High-temperature and high-pressure oil-gas well multifunctional fracturing completion pipe string and construction process

A completion pipe string, high temperature and high pressure technology, applied in the direction of wellbore/well components, wellbore/well valve device, drill pipe, etc., can solve the problem that the pipe string cannot be safely shut down, the blowout is out of control, and the pressure bearing capacity is low and other problems, to achieve the effect of solving the problem of high internal pressure resistance, improving the internal pressure resistance and strong erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with embodiment the present invention is further described.

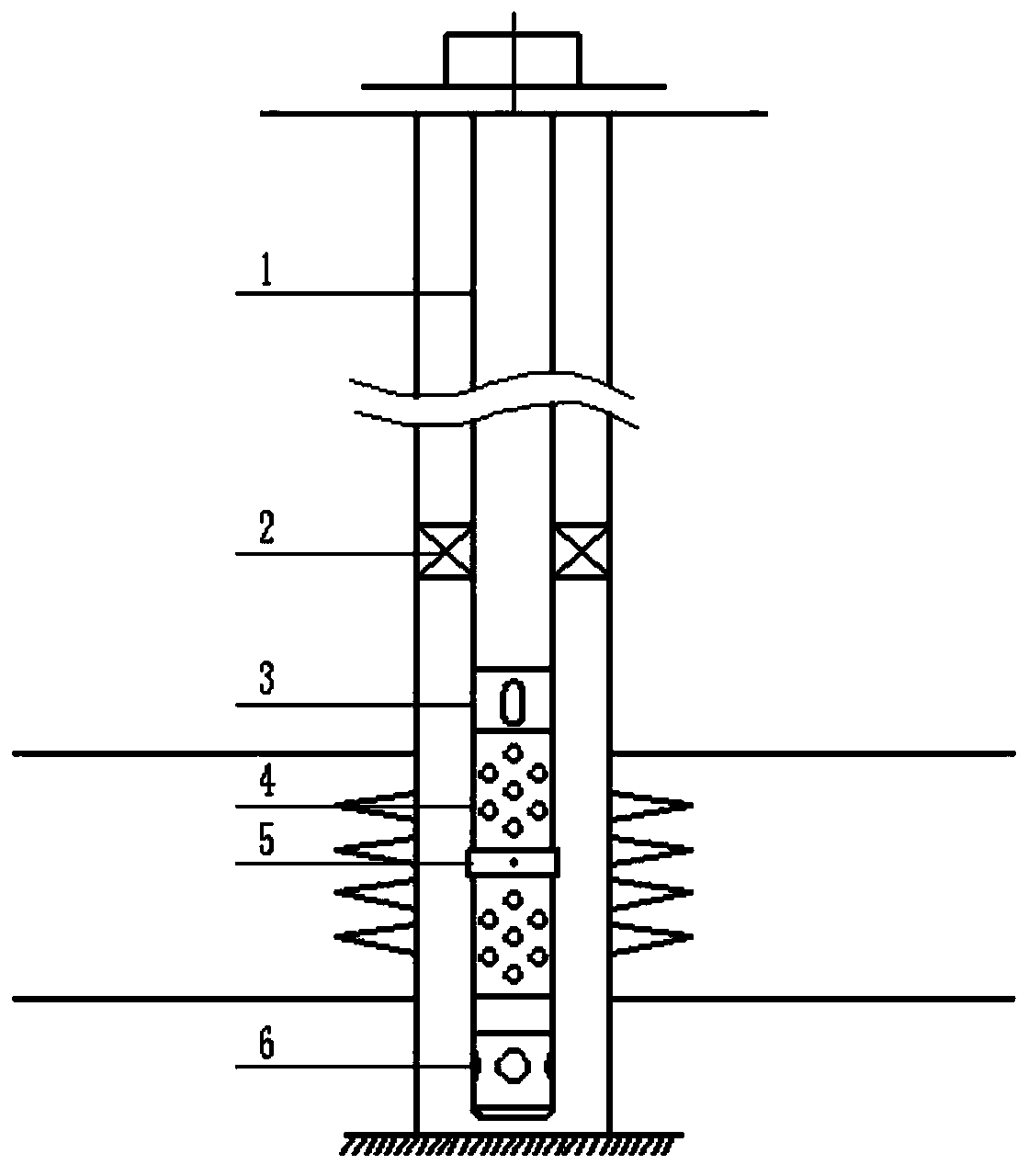

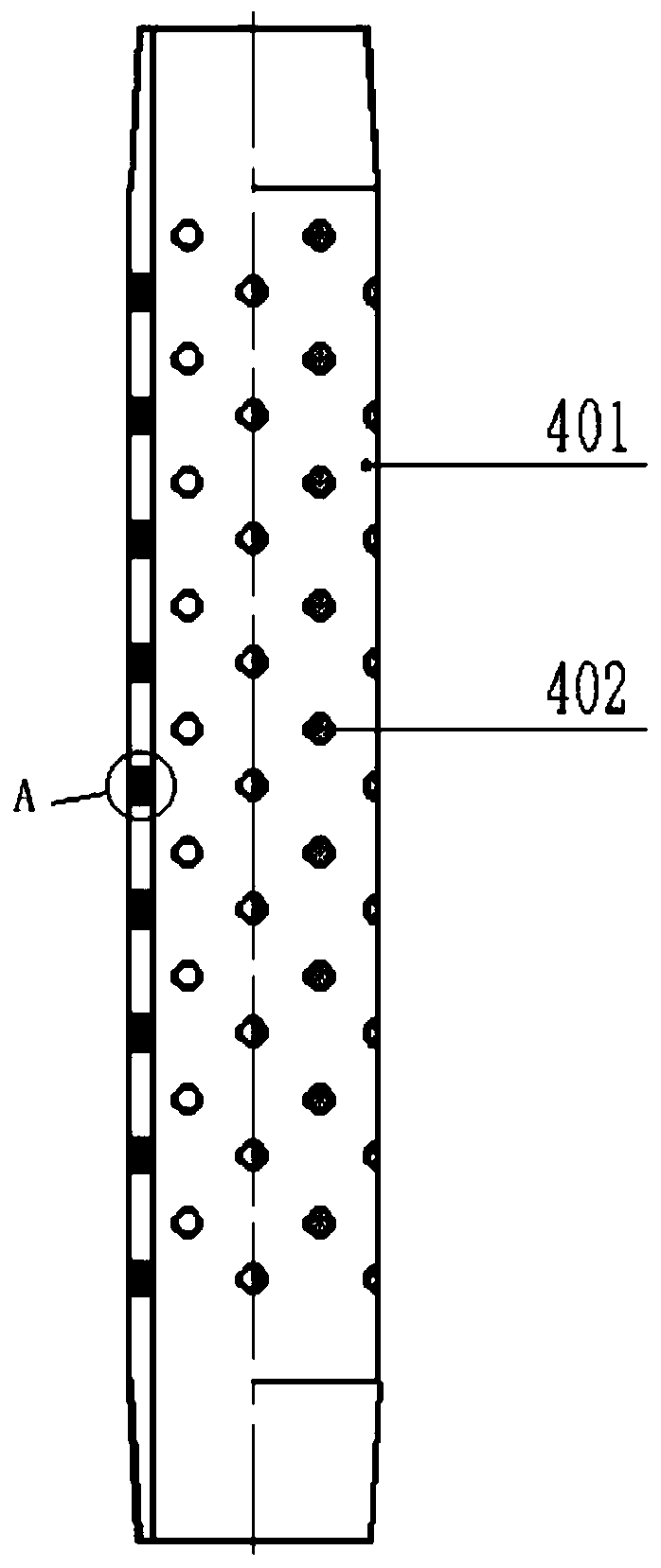

[0069] like figure 1 As shown, a high-temperature and high-pressure oil and gas well multifunctional fracturing completion string is connected in sequence from top to bottom with oil pipe 1, packer 2, fracturing sliding sleeve 3 that can be closed, sand control screen for temporary plugging 4, and bottom replacement Pulp valve 6. For the pipe string below the packer 2, a high-pressure sealing safety joint 5 is installed at intervals of 3-5 high-strength temporary plugging screens. The temporarily plugged sand control screen 4 is located in the production zone, the fracturing sleeve is located in the top boundary of the production zone, and the bottom slurry replacement valve 6 is located in the bottom boundary of the production zone.

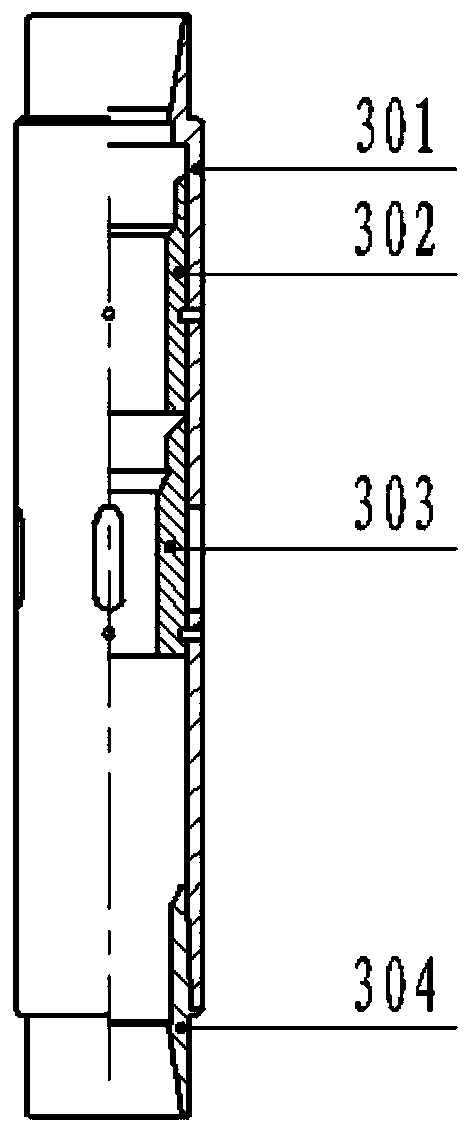

[0070] like figure 2 As shown, the closeable fracturing sliding sleeve 3 is composed of an outer sleeve 301 , an upper sliding sleeve 302 , a lower sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com