Plug-in heat dissipation power module

A technology of power module and heat conduction block, applied in electrical components, structural parts of electrical equipment, cooling/ventilation/heating transformation, etc., can solve the problems of waste of cost, low standardization, uneconomical disassembly, etc., to facilitate replacement and maintenance , Efficient heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

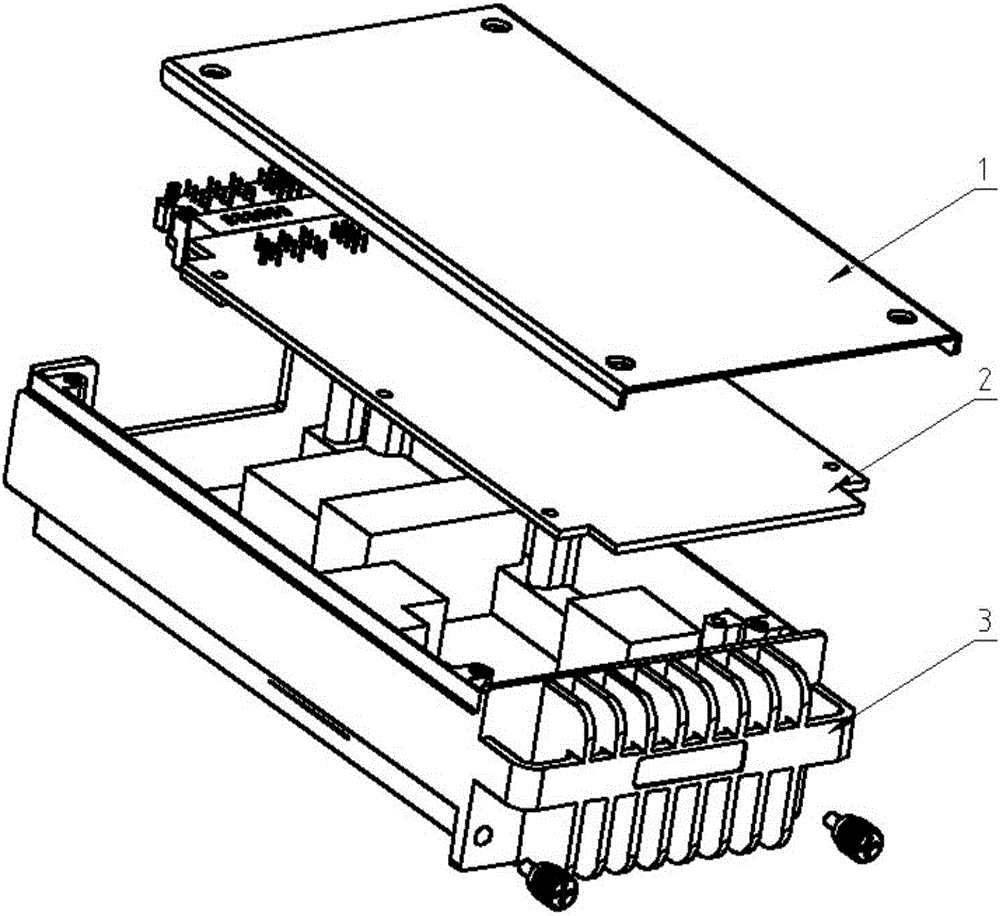

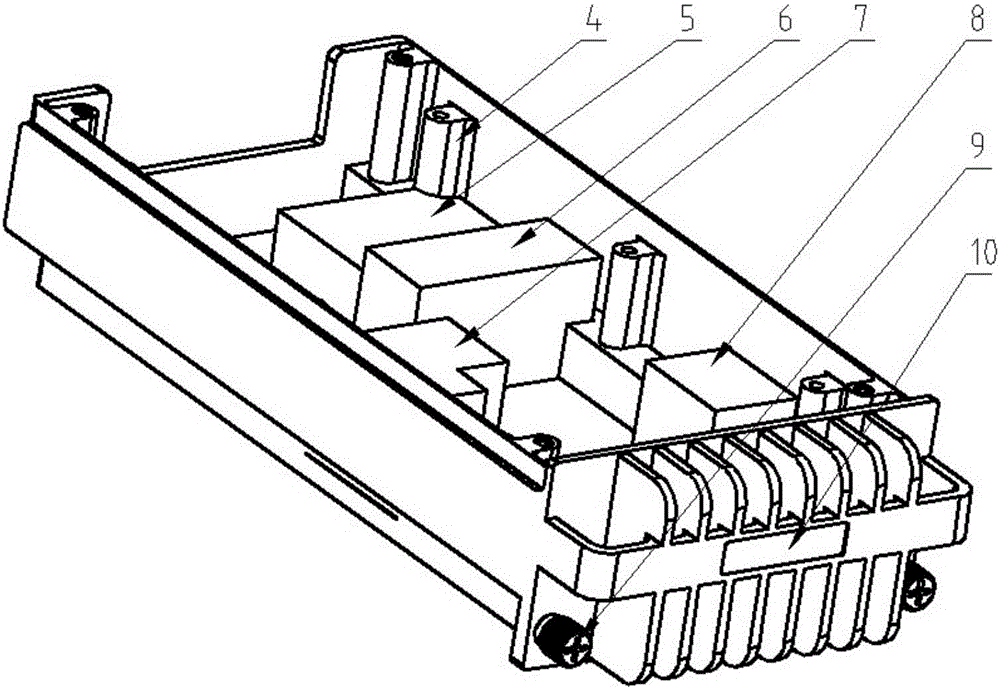

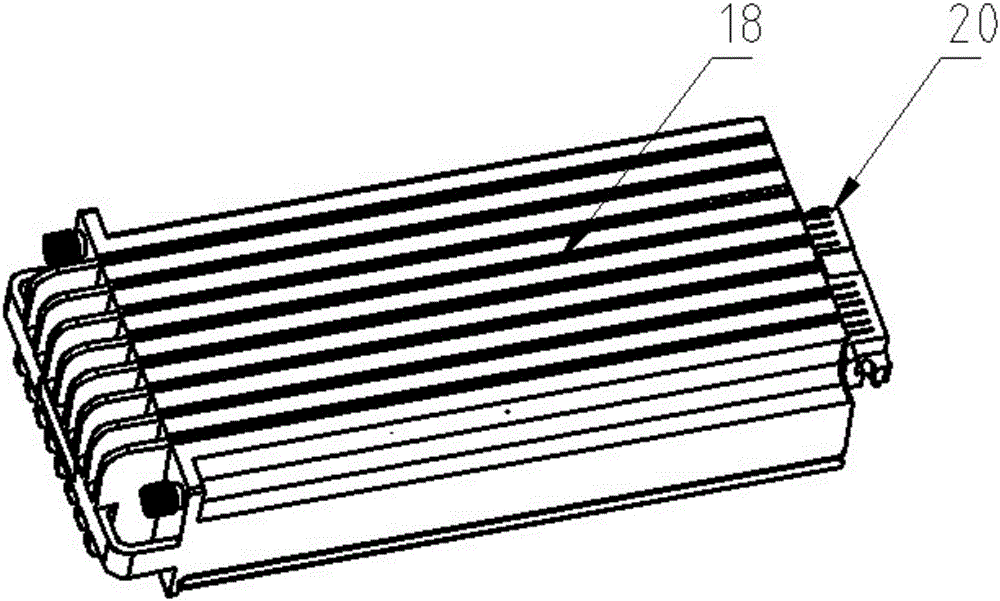

[0032] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a plug-in heat-dissipating power supply module includes a module cover 1, a PCB board 2 and a module housing assembly 3, and the PCB board 2 and the module The housing assembly 3 is fixedly connected, and the module cover plate 1 is fixedly connected to the module housing assembly 3;

[0033] The module housing assembly 3 includes a module heat dissipation housing 4 and a plurality of heat conducting blocks arranged in the module heat dissipation housing 4 , and the PCB card 2 is arranged above the plurality of heat conducting blocks.

[0034] Such as figure 2 As shown, in order to facilitate the transfer of the heat generated by the heating device on the PCB board 2, and to ensure efficient and reliable thermal conductivity of the heat-conducting copper block, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com