Patents

Literature

243results about How to "Guaranteed repair quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding repair method for large-sized heat-resistant steel castings

ActiveCN103962791AEliminate Large Area DefectsRelieve welding stressArc welding apparatusShielded metal arc weldingCrazing

The invention relates to a welding repair method for large-sized heat-resistant steel castings, and solves the problems that the welding stress is difficultly removed, the defects of incomplete fusion, incomplete penetration, delayed crack and slag inclusion are easily caused in a repair process and the repair quality is difficultly guaranteed as the heat-resistant steel castings are poorer in welding performance, complicated in defect position and large in workpiece in an existing manual arc welding type surfacing welding mode for repairing large-sized castings. The method mainly comprises the following steps: 1, removing the defects; 2, performing heat treatment; 3, performing dye check; 4, performing statistics on the repair welding quantity; 5, preheating before welding; 6, performing repair welding on defect parts; 7, cleaning and repairing; 8, performing post-welding heat treatment; 9, performing nondestructive inspection. According to the method, the large-area defects of the castings can be effectively repaired, the repair quality is guaranteed, the processing and use requirements of the castings can be met after repair, and the economic loss of scrapped important or major castings is reduced. The method is used for repairing the large-area defects of the large-sized heat-resistant steel castings.

Owner:HARBIN JIANCHENG GRP

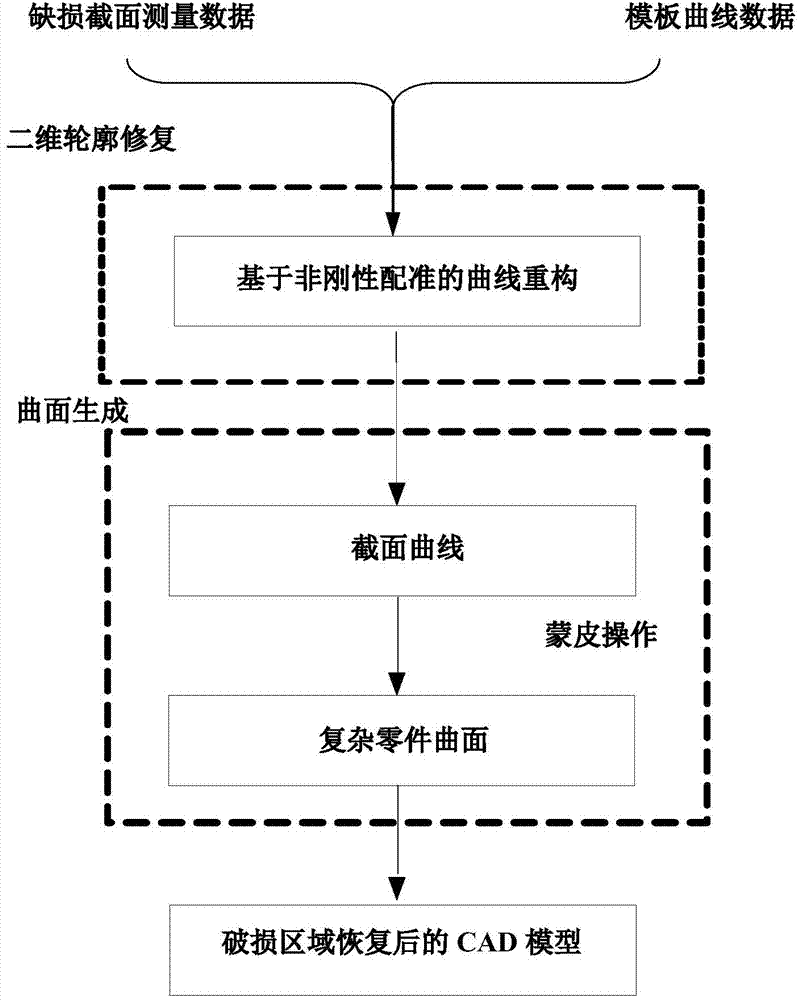

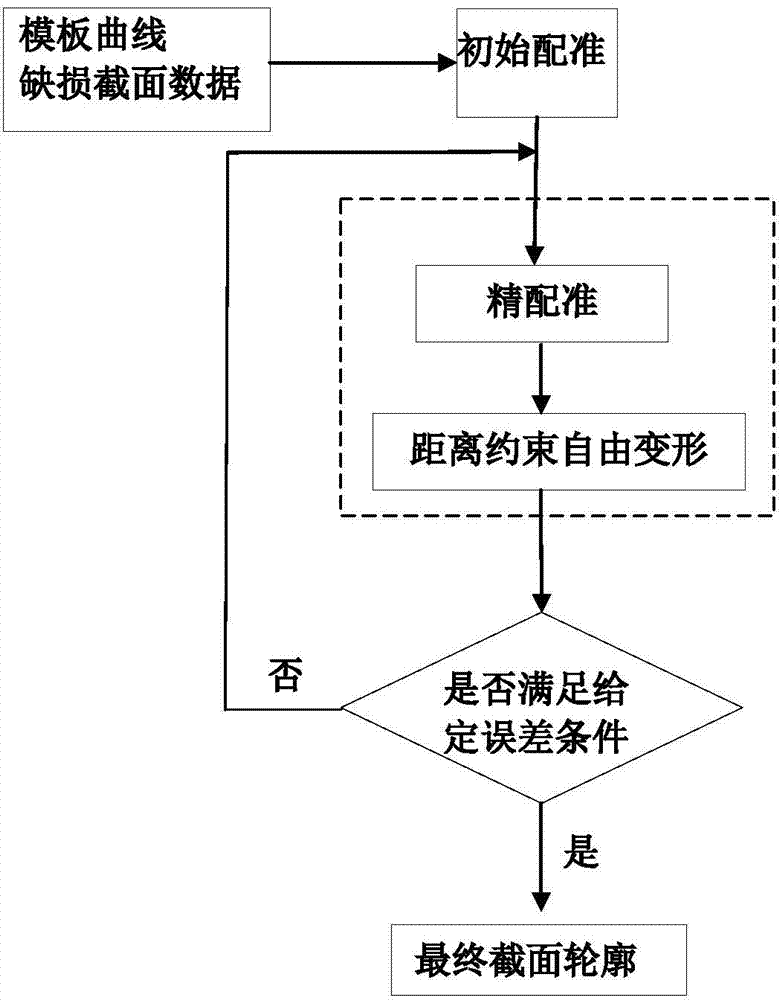

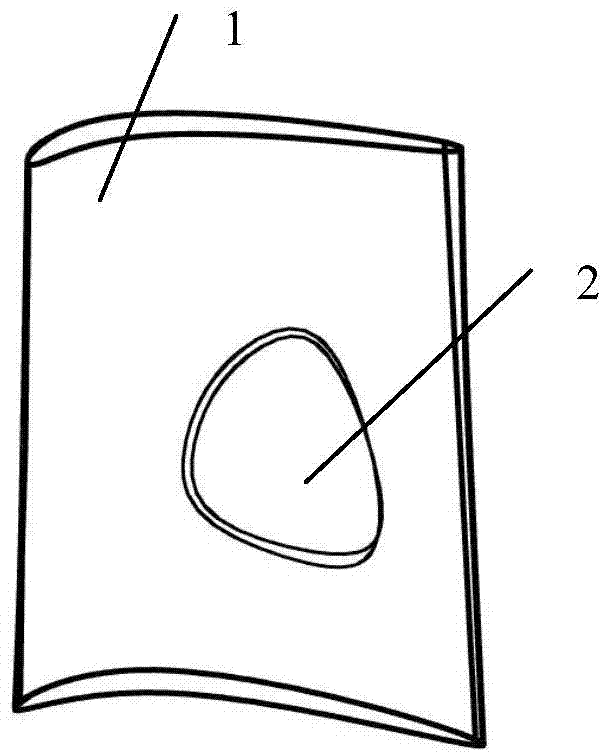

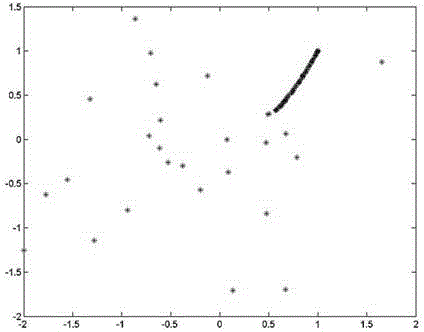

Geometry repair method for damaged area of complex curved surface part

ActiveCN103488832ASimplify the geometry repair processGuaranteed continuitySpecial data processing applicationsThree dimensional measurementQuantity method

The invention provides a geometry repair method for a damaged area of a complex curved surface part, belongs to the field of computer auxiliary design and manufacture, and relates to the repair method for a complex geometric curved surface with part damaged. According to the geometry repair method, by establishing the relation between actually-measured cross section data of the complex curved surface damaged part and a nominal geometry template curve of the complex curved surface damaged part, and utilizing an optimization method capable of achieving alternating iterative registration and free deformation, namely, alternating a quantity method to calculate the closest point from an actual measurement point to the template curve and solve of translation, rotation and deformation transformation matrices, geometric deviation between the template curve and actual measurement data of the damaged part is gradually decreased, the designed template curve and the measurement point can fit to the largest extent, therefore, a damaged cross section contour curve is reestablished, covering operation is performed on the cross section contour to generate the curved surface of the complex part, and the geometrical shape of the damaged area is effectively recovered. By means of the geometry repair method, the problem of large deviation between three-dimensional measurement data of the complex curved surface damaged parts and an original computer-aided design (CAD) model is solved, and accuracy and practical applicability of geometry repair are ensured.

Owner:DALIAN UNIV OF TECH

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

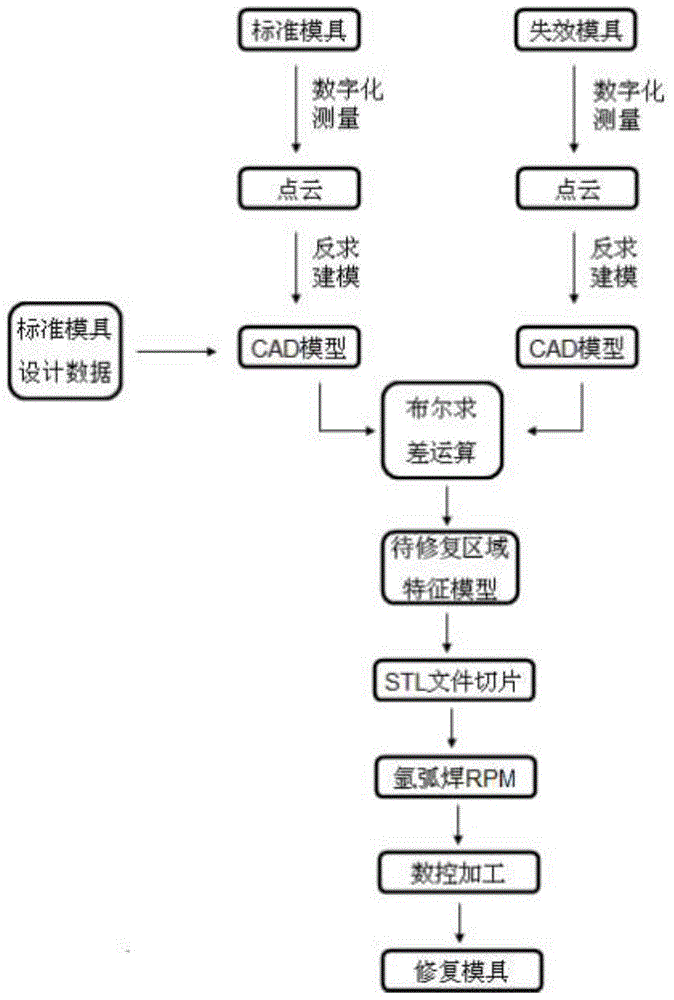

Mould three-dimensional rapid forming and repairing method based on reverse engineering

The invention discloses a mould three-dimensional rapid forming and repairing method based on reverse engineering. Three-dimensional reverse engineering is carried out on a faulted mould through the reverse engineering technology, comparison calculation of a faulted mould model and a standard mould model is finished in combination with a CAD technology, and recognition and obtaining of a CAD model in a to-be-repaired region of the mould are realized; slicing processing is carried out on the CAD model in the to-be-repaired region of the mould through the layering thought of the rapid forming technology, then three-dimensional rapid forming and repairing are carried out on the to-be-repaired region of the mould step by step and layer by layer through the argon arc welding technology, finally proper after-treatment and machining are carried out on the repaired region, and rapid repairing and re-manufacturing of the mould are finished. Accurate control over the repairing layer thickness and repairing amount of the mould is realized, the repairing after-treatment links are effectively reduced and even eliminated, the repairing accuracy and quality of the mould are improved, and an effective means with low cost, high accuracy and high efficiency is provided for on-site repairing and re-manufacturing of the mould.

Owner:NANJING INST OF ADVANCED LASER TECH

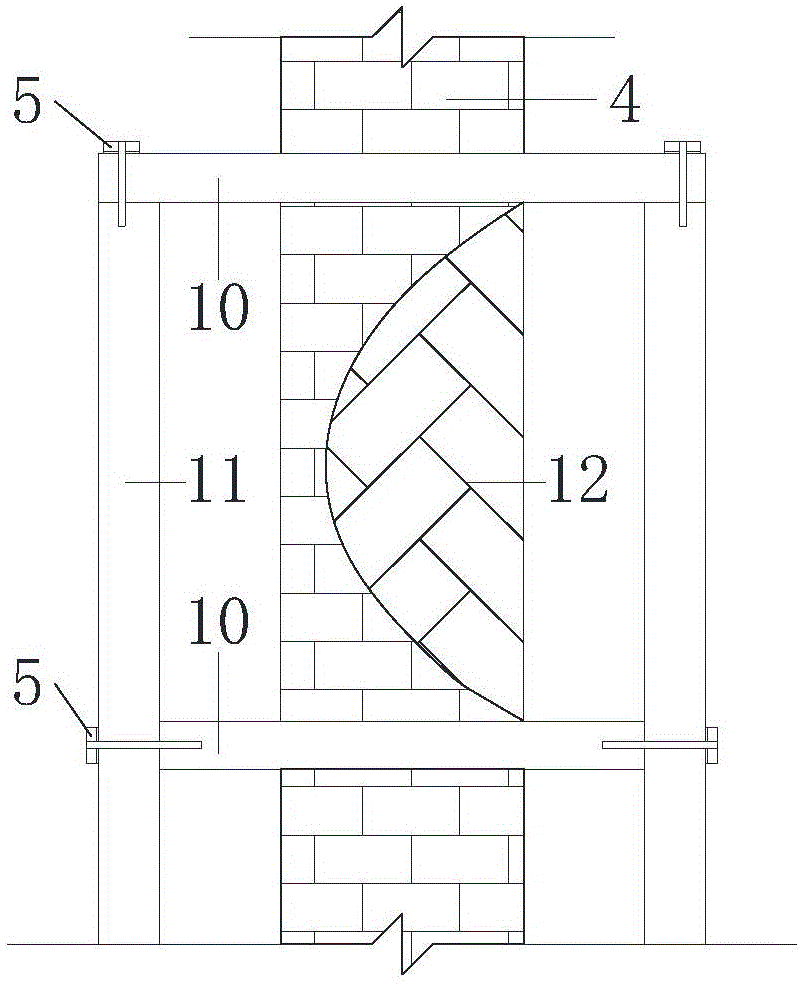

Synchronous cutting-off and unroofing repair method for coke side oven head of large-scale coke oven machine

ActiveCN102504837ASolve denudationSolve the holeCoke oven brickworkBrickwork leakage repair/preventionCombustion chamberMaterial consumption

The invention relates to a synchronous cutting-off and unroofing repair method for a coke side oven head of a large-scale coke oven machine, which belongs to a coke oven and particularly relates to a repair method for the coke oven. The synchronous cutting-off and unroofing repair method comprises the following steps of: cooling a repair area-reinforcing an oven column, correspondingly arranging a banking number and a buffer oven number, building a retaining wall, disassembling an ascending tube and cooling a repair number and relevant oven numbers; disassembling the ovens-disassembling a masonry body, installing a support and carrying out temperature monitoring on the repair number and the relevant oven numbers; repairing the building-determining a building centerline and a wall surface datum line and building according to the key points; and warming after repair-carrying out temperature rise speed control and disassembling the support and digging up the retaining wall. The repair method has the advantages that all the damaged parts of the oven head are disassembled and newly built; the wall surfaces of damaged coking chambers can be repaired within a large area so as to completely solve the abrasion and the hole through on the wall surfaces of the coking chambers and the inter-leakage of partition walls of a combustion chamber; after one-time repair, the damaged parts can beused for 5-8 years, so that the oven repair frequency, the time and the material consumption are reduced; the wall surfaces of the repaired parts are level, are small in coke pushing resistance, are beneficial to protecting a coke pusher and an oven body and producing the coke oven and also facilitates energy conservation and consumption reduction; and the high-temperature burn accident of maintenance personnel is also avoided.

Owner:MAGANG (GROUP) HOLDING CO LTD

Local coating defect repairing method for carbon/carbon composite material

The invention relates to a local coating defect repairing method for a carbon / carbon composite material. A coating repairing agent prepared from a thermosetting resin and an inorganic filling material is coated on a coating defect position. A coating crack defect is repaired by crack / hole filling and reinforcement repair and coating extension, and therefore the surface of the defect is coated with the repairing agent and the repairing agent permeates into the defect interior, thus forming a continuous layer and preventing carbon atoms from oxidation reaction with oxygen atoms. Then a drying and curing process is performed in an air dry oven or a ventilating environment. Finally, the thickness and the compactness of the repairing agent are increased through a vacuum impregnation and drying method. The repairing method is simple, convenient and prone to achievement. The repaired carbon / carbon composite material has good performances and high quality. The local defect area of the antioxidant carbon / carbon composite material is effectively protected from being oxidized and ablated in an oxidation environment with a temperature lower than 1200 DEG C, thus achieving long-time using and repeated using of a high-performance antioxidant carbon / carbon composite material coating.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

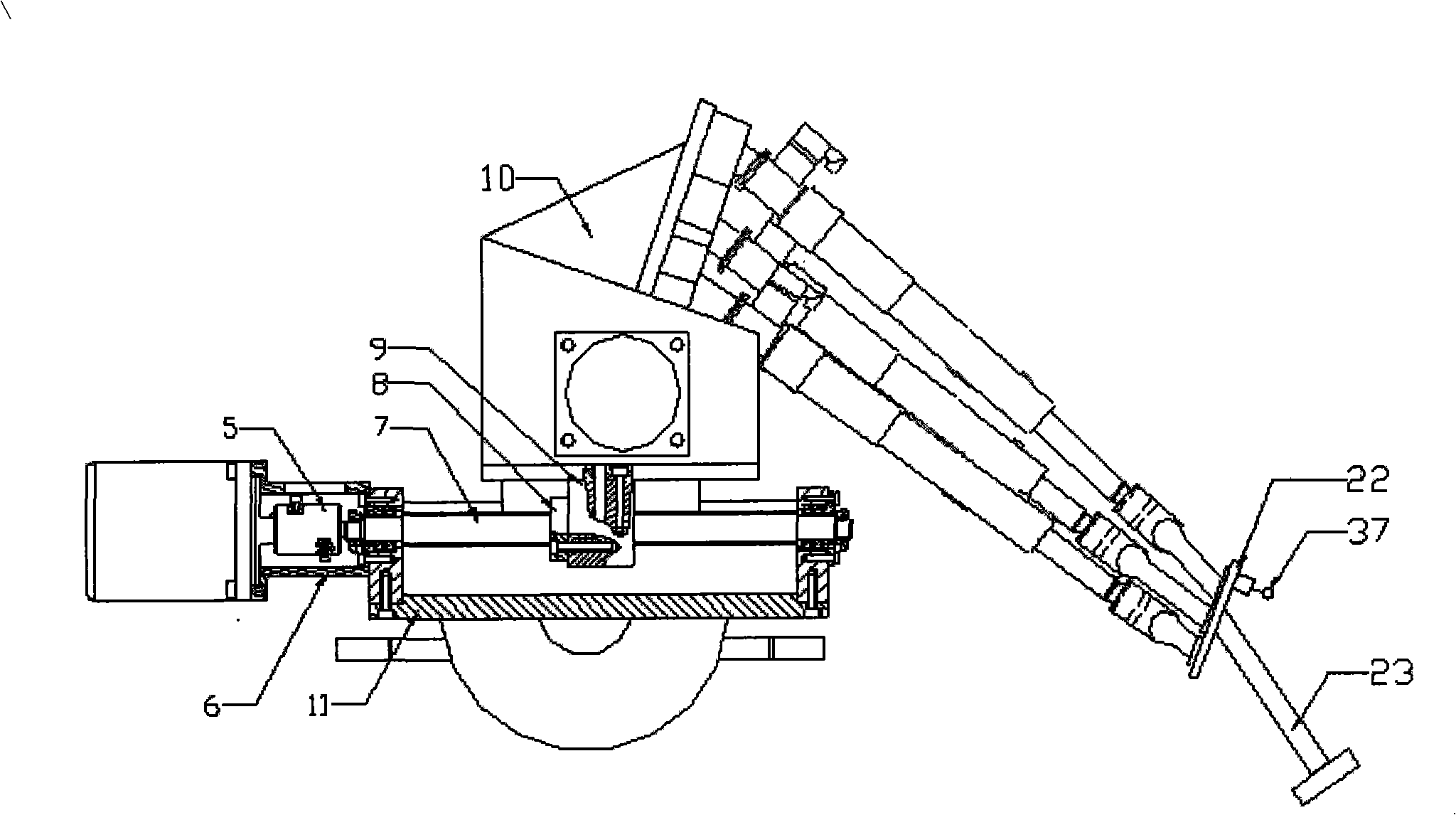

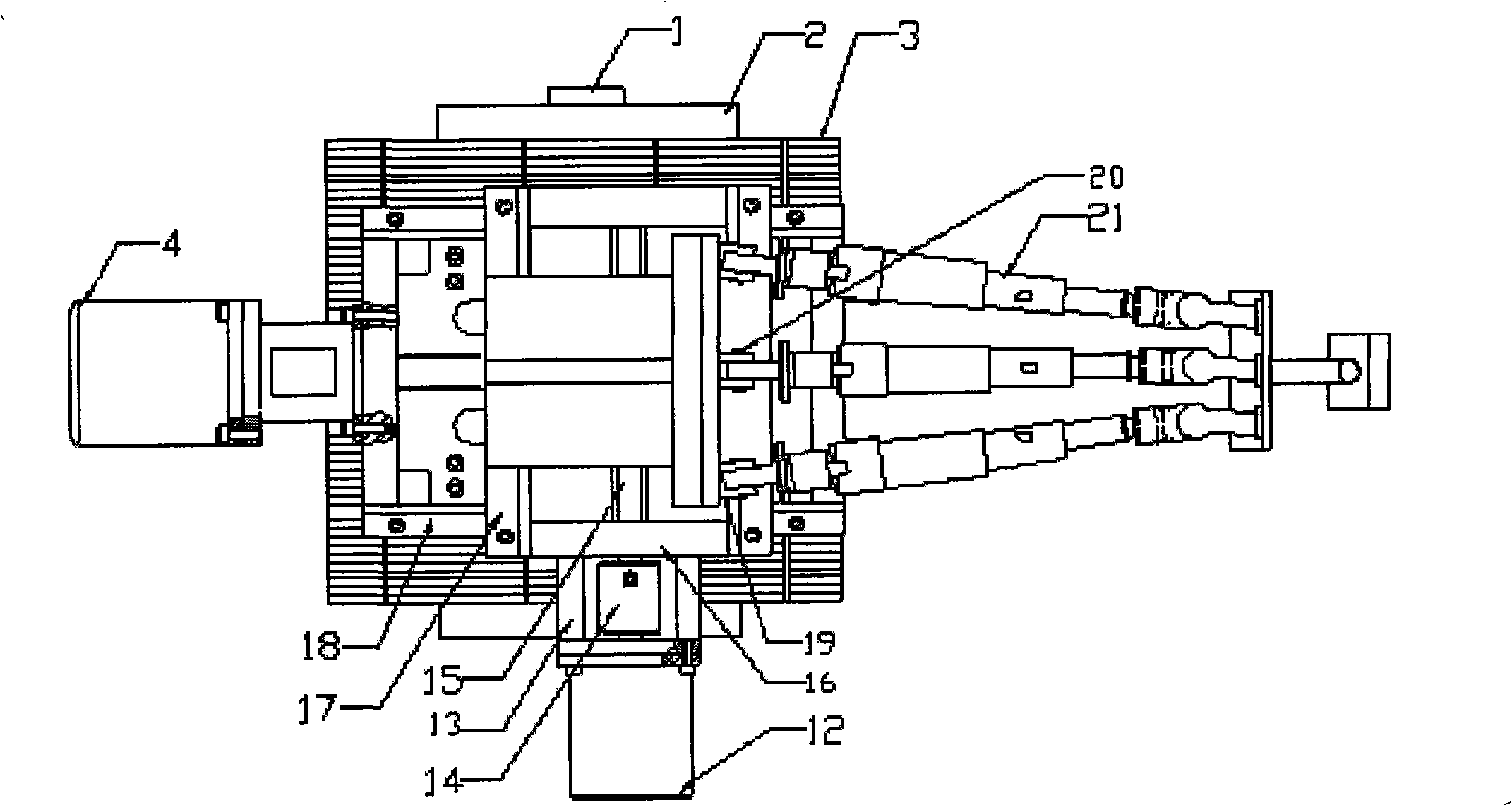

Five freedoms turbine blade series-parallel repair robot

The present invention provides a 5-degree of freedom hydraulic turbine blade series-parallel connection repair robot, which comprises a horizontal moving bracket and a trolley which is arranged on the horizontal moving bracket and consists of a road wheel, an electromagnetic plate and a road wheel moment motor. The horizontal moving bracket is provided with a horizontal moving mechanism; the horizontal moving mechanism is provided with a vertical moving mechanism; a parallel connection fixed platform is arranged on the vertical moving mechanism; one end of a parallel connection rod is articulated on the parallel connection fixed platform and the other end a parallel connection rod is connected with a parallel connection movable platform; an operating tool and a camera are arranged on the parallel connection movable platform. The blade repair robot provided by the present invention is used, which can not only ensure the blade repair quality and shorten the period, but also free workers from heavy and abominable working conditions and bring good economic benefit.

Owner:HARBIN ENG UNIV

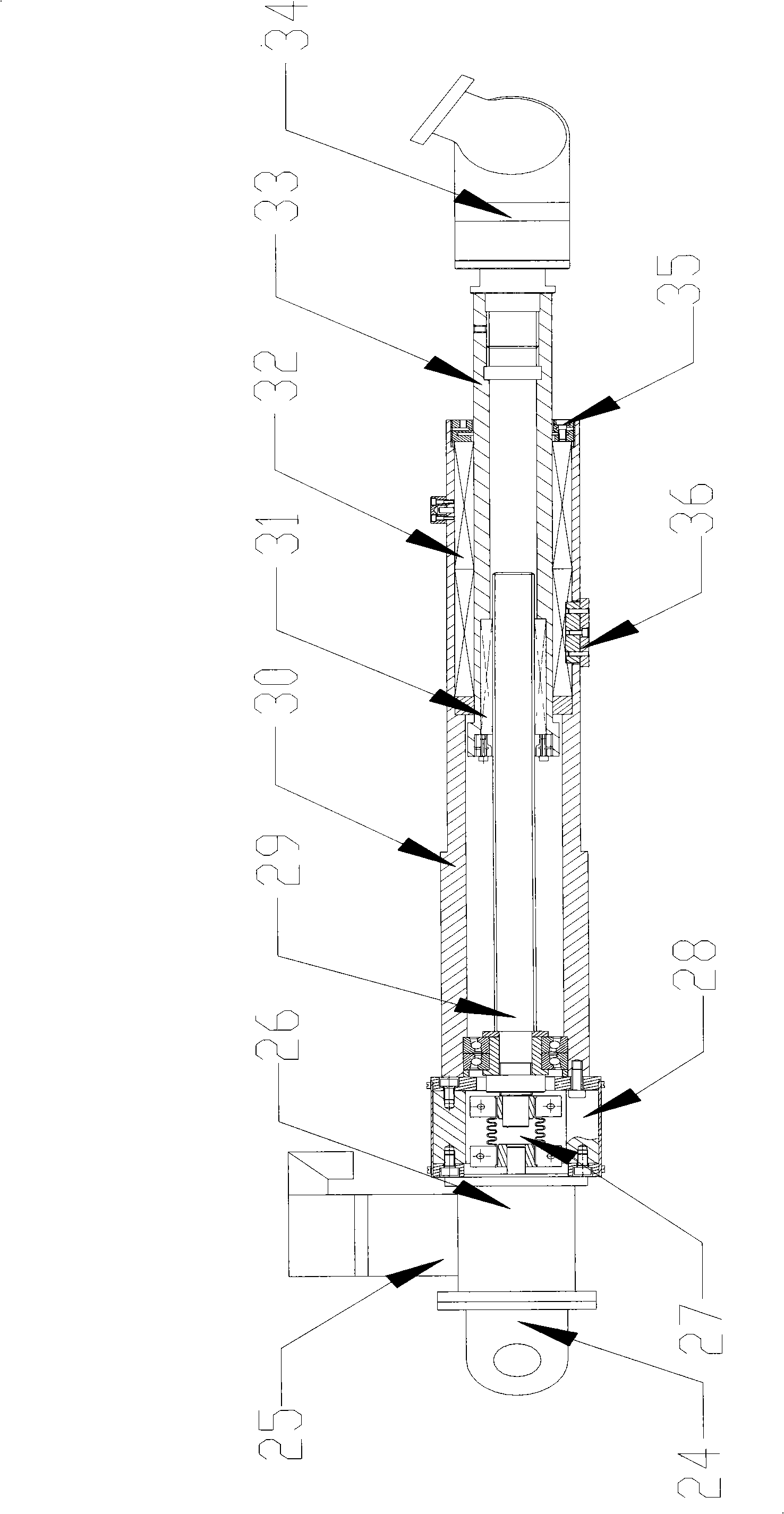

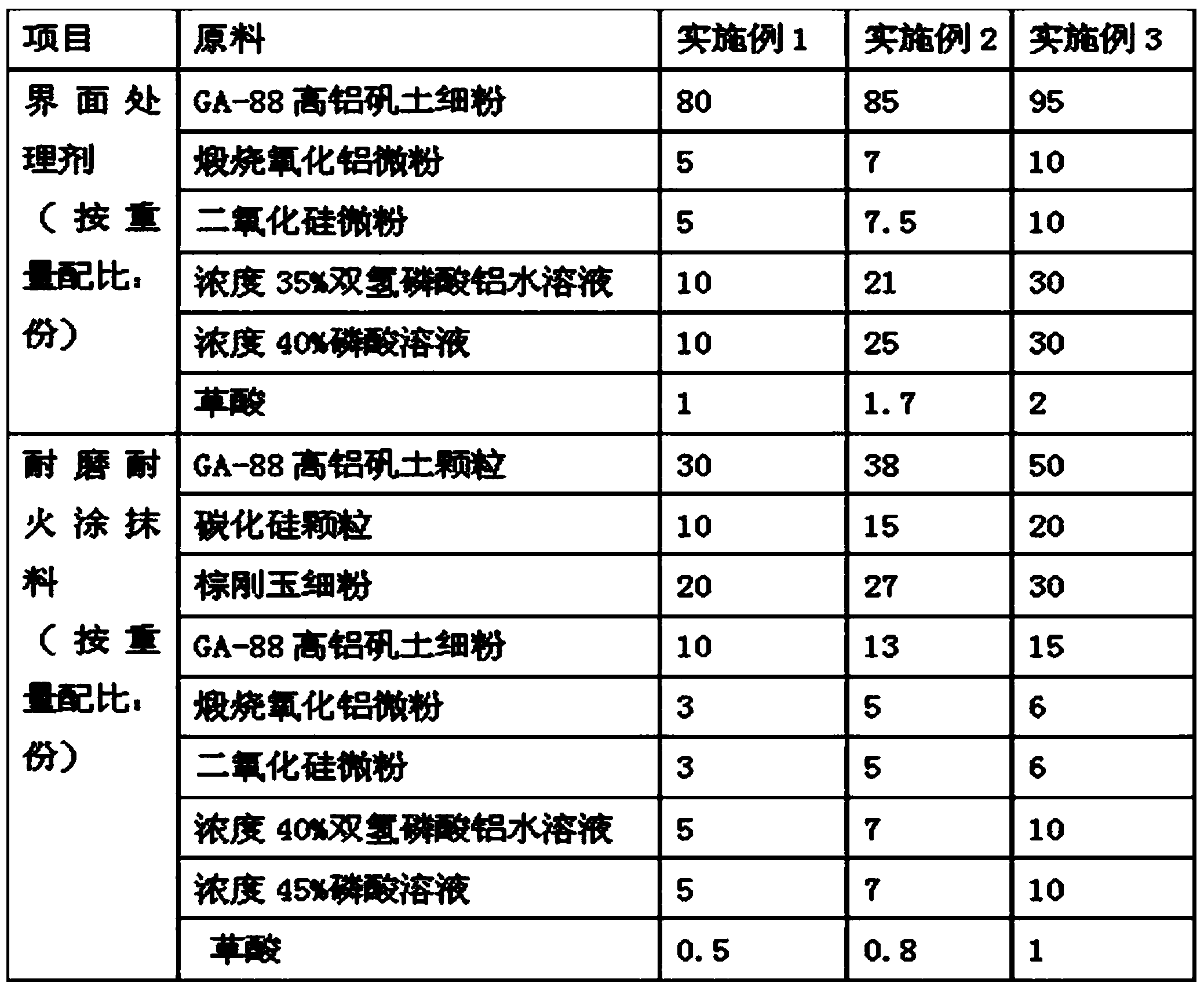

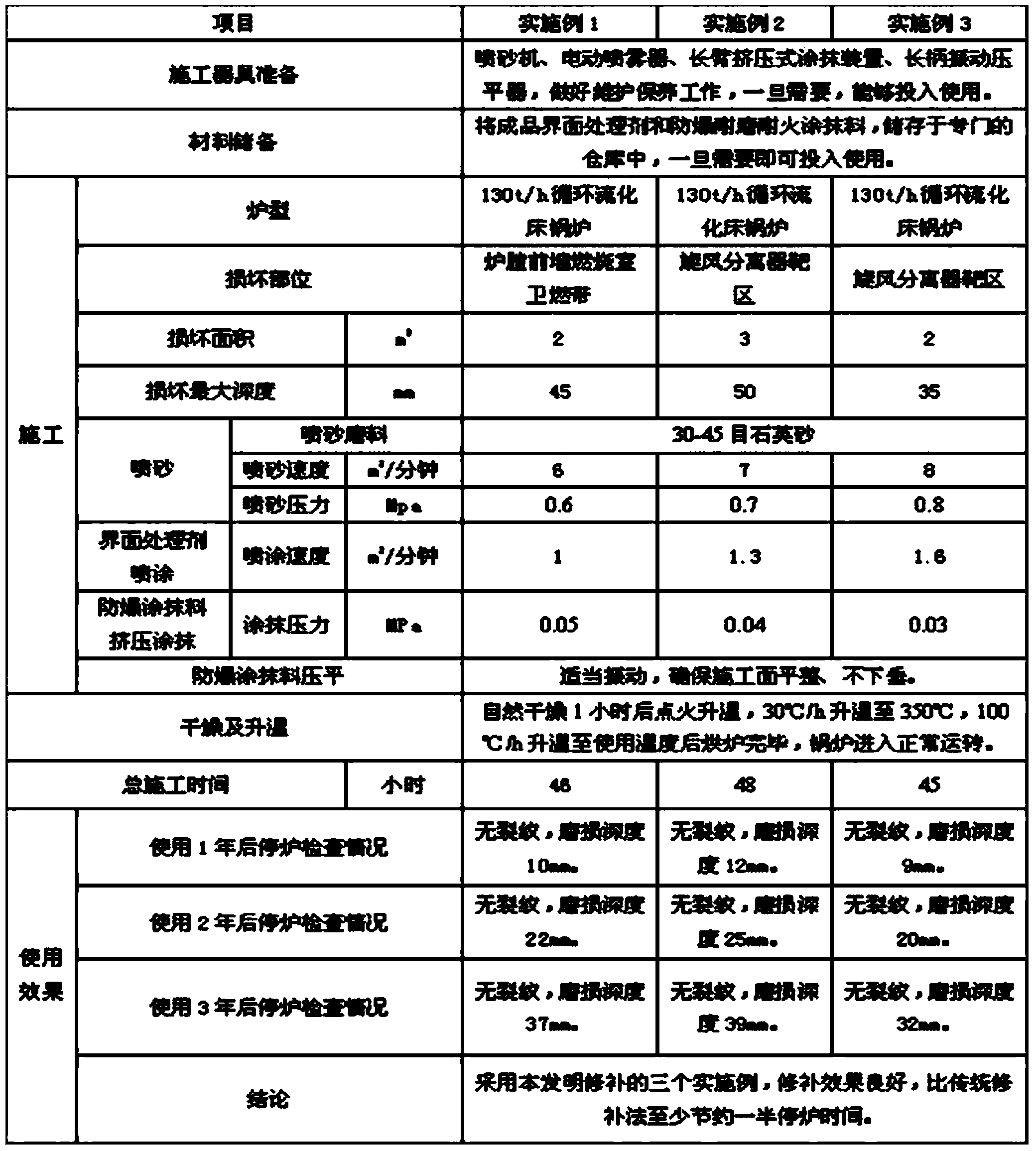

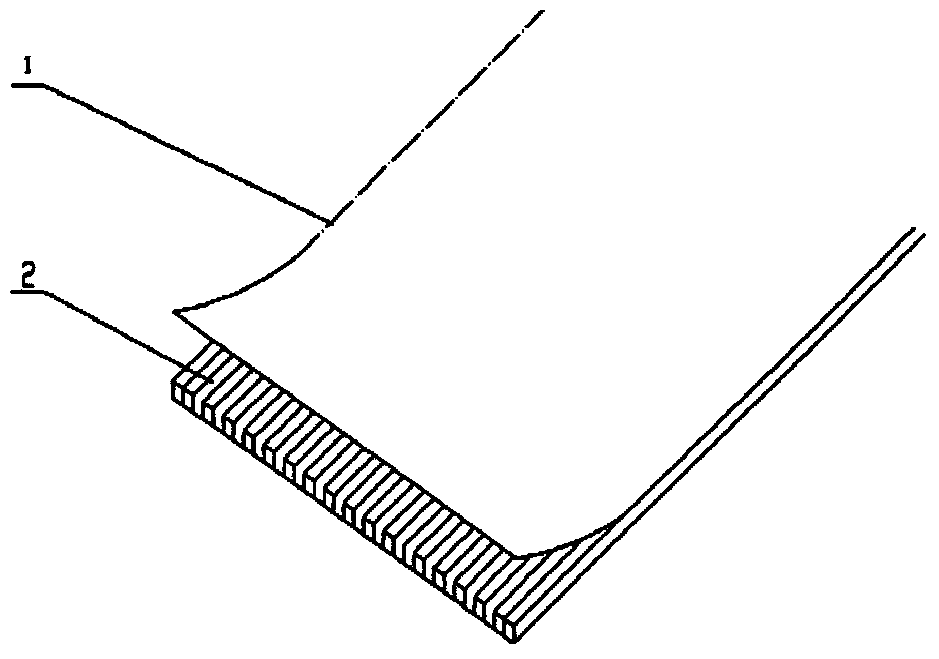

Quick repair method for boiler lining material

ActiveCN103939937AGuaranteed repair qualityReduce material usageCasings/liningsSprayerMaterials science

The invention belongs to the field of unshaped refractory application and particularly relates to a quick repair method for a boiler lining material. After cleaning and roughening processing are conducted on a damaged part through a sanding device, an interface processing agent is sprayed at the damaged position through an electric sprayer, later the damaged position is coated with wearproof plastic refractory in an extruded mode through an extruded type long arm coating device, the wearproof plastic refractory is compacted and flattened through a long handle vibration flattener, and fast boiler heating and slow boiler heating are conducted in two stages afterwards. According to the quick repair method for the boiler lining material, a traditional repairing method for a traditional boiler lining is replaced, and the boiler lining can be efficiently repaired with high quality.

Owner:SHANDONG YAOHUA REFRACTORY MATERIAL SCI & TECH CO LTD

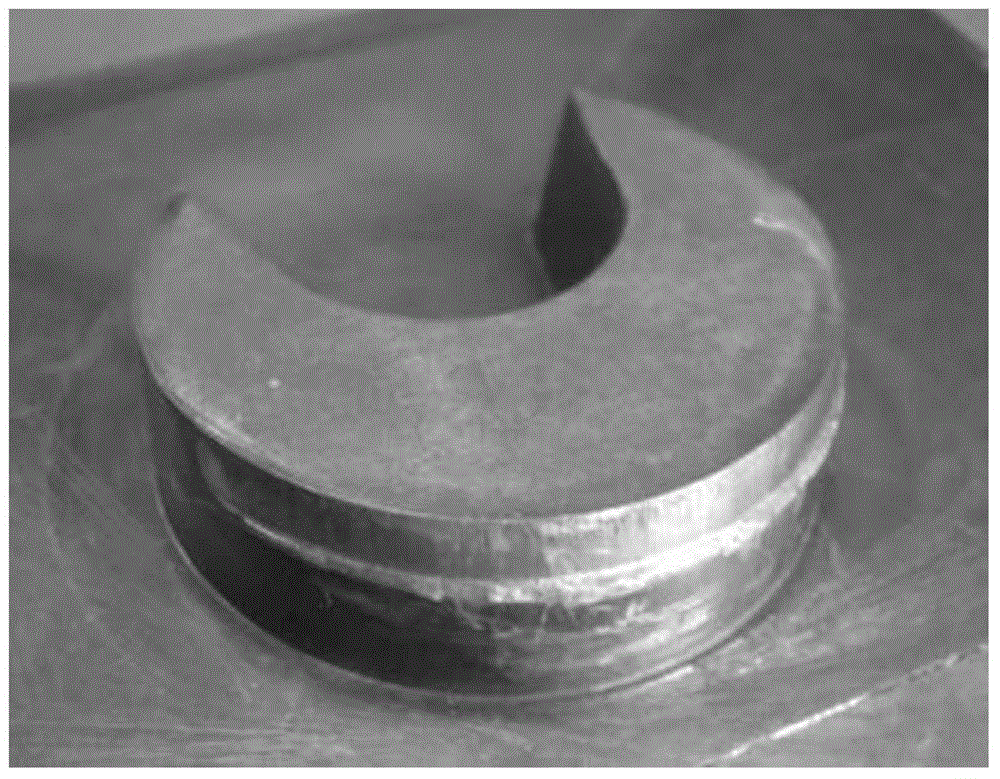

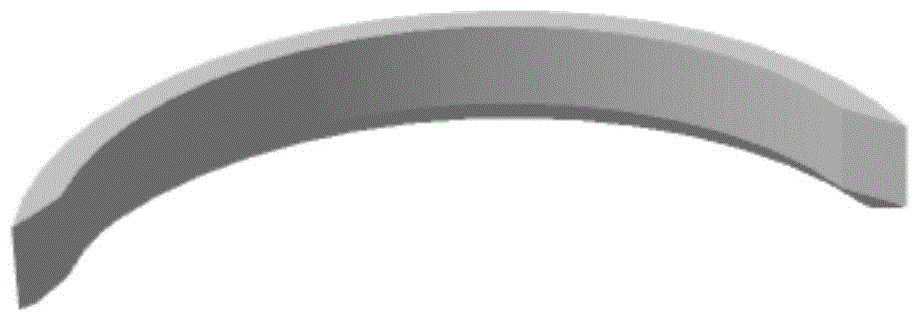

Method for repairing converter supporting ring

The invention relates to a method for repairing a converter supporting ring. The method comprises the following steps that (1) an old converter supporting ring is disassembled, and a transmission side trunnion and a non-transmission side trunnion assembly are obtained; (2) a tangential key on the transmission side trunnion is removed; (3) a large gear on the transmission side trunnion is dismounted; (4) new supporting ring fan-shaped sections are designed and made optimally; (5) two trunnion assemblies are repaired and the ends of the trunnion are sealed; (6) the two trunnion assemblies and the two fan-shaped sections are assembled on site; (7) the two trunnion assemblies and the two fan-shaped sections are welded and annealed on site. The method is used for repairing the converter supporting ring, greatly shortens the manufacturing period of the supporting ring, guarantees repairing quality and saves a great number of spare part expenses for enterprises.

Owner:甘肃酒钢集团西部重工股份有限公司

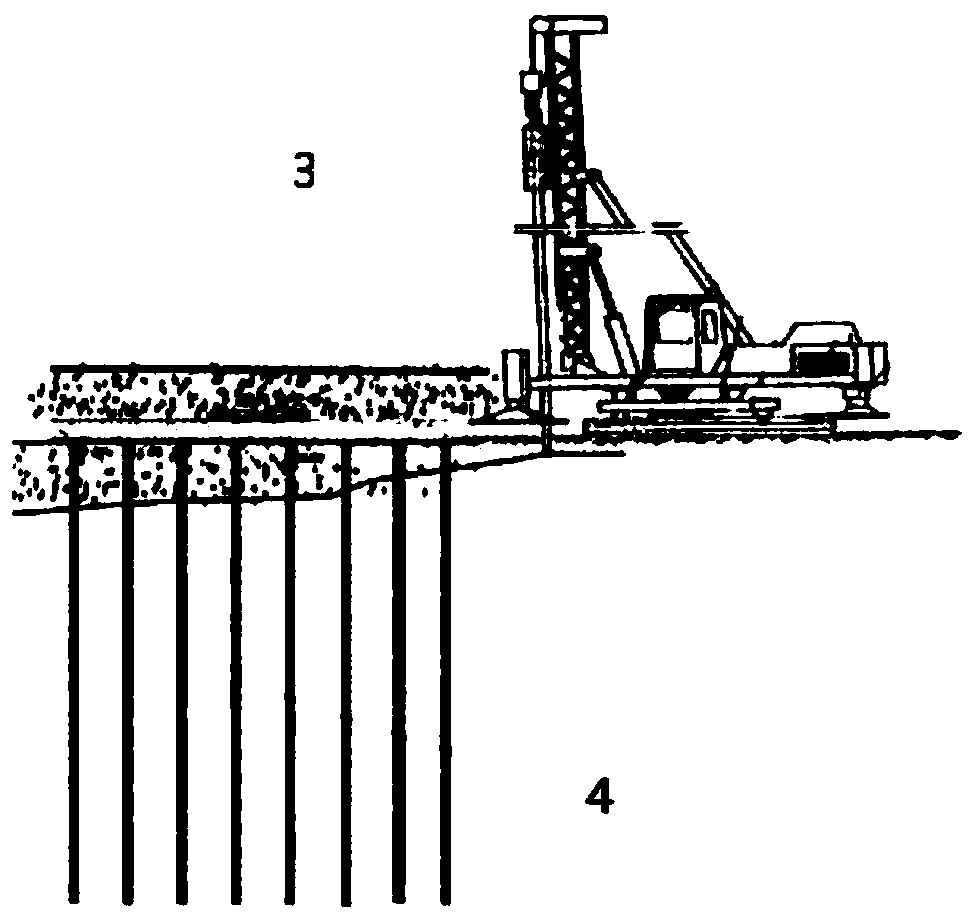

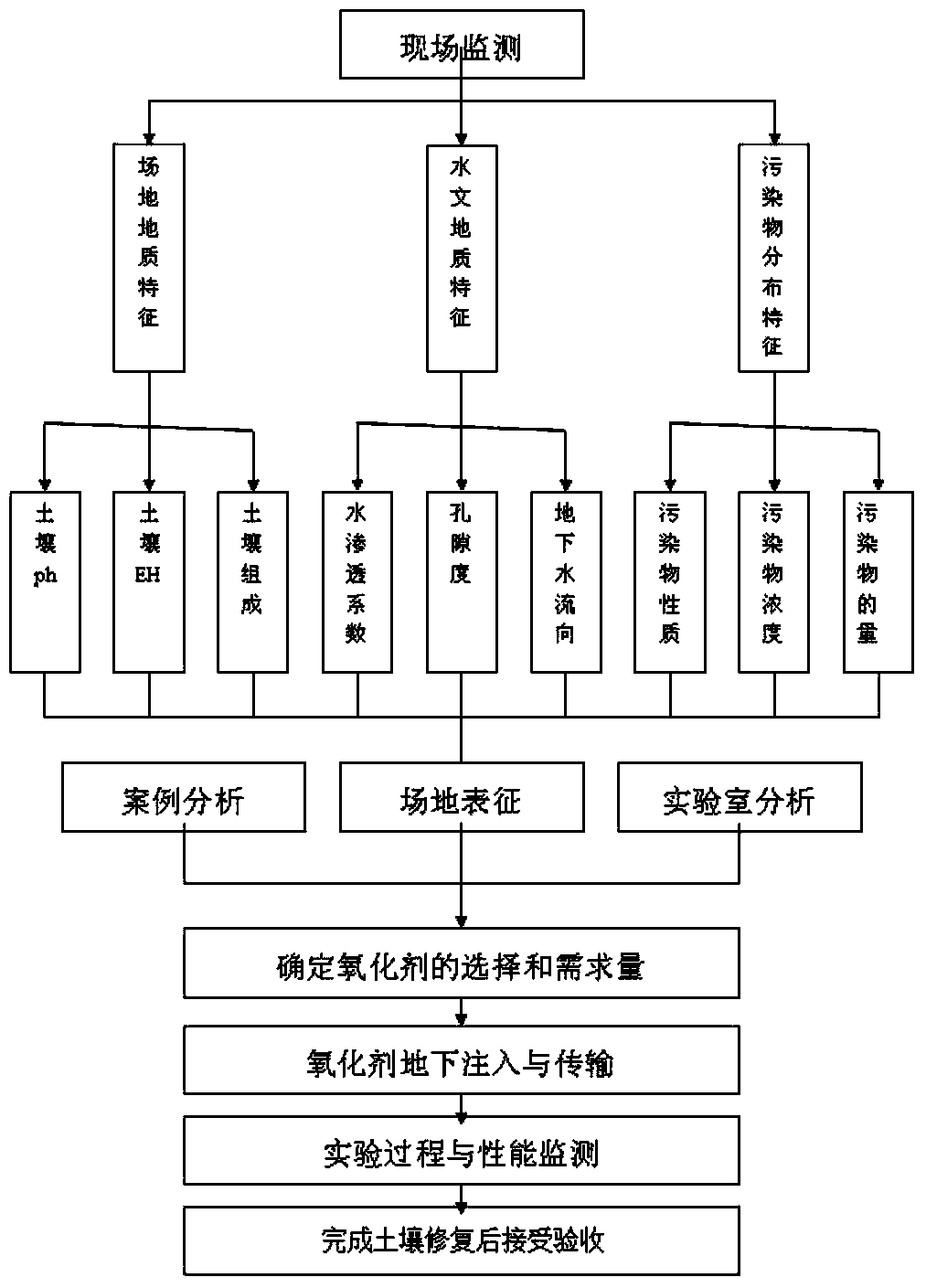

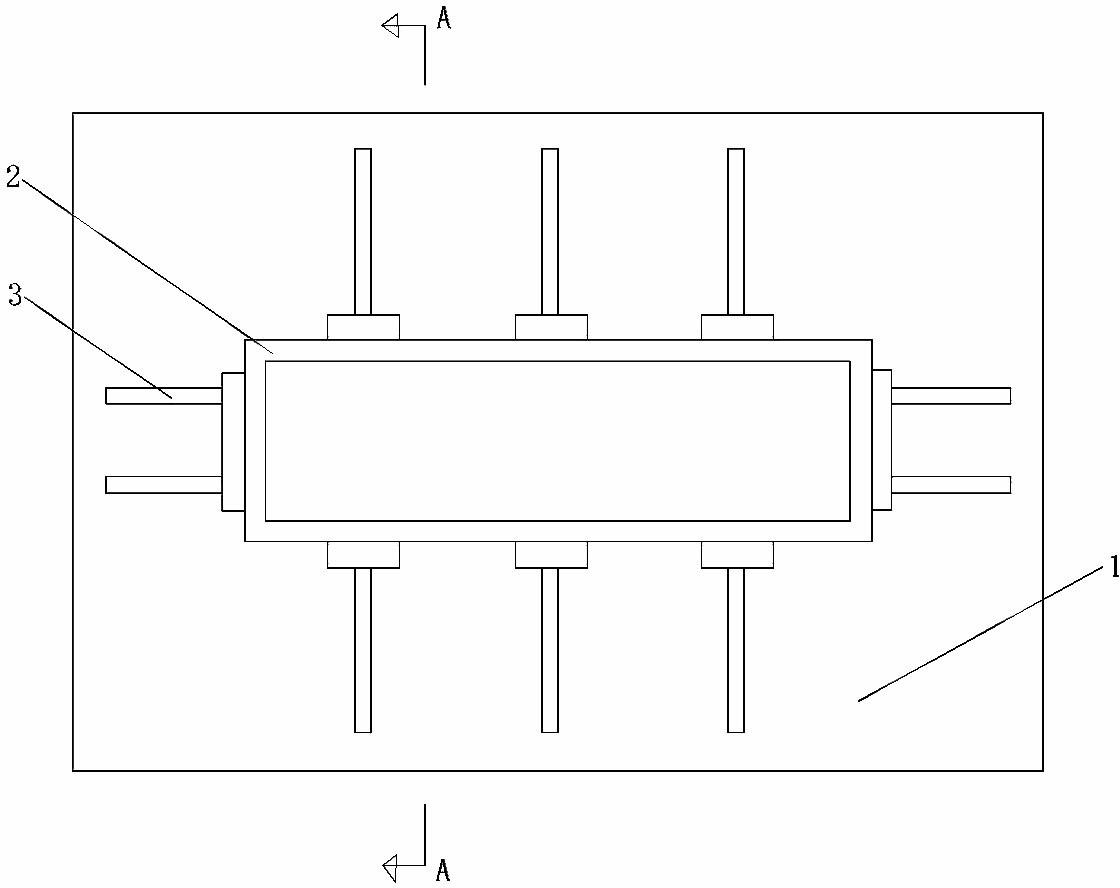

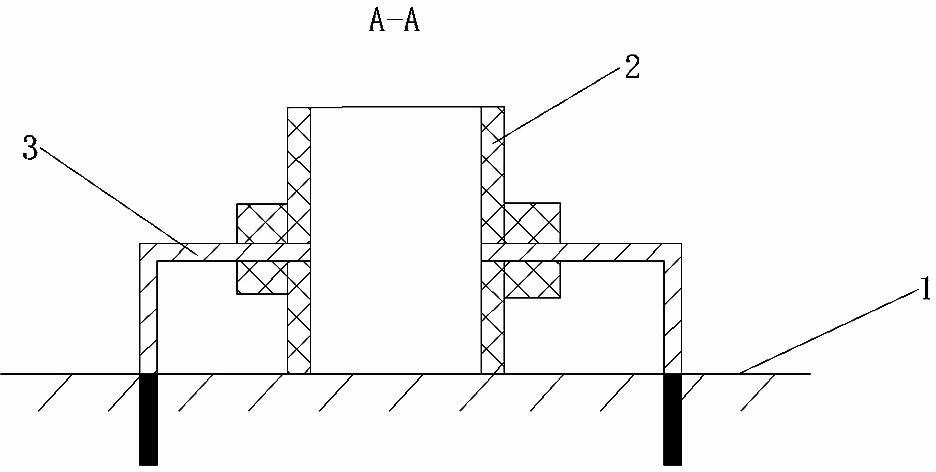

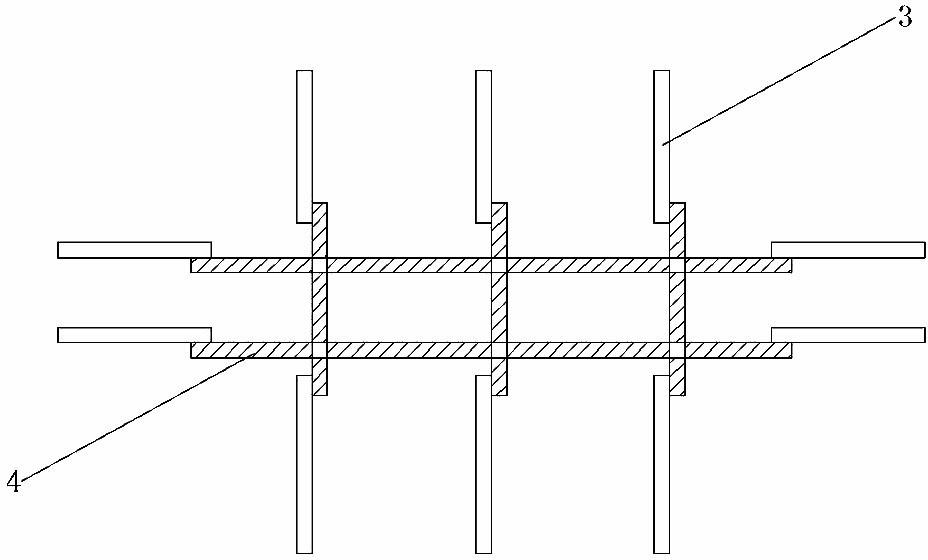

In-situ chemical remediation method of soil

ActiveCN103495601AEasy to sample and analyzeEnsuring the quality of soil remediationContaminated soil reclamationEnvironmental geologyPolluted soils

The invention belongs to the remediation filed of the polluted soil and in particular relates to an in-situ chemical remediation method of soil. The method comprises the following steps: (1) arranging an injection device; (2) injecting drug solution; (3) monitoring and adjusting; (4) repeating the above steps till the remediation of the soil is finished, wherein the injection device is arranged by using a board inserting machine; the injection device comprises an inner core and a permeation layer which coats the periphery of the inner core; the external surface of the inner core is provided with axial grooves and / or convex ribs; the permeation direction of the permeation layer is from inside to outside. Through the in-situ chemical remediation method of soil, the good injection effect can be guaranteed, the structure of the injection device is simplified, the construction speed of the arrangement of the injection device is improved, and the construction cost is lowered.

Owner:SUZHOU LVDI SOIL REMEDIATION TECH CO LTD

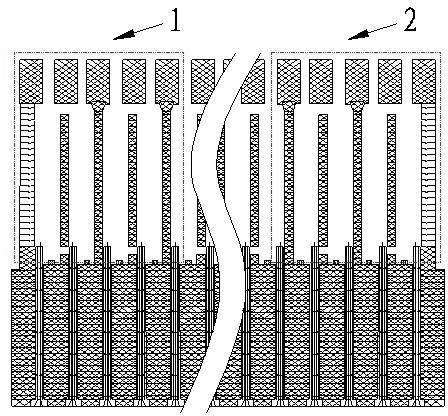

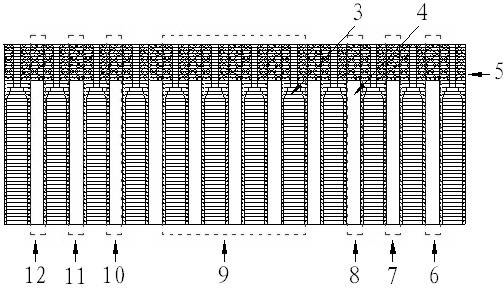

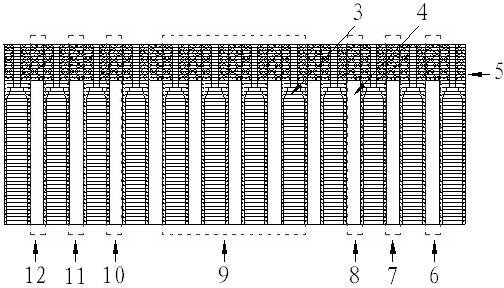

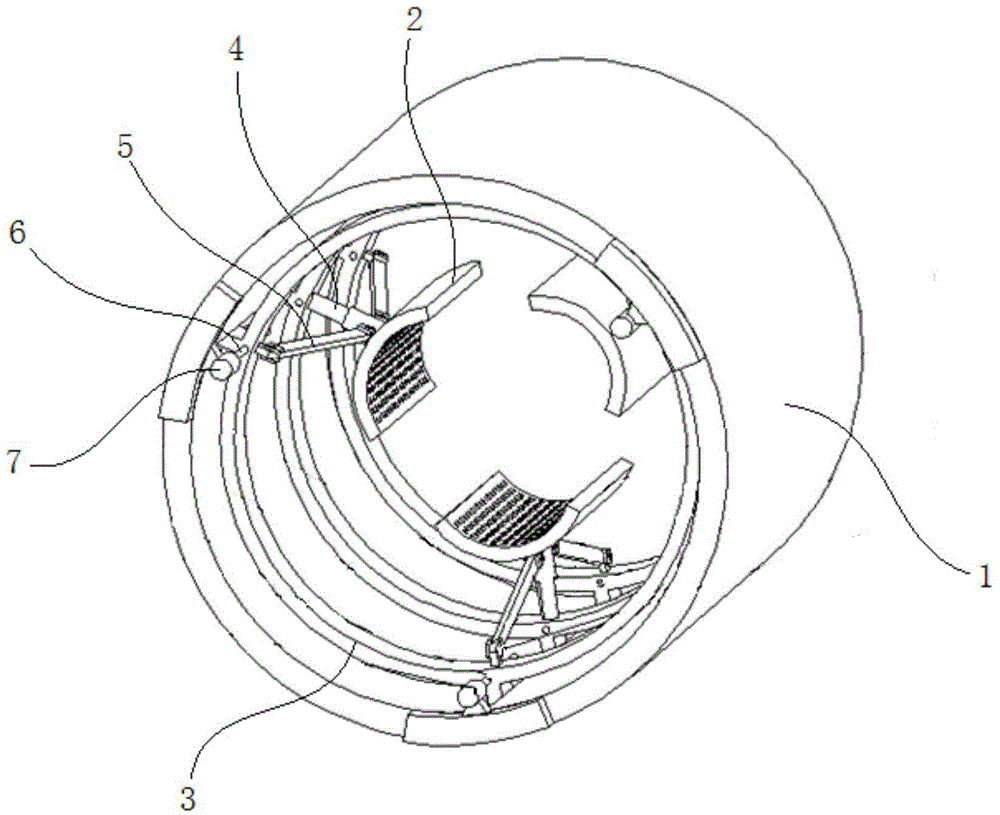

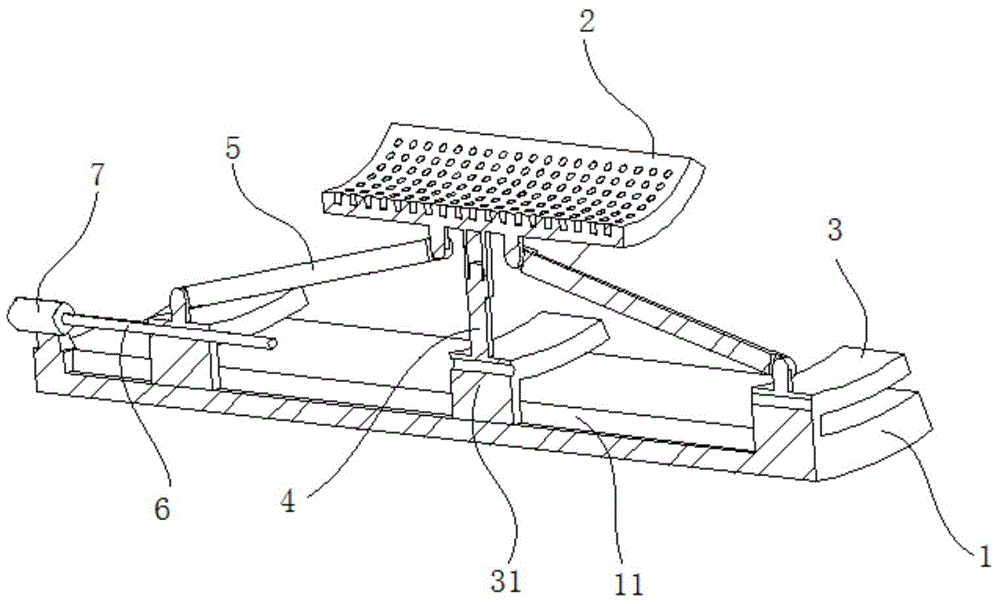

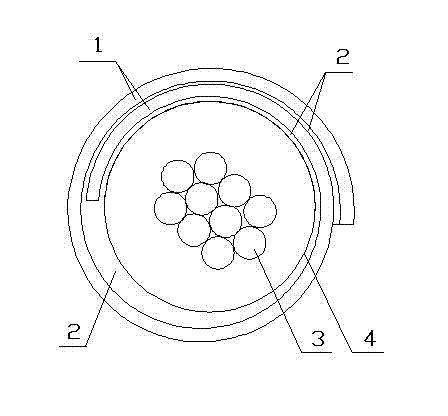

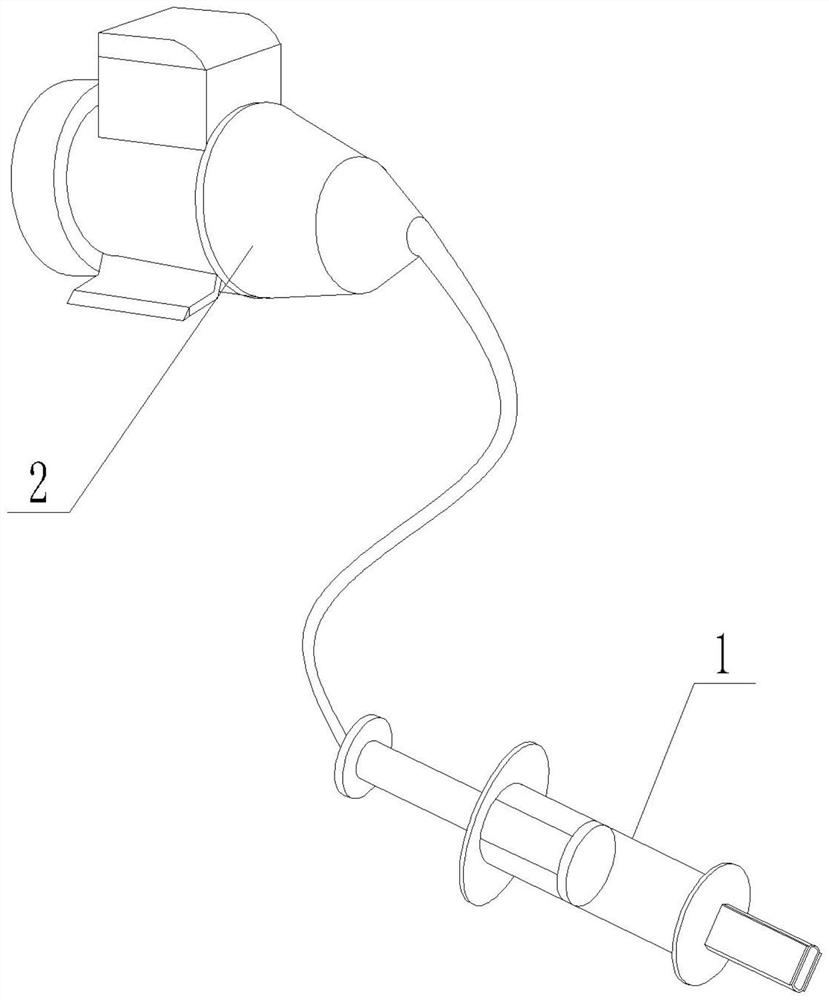

Plating pen for brush electroplating of shafts

ActiveCN104532312AImprove efficiencyReduce labor intensityElectrodesArchitectural engineeringElectroplating

The invention discloses a plating pen for brush electroplating of shafts. The plating pen comprises: a sleeve and plating pen brushes, wherein the inner wall surface of each of the plating pen brushes is provided with brush hair, and the plating pen brushes are circumferentially uniformly arranged in the inner bores of the sleeve through a variable diameter mechanism; and the variable diameter mechanism comprises: circular ring seats, wherein the three circular ring seats are axially equidistantly arranged in the inner bores of the sleeve, one of the circular ring seats is fixedly arranged, and the other two circular ring seats are arranged in an axial sliding mode; a plating pen brush support comprising telescoping rods and two connecting rods, wherein one ends of the telescoping rods are fixed to the middle circular ring seats respectively, the other ends of the telescoping rods are fixed to the middle portions of the outer wall surfaces of the plating pen brushes respectively, one ends of the two connecting rods are hinged to the circular ring seats at two sides respectively, and the other ends of the two connecting rods are hinged to the central portions of the outer wall surfaces of the plating pen brushes respectively; and a driving mechanism used for driving one of the circular ring seats capable of axially sliding to slide. The plating pen can realize mechanical brush electroplating of shafts and other parts with different diameters, has a high efficiency, and can guarantee the quality of the brush electroplating.

Owner:GUANGXI UNIV

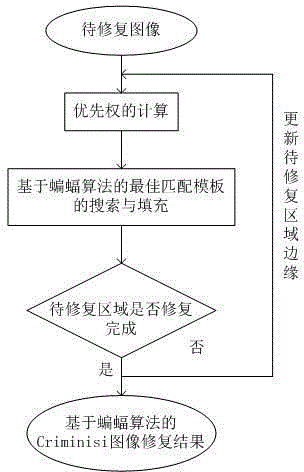

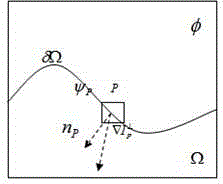

Criminisi image restoration method based on bat algorithm

InactiveCN103955906AMeet visual needsGuaranteed repair qualityImage enhancementBat algorithmImage restoration

A Criminisi image restoration method based on a bat algorithm comprises the steps of calculating the priority of each pixel point of to-be-restored region edges of to-be-restored images, selecting a pixel point with maximum priority as a pixel point with restoration priority, performing searching and filling on best matching blocks in perfect regions of the to-be-restored images, wherein searching (as mentioned) is performed by adopting the bat algorithm according to a matching principle; updating the to-be-restored region edges, returning the edges and performing repeated circulating operation till the restoration of to-be-restored regions is finished and obtaining an image restoration result. The Criminisi image restoration method is wide in image restoration range, improves the restoration speed, reduces the time consumption and meets the visual demands of people on the premise that the restoration quality of the to-be-restored images having different emphasis areas is ensured. Therefore, the Criminisi image restoration method has important practical significance.

Owner:WUHAN UNIV OF SCI & TECH

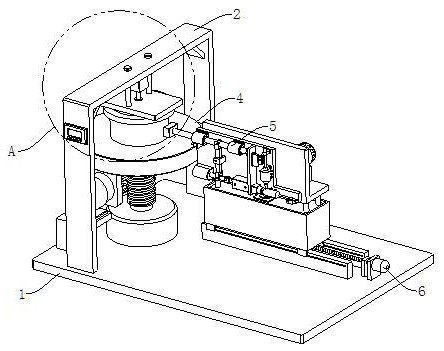

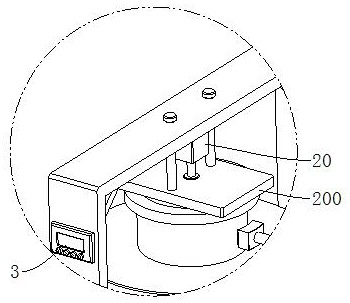

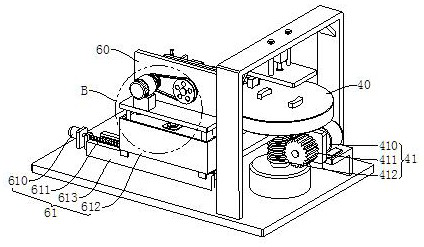

Shaping device for cylindrical flange plate after forging and working method

InactiveCN112171176AImprove efficiencyImprove qualityMetal working apparatusManufacturing engineeringFlange

The invention relates to the field of flange plate forging, in particular relates to to a shaping device for a cylindrical flange plate after forging and a working method. The shaping device comprisesa base, a supporting frame, a controller, a rotating mechanism, a repairing mechanism and a position adjusting mechanism, wherein the rotating mechanism comprises a machining table and a rotating component; the position adjusting mechanism is arranged at the top of the base so as to support the repairing mechanism to adjust the position, and the position adjusting mechanism comprises a lifting plate, a sliding component and a jacking component; the repairing mechanism comprises a bearing plate, a hammer head, a spray head, a material receiving pipe, a pushing component and a discharging component; and the rotating component, the sliding component, the jacking component, the pushing component and the discharging component are electrically connected with the controller. According to the shaping device for the cylindrical flange plate after forging and the working method, various defects on the outer wall of the flange plate can be detected in time and repaired in time, and meanwhile, most of repairing modes are automatic; and meanwhile, frequent contact of workers is not needed in the repairing process, and thus potential safety hazards are small.

Owner:含山县龙顺机械配件厂

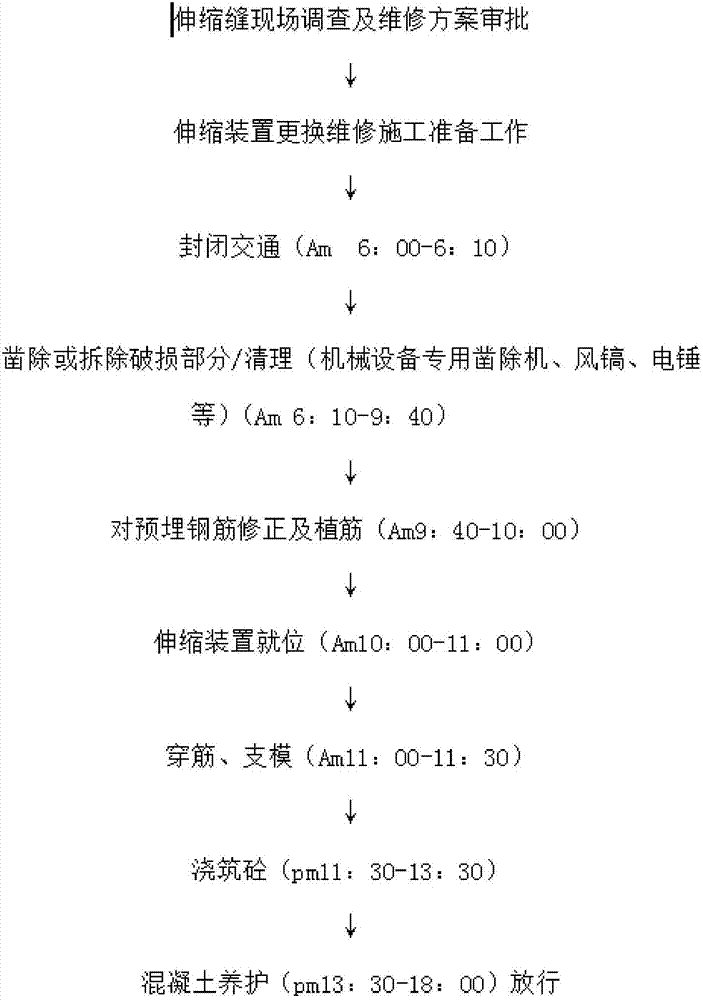

Modular-type telescopic seam fast repairing and replacing construction method

InactiveCN107476205AQuickly increase the strengthShort initial setting timeBridge structural detailsBridge erection/assemblyButt jointArchitectural engineering

The invention discloses a modular-type telescopic seam fast repairing and replacing construction method. The modular-type telescopic seam fast repairing and replacing construction method comprises the step of construction preparing, specifically, needed mechanical equipment is well prepared, and traffic closing is conducted on the construction site of replacing telescopic seams. According to the modular-type telescopic seam fast repairing and replacing construction method, a scientific maintenance program is worked out through professional technical service, appropriate measures are achieved, and the repairing quality is ensured; through professional seamless butt joint construction, the operation time of each process is compressed to the utmost extent, and especially the time of cleaning waste seams by using special equipment; damaged telescopic seams are replaced with a new type telescopic seam product; and 3h fast hard concrete is used, and the maintenance time is shortened.

Owner:JIANGSU PINGSHAN TRANSPORTATION FACILITIES CO LTD

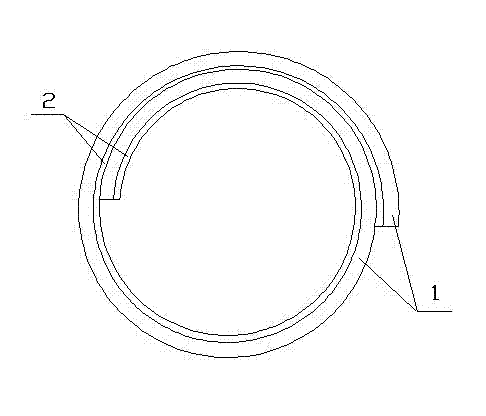

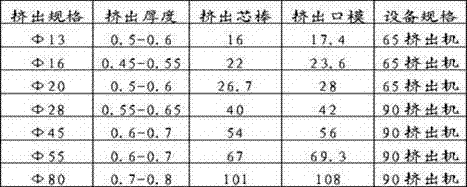

Patch for rapidly repairing damages of external insulating layers of thermal shrinkage wires and cables

ActiveCN102354589ASimple processGuaranteed repair qualitySynthetic resin layered productsInsulating bodiesRepair materialInternal layer

The invention discloses a patch for rapidly repairing damages of external insulating layers of thermal shrinkage wires and cables. The patch comprises an external layer and an internal layer, wherein the external layer is an insulating layer; and the internal layer is a hot melt adhesive layer. A preparation method is characterized by comprising the following steps: carrying out blending modification on the raw materials of the insulating layer, extruding the modified raw materials into a tubular shape by an extruder, then crosslinking, carrying out extension shaping after crosslinking to obtain the insulating layer, then carrying out adhesive application to obtain the hot melt adhesive layer and finally longitudinally cutting the tubular repair material to form a curly sheet. The patch has the following beneficial effects: without a free end, the patch can be used for rapidly repairing the damaged parts after the damaged parts are slightly washed and polished; the patch is suitable for various wire and cable external diameters even in an uninterrupted state, the process is simple and the repair quality of the wires and cables can be ensured; and as a radiation crosslinking technology is adopted, the service life of the patch can be at least more than 25 years, and at the same time the cost of the patch is lower than half the cost of zipper type thermal shrinkage products.

Owner:大连联合高分子材料有限公司

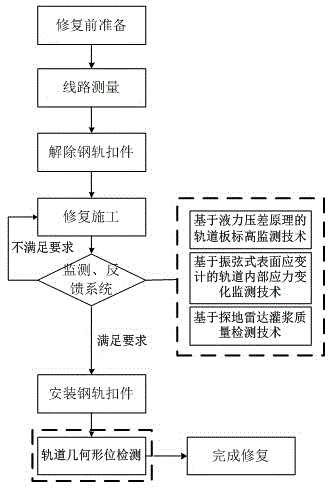

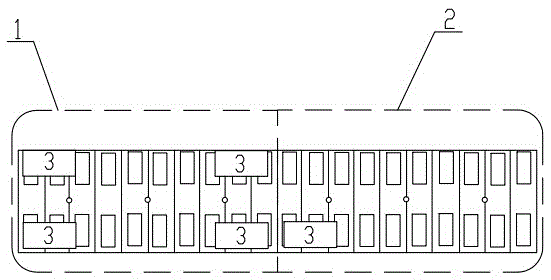

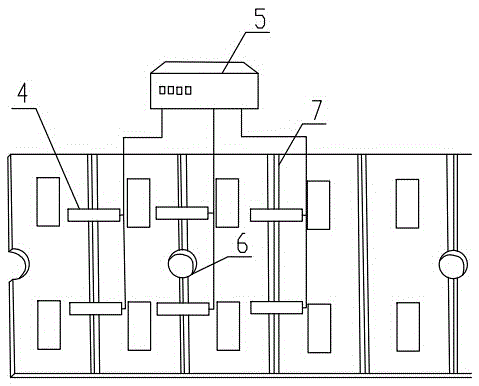

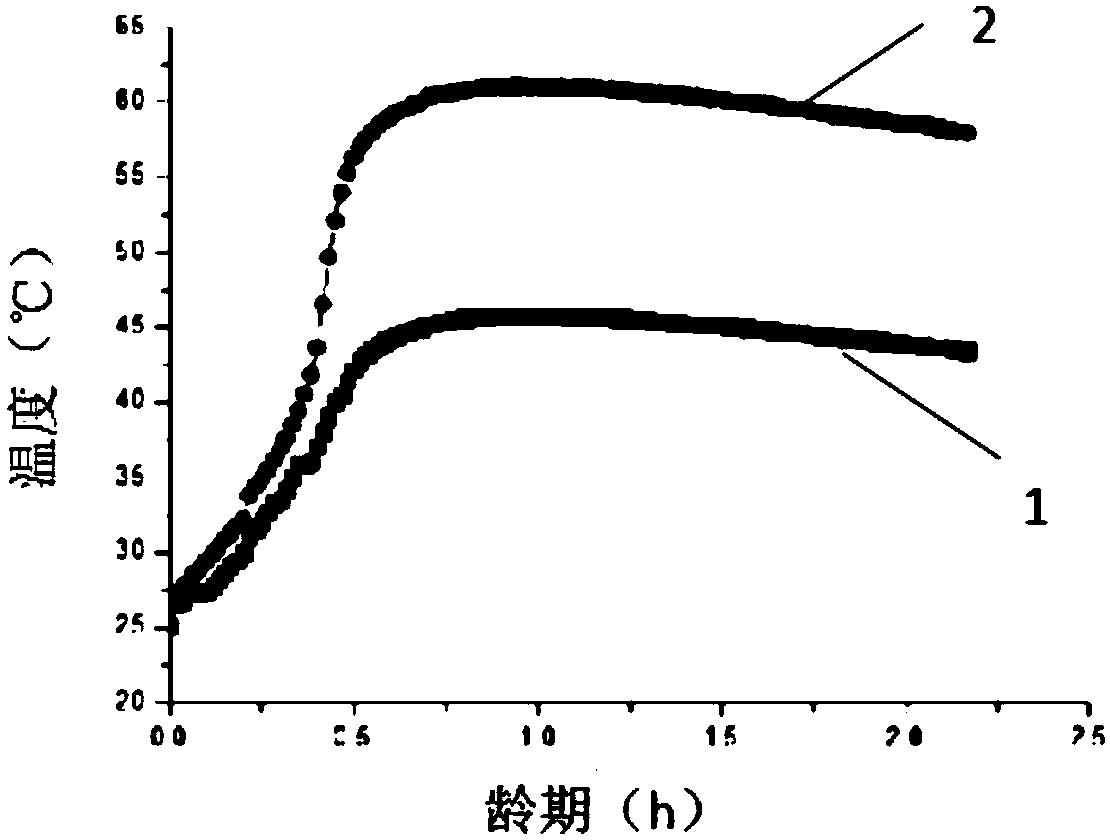

High speed railway ballastless track subgrade settlement repairing quality detection and control method

InactiveCN105625124ARealize macro monitoringRealize microscopic monitoring of force unevennessTrack maintainenceRepair timeTransducer

The invention discloses a high speed railway ballastless track subgrade settlement repairing quality detection and control method and relates to the technical field of repairing quality detection and control method of a railway track. The method comprises the following steps: respectively mounting a hydraulic pressure difference transducer and a vibrating wire sensor on relevant positions of a track board and a standard track board of a repaired subgrade section, recording parameters collected by both of the sensors in initial state, and taking the sensor parameters on the standard track board as a standard; adjusting grouting speed, pressure and grouting position according to parameter changes of the hydraulic pressure difference transducer and the vibrating wire sensor during repair; and finally detecting grouting repair quality by adopting ground penetrating radar, and detecting the geometric shape of the track by adopting a track detection trolley. The method is simple to operate, accurate in measurement and capable of meeting the requirements of short repair time and tense construction period in skylight time, thus ensuring high speed railway ballastless track subgrade repair quality, prolonging the service life and improving the operation safety.

Owner:CHINA RAILWAYS CORPORATION +1

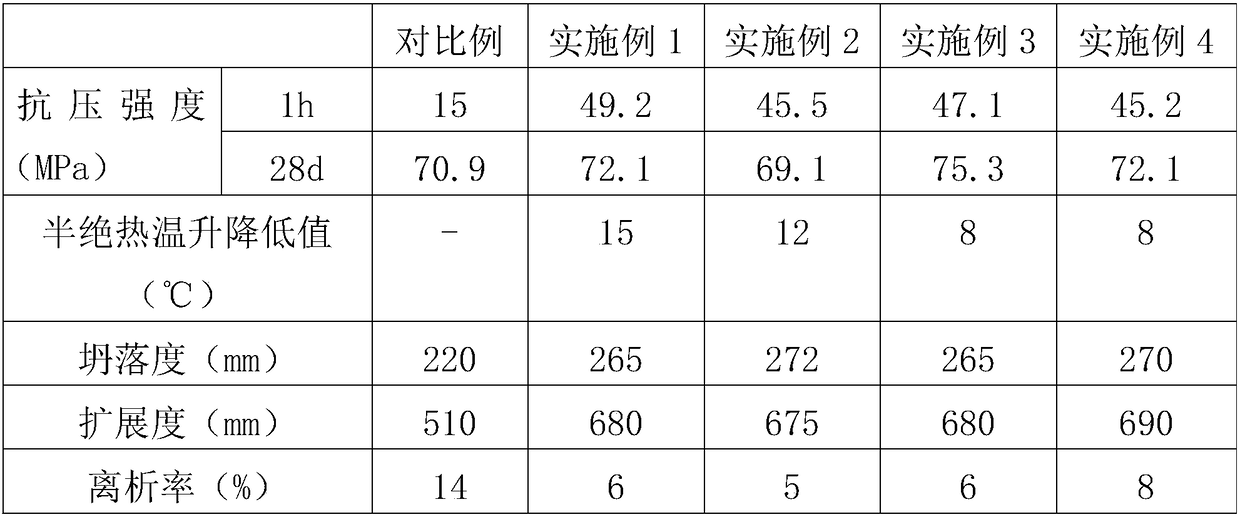

Low-temperature shrinkage self-leveling anti-segregation emergent road repairing material and preparation method thereof

The invention relates to a low-temperature shrinkage self-leveling anti-segregation emergent road repairing material and a preparation method thereof. The low-temperature shrinkage self-leveling anti-segregation emergent road repairing material comprises the following components: 30-50% of a composite cementing material, 1-2% of a hydration heat inhibitor, 0.1-0.3% of a chemical water reducer, 2-5% of a physical water reducer, 1-2% of an anti-segregation agent, 0.1-0.2% of a coagulation regulating component, 1-2% of fiber, 20-35% of sand and 20-35% of stone. Through addition of functional materials such as the hydration heat inhibitor, the anti-segregation agent and the physical water reducer, in combination with a high-speed stirring and slurrying technology, the relatively low-temperature shrinkage, segregation-free and self-leveling repairing material is prepared; the low-temperature shrinkage self-leveling anti-segregation emergent road repairing material can guarantee the repairing quality of an emergently repaired construction site, has the characteristics of high durability and long service life, and solves the problem of high rerepairing rate of the conventional repairing material.

Owner:BEIJING SHOUFA HIGHWAY MAINTENANCE & CONSTR +1

Method for testing flexural-tensile strength of concrete

InactiveCN102183417AReliable Repair QualityPromote repairPreparing sample for investigationMaterial strength using steady bending forcesRoad surfaceMaterials science

Owner:ANHUI & HUAI RIVER WATER RESOURCES RES INST

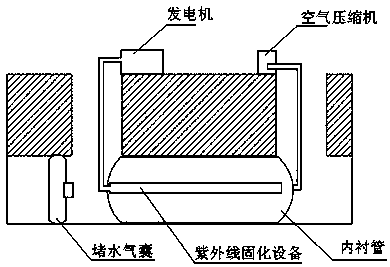

Urban groundwater drainage pipe network repair method

InactiveCN109680782AAvoid excavationImprove work efficiencySewer pipelinesSubsurface drainageUV curing

The invention relates to the technical field of drainage, and in particular relates to an urban groundwater drainage pipe network repair method which comprises the following operation steps of draining sewage in a groundwater drainage pipe network, and clearly cleaning sludge in the groundwater drainage pipe network to reach the repair requirement; laying a layer of mulching film on the bottom ofa pipeline to be repaired firstly, and then enabling a repair lining material to be in place by adopting a mechanical dragging manner; mounting ultraviolet curing equipment at a pipe mouth of the repair lining material, performing inflation on a lining pipe to enable the lining pipe to cling to the pipeline to be repaired, and illuminating the lining pipe with the ultraviolet curing equipment to enable the lining pipe to be cured to form a new pipeline; cutting a tying head of the pipe mouth with a cutting tool, and performing mouth plastering and edge sealing with rapid hardening cement; anddisassembling a water blockage air bag, and putting the pipeline into water passing use. The urban groundwater drainage pipe network repair method can realize that a great quantity of excavated groundis avoided during groundwater drainage pipe network repair, improves the working efficiency of repairing the pipeline and saves the cost.

Owner:YUNNAN DAHONGSHAN PIPELINE

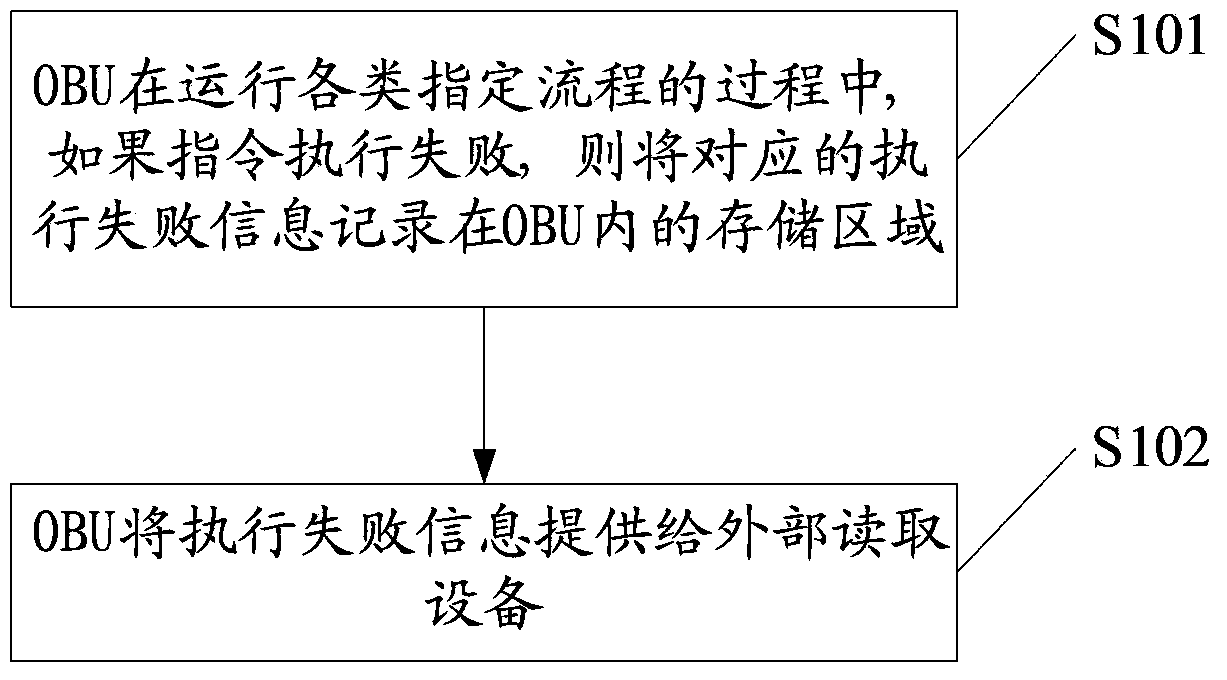

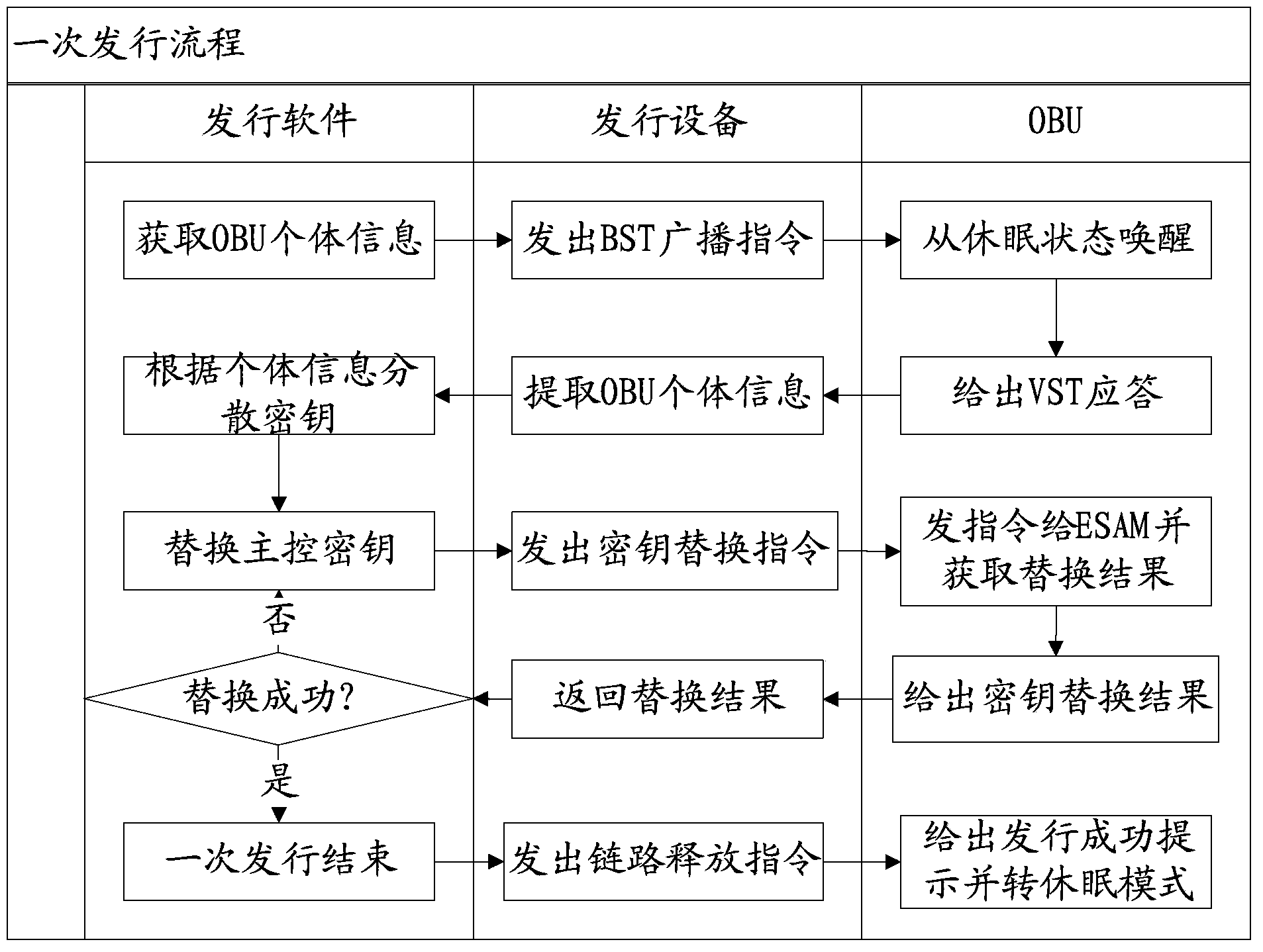

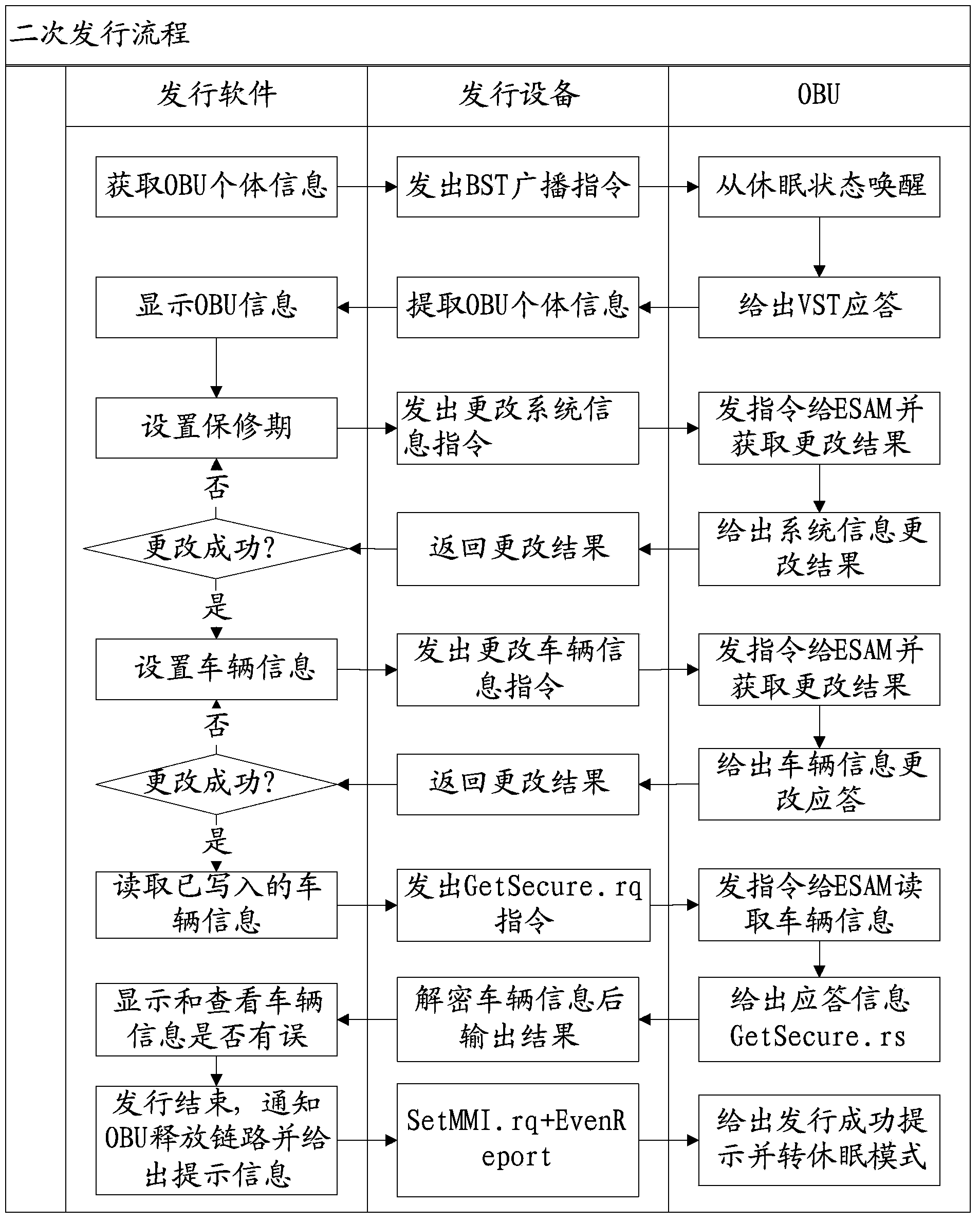

Fault diagnosis method and system of on-board unit and on-board unit

ActiveCN103630375AImprove repair speedGuaranteed repair qualityVehicle testingOn boardDiagnosis methods

The application discloses a fault diagnosis method and system of an on-board unit (OBU) and an OBU. The fault diagnosis method comprises the following steps of a failure information storage execution step and a failure information providing execution step. To be specific, according to the failure information storage execution step, when an OBU runs a designated flow, if the instruction execution fails, corresponding execution failure information is recorded to a storage zone in the OBU; and according to the failure information providing execution step, the OBU provides the execution failure information for external reading equipment. According to the application, the technicist can carry out diagnosing on the OBU fault accurately, rapidly and conveniently during the repairing process, thereby improving the repairing speed of the OBU and ensuring the repairing quality. Moreover, the technicist of the OBU manufacturer can analyze and evaluate the execution failure information recorded in the OBU so as to perfect all links, including designing, testing and using and the like, of the product, thereby minimizing the repair rate of the product.

Owner:SHENZHEN GENVICT TECH

Old pipeline repairing process

InactiveCN102788222AControllable curing timeEasy to manufacturePipe elementsEngineeringMechanical engineering

The invention relates to an old pipeline repairing process. The old pipeline repairing process comprises the steps of: first, soaking a barrel composite sandwich felt in UV resin to form a hose, and sticking an inner film and an outer film respectively on the inner and outer surfaces of the composite sandwich felt; then, dragging the hose into the oil pipeline with cleaned inner wall; placing a UV (ultraviolet) lamp in an end socket at one end of the hose, and connecting a traction rope and a power supply; and second, sealing both ends of the hose by the end socket, and pulling the UV lamp to move slowly to irradiate the hose by the traction rope to cure the hose. The hose provided by the invention is made of composite sandwich felt soaked in the UV resin, the curing time of the hose can be controlled, and the hose can be manufactured in a workshop, so that the construction time in a construction site is shortened, the curing time and speed of the UV resin can be effectively controlled, the success rate is improved, and the liner repairing quality is ensured.

Owner:HENAN ZHONGTUO PIPELINE ENG

Stator wire rod insulation onsite repairing method for large generator

ActiveCN106374690AGood electrical performanceImprove electrical performanceManufacturing stator/rotor bodiesEpoxyHigh dosage

The invention discloses a stator wire rod insulation onsite repairing method for a large generator. The stator wire rod insulation onsite repairing method uses materials of a mica tape with low dosage of adhesive, a mica tape with high dosage of adhesive, room-temperature cured epoxy resin adhesive, a pre-impregnated glass tape (PG band) and the like; a main insulation damaged part of the stator wire rod is repaired on the site of accident of the generator; through a reasonable and reliable repairing process, the main insulation repairing of the wire rod is completed within a short time; it is ensured that the repaired stator winding can satisfy long-term, stable and reliable operational requirements of a machine set; meanwhile, a technological process of stator wire rod insulation onsite repairing for the large generator is specified; all repaired machine sets are re-input into operation; the repaired winding is excellent and reliable in insulation performance; and compared with a former generator accident treatment method, the stator wire rod insulation onsite repairing method can ensure the repairing quality, avoid disassembling and replacing of the stator wire rod, save a huge repairing cost, greatly shorten the rush repairing period, and has great economic benefit and social benefit.

Owner:HARBIN ELECTRIC MASCH CO LTD

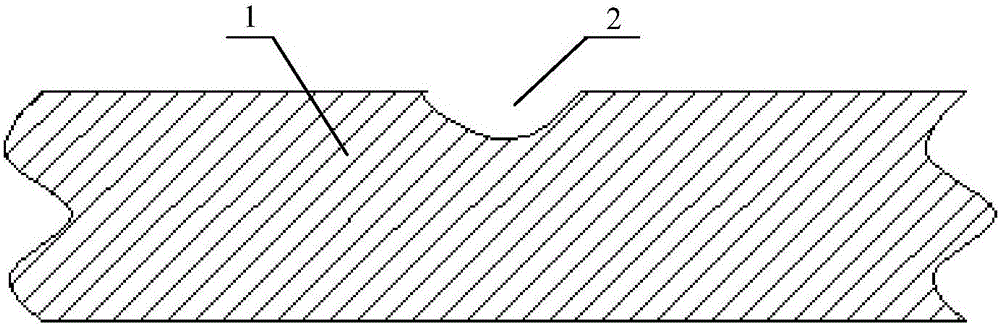

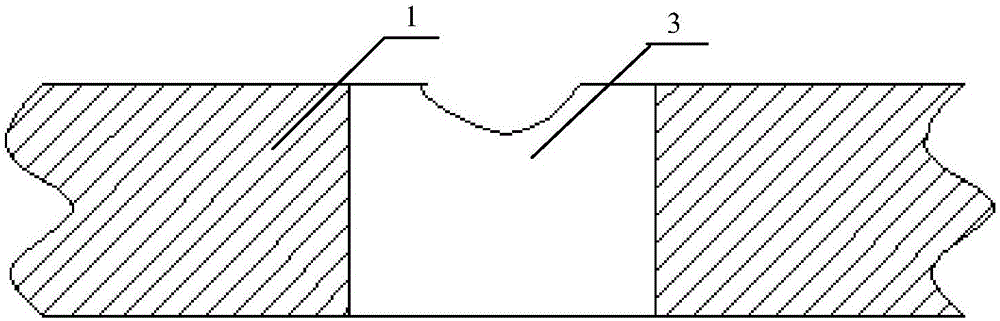

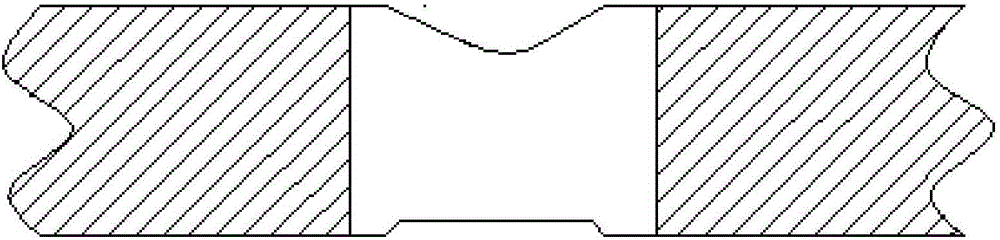

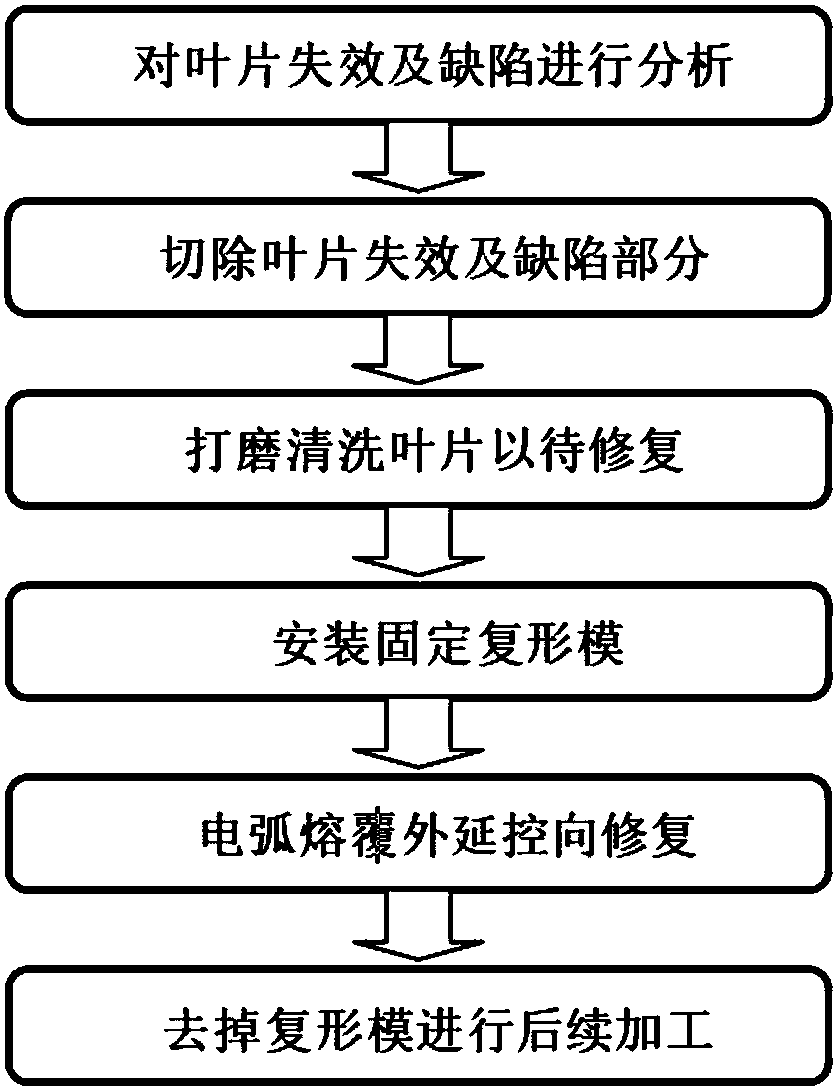

Repair method for complexing of inner flow passages of single-crystal or directional-crystal alloy blades

The invention discloses a repair method for complexing of inner flow passages of single-crystal or directional-crystal alloy blades. The repair method includes step S100, judging and analyzing blade failure and defects before repair; step S200, cutting failure or defective portions of the blades, and polishing and cleaning the blades; step S300, mounting pre-produced and pretreated complexing molds used for guaranteeing high-accuracy complexing of inner flow passage structures of the blades, and fastening the complexing molds in to-be-repaired blade cavities, wherein the complexing molds are core molds with outer surfaces capable of forming blade cavity flow passages through solidification of follow-up blade material melts; step S400, preheating to-be-repaired portions to more than 75% ofa material melting point calculated by Kelvin, and allowing the blade repair portions to extend externally to grow in a direction control way according to a metal melt filling method; step S500, removing the complexing molds after metal cladding, and performing follow-up processing on the blades. The repaired blades meet application requirements of the single-crystal or directional-crystal blades,service life of the blades is prolonged to the greatest extent, and the repair method has great theoretical and practical significance.

Owner:XI AN JIAOTONG UNIV

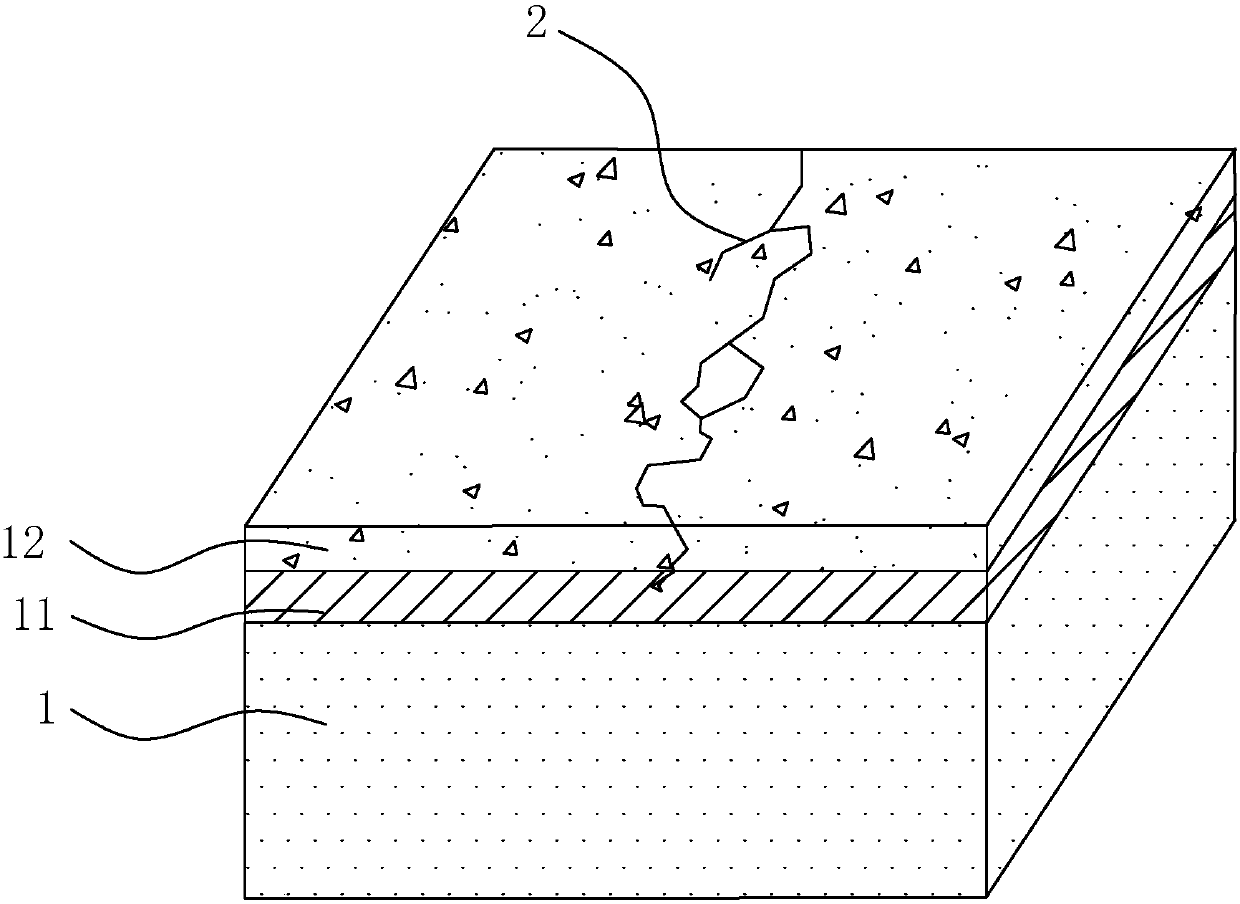

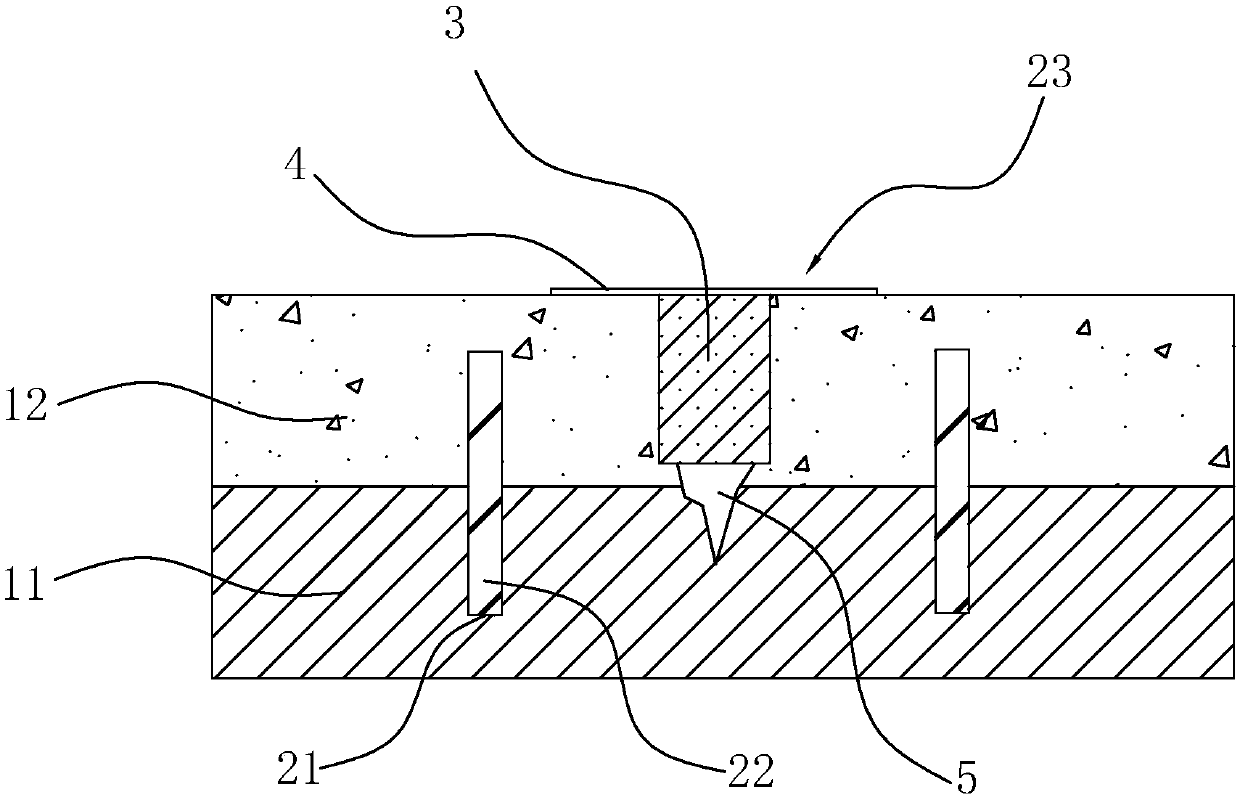

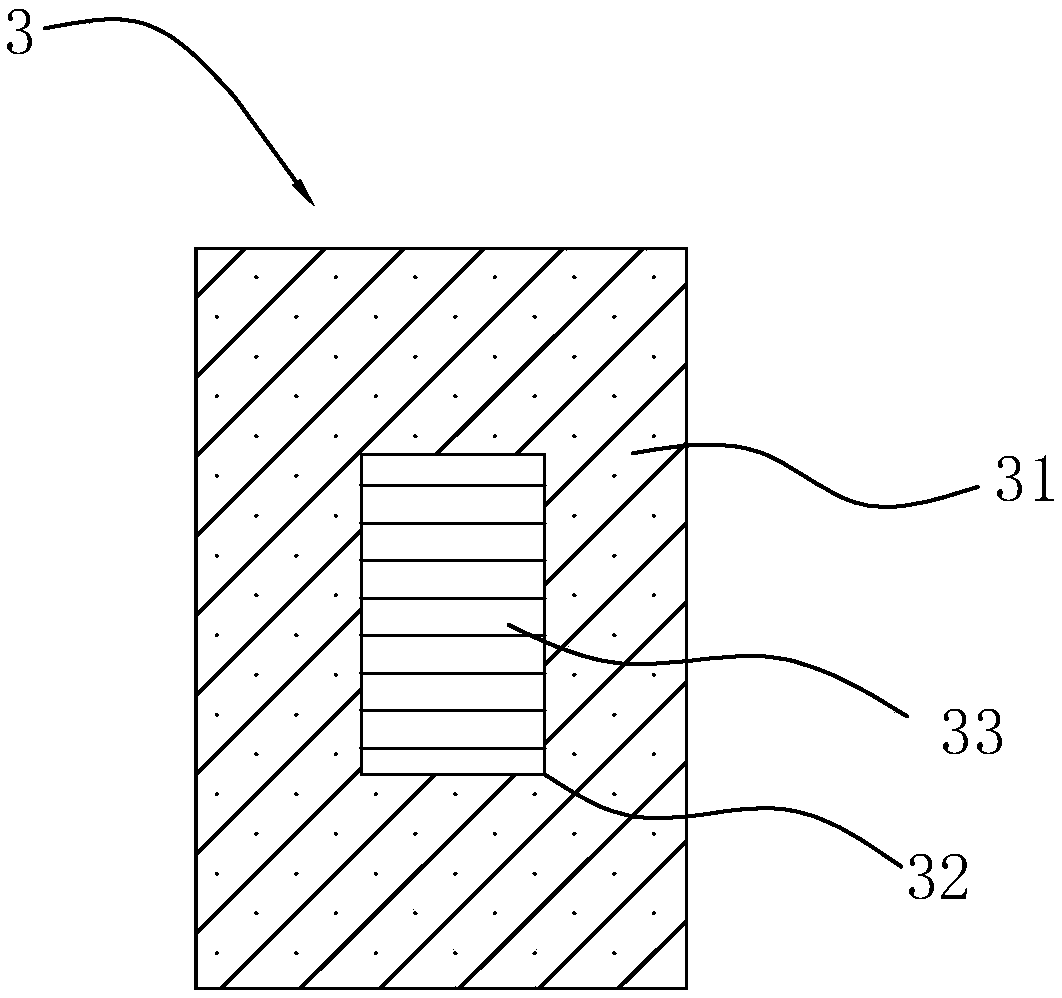

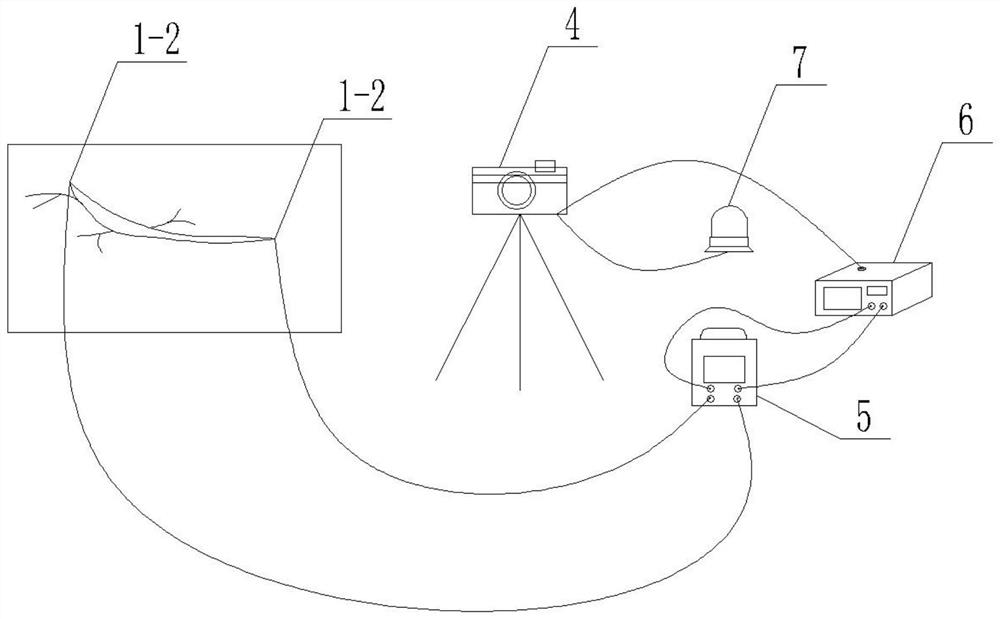

Grouting repair method for concrete cracks

InactiveCN107327158AGuaranteed repair qualityObserve and judge filling degreeBuilding repairsX-rayMaterials science

The invention relates to a grouting repair method for concrete cracks, and the method mainly used for repairing the concrete cracks through grouting. According to the method, the grouting liquid filling degree can be observed and judged, and the repair quality of the concrete cracks is ensured. In the method, an X-ray machine, a computer, a detection agent, grouting equipment and grouting liquid are mainly included. The working principle is as follows: the grouting equipment is used for pressing the detection agent in the concrete cracks, the X-ray machine is used for irradiating the concrete cracks, a crack distribution map is displayed on a display screen of the computer, a crack striograph A is formed, the grouting equipment is used for pressing the grouting liquid in the concrete cracks, meanwhile the X-ray machine is used for irradiating the concrete cracks, a striograph B is displayed on the display screen of the computer, working personnel compares the crack striograph A and the striograph B, if the striograph B can completely cover the striograph A, it shows that the concrete cracks are filled with the grouting liquid, and if the striograph B can not completely cover the striograph A, grouting needs to be conducted continually until the concrete cracks are completely filled with the grouting liquid.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

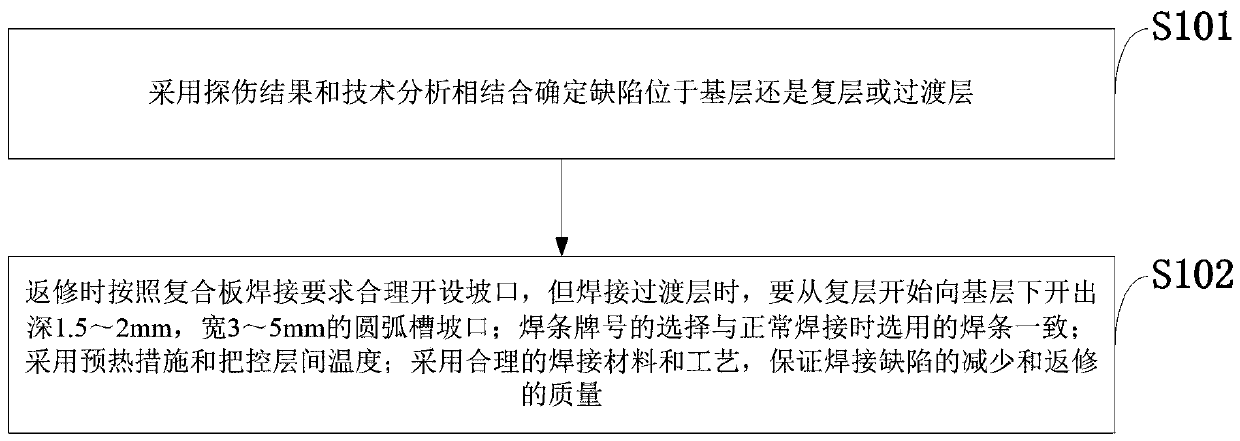

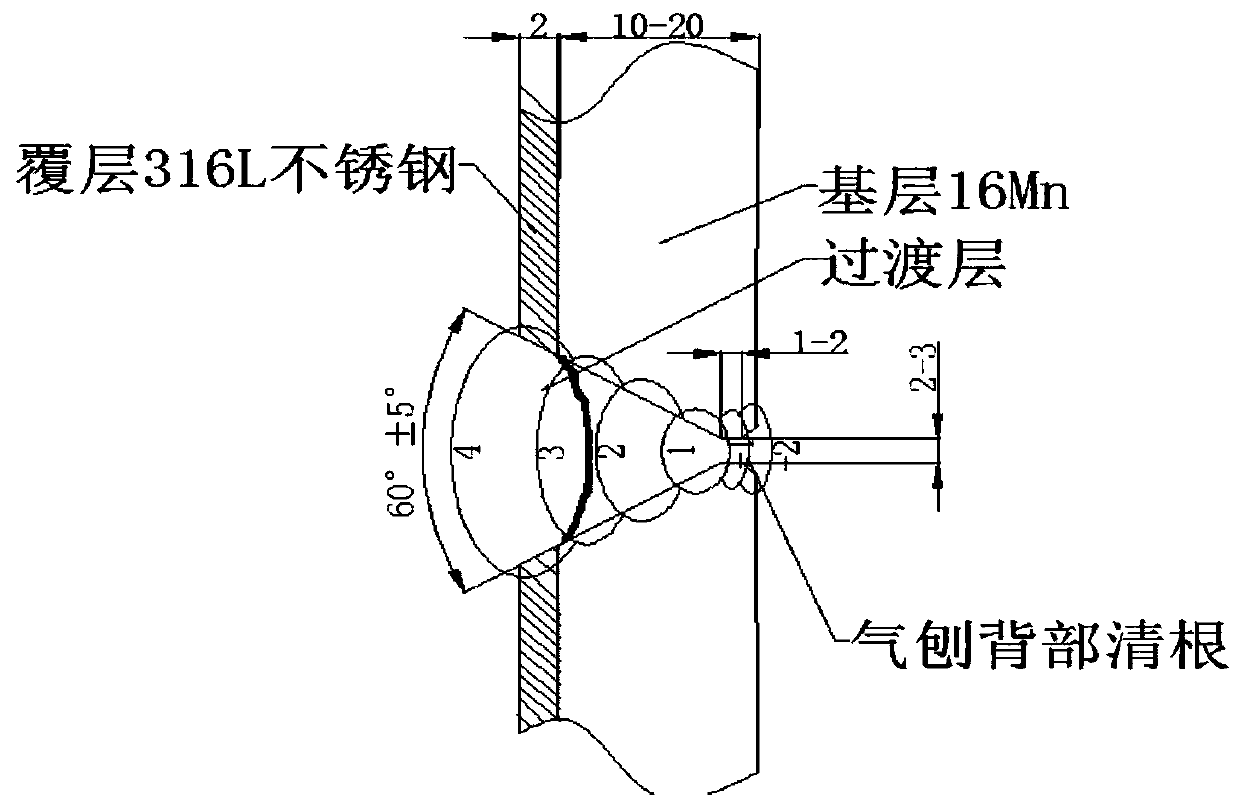

Stainless steel composite plate welding seam defect analyzing and repairing method

InactiveCN109719366AAvoid Rework DefectsGuaranteed repair qualityTesting metalsWelding accessoriesComposite plateWelding defect

The invention belongs to the technical field of defect, flaw or stain testing, and discloses a stainless steel composite plate welding seam defect analyzing and repairing method. The method includes the steps that the detection results plus technical analysis are adopted to replace complete relying on the detection results for judging, whether the defect position is located at a base layer, a composite layer or a transition layer can be accurately determined, a slop opening is formed reasonably according to the composite plate welding requirements during repairing, during welding of the transition layer, an arc groove slope opening with the depth of 1.5-2 mm and the width of 3-5 mm is formed from the composite layer to the base layer downwards, the arc groove slope opening design has manyadvantages, the transition layer repair defects are avoided advantageously, the repair quality of the transition layer is ensured, and a proper welding process is adopted to ensure welding defect reducing and repair quality. By means of the stainless steel composite plate welding seam defect analyzing and repairing method, the defect position can be more accurately and advantageously, the multiplerepair is avoided, the generation of welding cracks is avoided, the transition layer can be made to completely cover the base layer advantageously, and the height and welding quality of the transition layer welding seam metal are ensured.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Repairing construction method for exterior wall with blue bricks of historic building

ActiveCN105019675AGuaranteed repair qualityShould not fall offBuilding repairsSupporting systemBrick

The invention discloses a repairing construction method for an exterior wall with blue bricks of a historic building. The repairing construction method comprises following steps: arranging transverse supports along an original exterior wall with blue bricks in the periphery of a badly broken area by opening holes, connecting the transverse supports with vertical supports through connecting screws and finishing construction of a support system in the badly broken area; digging the badly broken area and making a framework based on the size of the dug area; arranging templates around the framework, pouring fine aggregate concrete to the extent that thickness of poured fine aggregate concrete reaches three quarters of that of the wall, performing construction to a hanging net, a plastering layer and a restoration layer of the exterior wall in a symmetrical way, slowing detaching the connecting screws and drawing out of the transverse supports and then removing the vertical supports, repairing the corresponding opening holes in the wall in order to restore the external appearance of the exterior wall with blue bricks of the historic building.

Owner:瑞宇建设有限公司

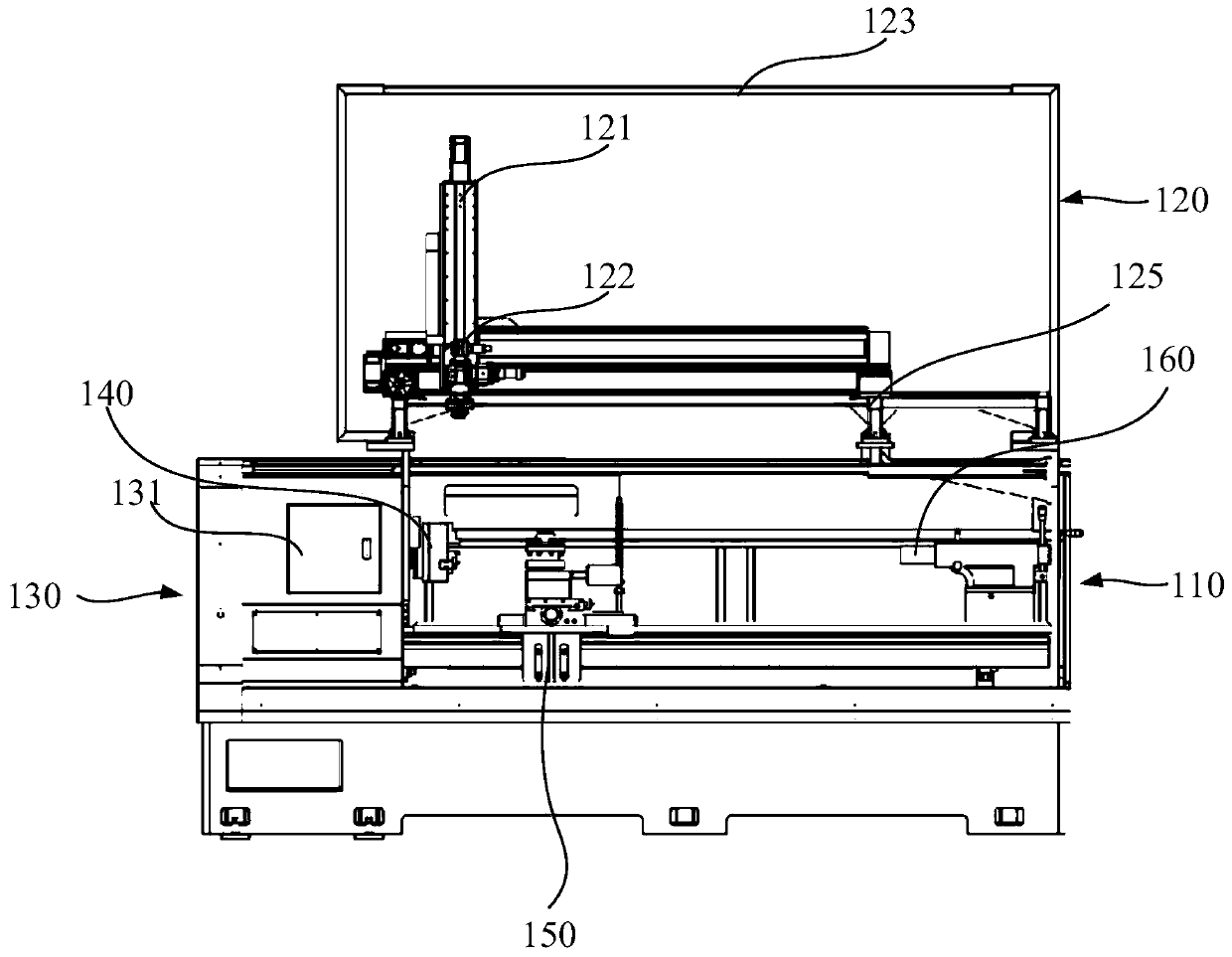

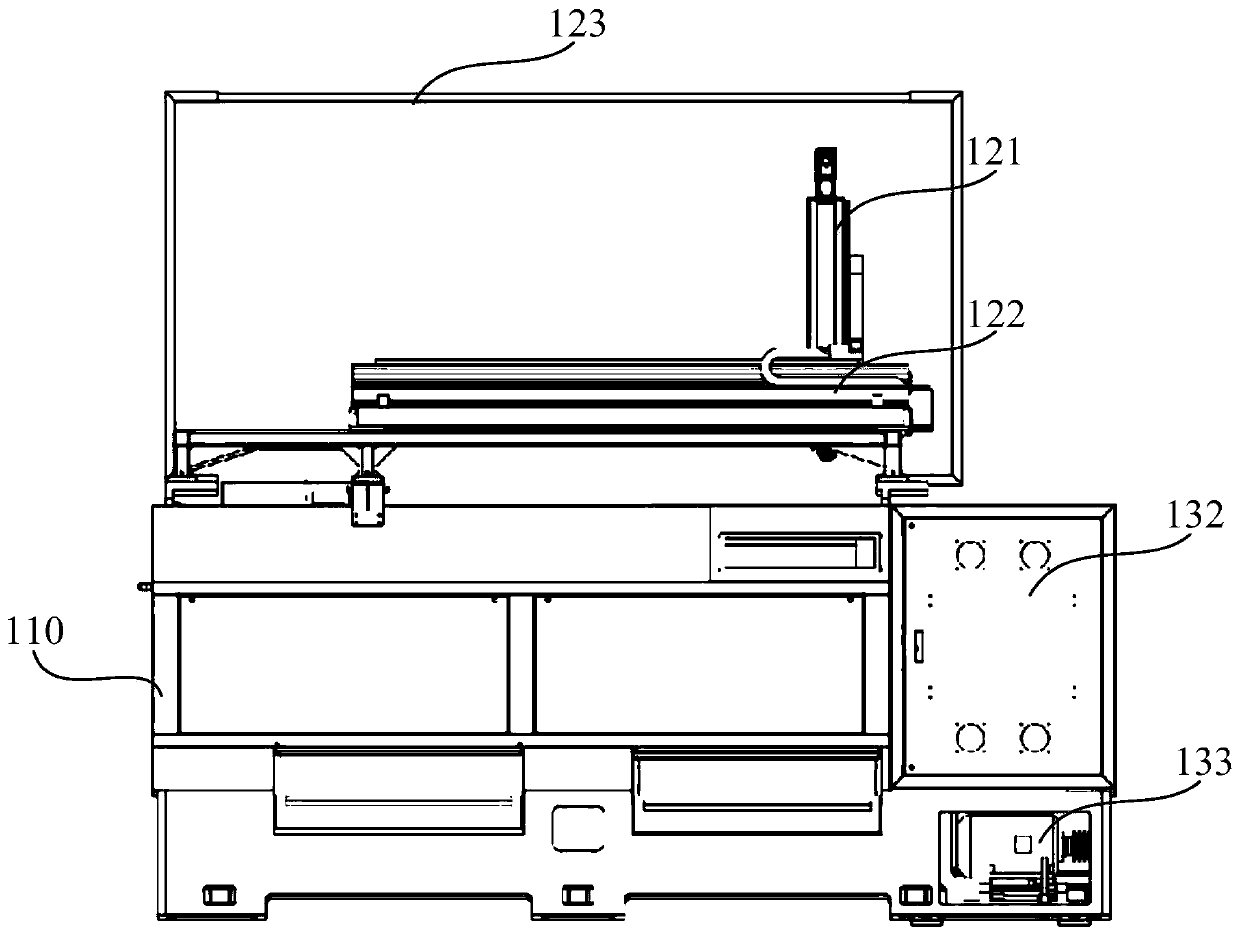

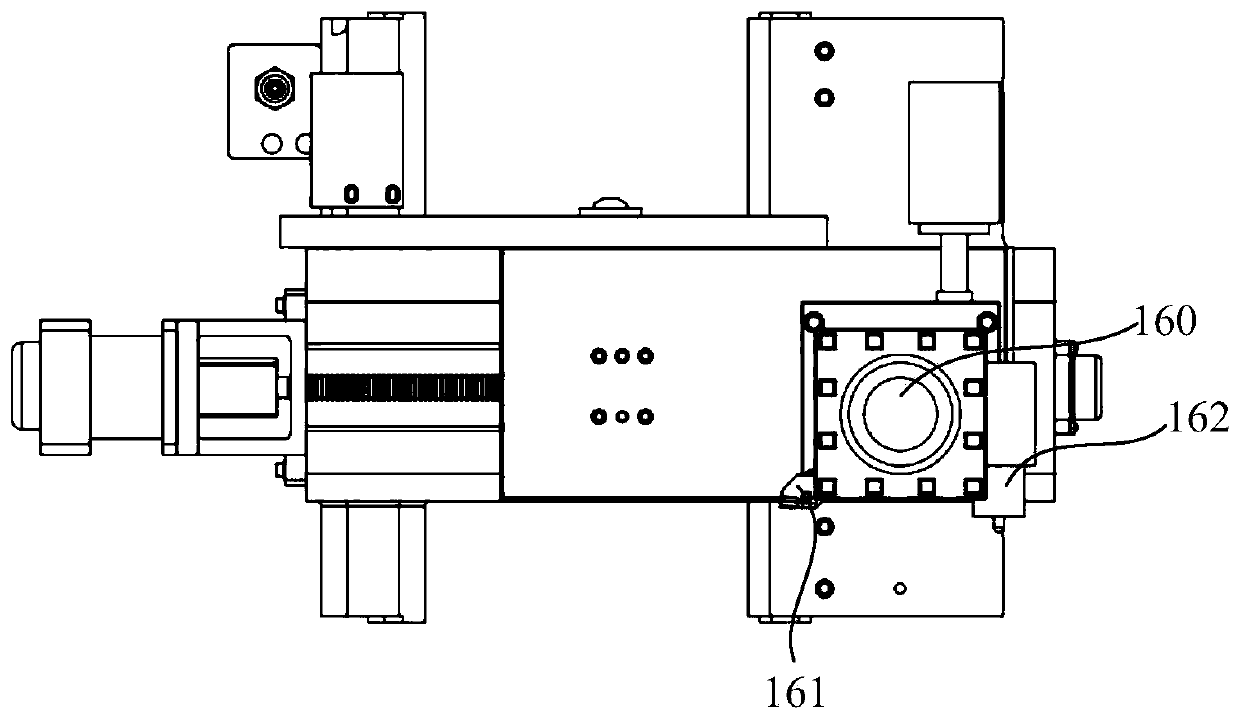

Turning, laser cladding and mirror finishing combination device

PendingCN109926834AGuaranteed uniformityImprove work efficiencyOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a turning, laser cladding and mirror finishing combination device. The turning, laser cladding and mirror finishing combination device comprises a turning lathe, a laser cladding part, a main control part, a three-jaw chuck, a tool rest feeding system, an automatic rotation tool rest, a turning tool and a Hawking tool. The laser cladding part comprises a three-axis movementmechanism, a laser head and a three-axis mounting rack. The main control part comprises a control box and a spindle motor. The control box controls the spindle motor so as to drive the three-jaw chuckto drive workpieces to rotate and further turns the workpieces with the turning tool. The control box controls the spindle motor so as to drive the three-jaw chuck to drive the workpieces to rotate and further conduct laser cladding on the workpieces with the laser cladding part. The control box controls the spindle motor so as to drive the three-jaw chuck to drive the workpieces to rotate and further conduct mirror finishing on the workpieces with the Hawking tool.

Owner:杭州辉锐激光技术有限公司

Damaged asphalt pavement repairing structure and seam sealant-pouring repairing method thereof

ActiveCN107604801AInhibit or even prevent extensionIncreased horizontal shear resistanceRoads maintainenceSurface layerNitrile rubber

The invention relates to a damaged asphalt pavement repairing structure and a seam sealant-pouring repairing method thereof. An asphalt pavement surface layer is included, slab-breaking seams are generated in the damaged asphalt pavement surface layer, multiple pairs of embedded steel bar holes are formed in the two sides of each slab-breaking seam in pairs, and the embedded steel bar holes are distributed in the extending direction of the slab-breaking seams. Steel bars are vertically inserted into the embedded steel bar holes, seam filling grooves are formed in the slab-breaking seams, and each seam filling groove is located between the corresponding embedded steel bar holes at the two sides. An asphalt repairing part with a rectangular cross section is arranged in each seam filling groove, the upper surface of each asphalt repairing part is covered with a sealing film, and the spaces between the slab-breaking seams and the asphalt repairing parts are filled with phenolic aldehyde-nitrile rubber adhesives. According to the key points of the technical scheme, in the repairing process, the durability of the repaired pavement is improved, the maintenance cost can be effectively lowered, the construction period is shortened, the slab-breaking seam repairing quality is guaranteed, and thus the road service life is prolonged.

Owner:苏州东振路桥工程有限公司

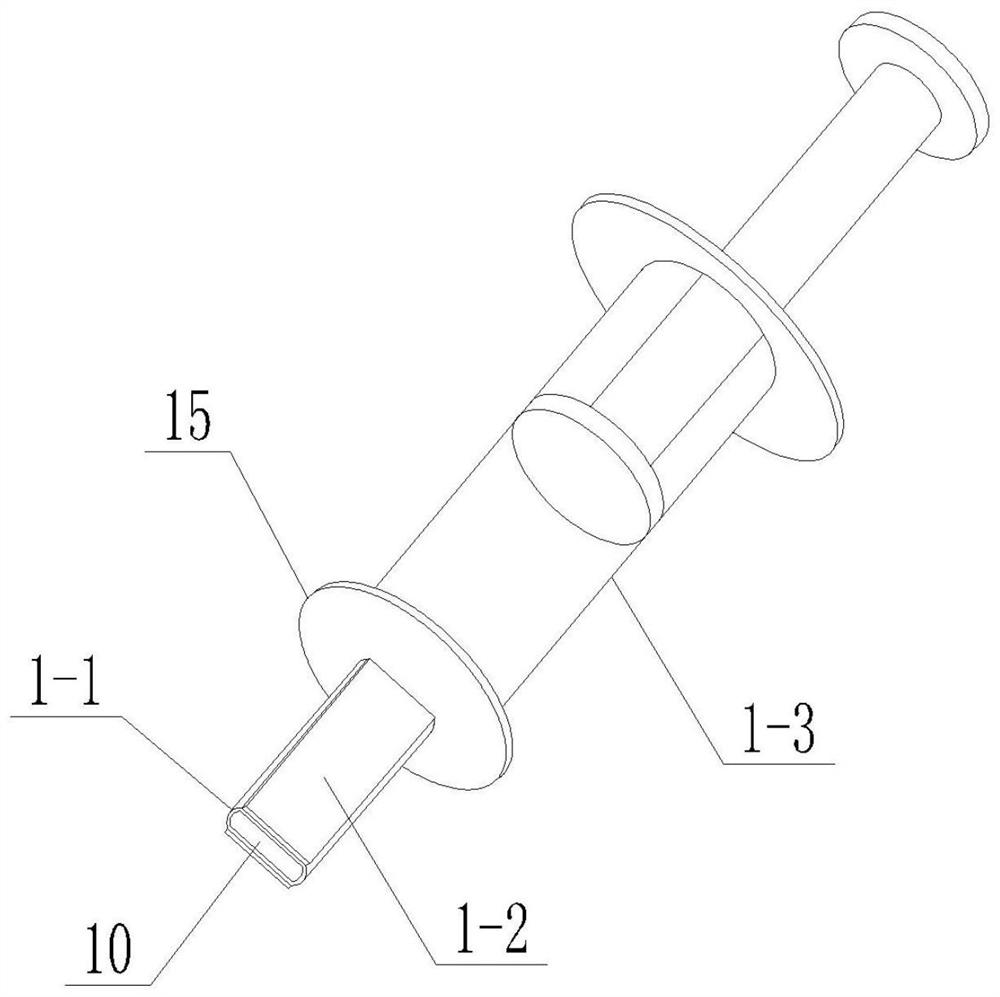

Filling type maintenance device and method for concrete crack repairing in winter in cold regions

ActiveCN112727139AEasy to useAvoid the defect of incoherent maintenance effectUnderground chambersBuilding repairsTemperature controlContinuous use

The invention discloses a filling type maintenance device and method for concrete crack repairing in winter in cold regions. The device and the method aim to overcome the defects that after a concrete structure is cracked in winter in a cold region, an existing method cannot achieve rapid repairing on site, and great problems are brought to continuous use of the structure. According to the filling type maintenance device, each electrode type injector of comprises a flat needle head, electrode plates and an injection body; the flat needle head is detachably connected to the discharging end of the injection body, a feeding port communicating with the discharging end of the injection body is machined in one end of the flat needle head, and a discharging port is machined in the other end of the flat needle head; and the electrode plates are arranged on the outer wall of the flat needle head, the injection body is filled with conductive concrete, the two electrode plates of the two electrode type injectors are electrically connected with a voltage regulator, the voltage regulator is connected with a thermal infrared imager through a temperature control switch, and the thermal infrared imager is further provided with an alarm in a matched mode. The filling type maintenance device is used for rapid repairing of the cracking part of the concrete structure in winter in the cold region.

Owner:HARBIN INST OF TECH

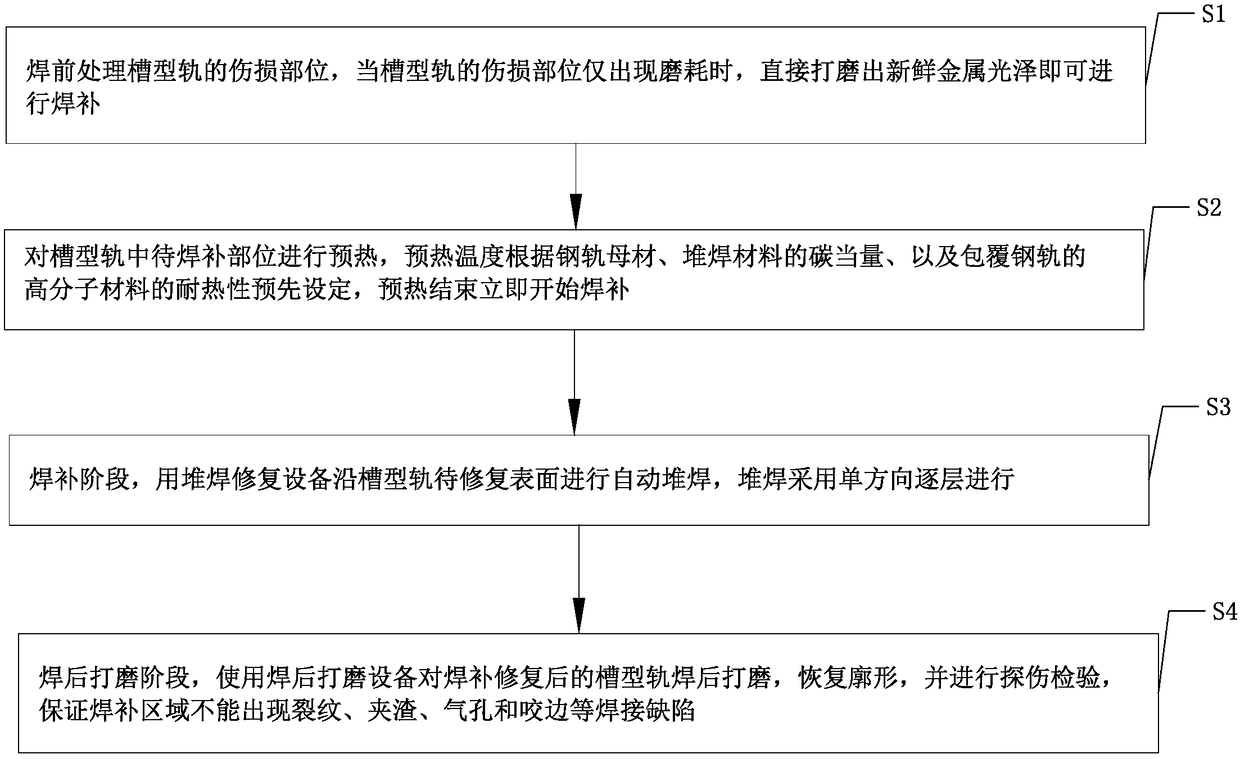

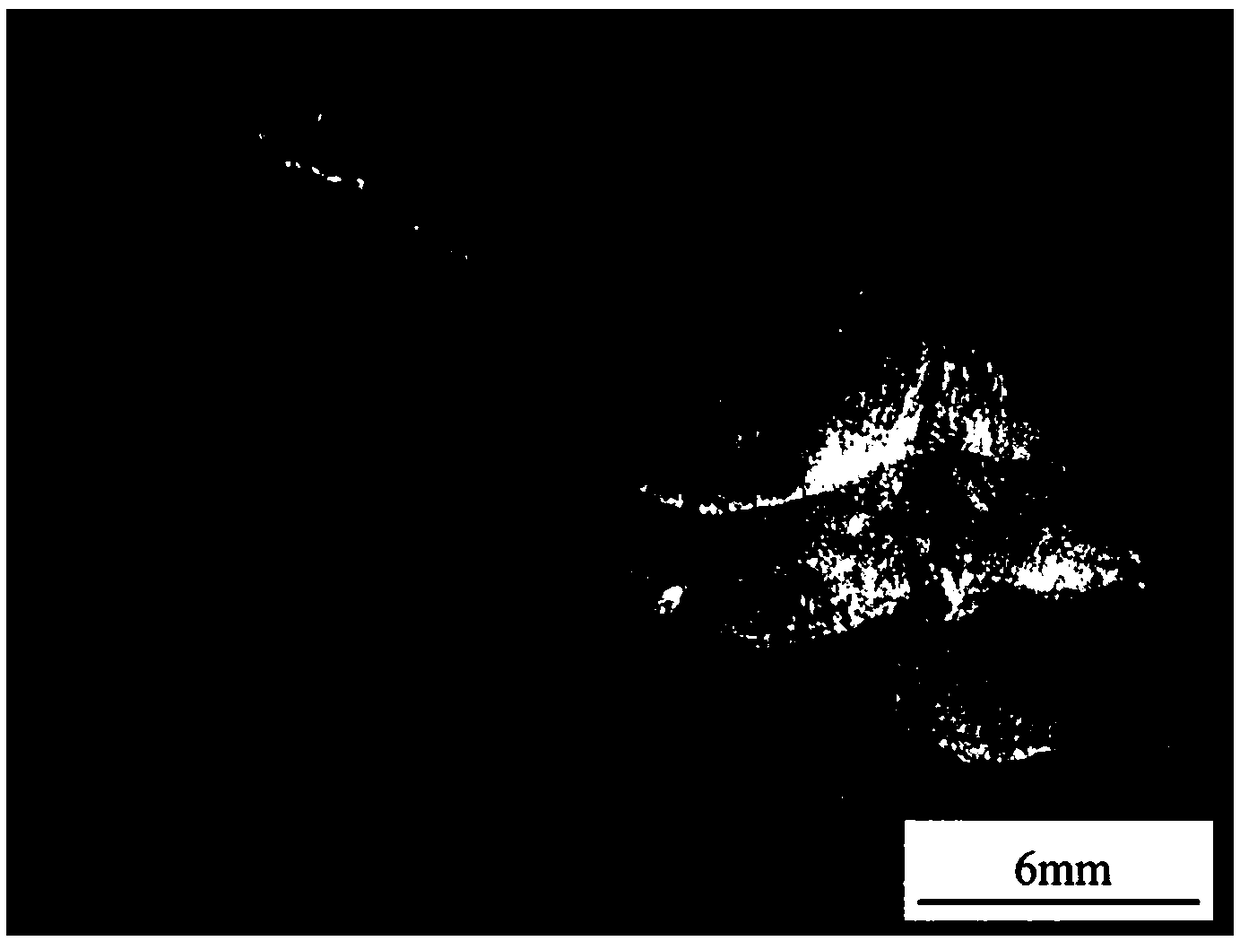

On-line welding and mending method for service damage of channel rail

InactiveCN108705180AWon't disturbImprove construction efficiencyWelding accessoriesSlagHeat resistance

The invention discloses an on-line welding and mending method for service damage of a channel rail. The on-line welding and mending method comprises the following steps that first, the damage part ofthe channel rail is treated before welding, and when the damage part of the channel rail is abraded, welding can be conducted after fresh metallic luster is directly polished; second, the to-be-weldedpart of the channel rail is preheated, the preheating temperature is set in advance according to the carbon equivalent of steel rail base metal and surfacing materials and the heat resistance of highpolymer materials wrapping the steel rail, and welding is conducted immediately after preheating is ended; third, in the welding stage, automatic surfacing is conducted along the to-be-mended surfaceof the channel rail through surfacing repairing equipment, and surfacing is conducted in the single direction layer by layer; and fourth, in the post-welding polishing stage, post-welding polishing is conducted on the channel rail after welding repair through post-welding polishing equipment, an outline shape is restored, and flaw detection is conducted. It is guaranteed that no weld flaws such as cracks, slag inclusion, and undercuts occur to the welding area.

Owner:SOUTHWEST JIAOTONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com