A Stowage Method for Improving the Stability of Container Ships and the Operational Efficiency of Quay Cranes

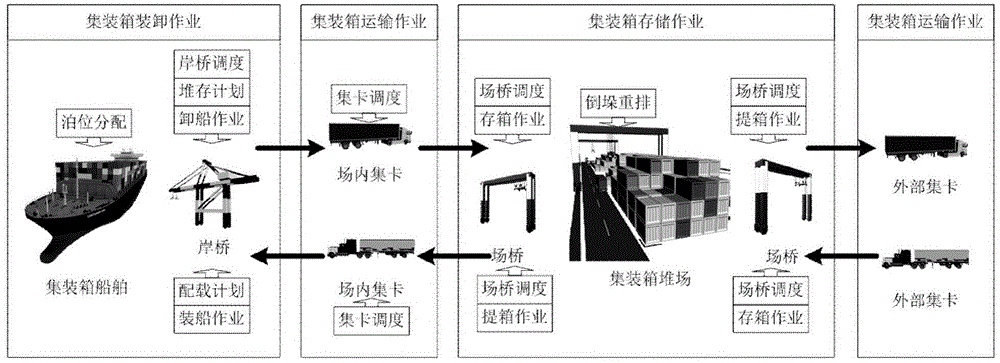

A container and stability technology, applied in the field of container terminals, can solve the problems affecting the operation efficiency of quay crane machinery, the threat of stability deviation to the safe navigation of ships, and prolonging the service time of ships in port, so as to shorten the docking and service time, reduce The number of ineffective operations and the effect of speeding up logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

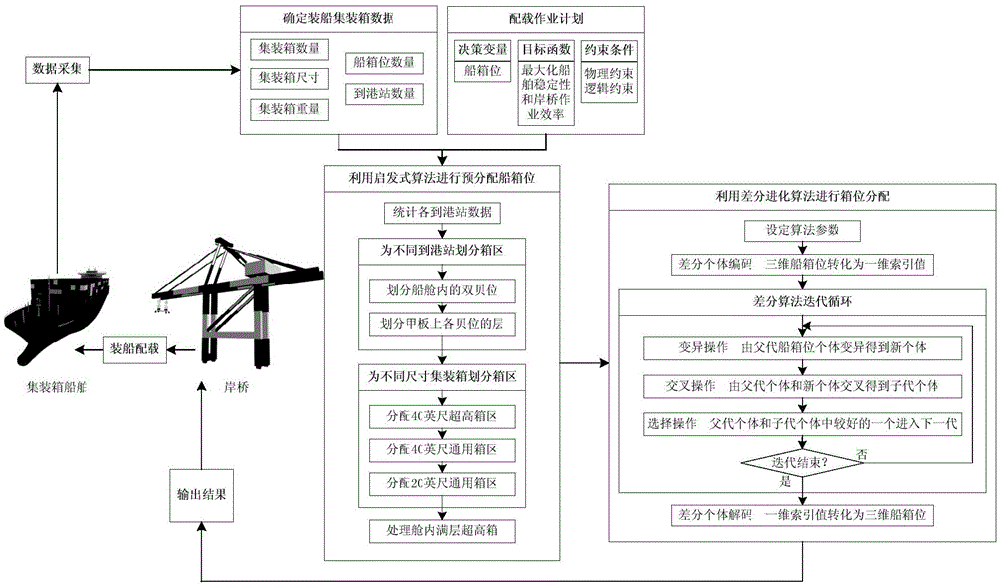

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] Taking China Ocean Shipping Company (COSCO) domestic trade container ship "Xin Hongxiang 76" as an example, the stowage plan formulation of export voyage 002N will be used to illustrate the specific implementation of the present invention.

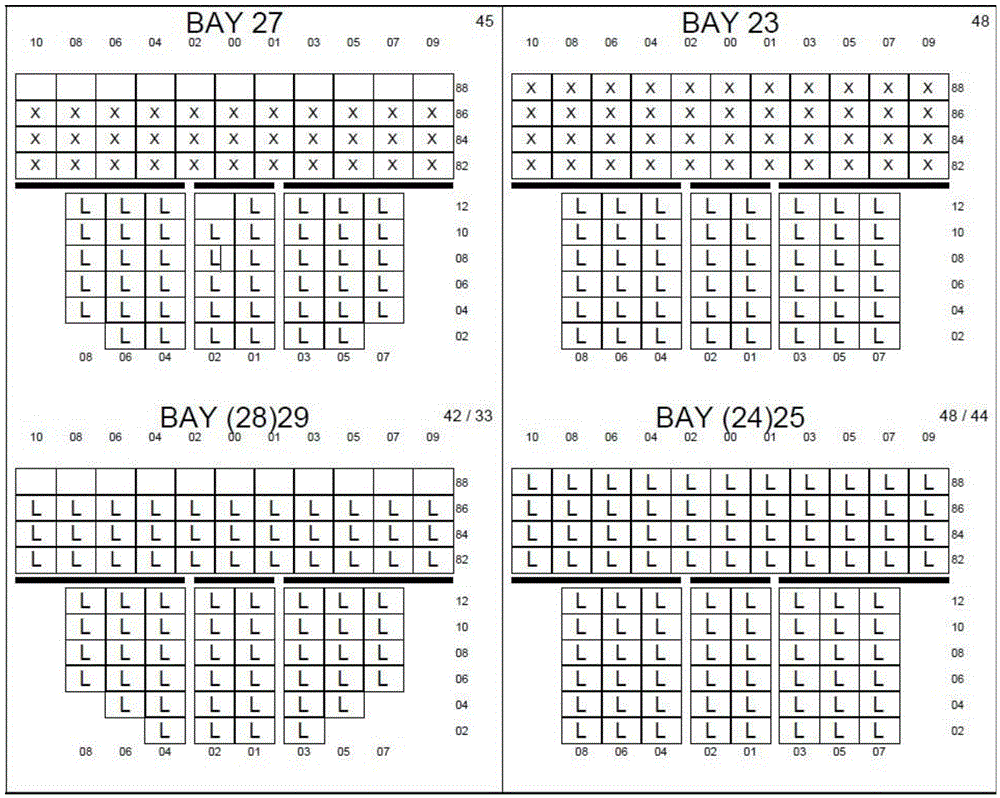

[0046] The ship has a total of 16 odd-numbered bays. The maximum number of layers on the deck is 4 layers, and the maximum number of rows is 8 rows. The maximum number of layers in the cabin below the deck is 4 layers, and the maximum number of rows is 6 rows. The box distribution of "Xin Hongxiang 76" is as follows: Figure 5 shown. There are two arrival stations for this voyage, namely Nansha, the first arrival station, and Shekou, the second arrival station. The ship docked at the container terminal with 6 single-container crane operating quay cranes, with an average daily loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com