Reinforcement cage quick-assembling positioning system

A technology of positioning system and steel cage, which is applied in the direction of erecting/assembling bridges, sheet pile walls, bridges, etc. It can solve the problems of prolonged pile-forming time, self-heavy reinforcement cage, and difficult operation, so as to save pile-forming cycle and installation time The effect of short, high-quality joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

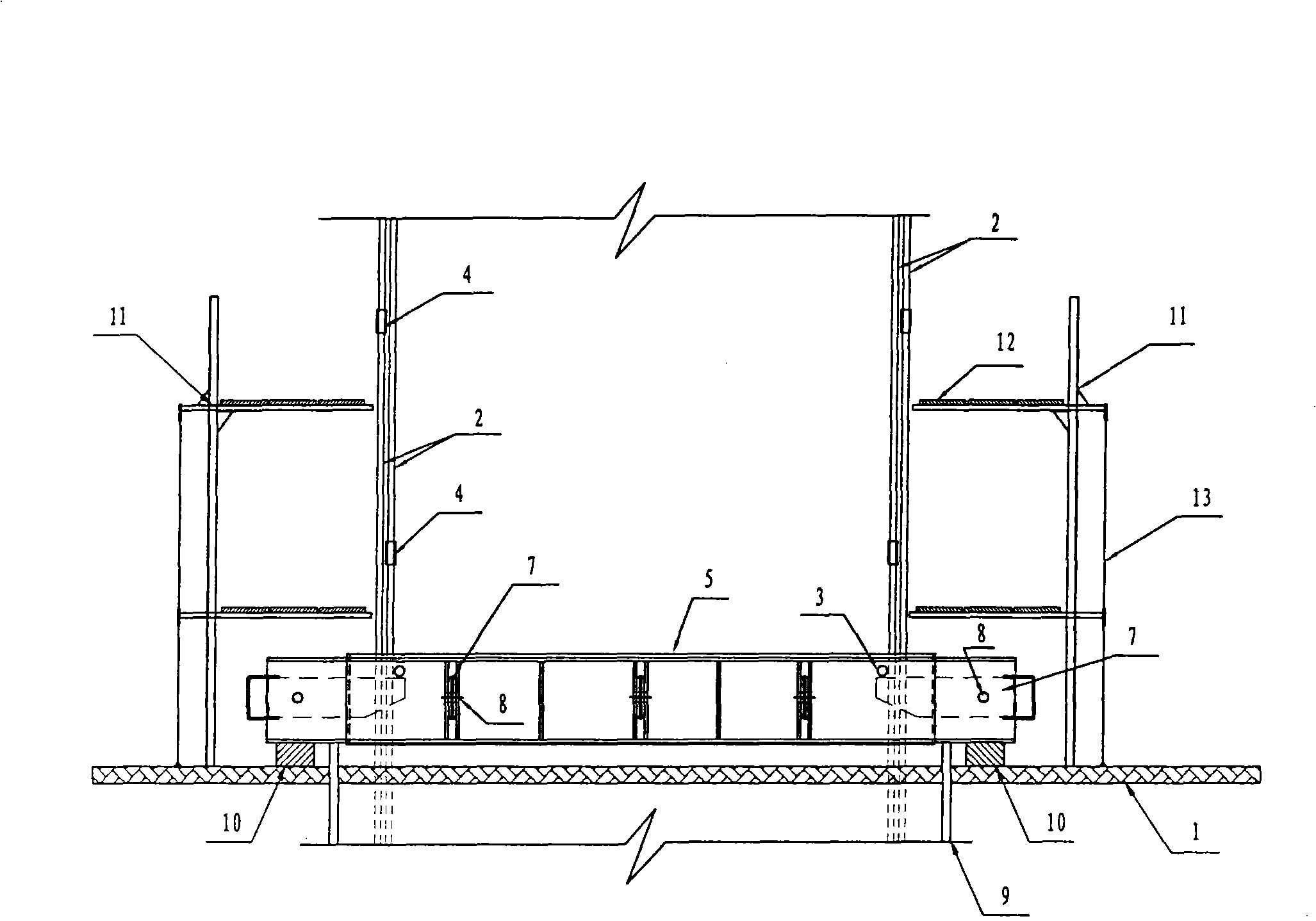

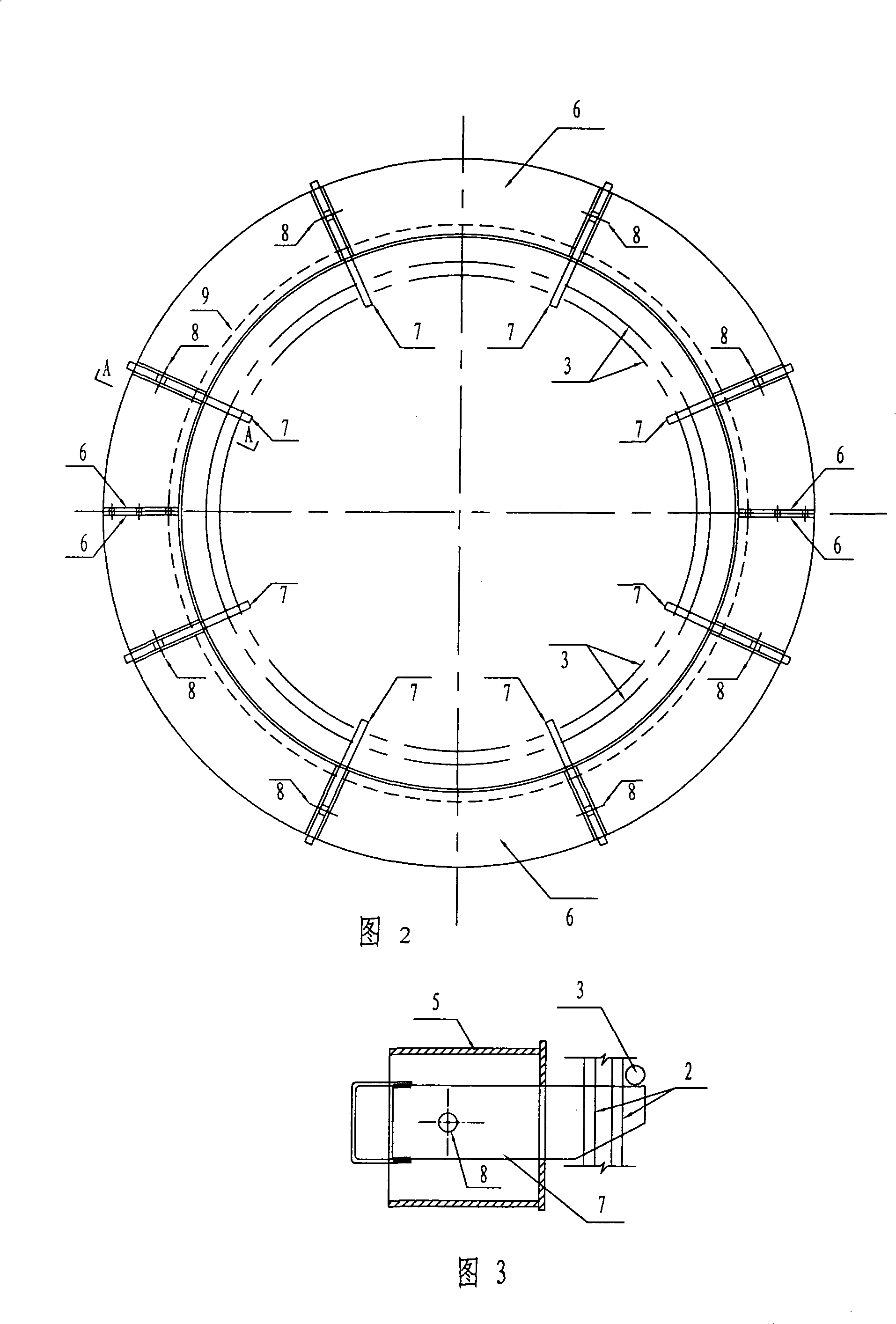

[0017] The φ2.8m bored pile of the main bridge of a certain bridge, the total length of the reinforcement cage is 110m, the total weight is 90t, the upper part of the reinforcement cage is designed as a double row of main reinforcement, and each layer has 136 φ40 grade II reinforcement; the lower part is a single row of main reinforcement , each layer has 68 φ40II grade steel bars. During the construction, the installation site is divided into 10 sections. Using this rapid installation system, the reinforcement cage of a pile can be put in place within 24 hours at the fastest, and the average installation time of the reinforcement cage is 30 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com