Patch for rapidly repairing damages of external insulating layers of thermal shrinkage wires and cables

A technology of external insulation and repair sheet, applied in the direction of insulators, insulators, circuits, etc., can solve the problems of complex operation process, difficult control of adhesive layer thickness, and reduced adhesion performance, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with specific examples.

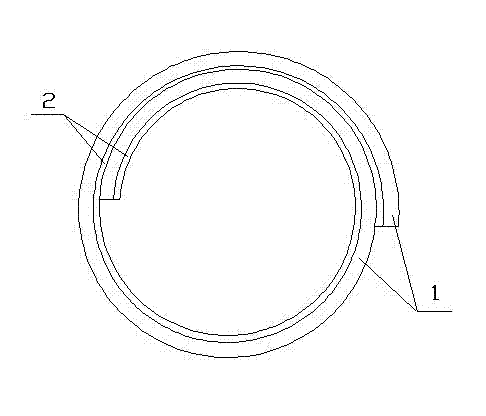

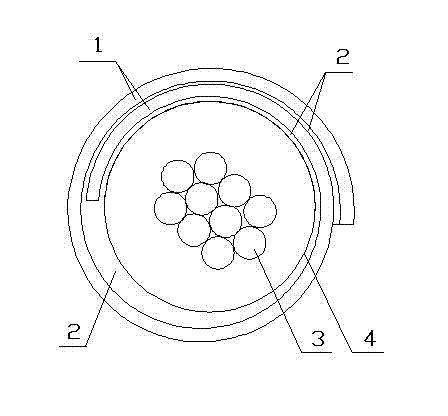

[0020] Such as figure 1 As shown, a heat-shrinkable wire and cable outer insulation damage quick repair sheet is composed of an outer layer and an inner layer, the outer layer is an insulating layer 1, and the inner layer is a hot-melt adhesive layer 2. Its preparation method is:

[0021] 1) Blend and modify the raw materials of the insulating layer, blend in a mixer at 600-900 rpm for 20-30 minutes, and then granulate and extrude on a two-stage parallel twin-screw extruder.

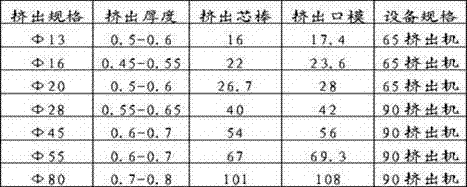

[0022] 2) It is extruded into a tube shape by an extruder, the length of the straight section of the die and the mandrel is 25-40mm, and the temperature is controlled at 140-170°C during extrusion. The extrusion specifications of several products are:

[0023]

[0024] 3) Then carry out cross-linking, using electron beam radiation for cross-linking, the degree of cross-linking is 55-65%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com