On-line welding and mending method for service damage of channel rail

A repair method and groove rail technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as unclear process specifications, interference with repair quality, etc., to achieve clear process specifications, guarantee repair quality, and low requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

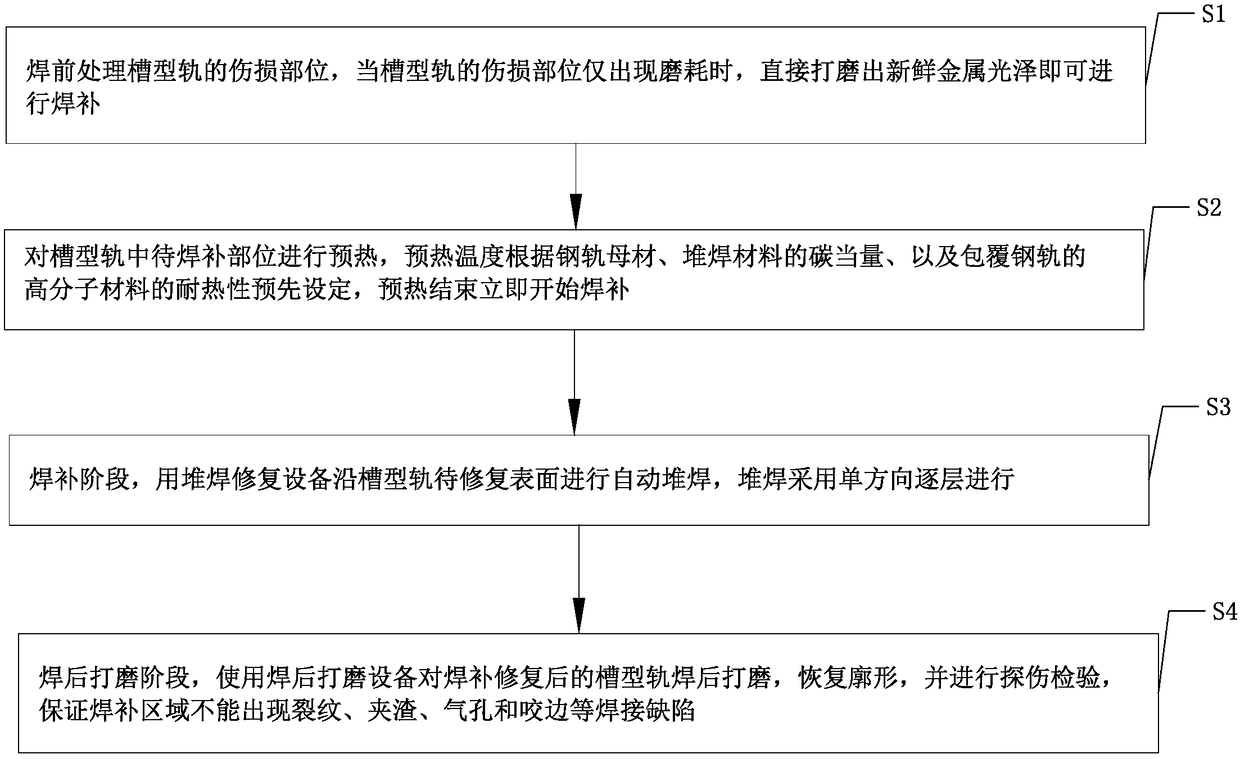

[0029] Such as Figure 1 to Figure 7 As shown, a kind of grooved rail service damage online welding repair method provided by the present invention comprises the following steps:

[0030] S1. Treat the damaged part of the grooved rail before welding. When the damaged part of the grooved rail is only worn, it can be repaired by directly grinding out a fresh metallic luster.

[0031] The repair method of this embodiment is only applicable to the damage situation of the grooved rail with no fracture in the damaged part, the surface wear of the rail head of the grooved rail not exceeding 8mm, and the depth not greater than 8mm. When crack damage with a depth greater than 2mm and less than 8mm occurs at the damaged part, the crack damage needs to be removed and then polished for welding repair.

[0032] Firstly, clean the oil stain, water stain and rust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com