Method for testing flexural-tensile strength of concrete

A bending and tensile strength and testing method technology, which is applied in the direction of applying a stable bending force to test the strength of materials and the preparation of test samples, can solve the problems of inaccurate test methods, and achieve reliable repair quality, simple repair, bending and pulling Intensity accurate and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method for testing the flexural strength of concrete includes the following steps:

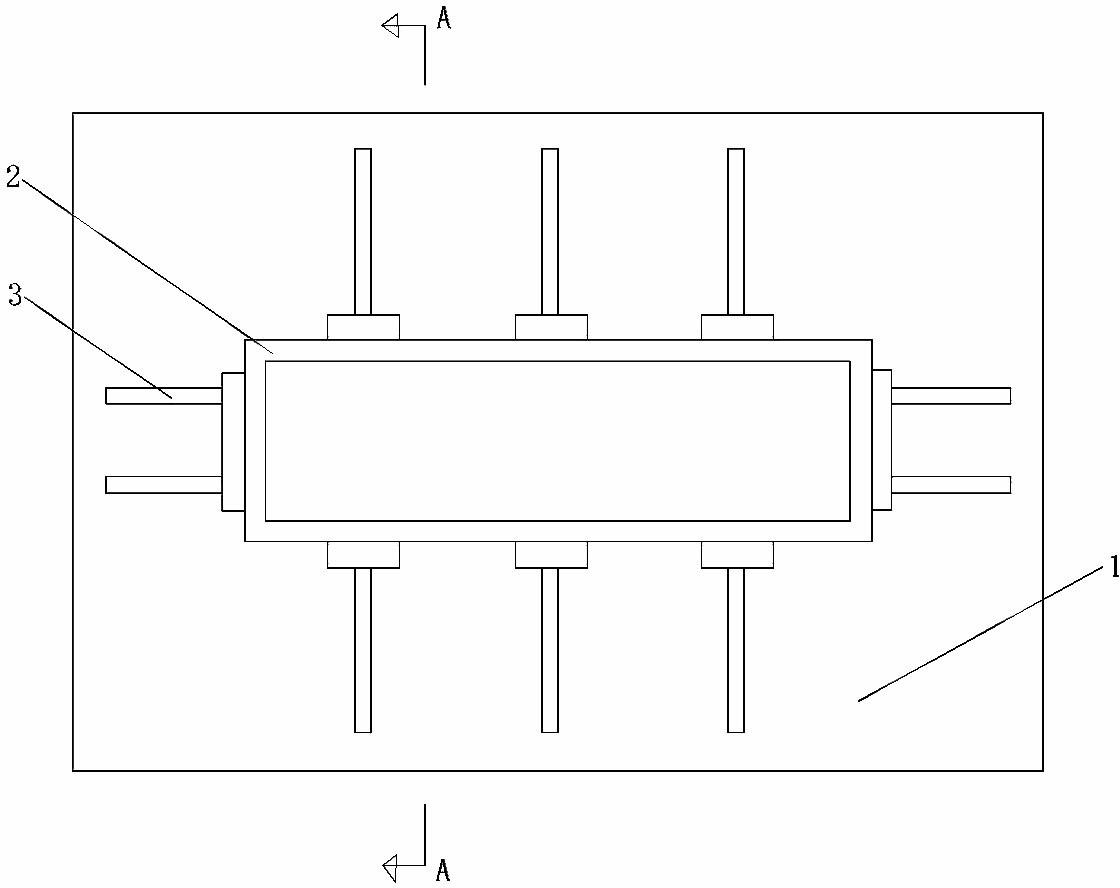

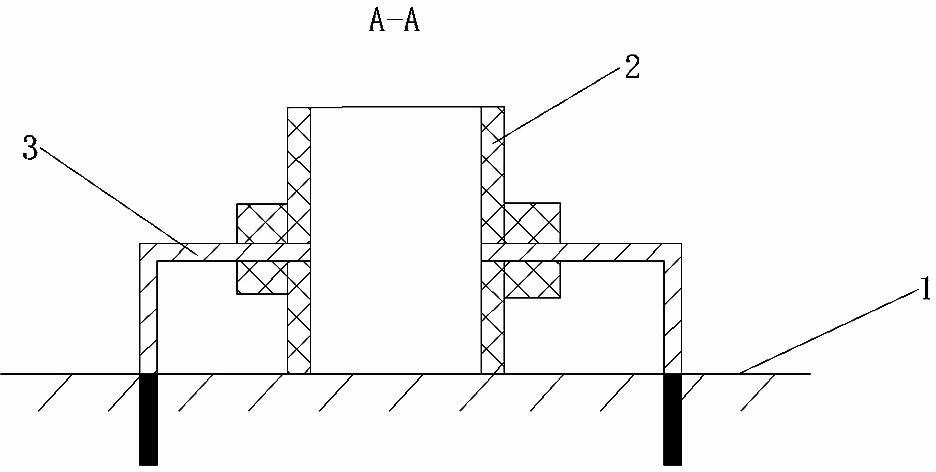

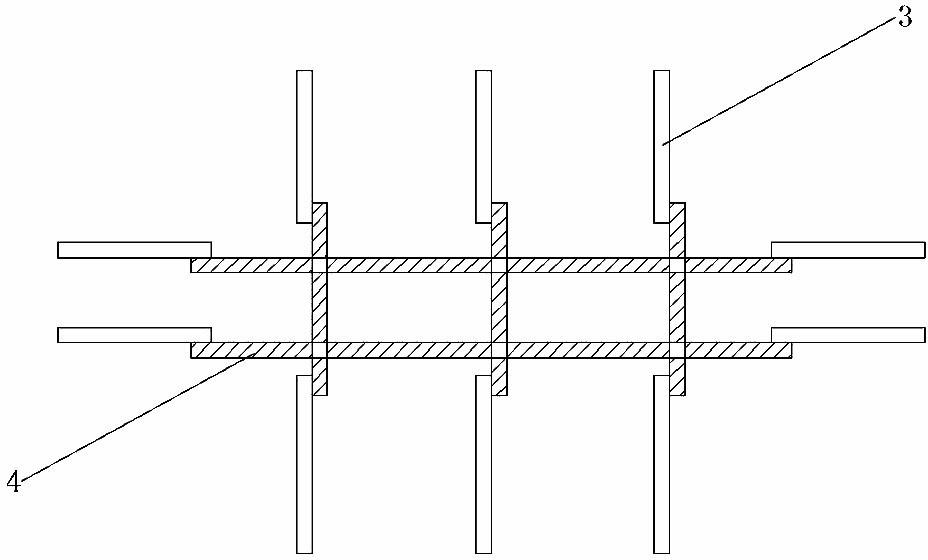

[0020] (1), see figure 1 , figure 2 , install three sets of L-shaped anchor bars symmetrically on one set of opposite side walls of the square ring-shaped wooden mold, and two sets of L-shaped anchor bars are symmetrically installed on the other set of opposite side walls, and the wooden mold 1 is fixed on the On the pavement base 1, the anchorage length is 80mm; among them, the planar size of the inner cavity of the wooden mold 2 is set to 150mm×550mm, and the height is 150mm. Choose hot-rolled ribbed steel bars with a diameter of 12mm, the length of the horizontal part is 200mm, and the length of the vertical part is the anchorage length plus the height of one half of the wooden mold;

[0021] (2) Concrete is poured on the pavement base 1. The pouring height of the concrete is the same as that of the wooden mold 2. Before the final setting of the concrete, screw the eye nails i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com