Device and method for improving metal wire utilization rate

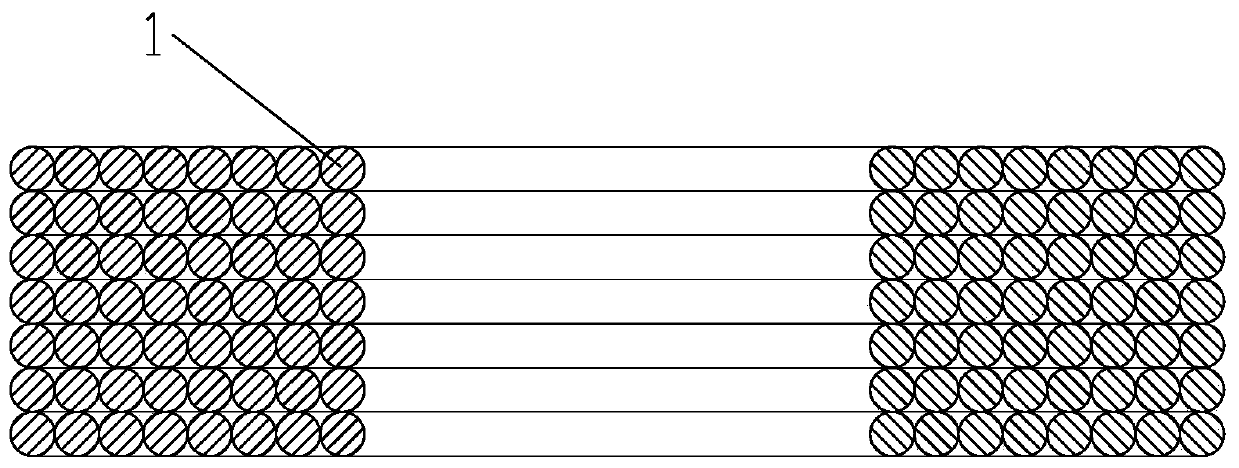

A technology of metal wire and utilization rate, applied in the field of continuous casting refining auxiliary equipment, can solve the problems of disordered arrangement, waste, fall, etc., and achieve the effects of simple overall structure, reduction of smelting cost, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

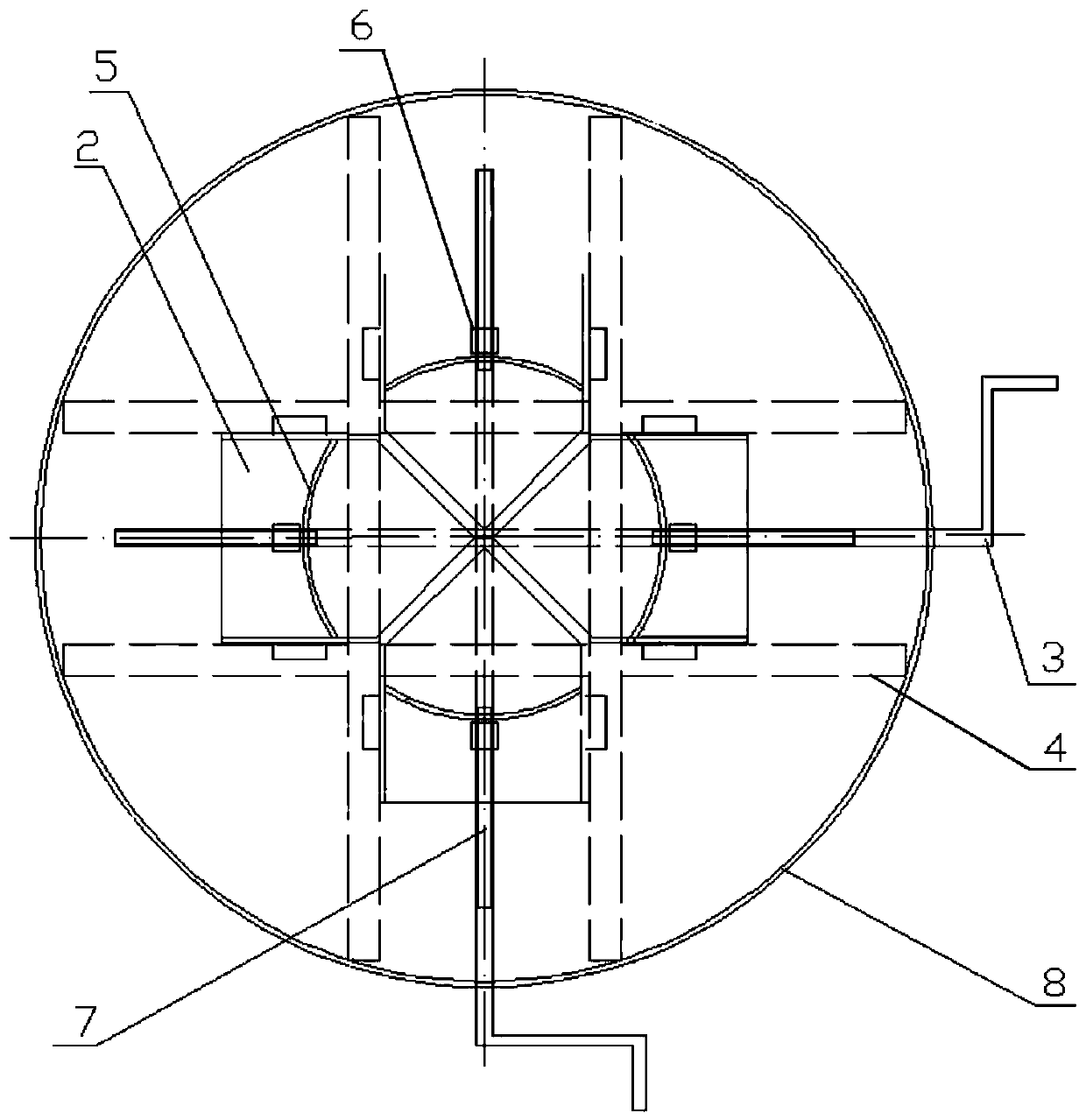

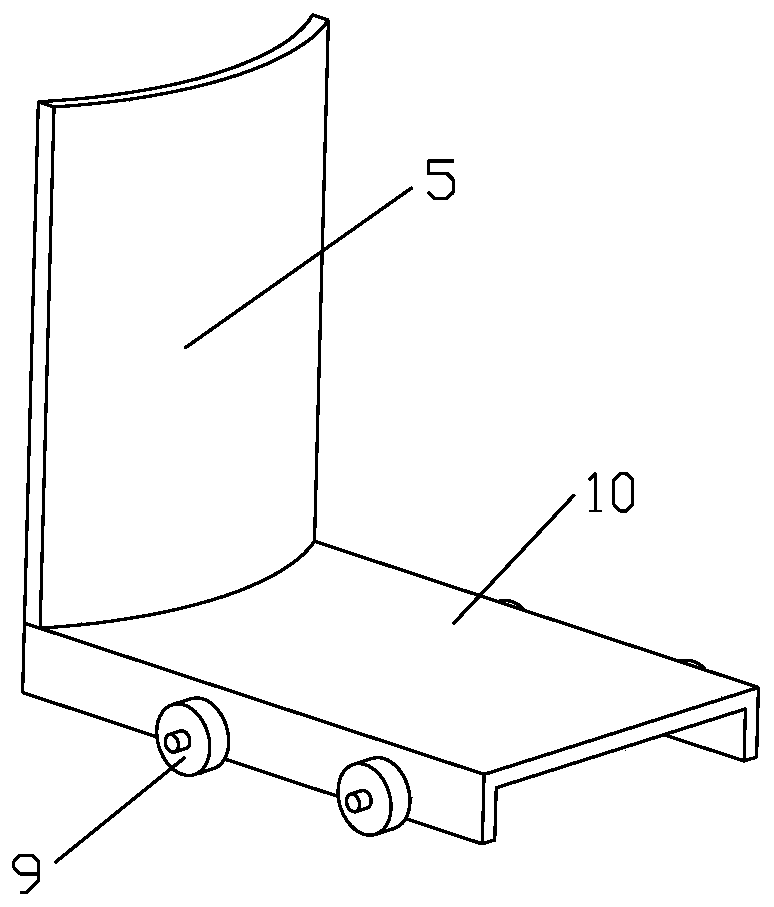

[0025] See figure 2 , image 3 , a device for improving the utilization rate of metal wire, including an outer baffle 8, a sliding trolley 2, an inner baffle 5, a lead screw 7, a track 4, and a screw nut 6, and two sliding trolleys are relatively arranged on each track 4 2. The sliding trolley 2 is slidingly connected with the track 4. One end of the screw 7 is provided with a left-handed thread, and the other end is provided with a right-handed thread. The two ends of the screw 7 are equipped with corresponding screw nuts 6, and the screw nut 6 is connected to the sliding trolley 2. The bottom is fixedly connected so that the sliding trolley 2 runs opposite or opposite to each other, the end of the lead screw 7 is connected with a handle 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com