Geometry repair method for damaged area of complex curved surface part

A geometric repair method and complex surface technology, applied in the field of computer-aided design and manufacturing, can solve the problems of not meeting the repair quality and accuracy requirements, manual intervention in cumbersome operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] specific implementation plan

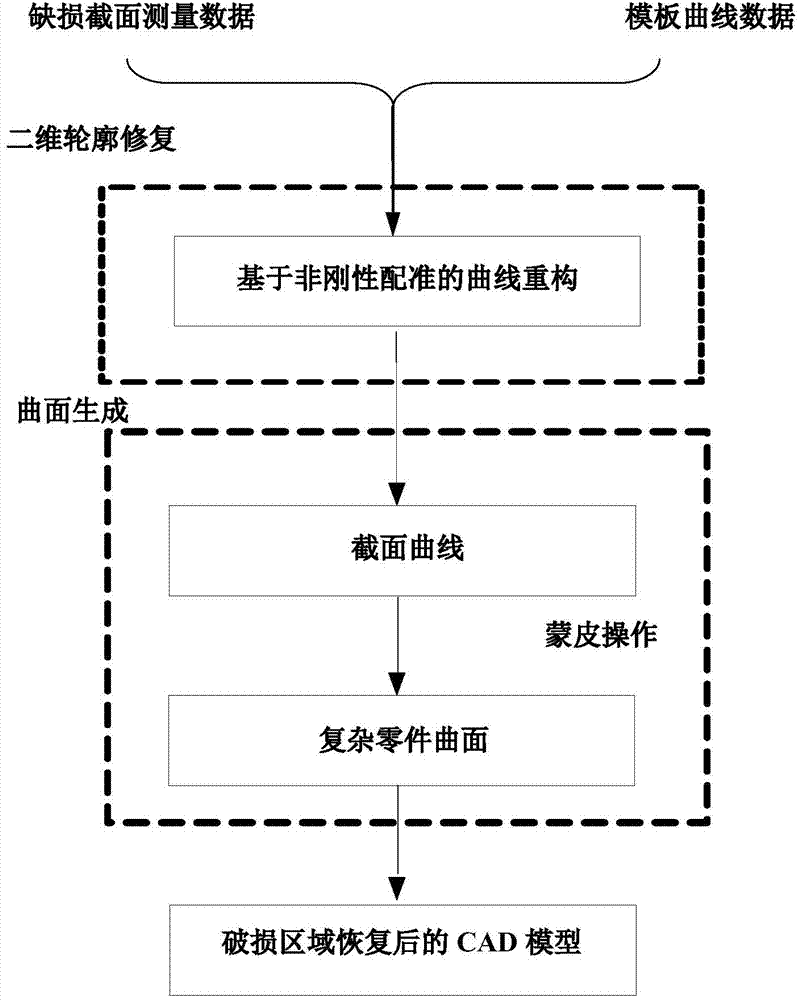

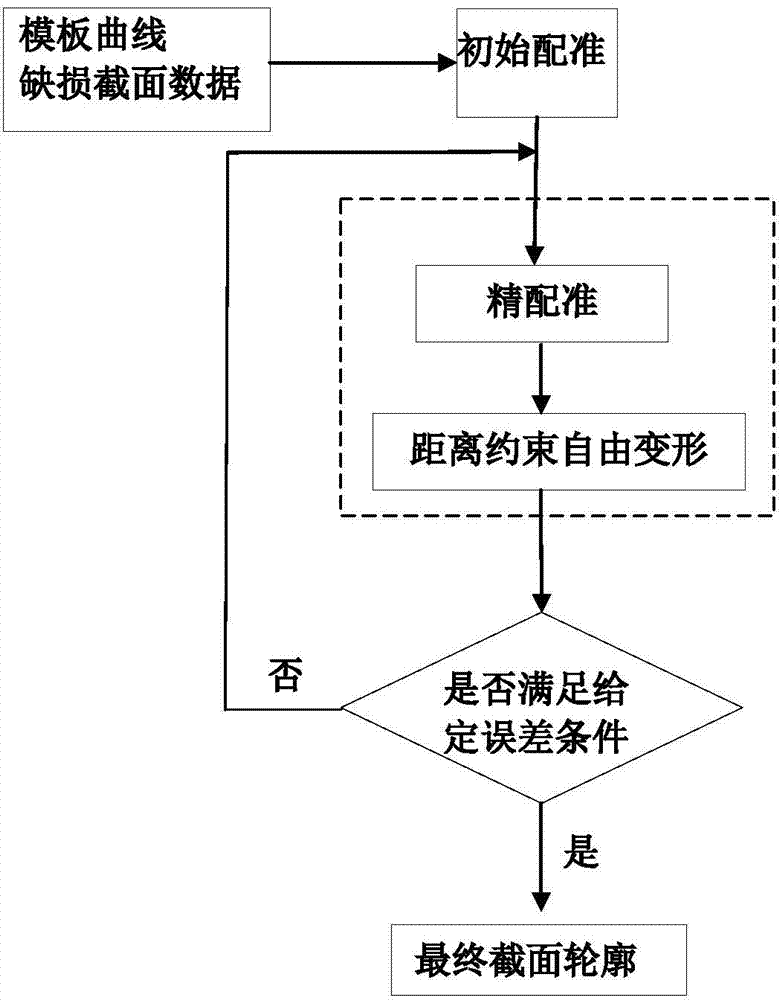

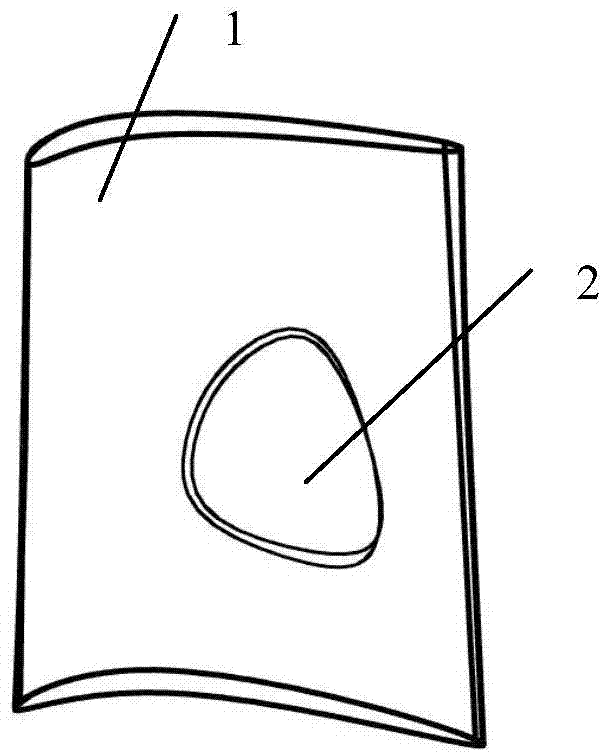

[0042] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. Complex surface parts such as aeroengine blades are prone to cracks, holes, corrosion and other damage after long-term operation in harsh environments, and deformation; the application of rigid registration technology cannot completely fit the design model of the damaged part with the actual measurement point, the design model It cannot continue to be used in steps such as design and processing. In view of this situation, the present invention adopts geometric repair of damaged parts with complex curved surfaces based on non-rigid registration, such as figure 1 As shown in the flow chart, firstly transform the given template curve and measurement point set, and then use the non-rigid registration optimization strategy composed of alternating iterative ICP fine registration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com