Mould three-dimensional rapid forming and repairing method based on reverse engineering

A forming repair and reverse engineering technology, applied in the field of mold processing, can solve the problems of long repair process, difficulty in guaranteeing the dimensional accuracy and shape accuracy of repair area, and low repair efficiency, so as to improve repair efficiency, improve repair accuracy, and reduce work. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is metal die-casting mold repair, and the present invention will be further described below in conjunction with the accompanying drawings through the embodiment.

[0026] The die is used for die-casting of aluminum alloy, and its material is H13 alloy, which belongs to hot work die steel. The steel has high hardenability and thermal cracking resistance, good heat resistance and thermal fatigue stability, excellent comprehensive mechanical properties and high tempering resistance stability at higher temperatures.

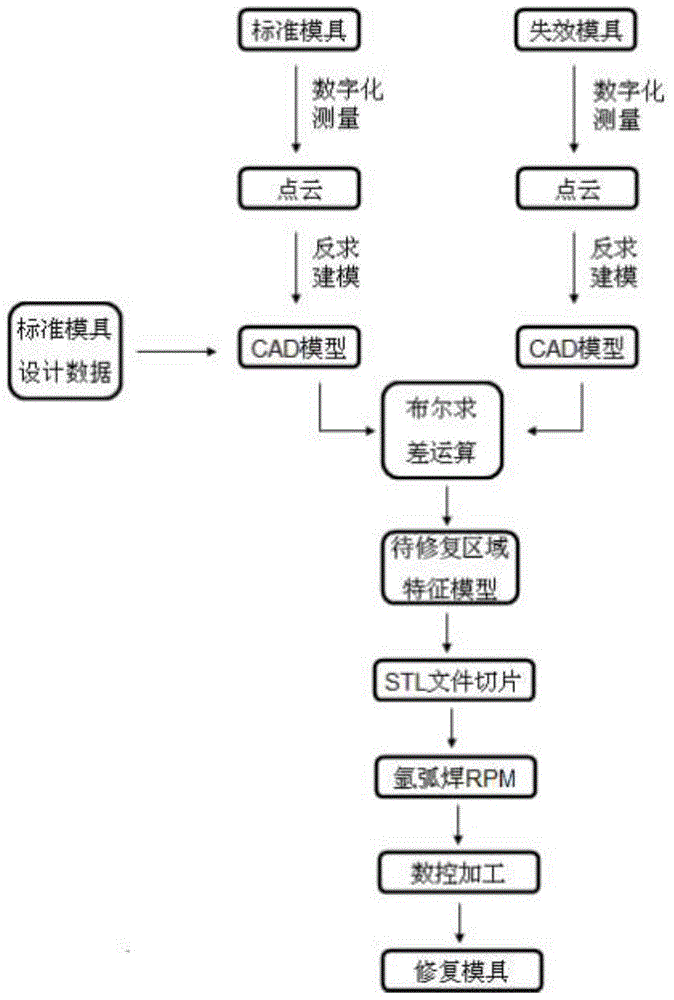

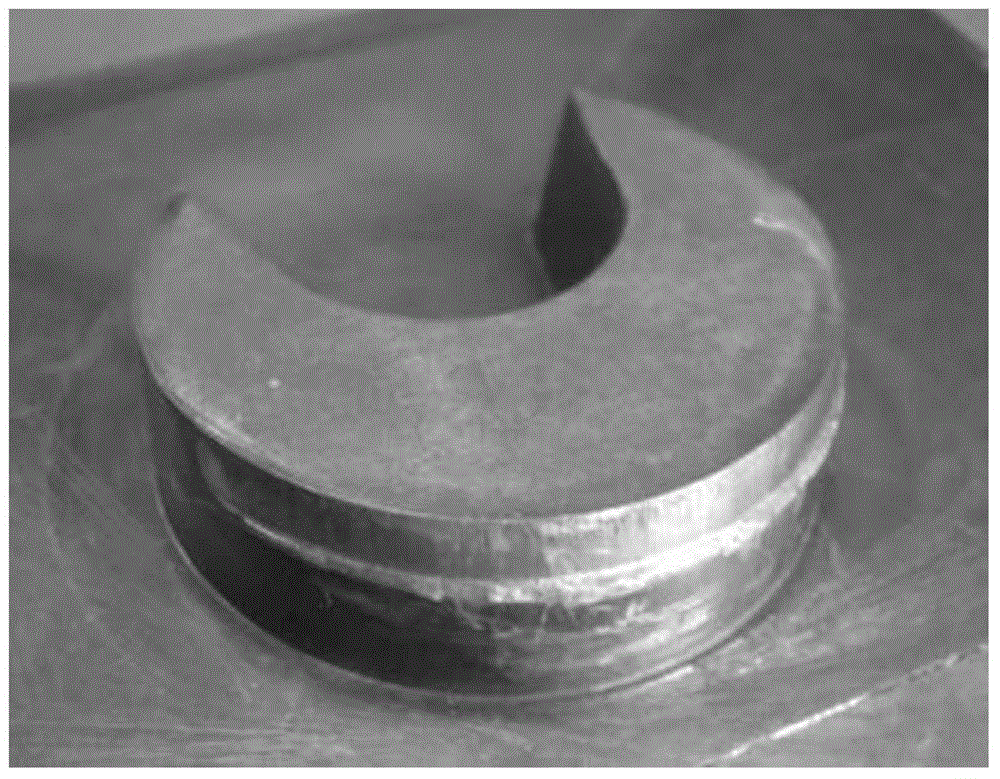

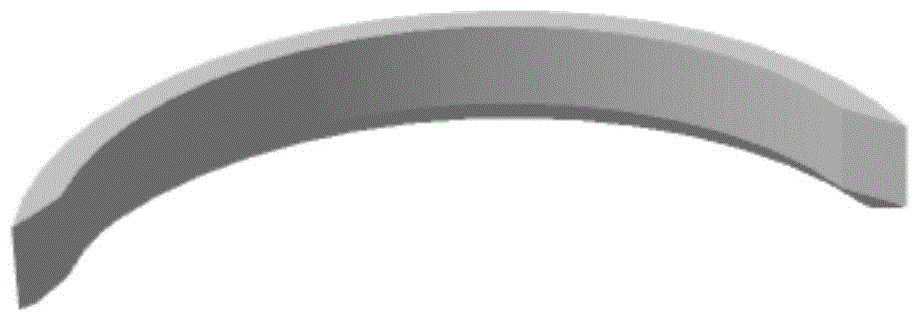

[0027] After long-term service, there is a large extrusion wear damage at the positioning flange of the mold. Now the patented process technology of the present invention is used to repair and remanufacture the damaged area, such as figure 1 As shown, the implementation process is as follows:

[0028] 1. Grind the area to be repaired of the failed mold, remove the fatigue layer and oxide layer, and clean it with acetone and alcohol;

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com