Damaged asphalt pavement repairing structure and seam sealant-pouring repairing method thereof

A technology for asphalt pavement and repairing structures, applied in road repair, roads, roads, etc., can solve the problems of complicated on-site treatment process and long repair time, and achieve the effects of convenient and fast on-site treatment, improved durability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

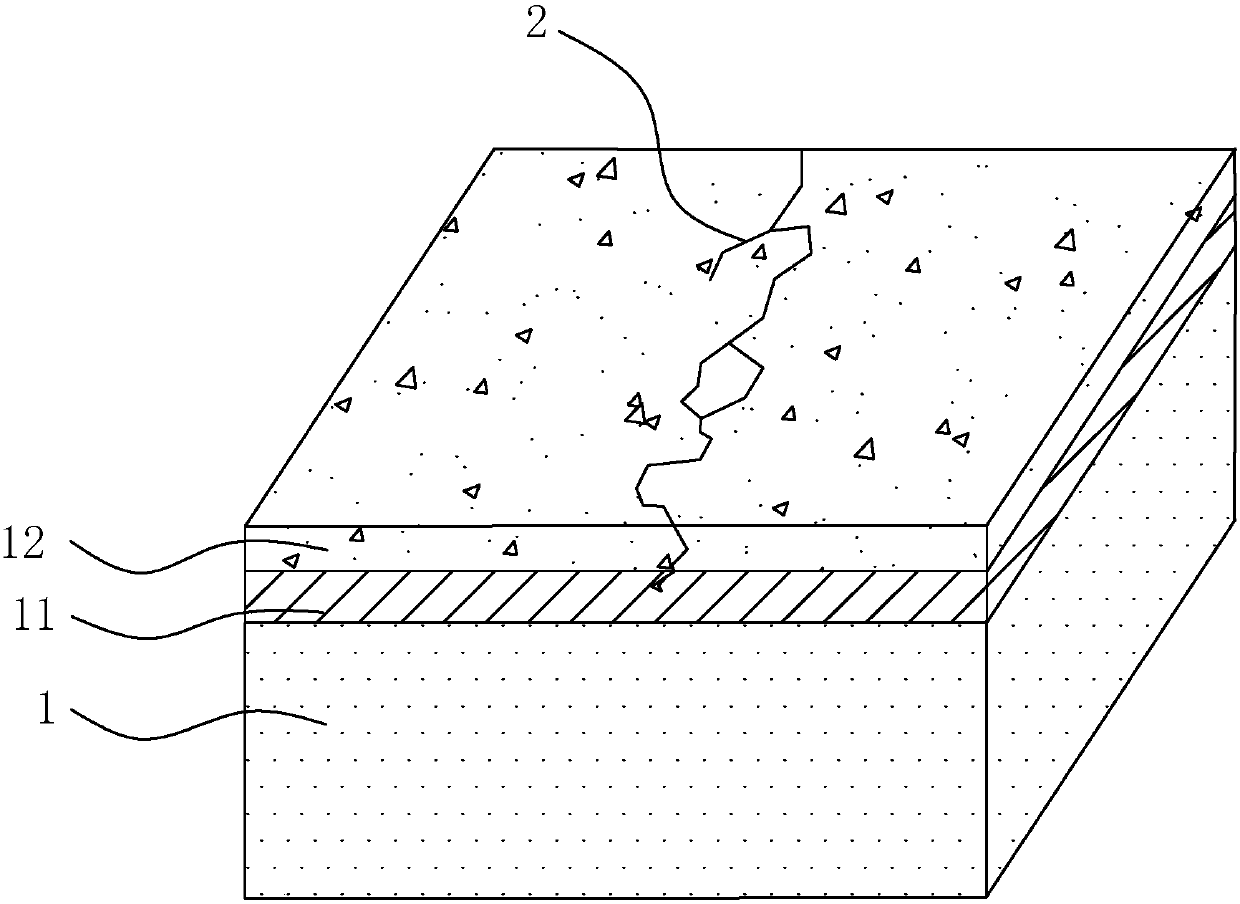

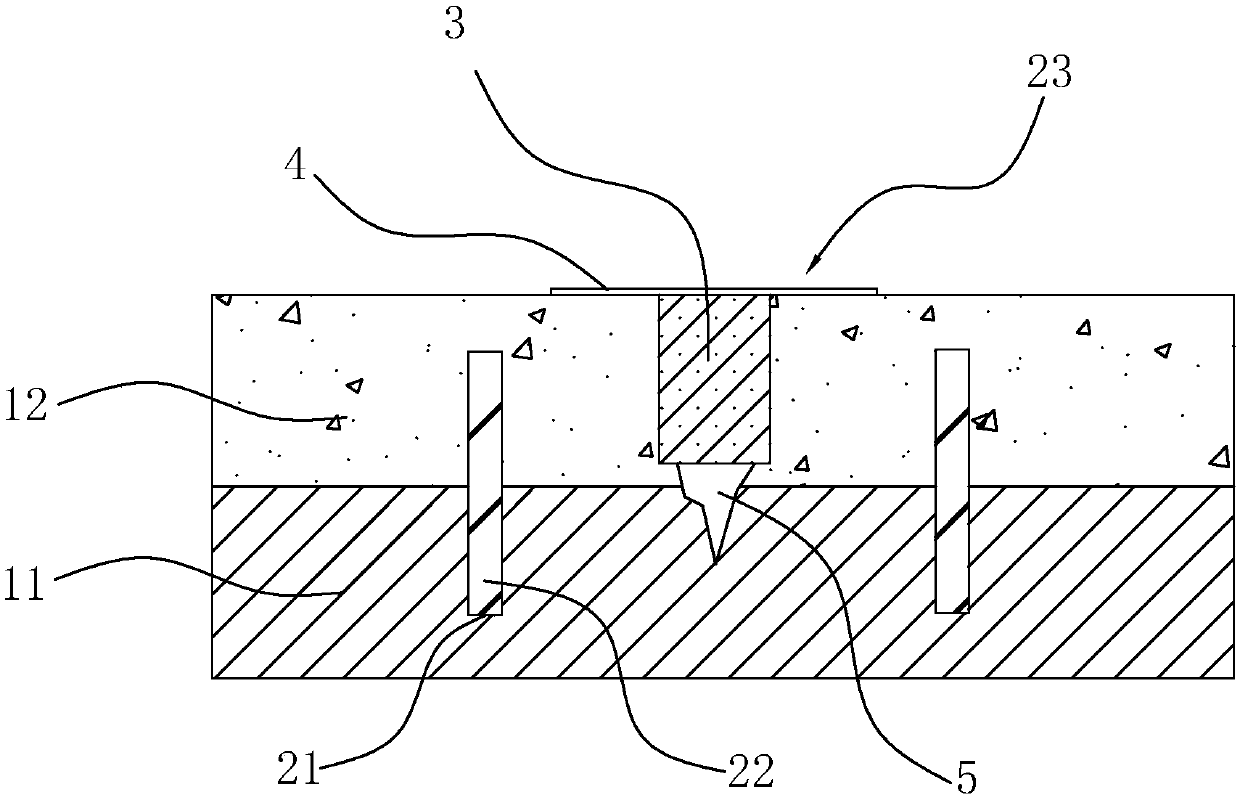

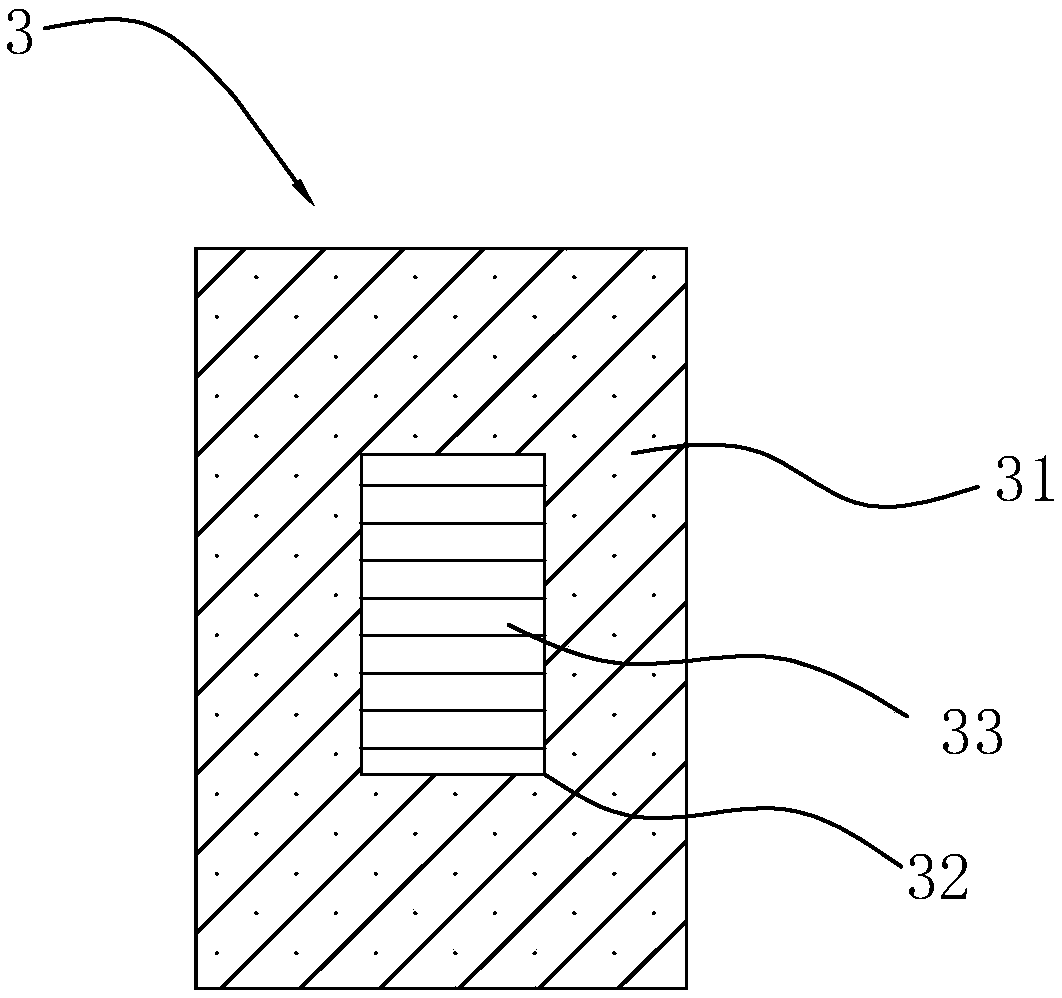

[0045] A repair structure for damaged asphalt pavements such as figure 1 As shown, it includes an asphalt pavement surface layer 12, the bottom of which is provided with a load-bearing roadbed 1 and a base layer 11, wherein the asphalt pavement surface layer 12 is damaged with a broken plate gap 2. Therefore if figure 2 As shown, a plurality of pairs of reinforcement holes 21 are arranged in pairs on both sides of the gap 2 of the broken board, and the reinforcement holes 21 are distributed along the extension direction of the gap 2 of the broken board, and steel bars 22 are vertically inserted in the reinforcement holes 21. The anchoring effect of the steel bar 22 improves the horizontal shear resistance and vertical tensile capacity of the repaired part, and can restrain or even prevent the expansion of the gap 2 of the broken plate. Secondly, there is a caulking groove 23 on the broken plate gap 2, and the caulking groove 23 is located between the reinforcement holes 21 o...

Embodiment 2

[0050] A gap potting glue repair method for damaged asphalt pavement, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com