A structure for water-cooled throat of high Mach number surface nozzle in hypersonic wind tunnel

A high Mach number, hypersonic technology, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of long processing cycle, high cost, deformation, etc., and achieve simple manufacturing process and reliable high-pressure and high-temperature sealing , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] According to an embodiment of the present invention,

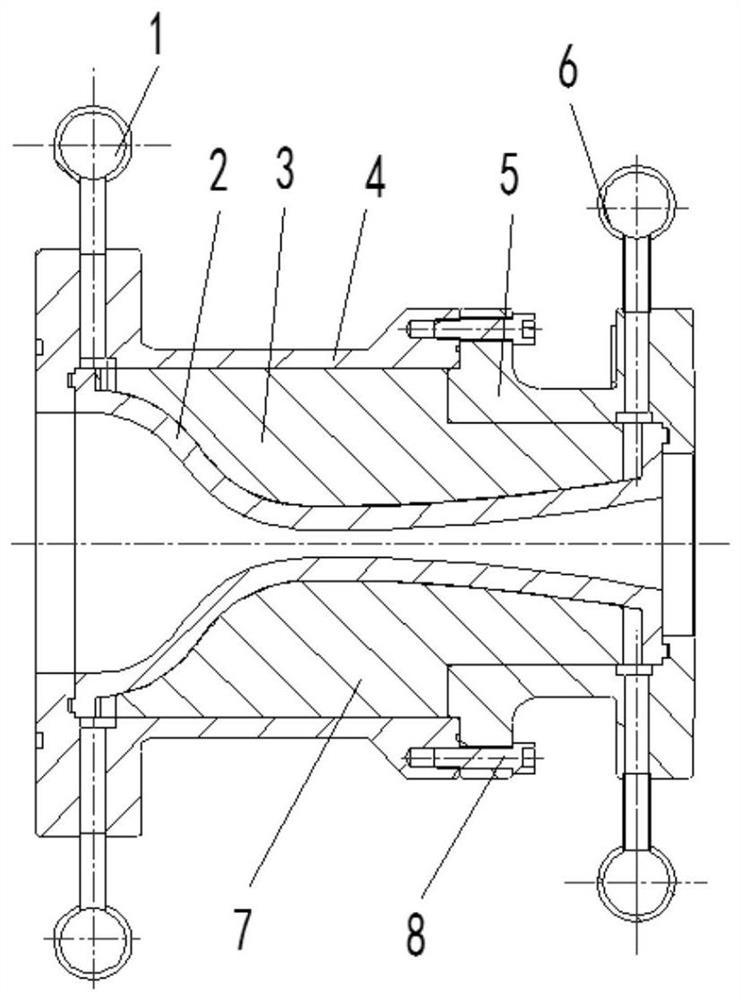

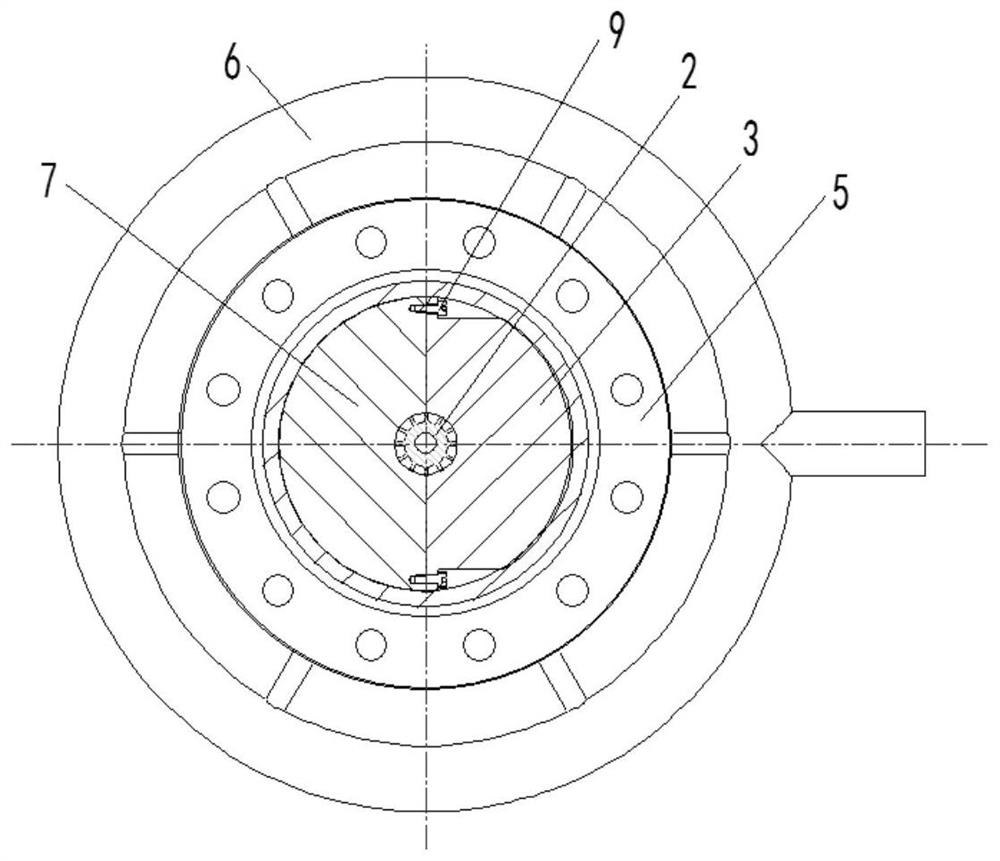

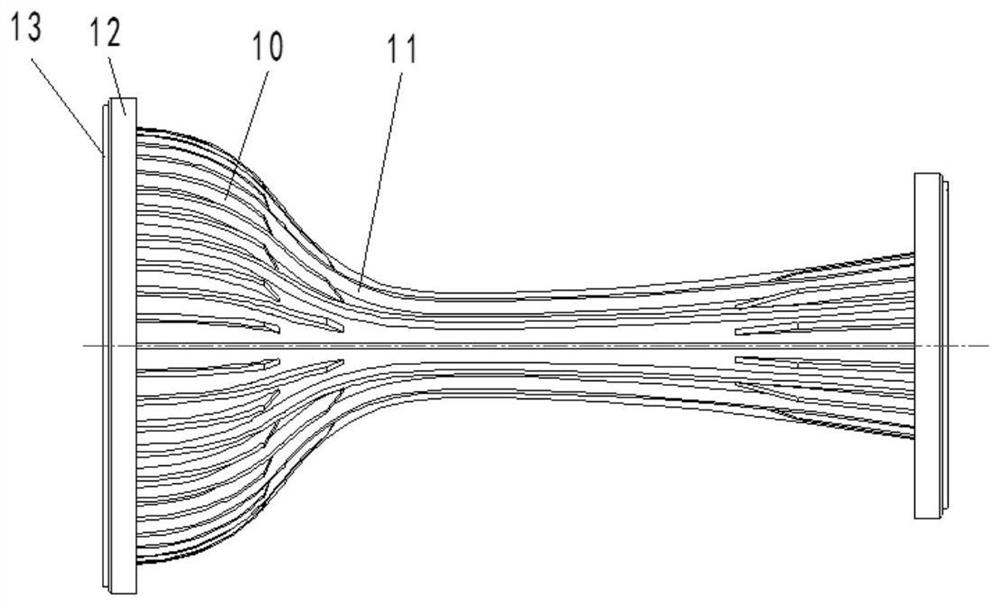

[0050] see Figure 1-11 , a structure for the water cooling throat of a high Mach number profile nozzle of a hypersonic wind tunnel, comprising a first water channel lining block 3 and a second water channel lining block 7, wherein the first water channel lining block 3 and the second water channel lining block 3 The block 7 is installed on the outside of the throat inner shell 2, and the first water channel lining block 3 and the second water channel lining block 7 are fixed on the throat inner shell 2 through the lining block connecting screws 9 on both sides; The assembly of a water channel lining block 3 and a second water channel lining block 7 is installed in the first casing 4 and the second casing 5;

[0051] One end of the first shell 4 and one end of the second shell 5 are fixedly connected together by the shell connecting screws 8, and a rubber sealing ring is also provided between the ends of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com