Urban groundwater drainage pipe network repair method

A technology for a drainage pipe network and a repair method, which is applied in the field of water supply and drainage, can solve the problems of road traffic impact, living environment hazards, large waste, etc., and achieves the effects of saving costs, improving repair efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for repairing urban groundwater drainage pipe network, the operation steps of the method are as follows,

[0030] S1. Prepare for the repair of the groundwater drainage network, determine the location of the repaired groundwater drainage network, measure the repaired pipeline, measure data and repair requirements;

[0031] S2. Clean the groundwater drainage network, drain the sewage in the groundwater drainage network, and clean up the silt in the groundwater drainage network to meet the repair requirements;

[0032] S3. Laying of repair materials, first lay a layer of plastic film on the bottom of the pipeline to be repaired, and then put the repair lining material in place by mechanical traction;

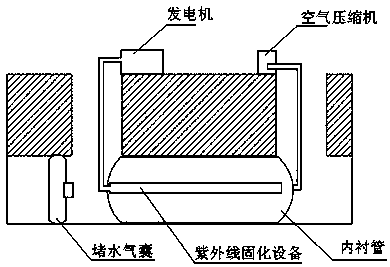

[0033] S4. The repair material is cured. Install ultraviolet curing equipment at the mouth of the repair lining material and inflate the lining pipe so that it is close to the pipeline to be repaired. The ultraviolet curing equipment irradiates the lining pipe to c...

Embodiment 2

[0037] On the basis of Example 1, the preparation for the repair of the S1 groundwater drainage pipe network uses the urban underground drainage pipe network detection device before the repair to detect the smoothness of the repaired groundwater drainage pipe network on the spot and prepare the size of the repair materials. Fully understand the situation of the damaged pipeline before repairing, and formulate a comprehensive plan.

Embodiment 3

[0039] On the basis of Example 1, the S2 groundwater drainage pipe network is cleaned, and the water blocking air bag is used to temporarily block the drainage upstream of the repair pipe, and then the high-pressure water gun provided on the urban underground drainage pipe network detection device is used to detect the wellhead from the upstream. Entering and moving to the downstream detection wellhead and cleaning repeatedly until the pipeline meets the repair requirements, the pipe wall can be clean and clean, and there will be no sewage to affect the repair process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com