Double-channel variable geometry rocket base combined cycle engine

A dual-channel, variable-geometry technology, applied to combined engines, machine/engines, ramjet engines, etc., can solve problems such as aircraft redundant mass, poor matching between air inlets and rockets, and restrictions on rocket engine layout, etc., to meet the requirements of The effect of power demand, good structural rigidity, and easy sealing at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

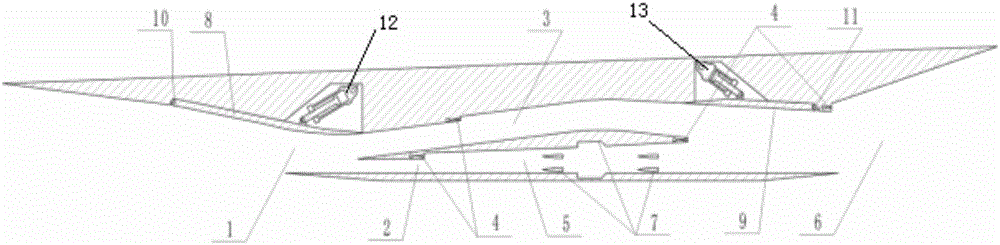

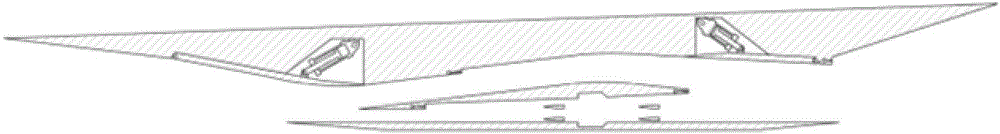

[0027] In this embodiment, the intake port 1 is arranged at the front of the rocket-based combined cycle engine, wherein the design point of the intake port is selected as Mach 5, and the flight altitude is 21 km. The tail nozzle 6 is a single-side expansion nozzle, which is arranged at the tail of the rocket-based combined cycle engine. The low-velocity channel 3 is located above the high-speed channel 2, and the angle between the flow direction of the two channels is 7°, and they converge at the front of the tail nozzle 6, and the converging angle of the airflow is 10°. Among them, the two-stage external compression angles of the high-speed channel 2 are 6.8° and 11.3°, respectively, and the two-stage external compression angles of the low-speed channel 3 are 6.8° and 4°, respectively. The top pressure plate 8 is connected with the first actuating mechanism and the first rotating shaft, and the conversion plate 9 is connected with the second actuating mechanism and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com