Stainless steel composite plate welding seam defect analyzing and repairing method

A defect analysis and composite board technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of multiple repairs, easy damage to the transition layer, difficulty in ensuring the height of the base weld, etc., to achieve the guaranteed height and The effect of welding quality, avoiding multiple repairs, and avoiding repair defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

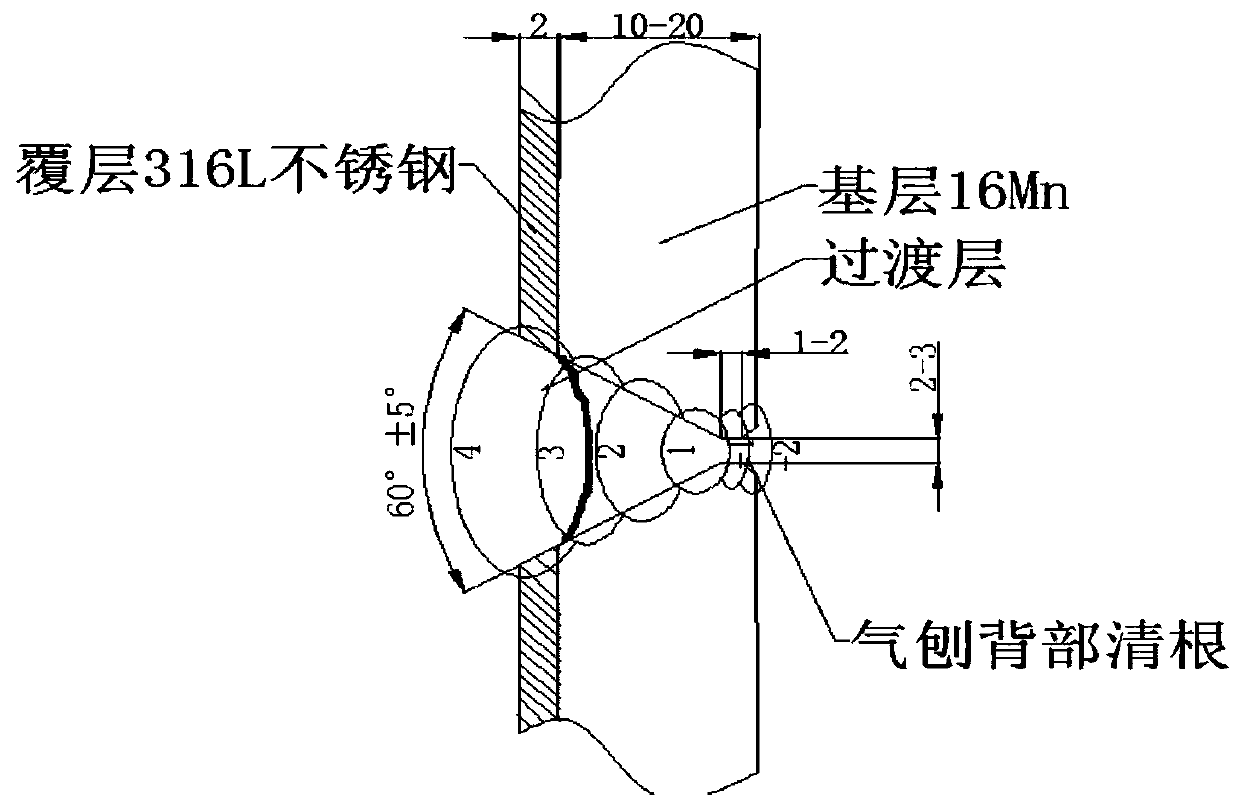

[0025] Such as figure 1 As shown, the method for analyzing and repairing weld defects of stainless steel clad plate provided by the embodiment of the present invention includes the following steps:

[0026] S101: Use flaw detection results and technical analysis to determine whether the defect is located in the base layer or the multiple layer or transition layer;

[0027] S102: When repairing, set up grooves reasonably according to the welding requirements of the composite plate, but when welding the transition layer, an arc groove groove with a depth of 1.5-2mm and a width of 3-5mm should be opened from the cladding laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com