Self-cleaning gluing scheme

A self-cleaning, scheme-based technology, applied in the direction of architecture, building structure, etc., can solve the problems of affecting the appearance, increasing the follow-up cleaning work, and heavy workload, so as to improve the construction quality and speed, reduce the follow-up cleaning work, installation and disassembly simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

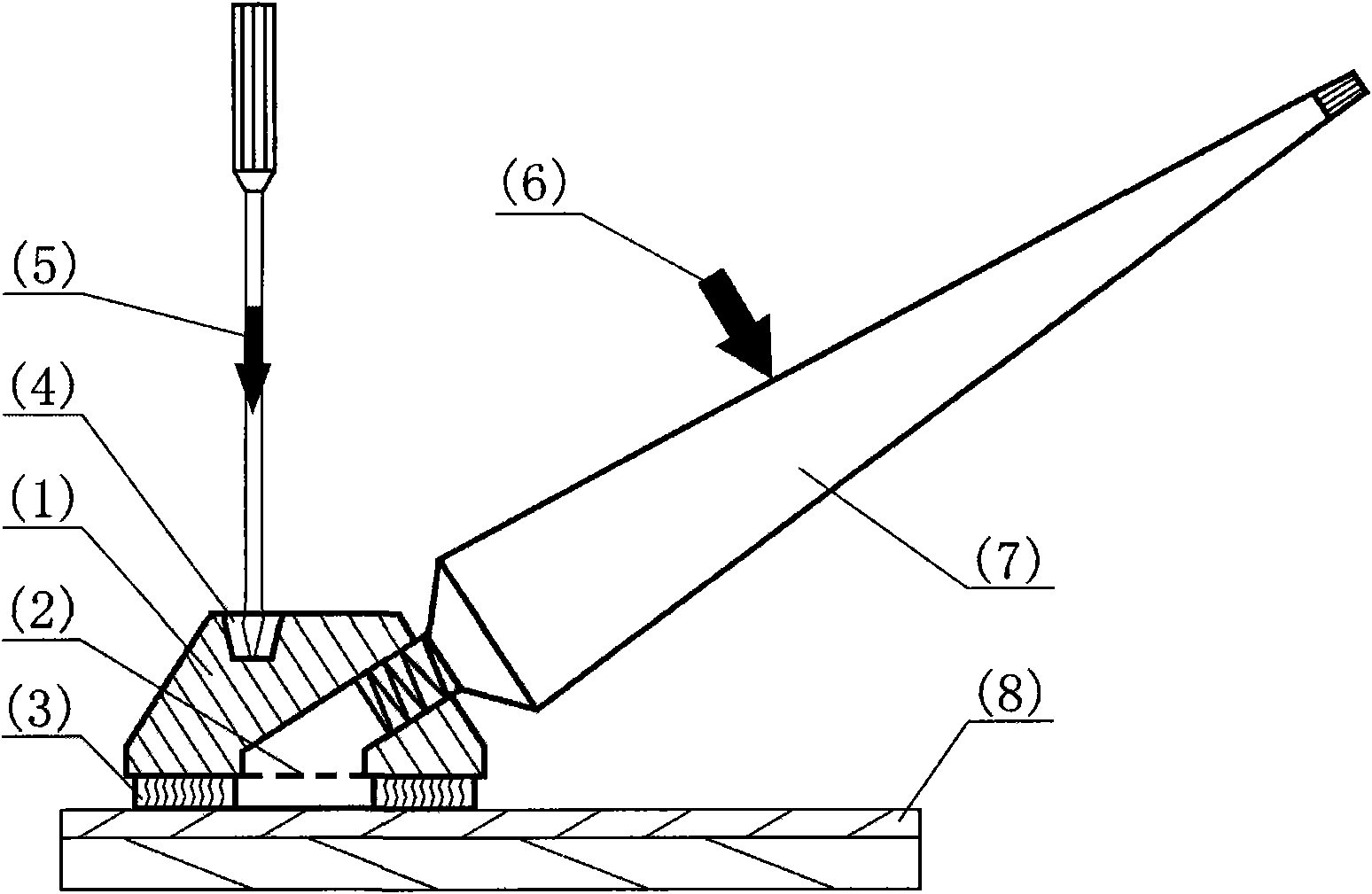

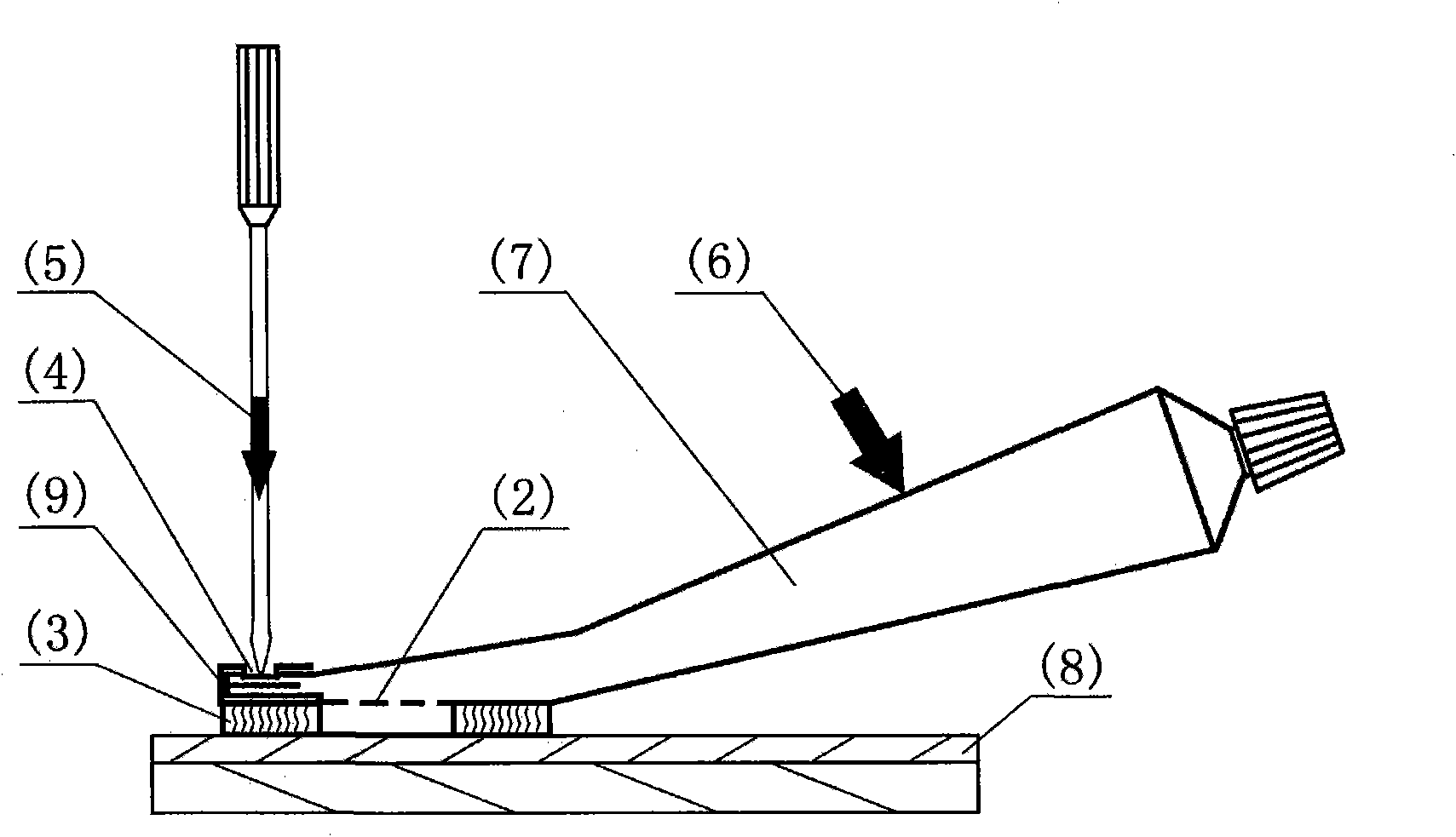

[0013] The packaging body (7) in the schematic diagram of the present invention refers to the outer packaging of colloidal materials such as plunger-type rubber barrels, aluminum-plastic composite hoses, and punched aluminum hoses. figure 1 , figure 2 Among them, the packaging body (7) is expressed in the shape of a toothpaste bag, which more fully expresses the intention of the present invention.

[0014] exist figure 1 Among them, the outlet of the packaging body (7) is connected to a sizing head (1), the front end of which has an external force pressure groove (4), the sizing port (2) is pasted with a liner with holes (3), and the sizing head (1 ) with internal thread for easy installation and removal.

[0015] exist figure 2 Among them, there is a metal tail clip (9) with an external force pressure groove (4) on the abdomen and tail of the package (7), and a glue opening (2) is opened on the abdomen and tail of the package (7) and pasted A liner (3) with holes can ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com