Construction technology for line slot reserving of fabricated building prefabricated composite slab

A construction process and technology of laminated boards, which are applied in the on-site preparation of building components, construction, building components, etc., can solve the problems such as the thickness of the protective layer of the surface layer steel bar does not meet the requirements, exposed steel bars, etc., so as to achieve simple and lightweight construction materials. Simple construction operation, flexible and convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

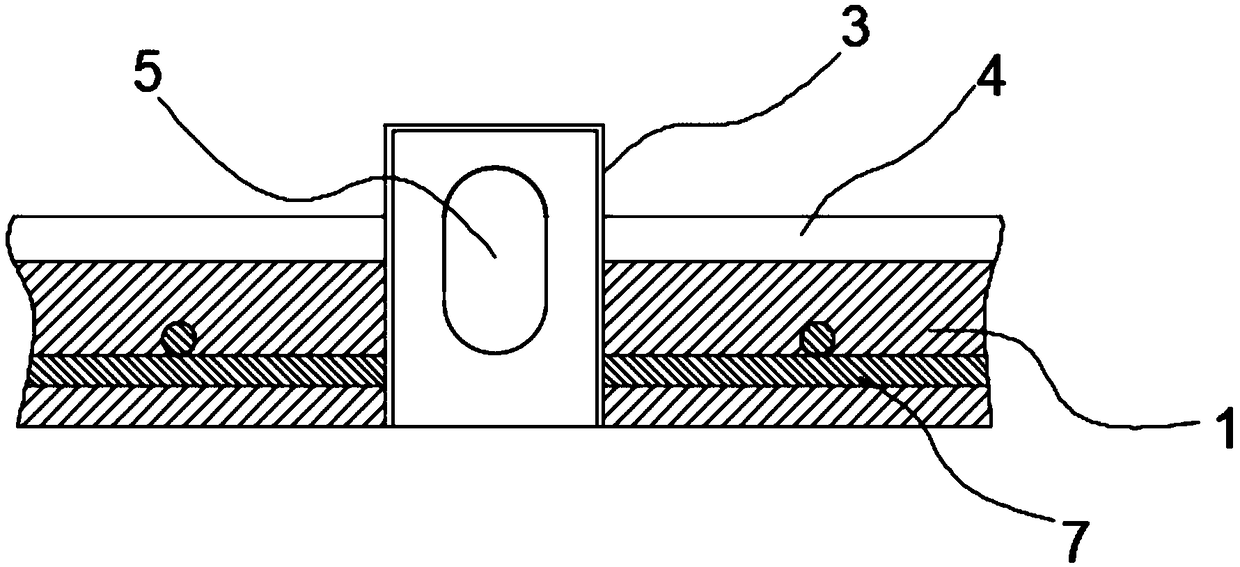

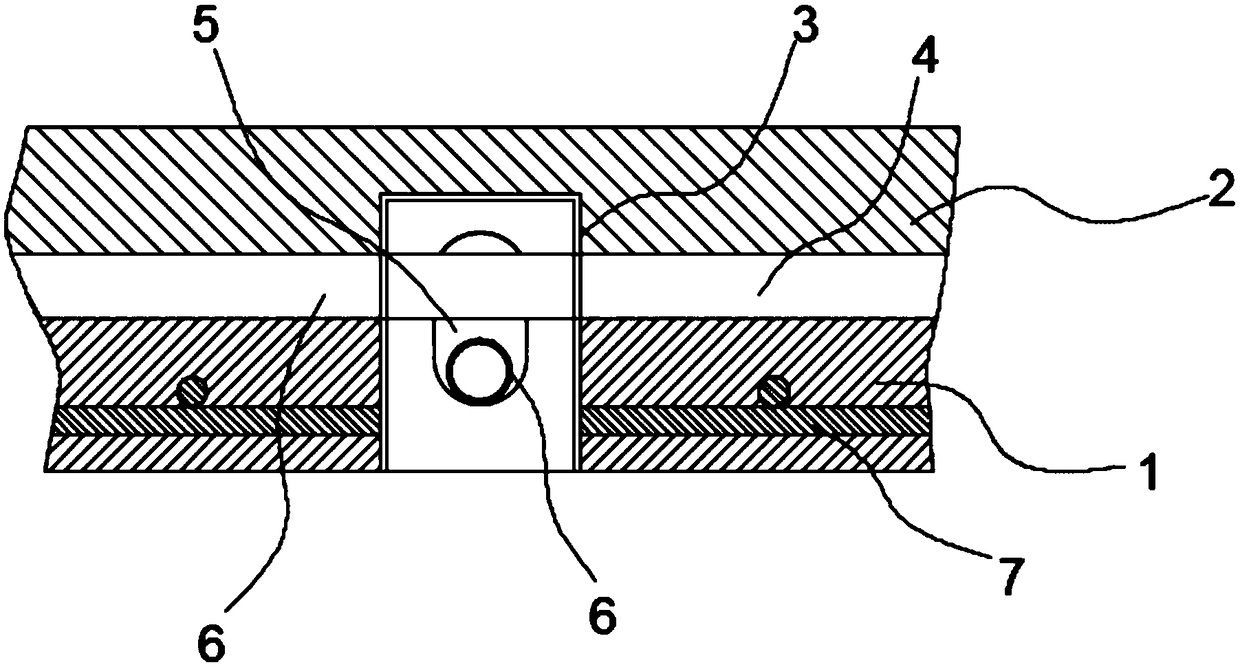

[0024] A construction technique for reserved wire grooves of prefabricated laminated slabs in prefabricated buildings, such as figure 1 with figure 2 shown, including the following steps:

[0025] Step 1: In the design stage, by using BIM technology to integrate the installation model and civil engineering model, adjust the elevation and position of the internal pipeline, determine the specific direction of the pipeline, optimize the laying route of the electrical pipeline on the floor, and issue an accurate laying diagram of the electrical pipeline; specifically Use BIM software to comprehensively arrange the electrical pipelines on the floor and issue electrical pipeline laying diagrams; adjust the elevation and position of the internal pipelines of the electromechanical system, and determine the specific direction of the pipelines. Embed wire boxes and arrange wire grooves during the production stage of laminated panels to avoid subsequent on-site Conflicts occur when pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com