Channel deep suppressing foot fast construction method

A construction method and technology of deep-rooting, which are applied in water conservancy projects, marine engineering, infrastructure engineering and other directions, can solve the problems that the stability of the backfill structure cannot be guaranteed in a small working space, there are many construction procedures, and the cost is high, so as to avoid The effect of waste soil transportation to ensure safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

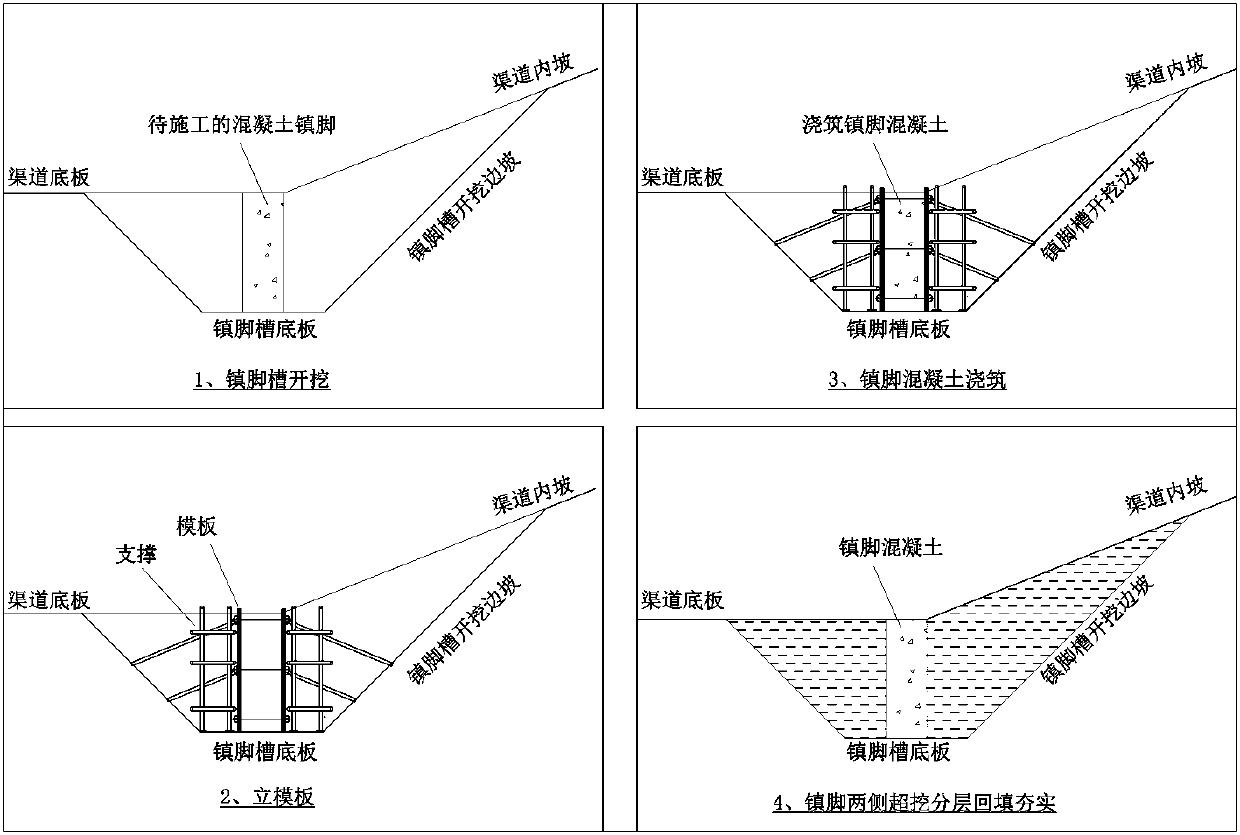

[0043] A rapid construction method for deep canal town feet, comprising the following steps:

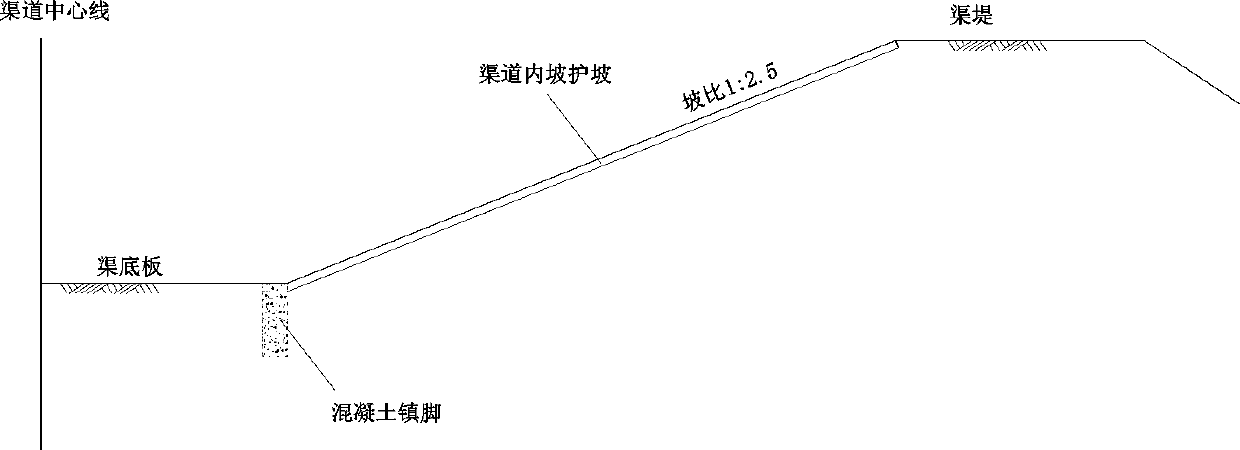

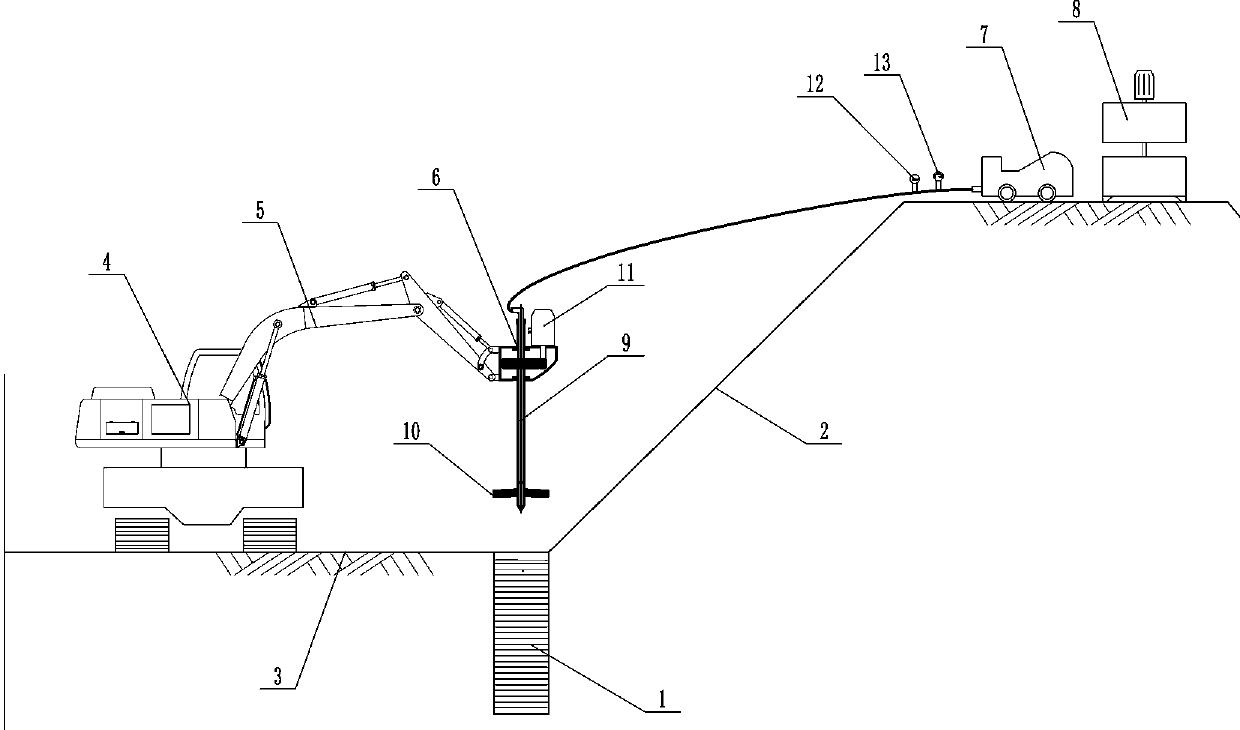

[0044] 1) Measure and set out the sideline of the town foot. After the channel is excavated and formed, use the total station to stake out the side line of the town foot 1 at the slope toe of the inner slope 2 of the channel.

[0045] 2) Excavate the pilot groove first, with the edge of the township as the boundary, excavate the pilot groove with a shallow depth, about 20cm deep, and its main function is to ensure that the cement slurry does not overflow outside the township when spraying and mixing; then In the pilot groove, set out the pile position center of the foothold pile. In this embodiment, the pile diameter of the foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com