Hydraulic ejection nut disassembly mechanism

An ejector type, hydraulic type technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of corrosion, inability to disassemble, etc., to achieve the effect of easy portability, simple structure, and solve the problems of disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

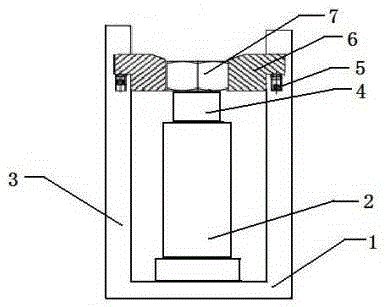

[0013] This embodiment provides a hydraulic ejector nut removal mechanism, which is characterized in that: the fully automatic nut removal device includes a fixed mounting frame (1), a jacking drive cylinder (2), a side column (3), a telescopic piston (4), fixed bolt (5), fixed clamp block (6), nut (7);

[0014] Among them: including the fixed fixture, fixed installation frame (1) and jacking drive cylinder (2), the middle position of the fixed installation frame (1) is equipped with jacking drive cylinder (2), and the telescopic piston of jacking drive cylinder (2) ( 4) Arrest the core position of the nut (7). There are two fixed clips (6) on both sides of the nut (7). The fixed clips (6) are set on both sides of the fixed mounting bracket (1) The inner side of the jamb (3).

[0015] The fixed installation frame (1) is U-shaped.

[0016] The jacking drive cylinder (2) is a pneumatic cylinder.

Embodiment 2

[0018] This embodiment provides a hydraulic ejector nut removal mechanism, which is characterized in that: the fully automatic nut removal device includes a fixed mounting frame (1), a jacking drive cylinder (2), a side column (3), a telescopic piston (4), fixed bolt (5), fixed clamp block (6), nut (7);

[0019] Among them: including the fixed fixture, fixed installation frame (1) and jacking drive cylinder (2), the middle position of the fixed installation frame (1) is equipped with jacking drive cylinder (2), and the telescopic piston of jacking drive cylinder (2) ( 4) Arrest the core position of the nut (7). There are two fixed clips (6) on both sides of the nut (7). The fixed clips (6) are set on both sides of the fixed mounting bracket (1) The inner side of the jamb (3).

[0020] The fixed installation frame (1) is U-shaped.

[0021] The jacking drive cylinder (2) is a hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com