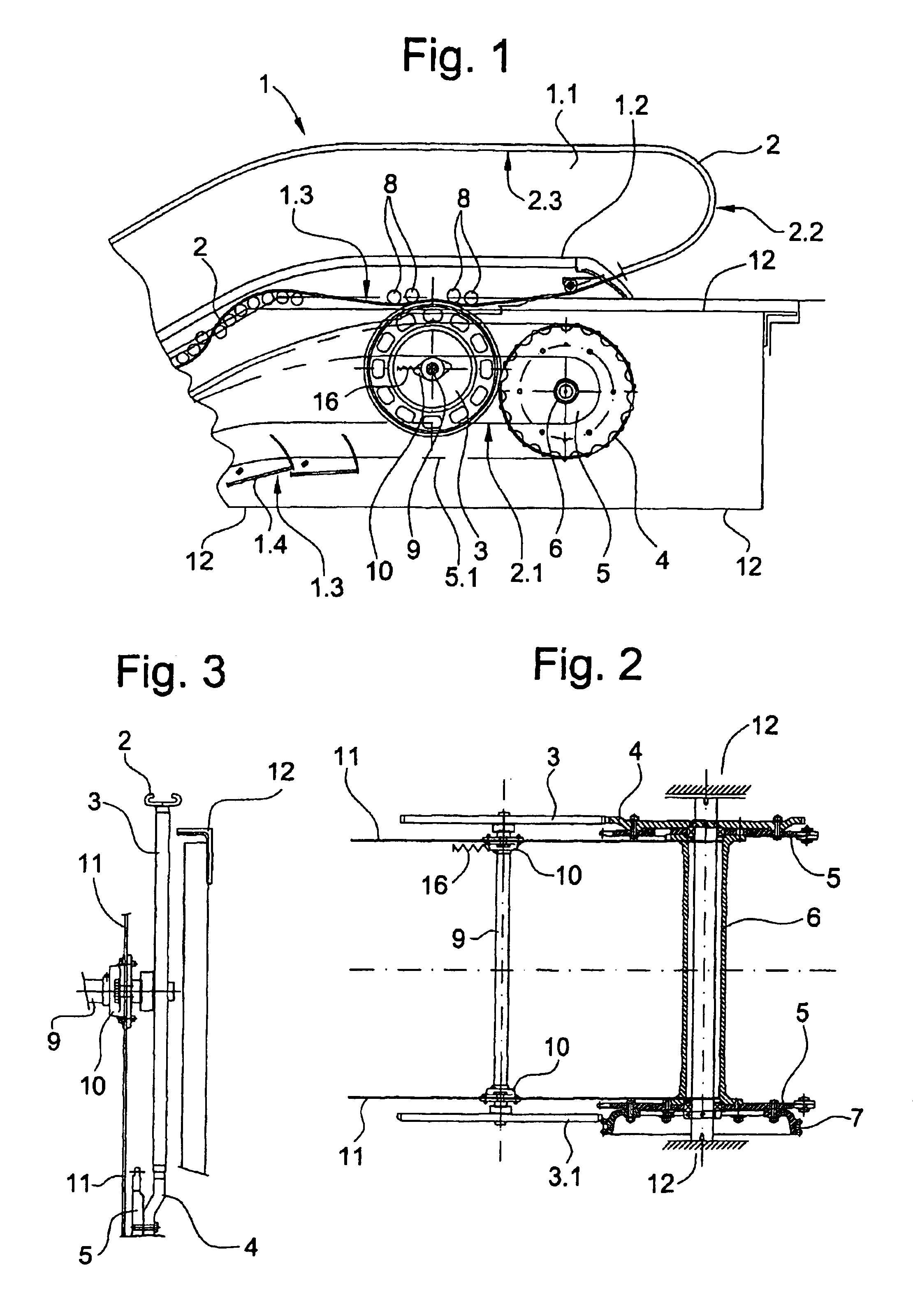

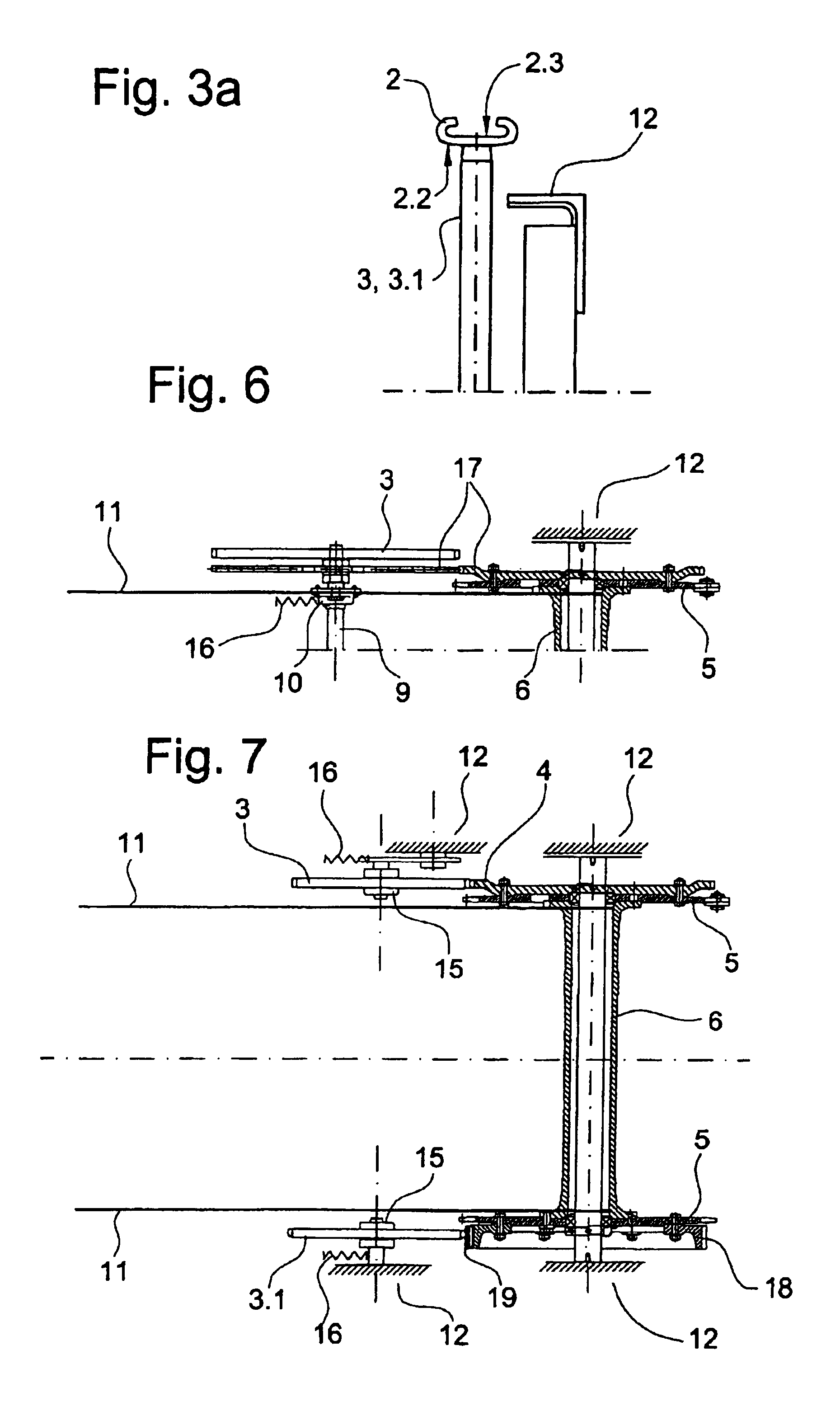

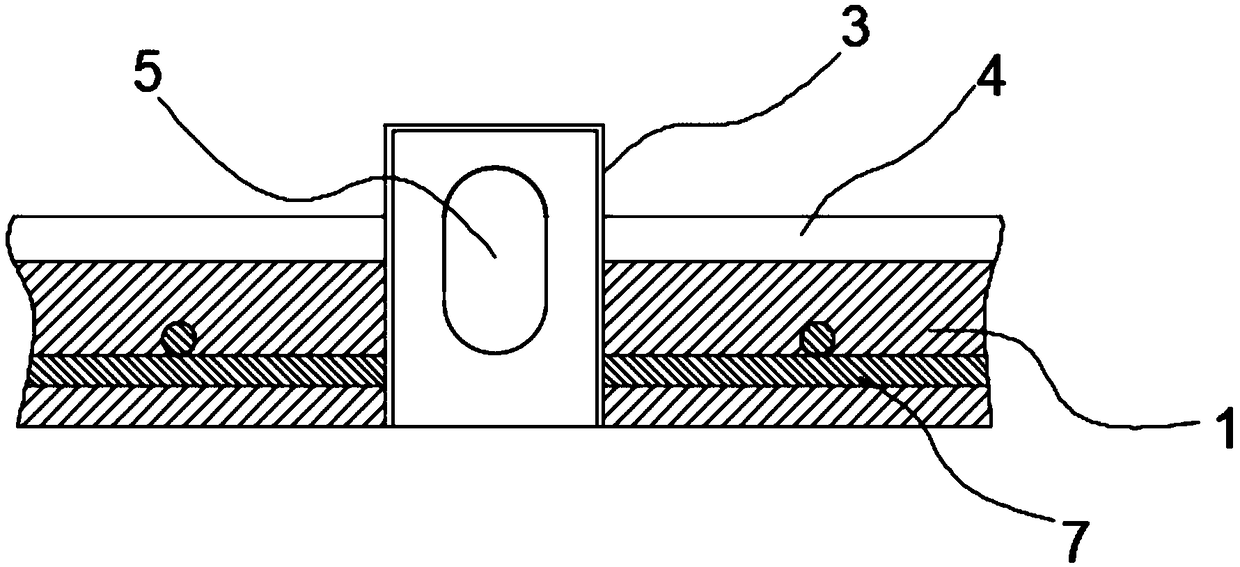

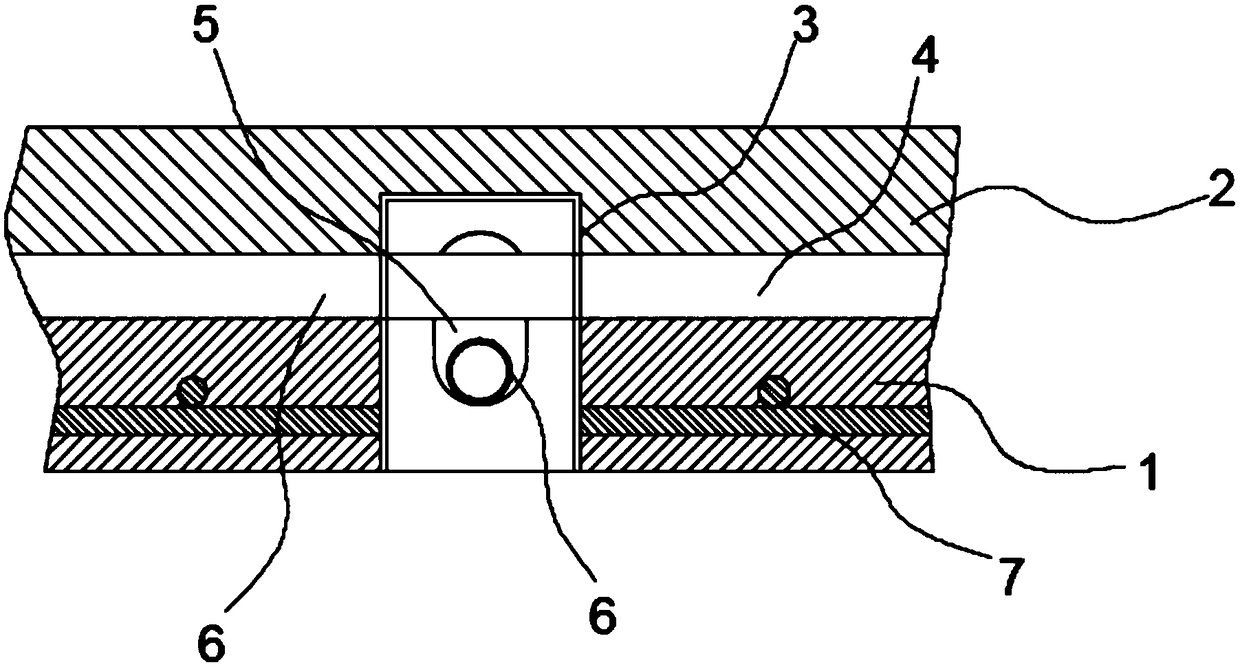

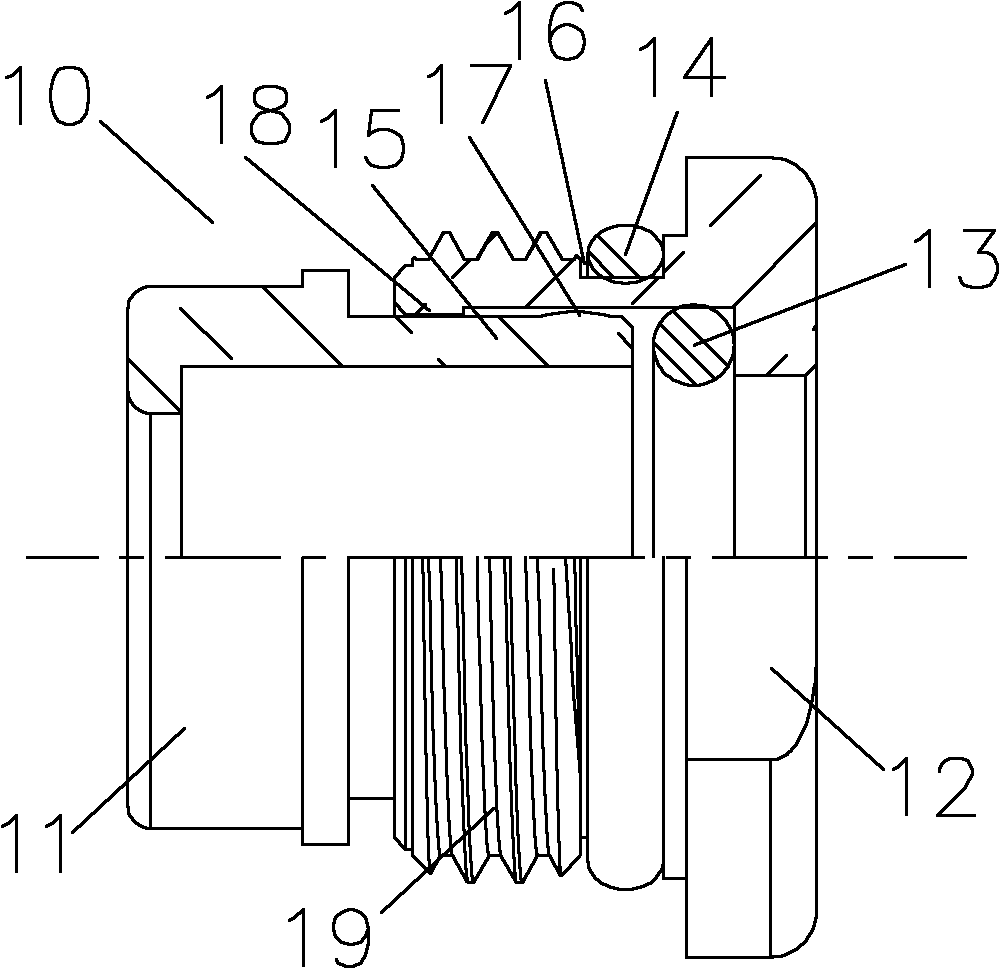

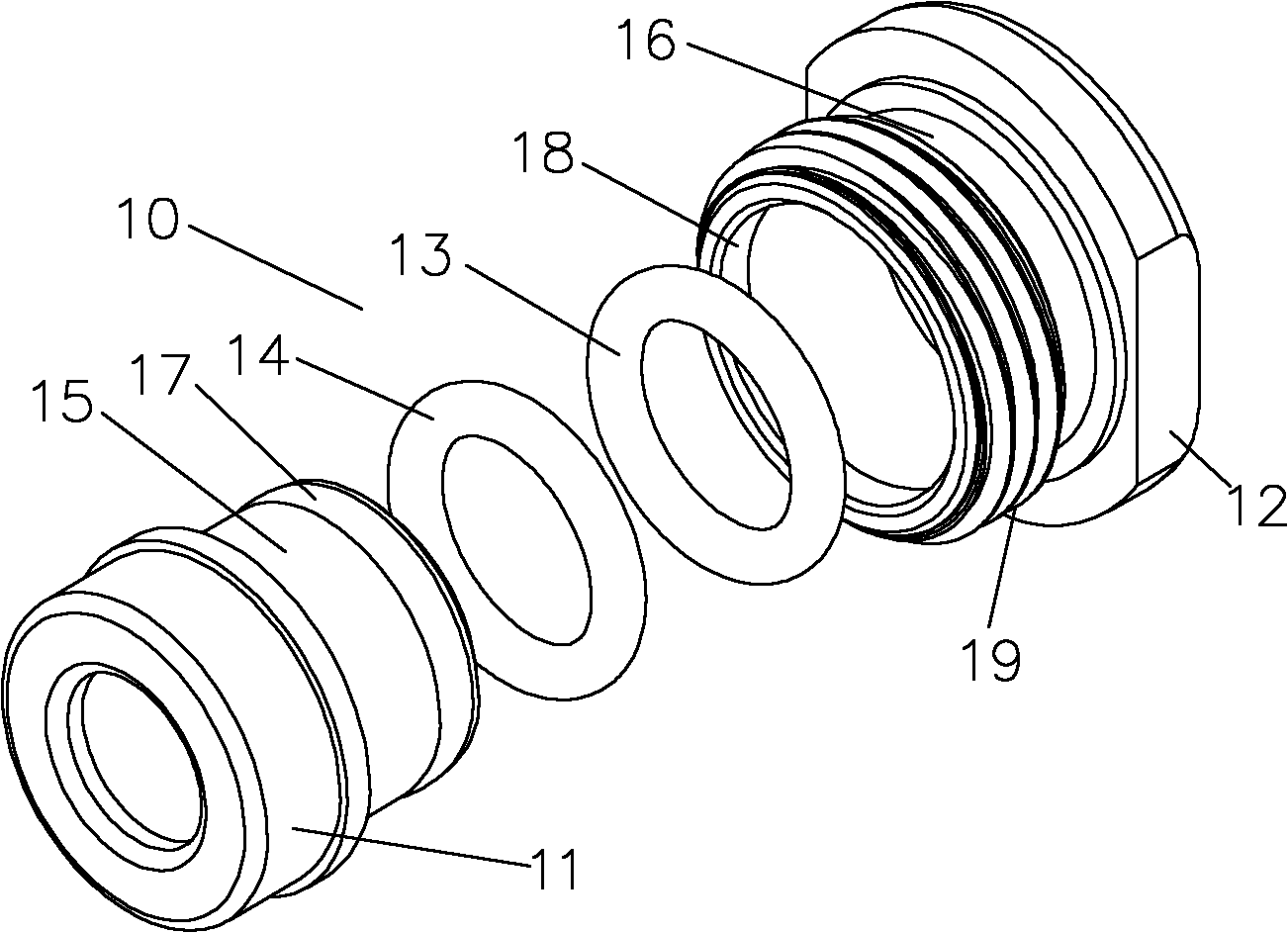

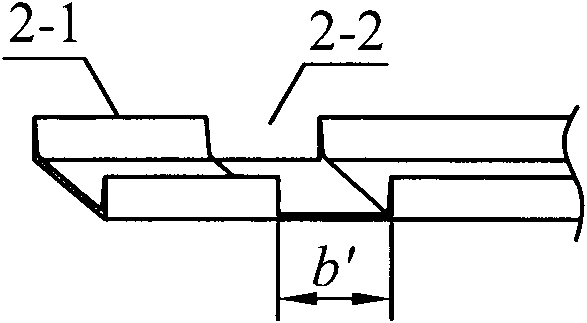

Fastener for application to a threaded stud

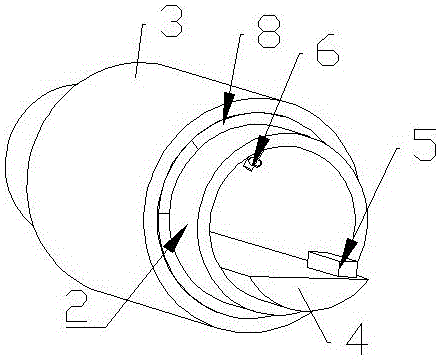

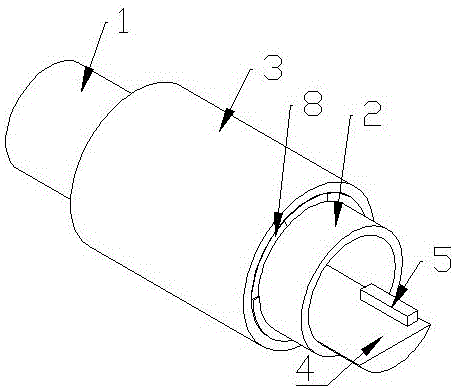

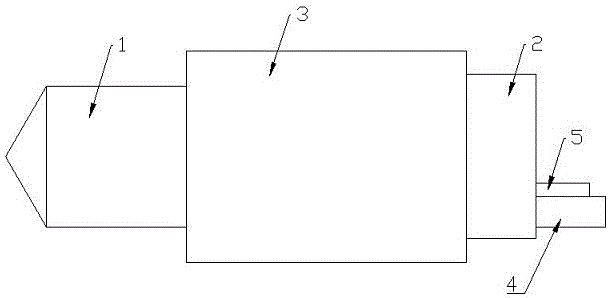

InactiveUS20050135901A1Prevent rotationShort installation timeNutsBoltsCouplingBiomedical engineering

Described here is a fastener (1) to be applied to a threaded stud with a sleeve-like clamping element (2) that has a cavity (7) extending in the direction of its longitudinal axis to accommodate the threaded stud and at least one clamping region (10) that can deform into the cavity (7) and that forms at least one clamping ramp (14) inclined toward the longitudinal axis on the outside of the clamping element (2). A clamping sleeve (3) can be pushed onto the clamping element and in the installed state grips around the clamping element, wherein an inner surface of the clamping sleeve (3) works together with the clamping ramp (14) such that the clamping region (10) reaches a clamping position that is deformed into the cavity (7) and holds the threaded body. The clamping element (2) has, at its forward end in the direction of installation, a flange (5). On the flange (5) and on the end of the clamping sleeve (3) facing the flange (5), there are arranged coupling elements and mating coupling elements that interlock and prevent rotation of the clamping sleeve (3) relative to the clamping element (2) when the clamping sleeve (3) is located on the clamping element (2) in the assembled state.

Owner:NEWFREY

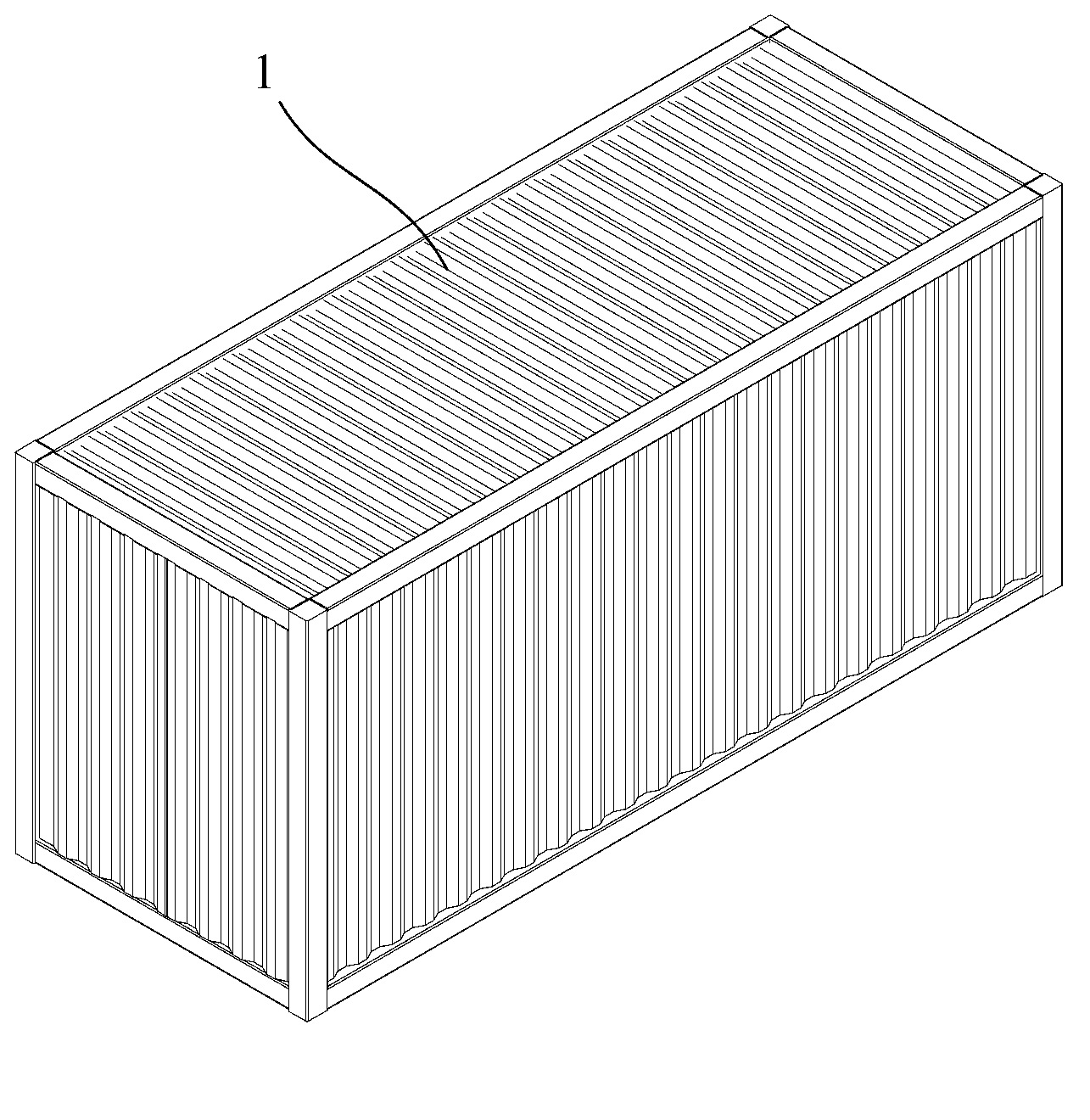

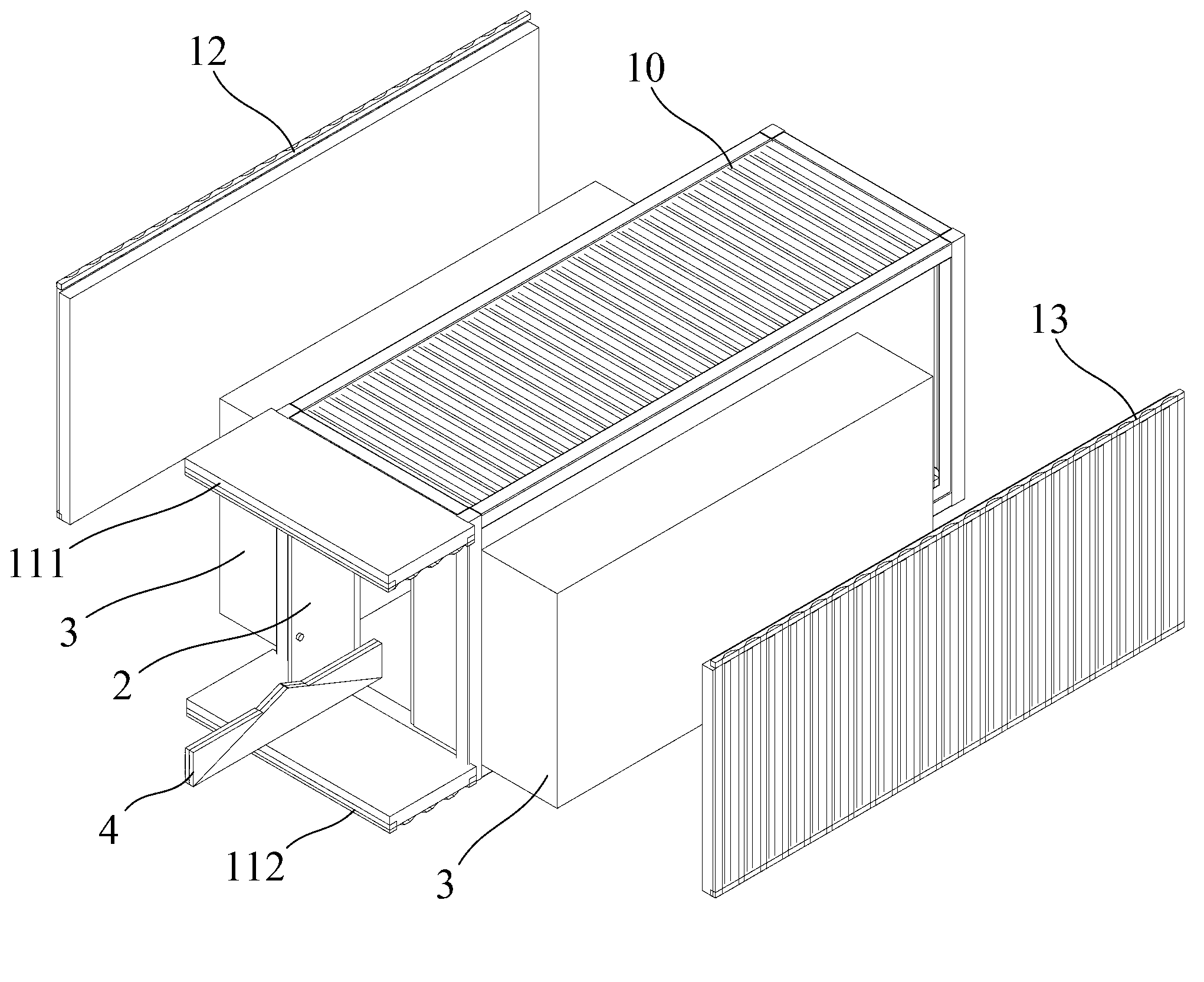

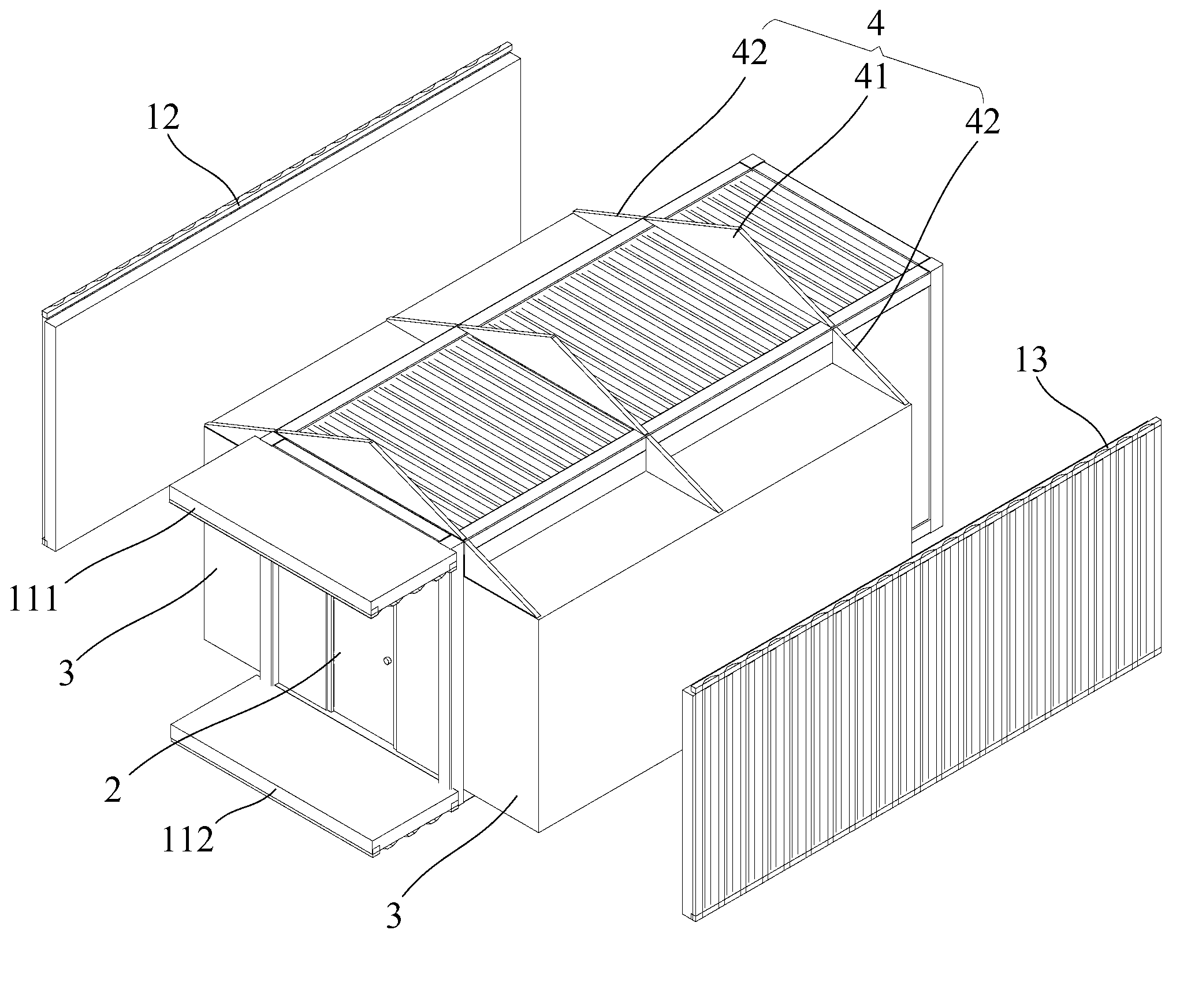

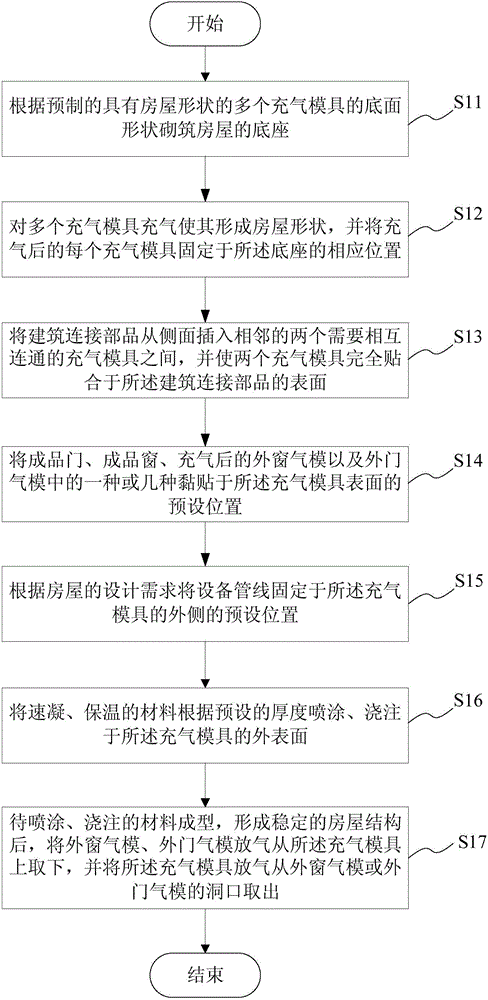

Method for building container house

ActiveCN102839826AShort installation timeReduce laborSpecial buildingBuilding constructionsFunctional spaceEngineering

The invention discloses a method for building a container house, which is used for loading a prefabricated building structure in a container-type box body so as to assembly a house by the building method when the house is transported to the building foundation; particularly, the building method comprises the steps of: unloading end wallboards at one end side of a box body, and mounting the end wallboards on the upper edge and the lower edge of an opening at the end side to form an entrance awning and an entrance slope; detaching the two side wallboards, moving out and fixing two integrated function space bodies which are movably arranged in the box body through a guide rail structure in the box body towards the directions of the two side wallboards so as to expand an inner space; assembling the plurality of groups of roof beams in the box body on a box cover and on the integrated function space bodies to form a beam frame structure; respectively fixing the two side wallboards on the beam frame structure to form a roof structure, thereby building the container house. The building method aims at solving the problems the existing detachable container house that the structure is complex, the space utilization rate is low in transportation, the plasticity is comparatively weak, the using space of the house is limited, etc.

Owner:SHANGHAI ETOPIA BUILDING TECH CO LTD

Handrail-drive for an escalator or a moving walk

InactiveUS6974018B2Shorten the lengthLess reverse bendingEscalatorsStairway-like structuresSprocketWheel drive

An escalator has a step-band with steps for the transport of persons. The step-band is bounded on its sides by a balustrade held by a balustrade base. A handrail-drive drives the handrails, and has friction-wheels driving the handrails on the outside of the handrails. Rollers press upon the insides of the handrails, pressing the handrail against the friction-wheel. At least one further friction-wheel arranged on a step chain-wheel drives the friction-wheel through frictional or mechanical engagement.

Owner:INVENTIO AG

Inverted installation method of embedded foundation bolts of large tower-type equipment foundation

The invention discloses an inverted installation method of embedded foundation bolts of a large tower-type equipment foundation, and belongs to the field of building construction. The inverted installation method is characterized in that locating formworks and the embedded foundation bolts are placed in the foundation for conducting concrete pouring after being manufactured and assembled firstly. The inverted installation method is short in installation time, thereby shortening the construction period and reducing the project cost. Meanwhile, center displacement between all the embedded foundation bolts, the topmark height difference of all the bolts and the exposed length deviation of all the bolts are all within the standard permissible range, and the construction precision is high.

Owner:CHINA CHEM ENG SECOND CONSTR

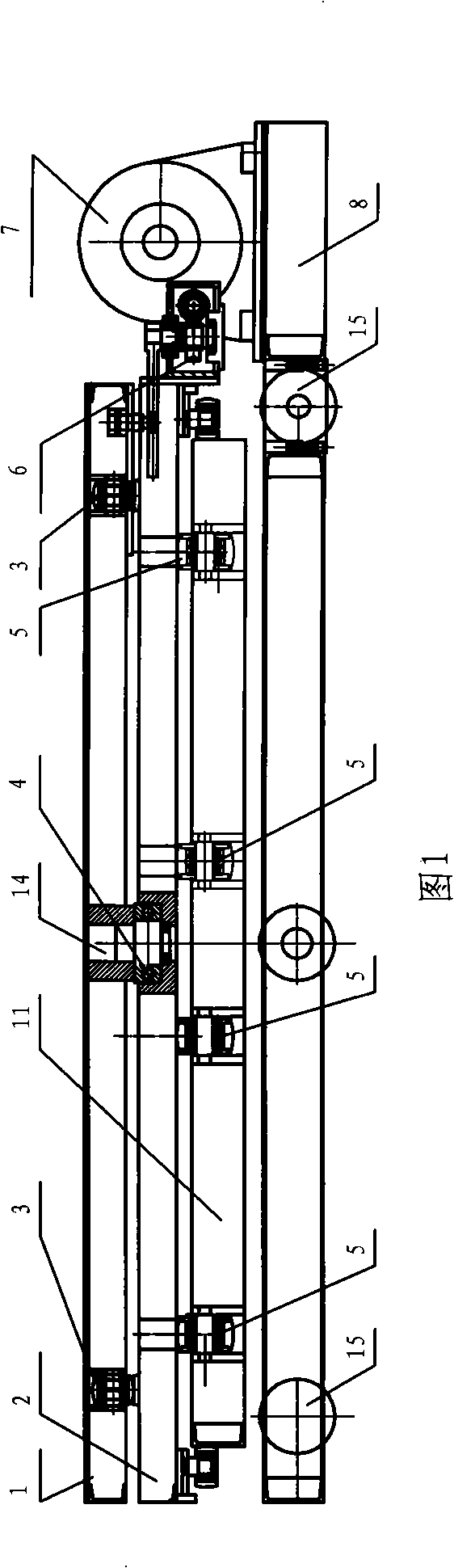

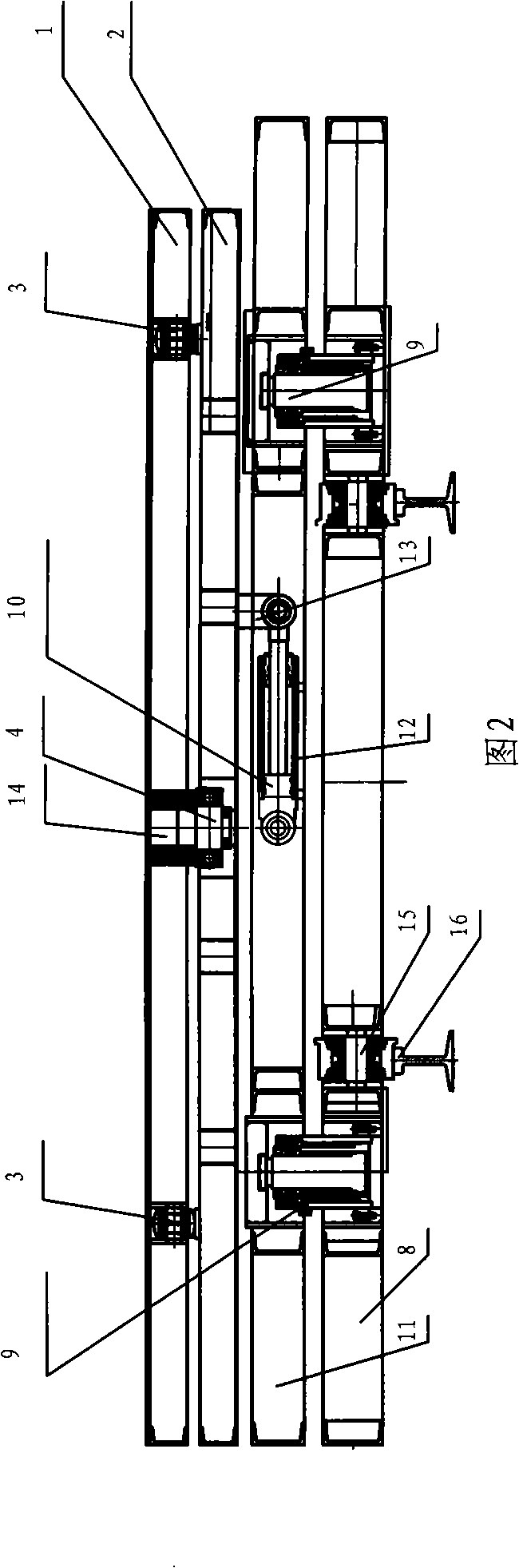

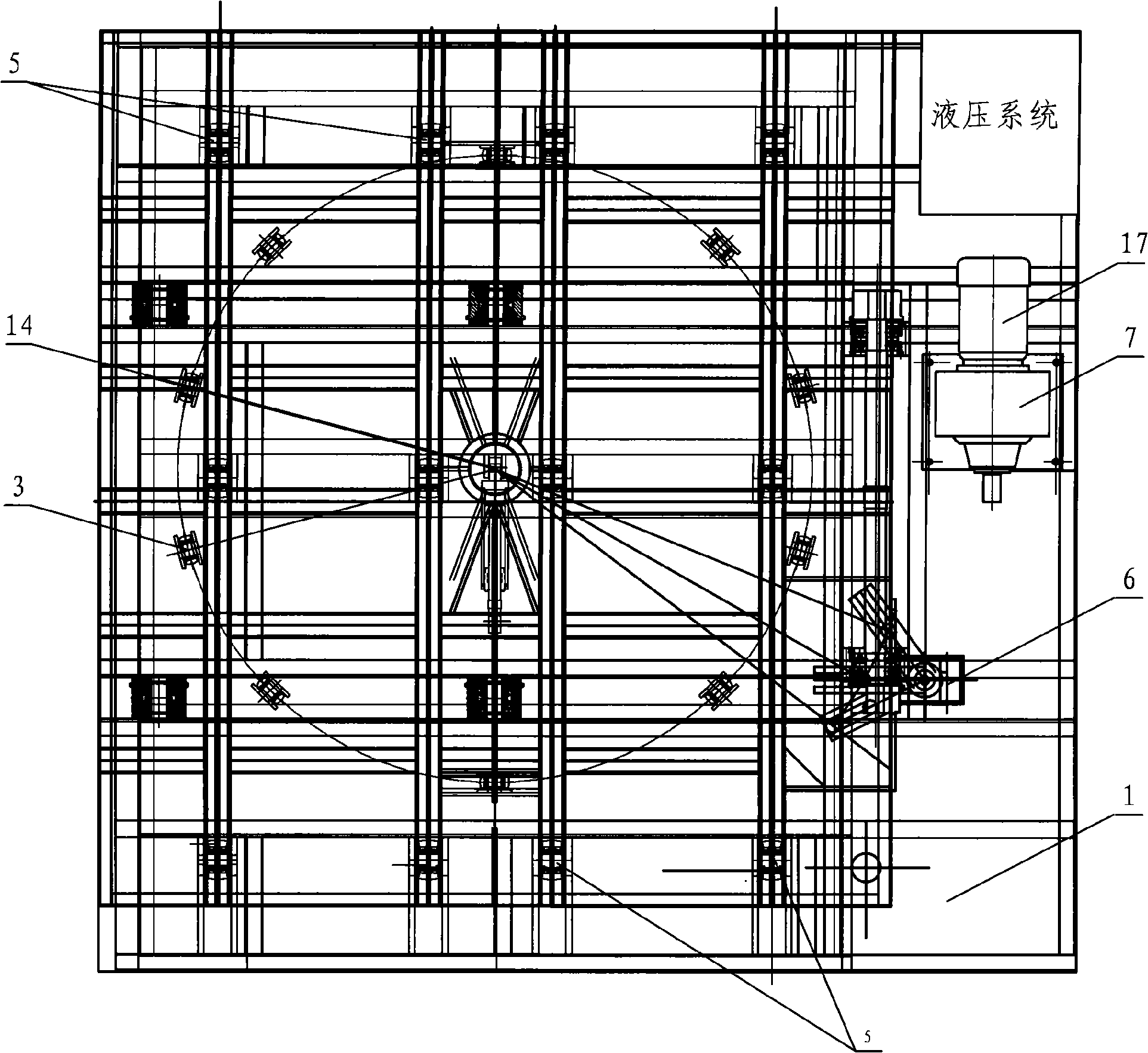

Installation platform of electric locomotive main transformer

The present invention belongs to the device which is used for repairing the electric locomotive in the railway factory, and in particular relates to a main transformer installation platform of the electric locomotive. In the technical proposal, a plane vehicle body of the running part is provided with a lifting platform, a side moving platform and a turntable; the lifting platform is connected with the plane vehicle body of the running part through a group of lifting oil cylinders; the side moving platform is arranged on the lifting platform; a side moving oil cylinder is arranged between the upper surface of the lifting platform and the lower surface of the side moving platform; the turntable is arranged on the side moving platform and rotates around the center of gyration. Because of the lifting, turning, translating and other functions, the application efficiency of the installation platform is improved by more than 6 times. Because of the reliable positioning accuracy, the main transformer can be accurately and safely installed, and is guaranteed to be complete; and the installation platform has the characteristics of time-saving, labor-saving and cost-saving capacities, excellent security, high degree of mechanization, convenient maintenance, and so on.

Owner:DALIAN TONGBAO HYDRAULIC CYLINDER

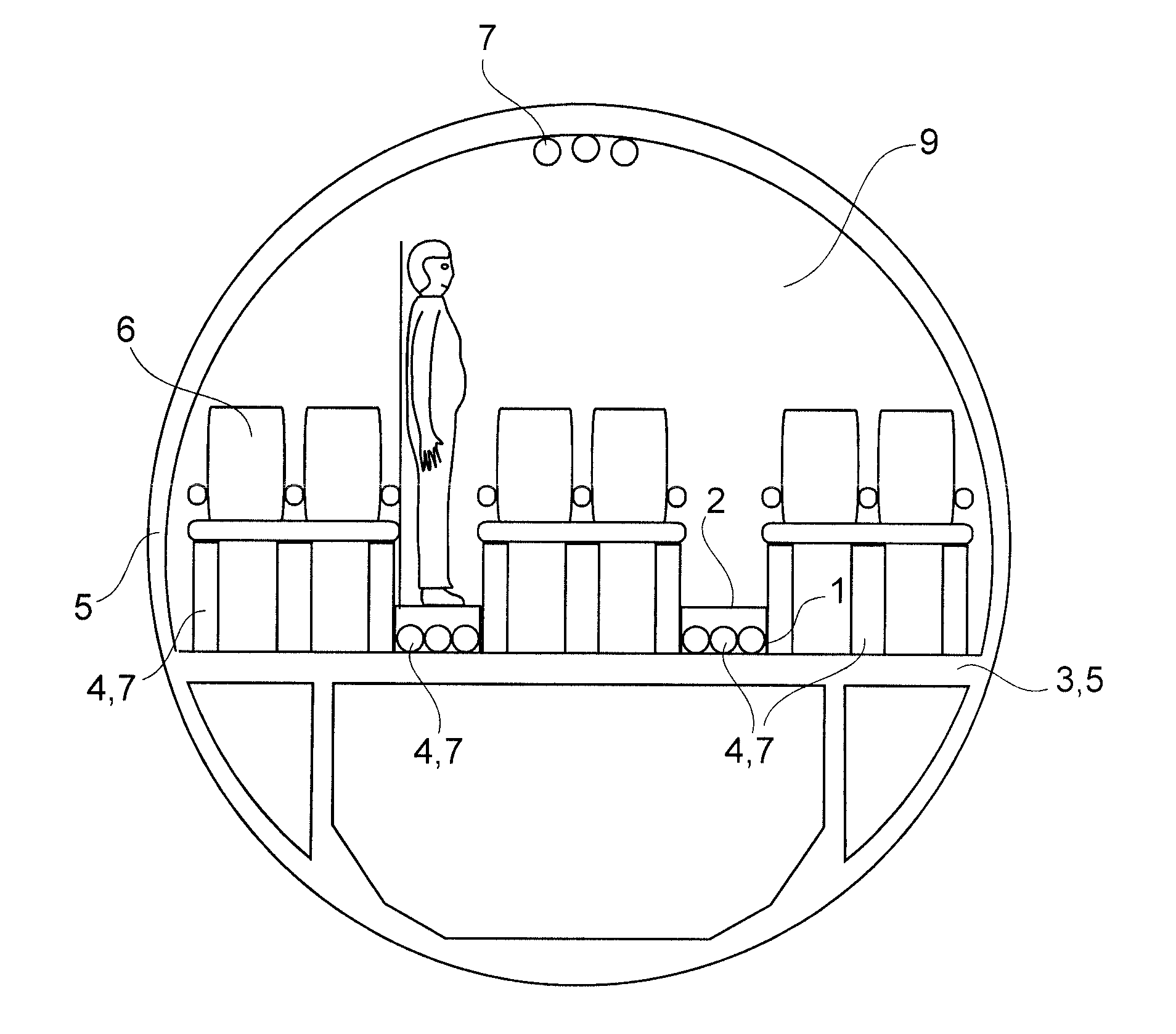

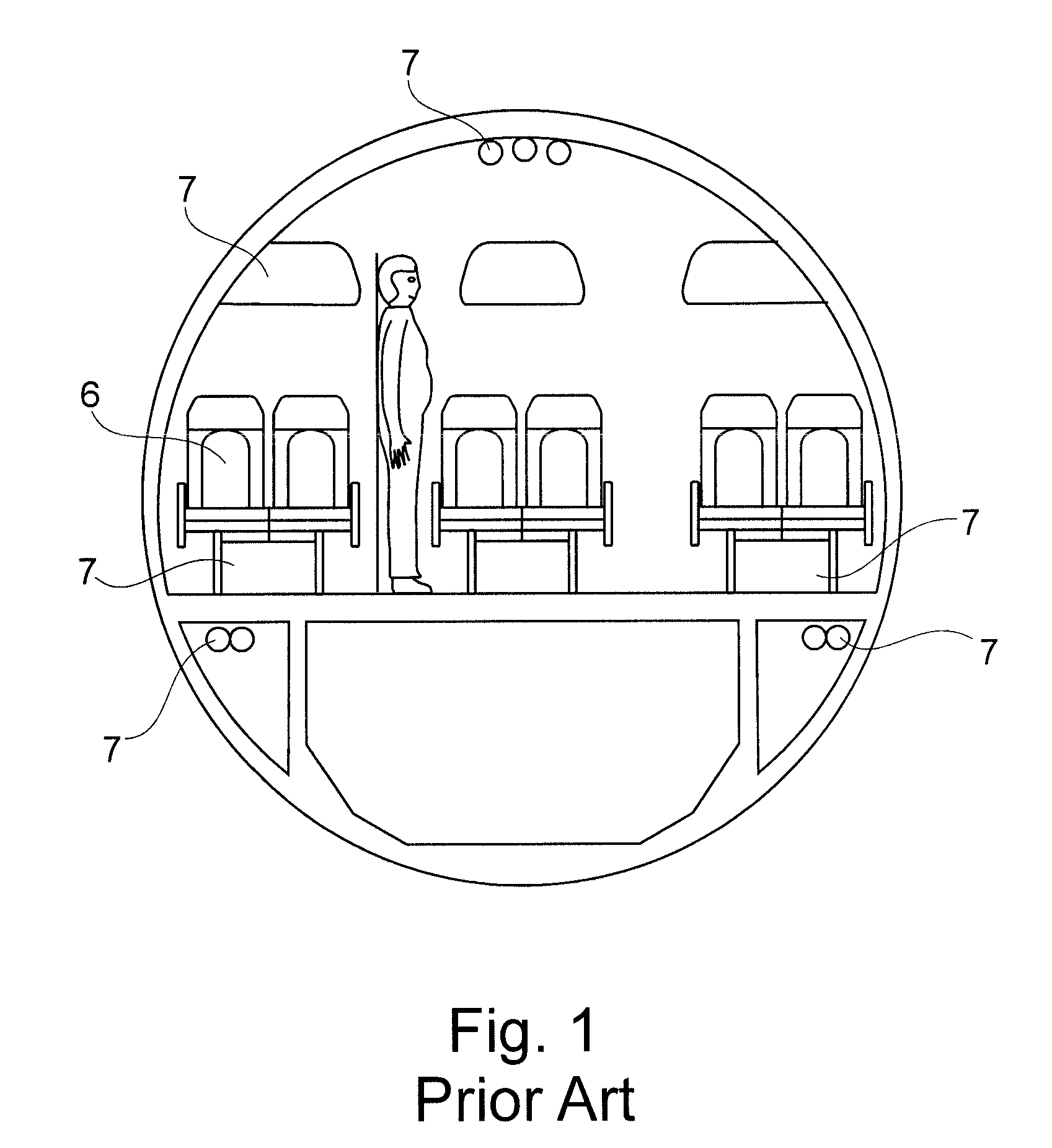

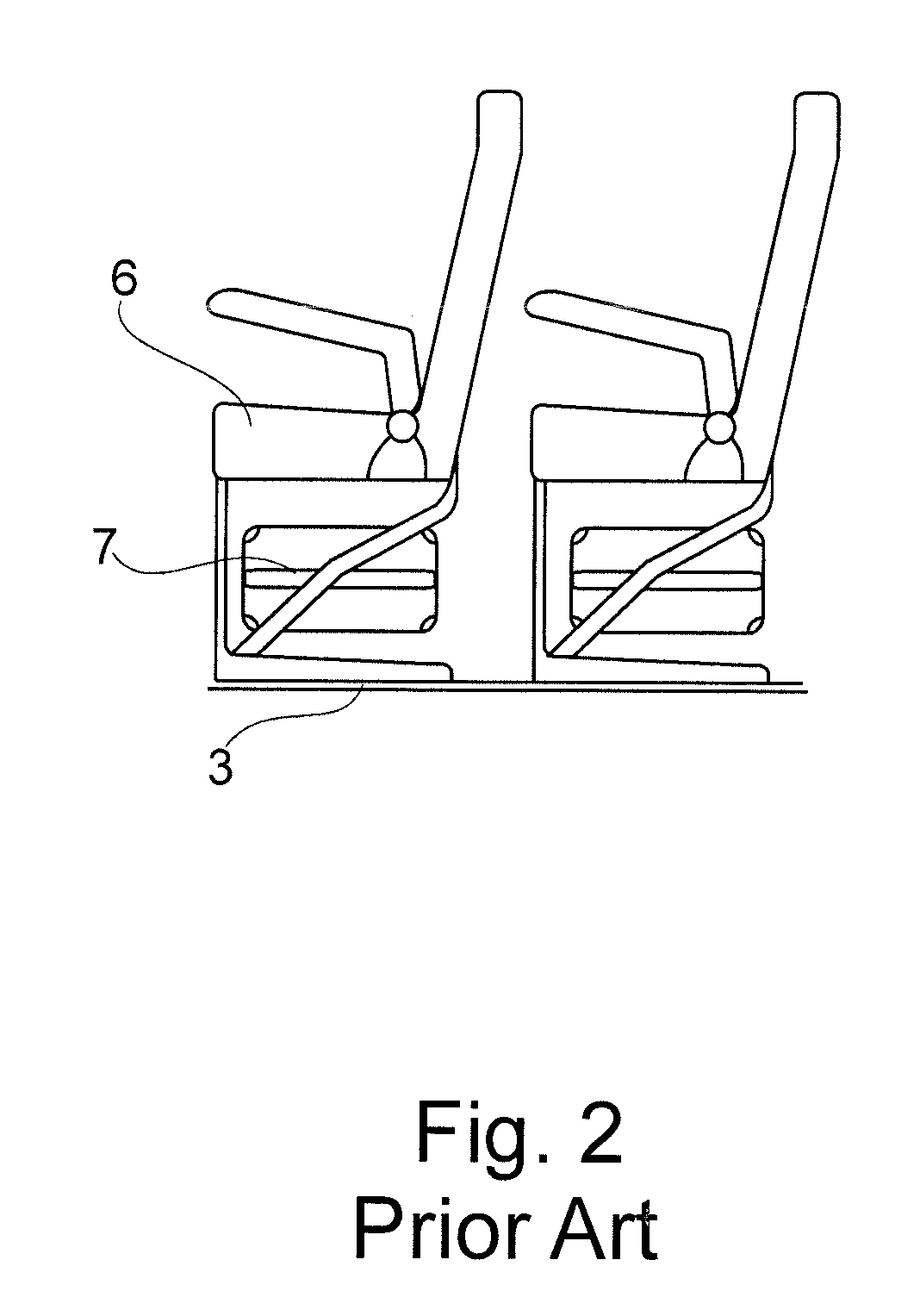

Under-floor system for an aircraft

InactiveUS20100116934A1Improve protectionEasy accessSeating arrangementsAir-treatment apparatus arrangementsEngineeringStructuring element

The present invention relates to an under-floor system for providing a functional space for an aircraft. The under-floor system comprises a support-member structure and a cover element. The support-member structure is designed such that the support-member structure can be fastened to an aircraft structure element. The cover element can be fastened to the support-member structure such that the cover element is spaced apart from, for example, the aircraft floor. By means of spacing the cover element apart from the aircraft floor, the functional space can be provided.

Owner:AIRBUS OPERATIONS GMBH

Construction technology for line slot reserving of fabricated building prefabricated composite slab

InactiveCN108661223ASimple construction operationSimplify the construction processFloorsForms/shuttering/falseworksElectrical junctionComposite slab

The invention relates to the technical field of building construction, in particular to a construction technology for line slot reserving of a fabricated building prefabricated composite slab. The construction technology comprises the steps that a model and a civil model are comprehensively mounted by adopting a BIM technique, a precise electrical pipeline laying diagram is provided, then at the pouring state of a prefabricated layer of a reserved slab, an electrical junction box is buried, and electrical pipeline reserved slots are reserved, then a cast-in-place layer is poured, and thus a final finished product is obtained. According to the construction technology, it is ensured that enough line pipes are arranged under the premise that the composite slab is not affected by pipeline laying as far as possible.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

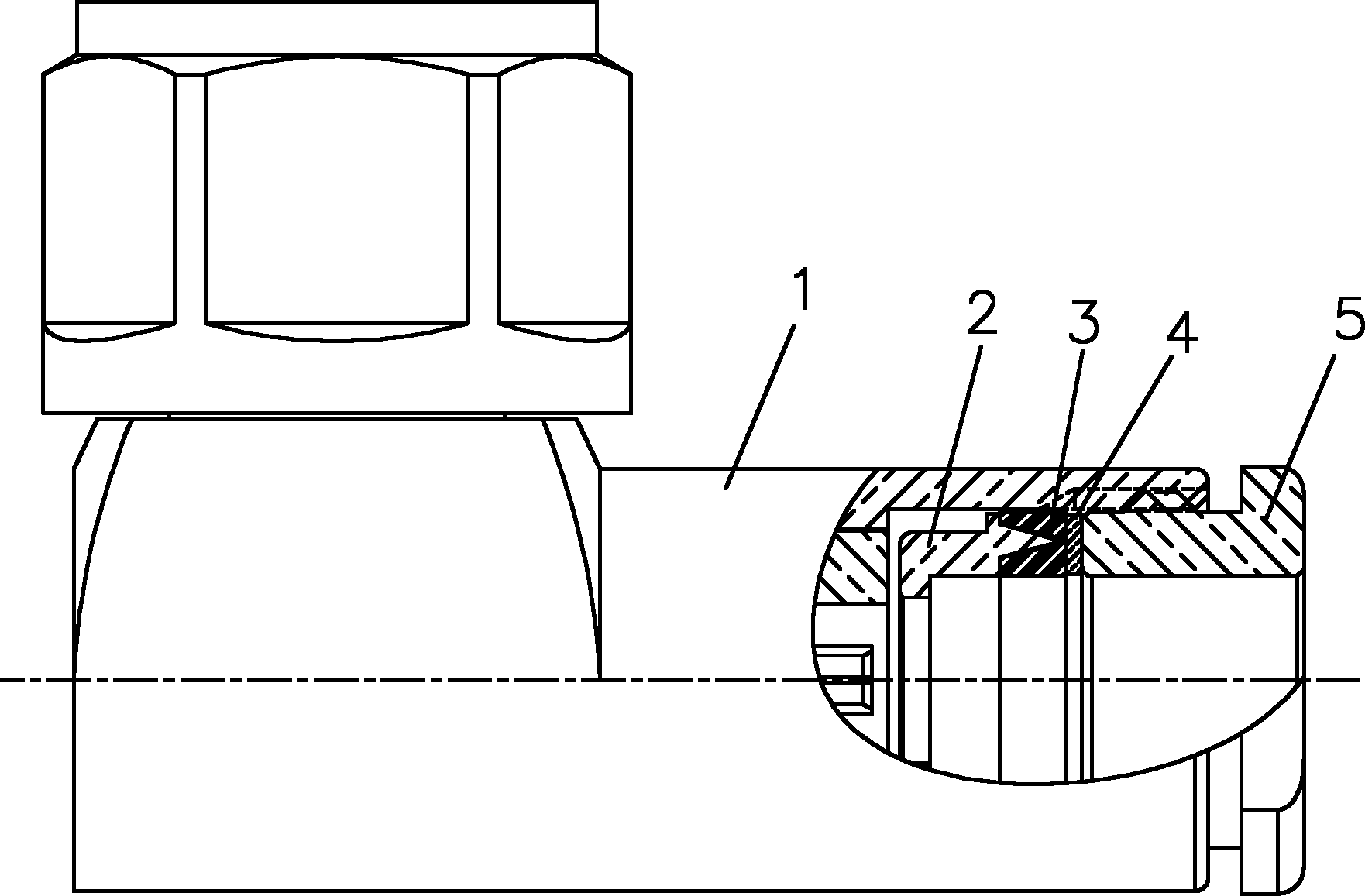

Double-sealing structure of radio frequency coaxial connector and related radio frequency coaxial connector

InactiveCN102176581AAchieving a double sealUnique designRelieving strain on wire connectionCouplings bases/casesEngineeringRadio frequency

The invention relates to a double-sealing structure of a radio frequency coaxial connector. The double-sealing structure comprises a cable clamping part, a locking nut for connecting a connector body of the radio frequency coaxial connector, a first sealing ring and a second sealing ring, wherein the cable clamping part comprises a first end part, and can be movably arranged in the locking nut; the first sealing ring is positioned in the inner surface of the locking nut and between the end face of the first end part and the inner wall of the locking nut; the second sealing ring is arranged on the outer surface of the locking nut, and is used for realizing sealing with the connector body; the first end part is limited by the locking nut in a direction away from the locking nut, and can be in press fit connection or threaded connection with the locking nut; and the first and second sealing rings may be O-shaped, rectangular or square. The invention also relates to the related radio frequency coaxial connector. The double-sealing structure is ingeniously and uniquely designed, good in sealing effect, smaller in part number, simply manufactured, low in production cost and using cost, short in mounting time, repetitively mountable and suitable for large-scale popularization and application, and the parts of the double-sealing structure are difficult to lose.

Owner:ANDREW CORP

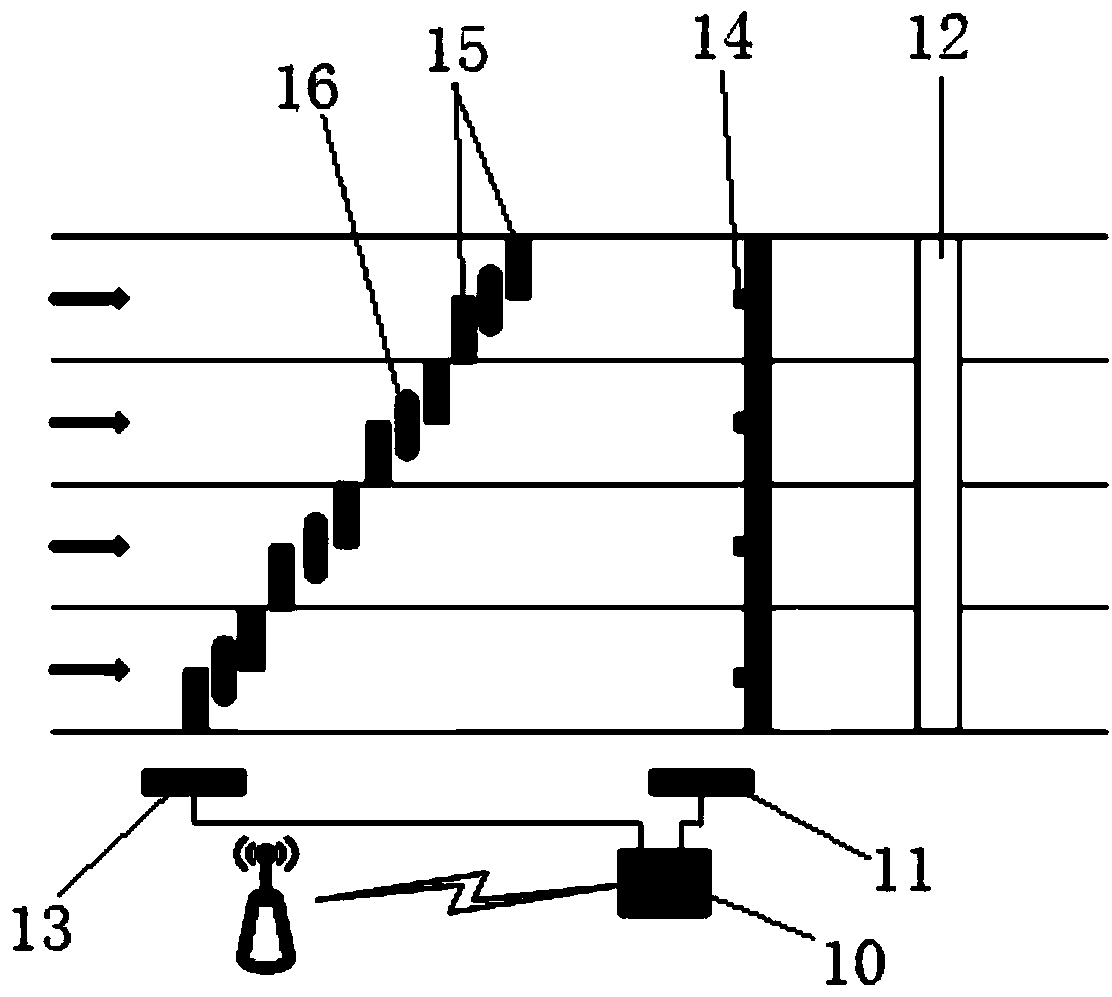

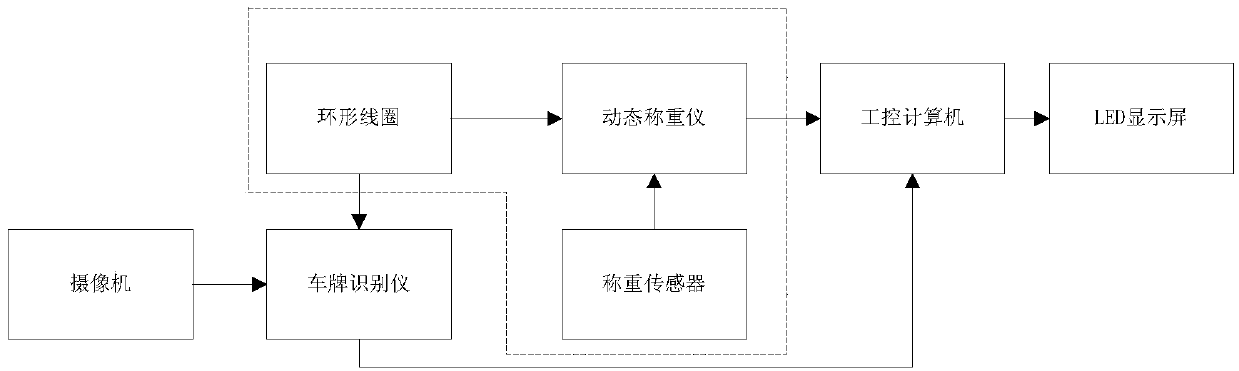

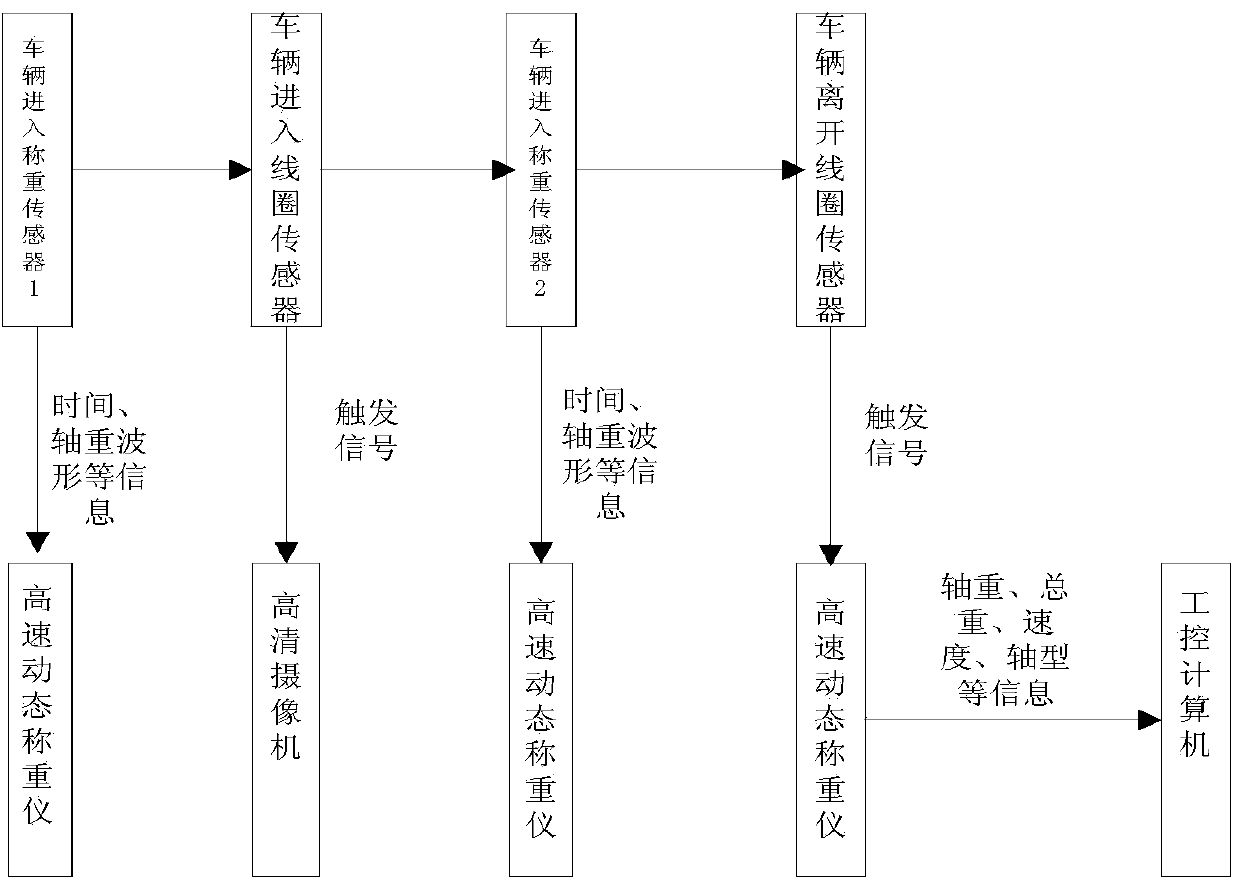

High-speed pre-inspection system

InactiveCN104200663ACalculation speedQuickly Calculate Gross WeightDetection of traffic movementLED displayRoad surface

The invention discloses a high-speed pre-inspection system comprising a high-speed dynamic weighing system, a camera, a license plate recognizer, an LED variable information board and an industrial personal computer. The high-speed dynamic weighing system is connected with the license plate recognizer and the industrial personal computer. The camera is connected with the license plate recognizer which is connected with the industrial personal computer. The industrial personal computer is connected with a LED display screen. The high-speed dynamic weighing system comprises a weighing sensor, a circular coil and a dynamic weigher; the circular coil is connected with the dynamic weigher and the license plate recognizer; the weighing sensor is connected with the dynamic weigher; the dynamic weigher is connected with the industrial personal computer. The high-speed pre-inspection system has the advantages that calculation speed is high, test precision is high, installation time is short and small damage is caused to the road surface.

Owner:重庆市华驰交通科技有限公司

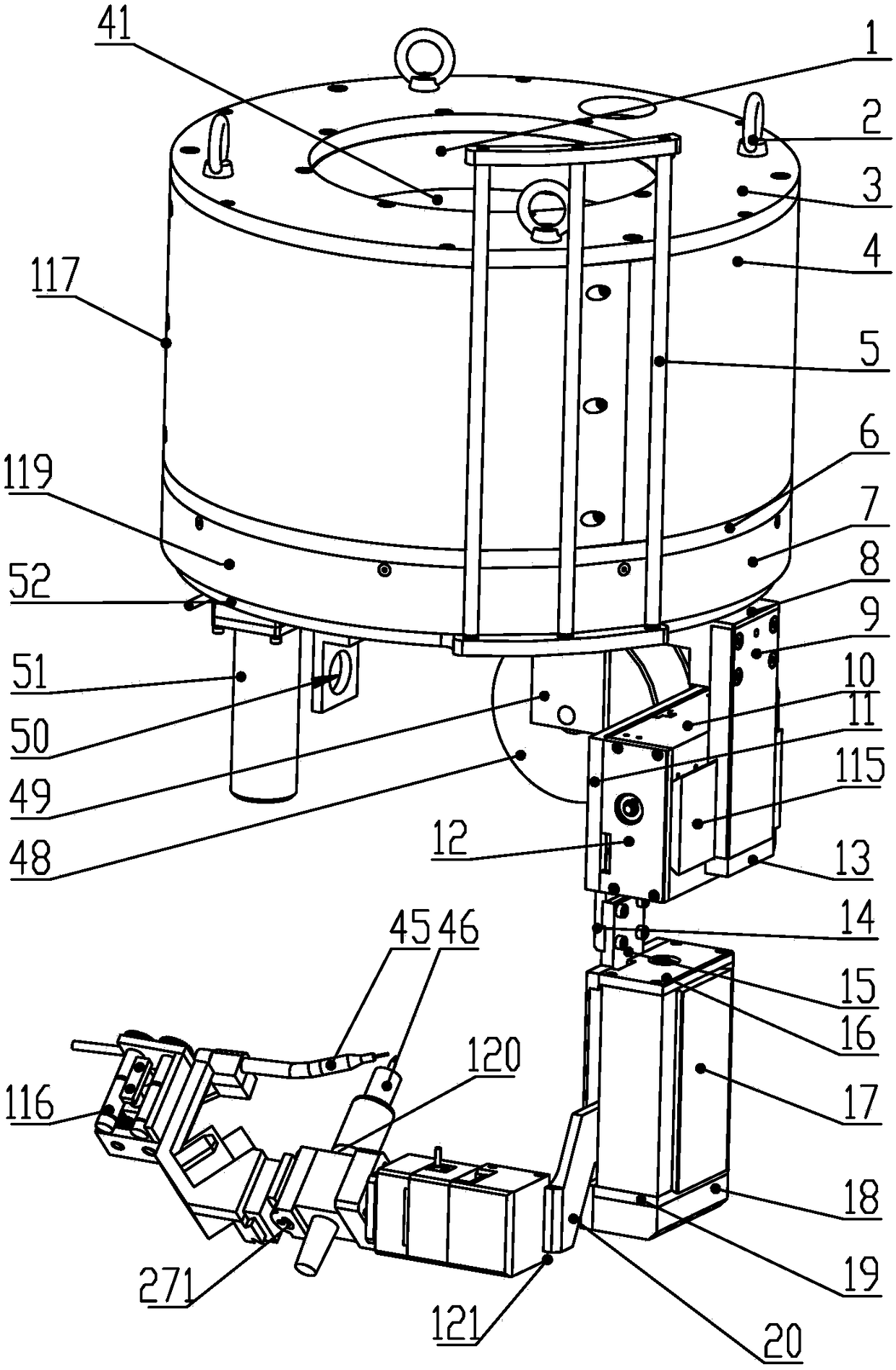

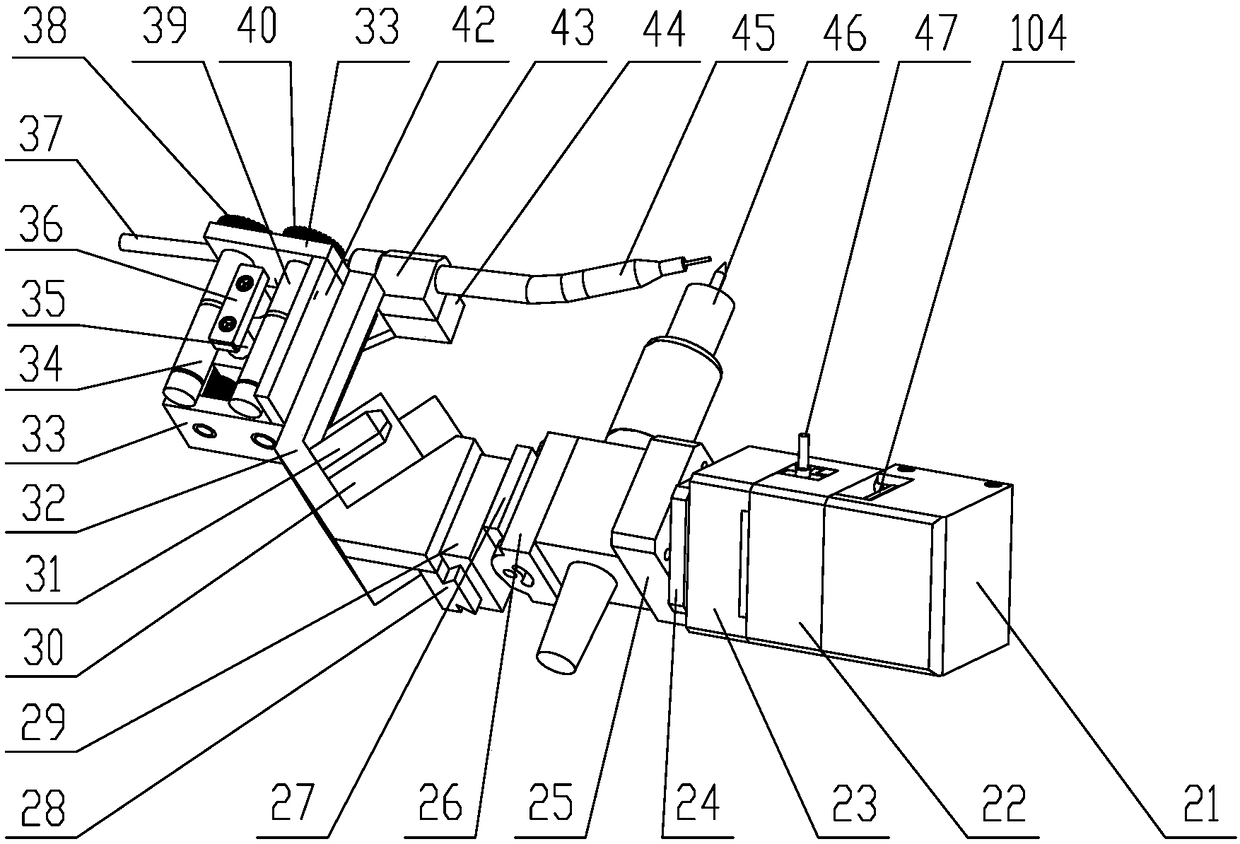

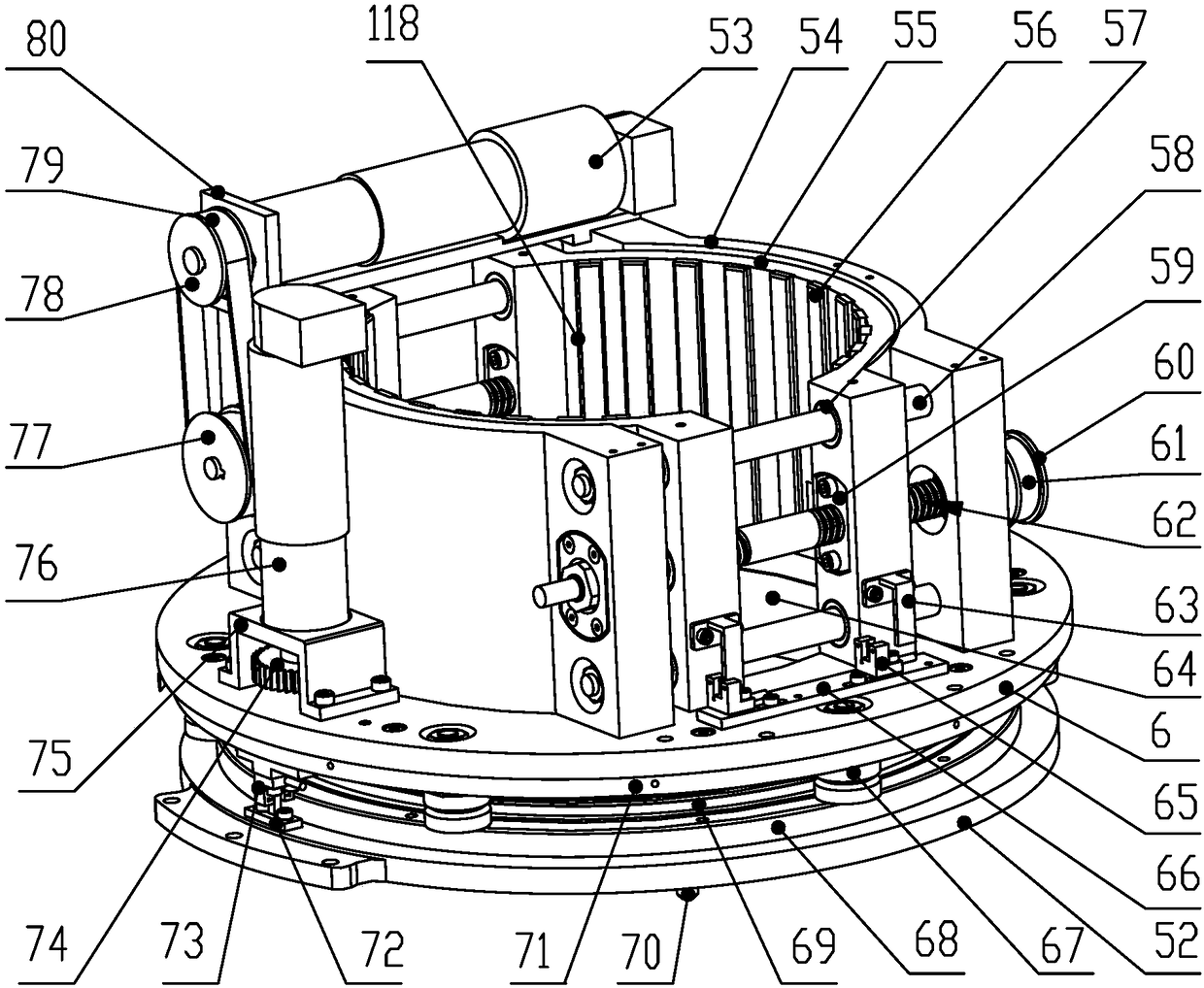

Seal weld surfacing maintenance device

ActiveCN108500422AShorten maintenance cycleImprove operational efficiencyNuclear energy generationArc welding apparatusEngineeringStirrup

The invention provides a seal weld surfacing maintenance device. The seal weld surfacing maintenance device comprises a mounting base with a containing inner cavity, a clamping mechanism, a rotating mechanism and a welding module. A mounting through groove which is vertically through and is used for allowing a seal weld carrier to penetrate into is formed in the mounting base. The mounting base isprovided with a rotating mechanism fixing plate located at the lower end of the containing inner cavity. The clamping mechanism is arranged in the containing inner cavity of the mounting base and provided with two symmetrically-arranged clamping stirrups, and the two clamping stirrups can oppositely move in the radial direction of the seal weld carrier so as to fix the mounting base to the periphery of the seal weld carrier. The rotating mechanism is installed on the lower end face of the rotating mechanism fixing plate and provided with a welding motion fixing plate capable of rotating in the circumferential direction of the seal weld carrier. The welding module is installed on the welding motion fixing plate and provided with a welding assembly and a wire feeding nozzle assembly. By means of the seal weld surfacing maintenance device, the automatic surfacing operation can be achieved, operation is simple, the mounting time is short, the surfacing maintenance time is shortened, and the seal weld maintenance operation cost is greatly reduced.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Grouting structure in tunnel driving process and grouting method matched with grouting structure

ActiveCN106761837AIncrease profitReduce grouting costsUnderground chambersTunnel liningSlurryUtilization rate

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

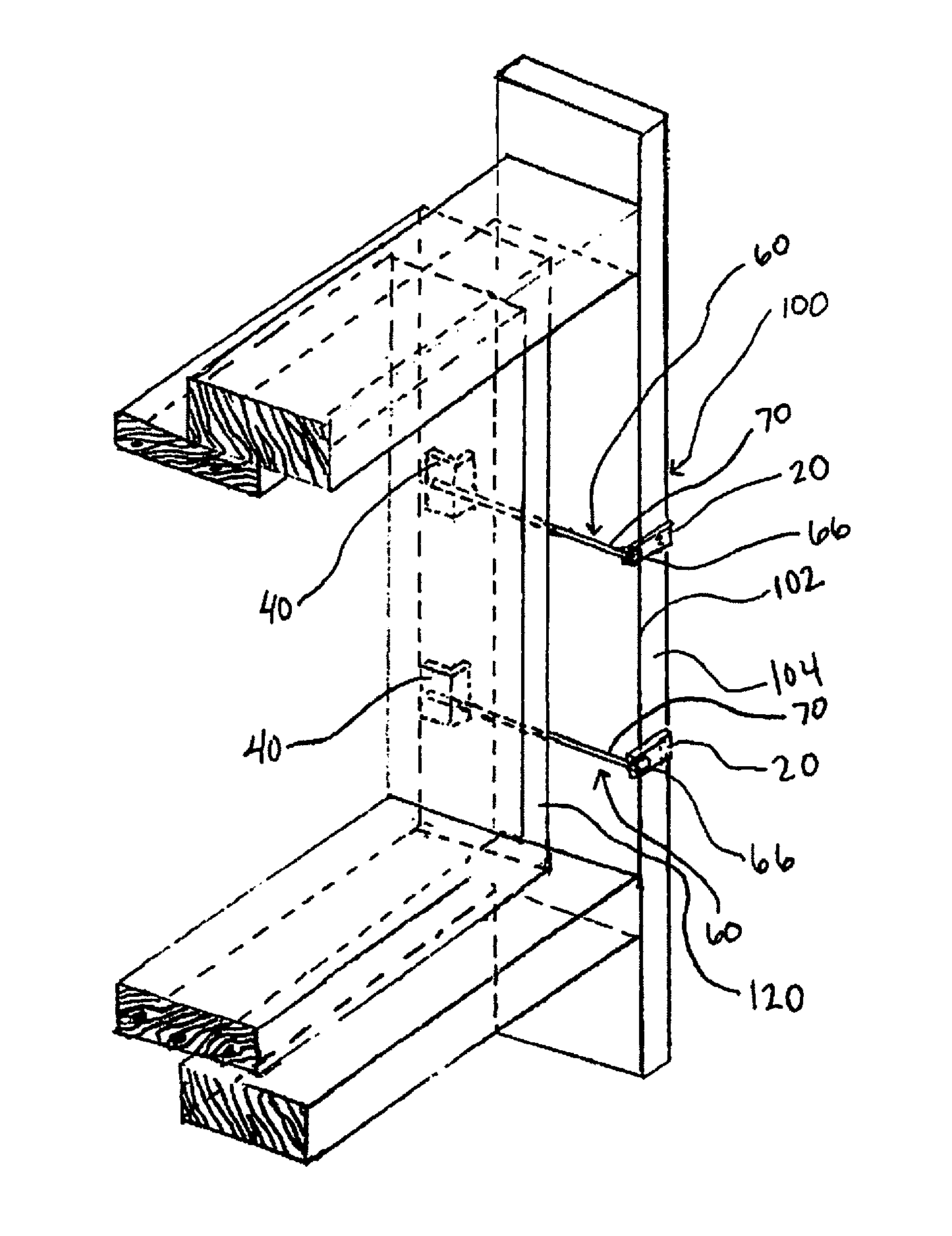

Adjustment device and system

InactiveUS20120211636A1Long installation timeIncrease raw material costMachine supportsCorner/edge jointsLinear motionScrew thread

The invention includes an alignment device and system having a guide member, a support member and a connector which engages the guide member and the support member. The guide member may be a relatively flat piece attachable to and edge of a frame. In one aspect the guide member includes a perimeter slot. The support member may have a first portion generally perpendicular with a second portion and the first portion may be attached to an object (or integral with an object such as a window or door casing) which is to be aligned with a frame. The second portion may have a connector portion or threaded hole for receiving a connector. The connector may also engage the slot of the guide member. The device allows for desired alignment of an object within a frame by transferring rotational movement to linear movement.

Owner:SIREK ANDREW +1

Governance method of floor heave of mine roadway during mining

InactiveCN101936172AImprove support strengthThe supporting strength is sufficientProps/chocksEngineeringUltimate tensile strength

Owner:CHINA UNIV OF MINING & TECH

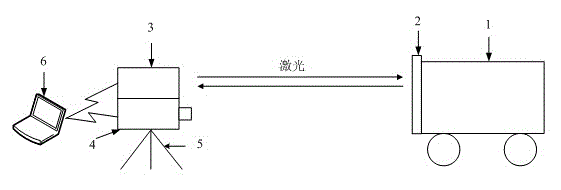

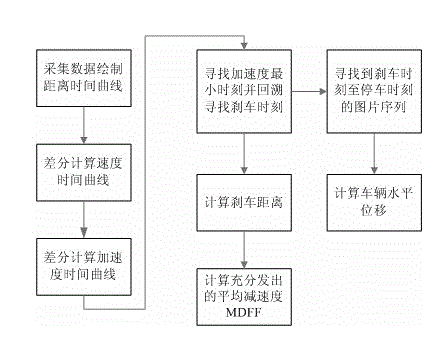

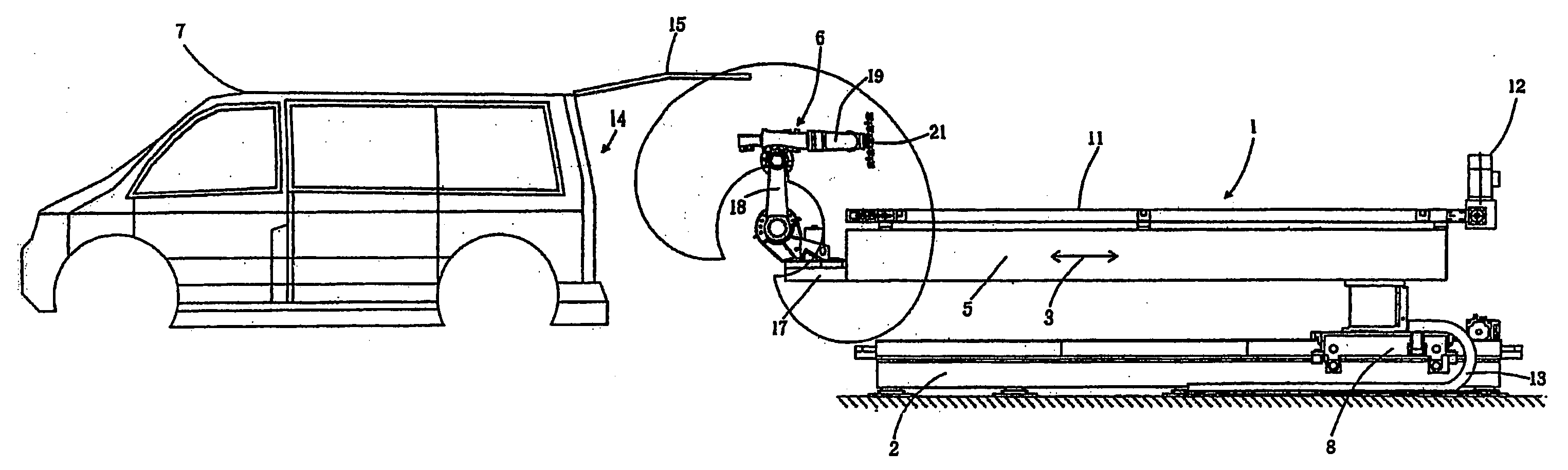

Vehicle road test brake performance detection system based on laser ranging

InactiveCN102914437AEasy to installShort installation timeVehicle testingOptical rangefindersLaser rangingLaser rangefinder

The invention discloses a vehicle road test brake performance detection system based on laser ranging. The system comprises a laser range finder, a laser reflector, a camera and a processor, the laser range finder is connected with the processor, laser emitted by the laser range finder returns to the same after being reflected by the laser reflector, and the camera is connected with the processor. The detection system is simple to mount and operate, and can accurately and comprehensively detect the vehicle road test brake performance.

Owner:ZHEJIANG UNIV +1

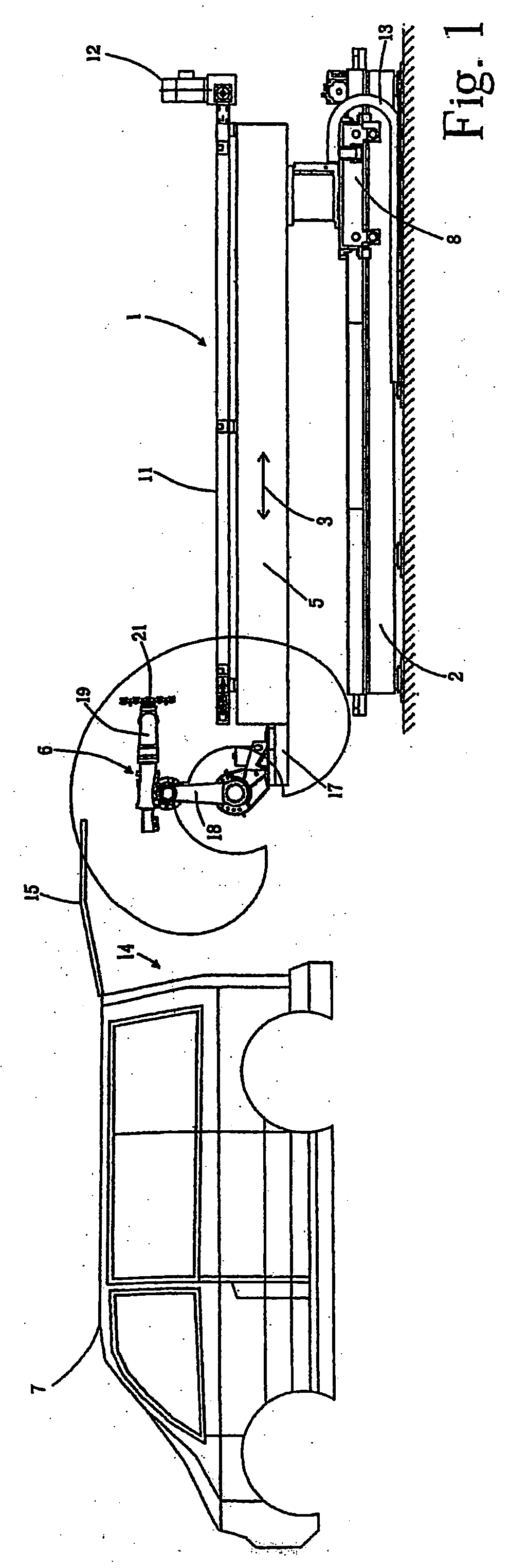

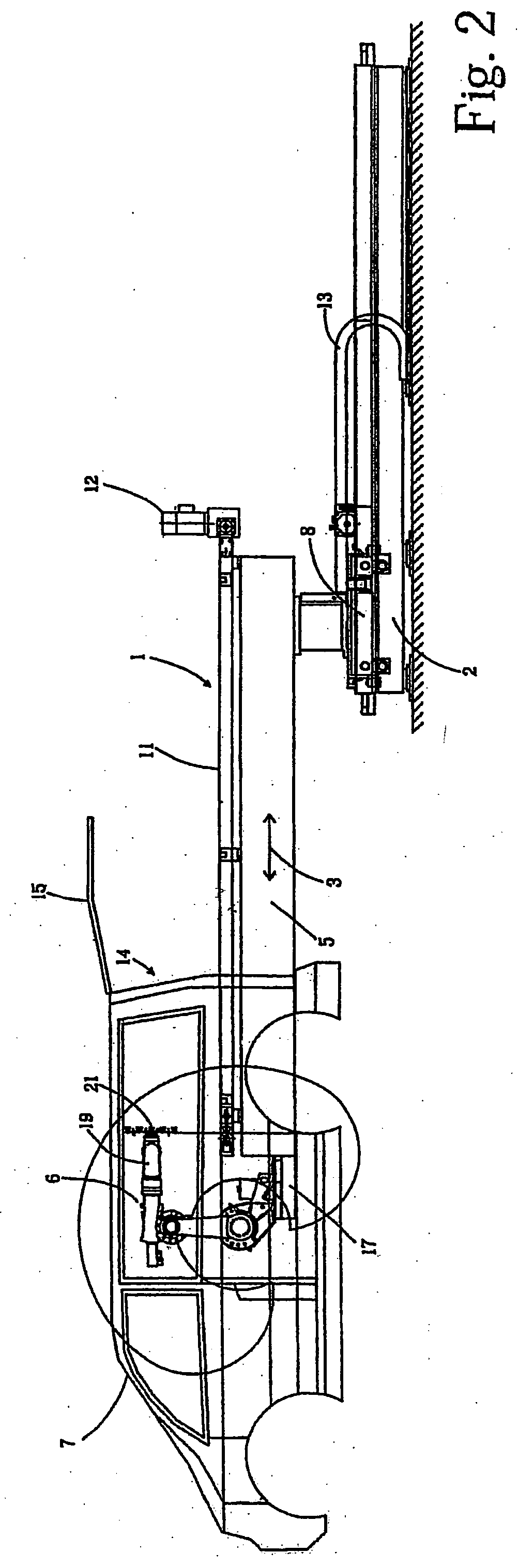

Method and Devices for Applying Films to Interior Wall Sections of Vehicle Bodywork

InactiveUS20080000070A1Short installation timeSmall designAutomatic control devicesAssembly machinesEngineeringMechanical engineering

The invention relates to a method and a device for applying films (10) to interior wall sections of the bodywork (7) of a vehicle with the aid of an instrument or robot (6) comprising a multi-membered articulated arm (18, 19) and gripping elements (21) for the films. To reduce the mounting time, the robot (6) is driven through an opening (14) in the interior of the bodywork (7), the films (10) to be applied are transported by transport elements (11) to the vicinity of the interior or into the interior of the bodywork (7) and the delivered films (10) are taken from the transport elements by the robot (6) and its gripping elements (21) and are applied to the respective interior wall sections.

Owner:FAIST CHEMTEC

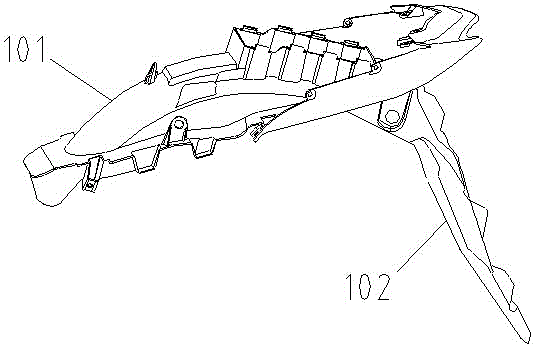

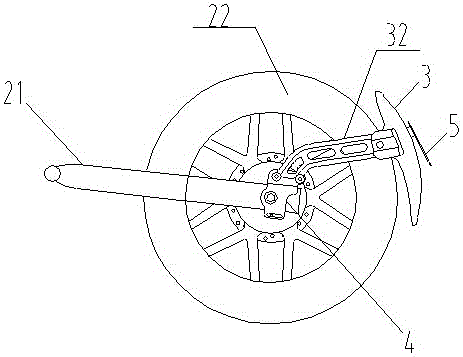

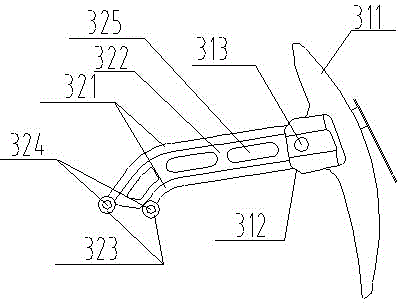

Two-wheel motor vehicle with new rear-fender mounting state

The invention discloses a two-wheel motor vehicle with a new rear-fender mounting state. The two-wheel motor vehicle comprises rear bottom forks, a rear wheel mounted in two side rods of the rear bottom forks through a rear bottom-fork shaft, and a rear fender positioned behind the rear wheel, wherein the rear fender comprises a rear fender body and two supporting components; connecting lugs are respectively and symmetrically arranged on two sides of the rear fender body; rear ends of the two supporting components are connected with the rear fender body through the two connecting lugs; front ends of the two supporting components are respectively mounted on the two side rods of the rear bottom forks in a demountable manner; the distance between the two supporting components is larger than the section width of the rear wheel. The two-wheel motor vehicle has a new rear-fender mounting manner and a new rear-fender mounting state, so that the overall length of the rear fender can be shortened, and the assembling time of the rear fender can be shortened.

Owner:力帆科技(集团)股份有限公司

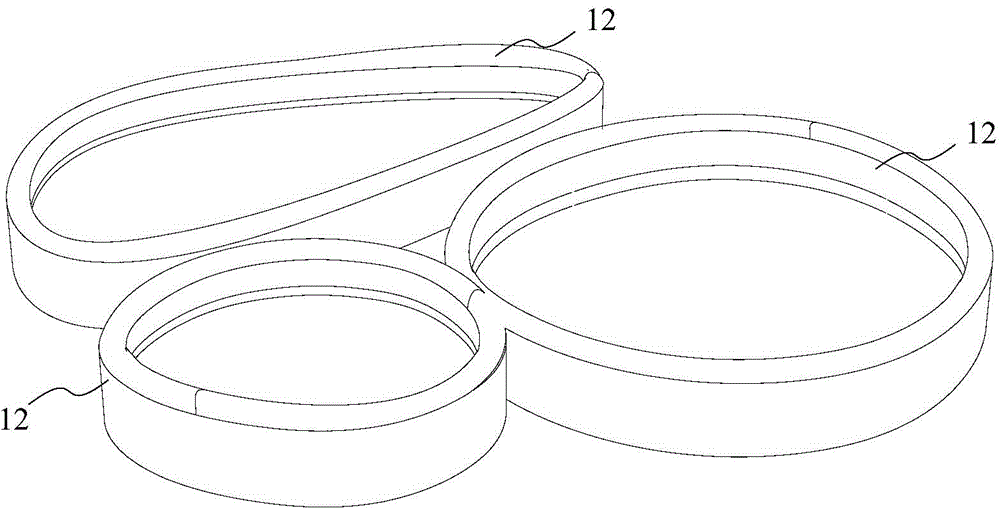

Water bag and air bag combined floating bridge

ActiveCN105625159AImprove stabilityImprove carrying capacityFloating bridgesMarine engineeringBridge deck

The invention provides a water bag and air bag combined floating bridge. According to the water bag and air bag combined floating bridge, vehicles and persons can pass safely, and a wave resisting effect can also be achieved; rapid installation and construction can be achieved, and the warehousing and transportation space and weight can be greatly reduced. According to the technical scheme, the water bag and air bag combined floating bridge comprises a water surface air bag set, a water bag set arranged below the water surface air bag set, a pipeline assembly used for inflating the water surface air bag set and injecting water into the water bag set, and a rapid bridge deck arranged on the water surface air bag set.

Owner:武汉速安达建筑橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com