Inverted installation method of embedded foundation bolts of large tower-type equipment foundation

A technology of anchor bolts and equipment foundations, which is applied in the field of pre-buried anchor bolts flip-chip construction of large-scale tower equipment foundations, can solve the problems of long installation period, difficult construction, and low installation accuracy, and achieve project cost reduction and construction The effect of high precision and short installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example: Inner Mongolia 3052 chemical fertilizer production project installation and construction example of ammonia plant.

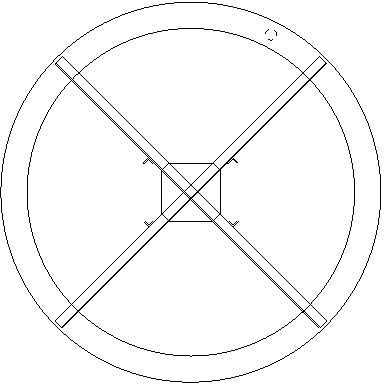

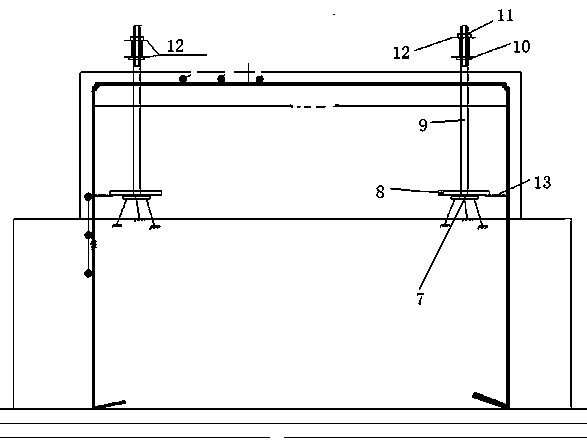

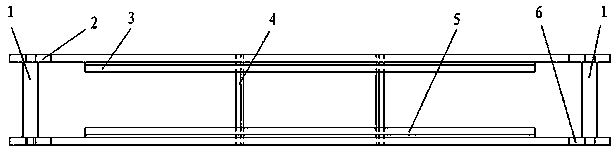

[0022] The process flow of the present invention is: assemble the construction platform → make positioning templates and fix and level them on the construction platform → pre-embedded anchor bolts are inverted → pre-embedded anchor bolts are transported as a whole and hoisted in place → pre-embedded anchor bolts installation size review → Rebar binding → Concrete pouring → Removal of positioning formwork and protection of exposed threads.

[0023] The assembled construction platform.

[0024] 1. The construction platform is erected. This platform is the same as the prefabricated assembly platform of non-standard equipment, H-shaped steel and steel structure. The existing prefabricated platform or assembled construction platform can be used. When the platform is assembled, the prefabrication of future steel structures and non-standard equipment sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com