A rotary kiln support device and its adjustment method

An adjustment method and rotary kiln technology, applied in the fields of building materials, metallurgy, and chemical industry, can solve the problems of difficulty and cost in transportation and installation, large tire size, and high manufacturing cost, and achieve reduced width and thickness, reduced maintenance times, and reduced The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

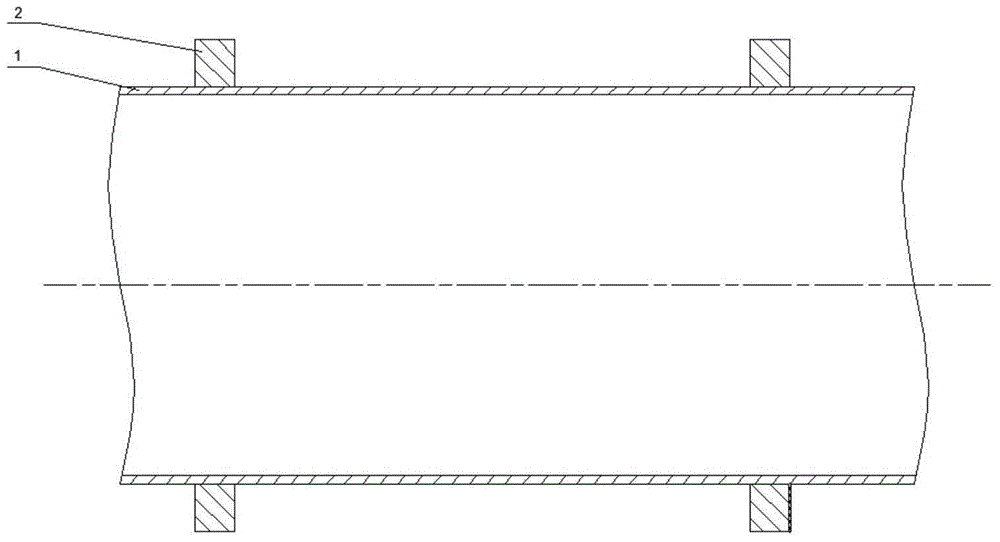

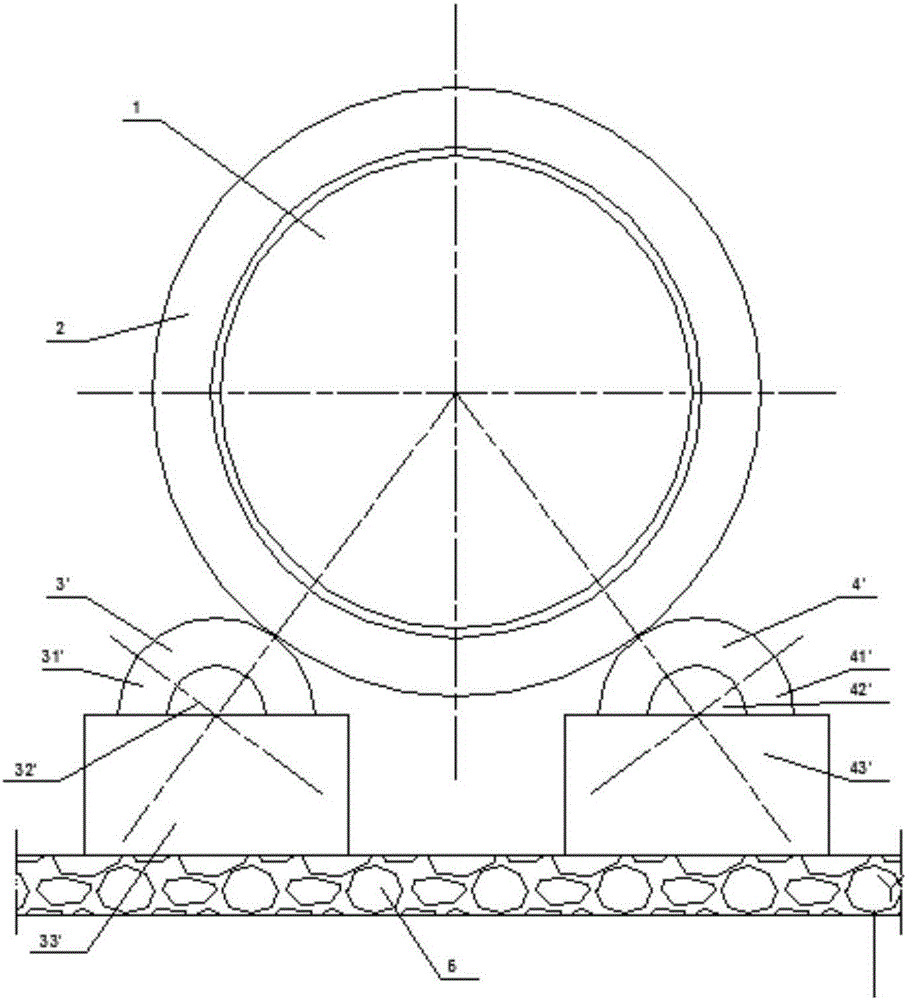

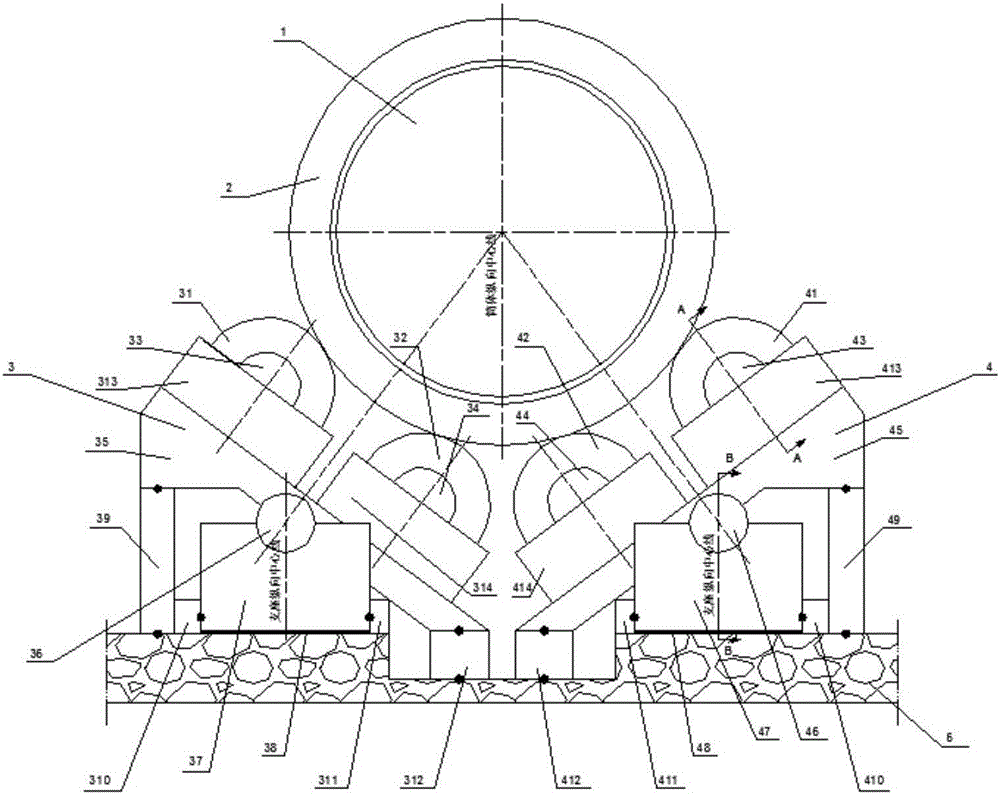

[0017] The following will be combined with Figure 1-3 The technical solution of the present invention is described in detail.

[0018] The present invention provides a rotary kiln support with a support structure of multiple supporting rollers, which includes: two left supporting rollers, namely the first supporting roller 31 and the second supporting roller 32; two right supporting rollers, namely the third supporting roller Supporting roller 41, fourth supporting roller 42, first hydraulic cylinder 39, third hydraulic cylinder 312, fifth hydraulic cylinder 310, seventh hydraulic cylinder 311; second hydraulic cylinder 49, fourth hydraulic cylinder 412, sixth hydraulic cylinder 410, the eighth hydraulic cylinder 411; the first supporting wheel shaft 33, the second supporting wheel shaft 34, the third supporting wheel shaft 43, the fourth supporting wheel shaft 44,

[0019] Such as image 3 As shown, four supporting rollers are set at each support position in this way. Duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com