Modular-type telescopic seam fast repairing and replacing construction method

A technology of maintenance and replacement and construction methods, which is applied in bridge maintenance, bridge parts, erection/assembly of bridges, etc., can solve problems such as threatening driving safety and damage, and achieve the effect of ensuring maintenance quality, short initial setting time, and shortening maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

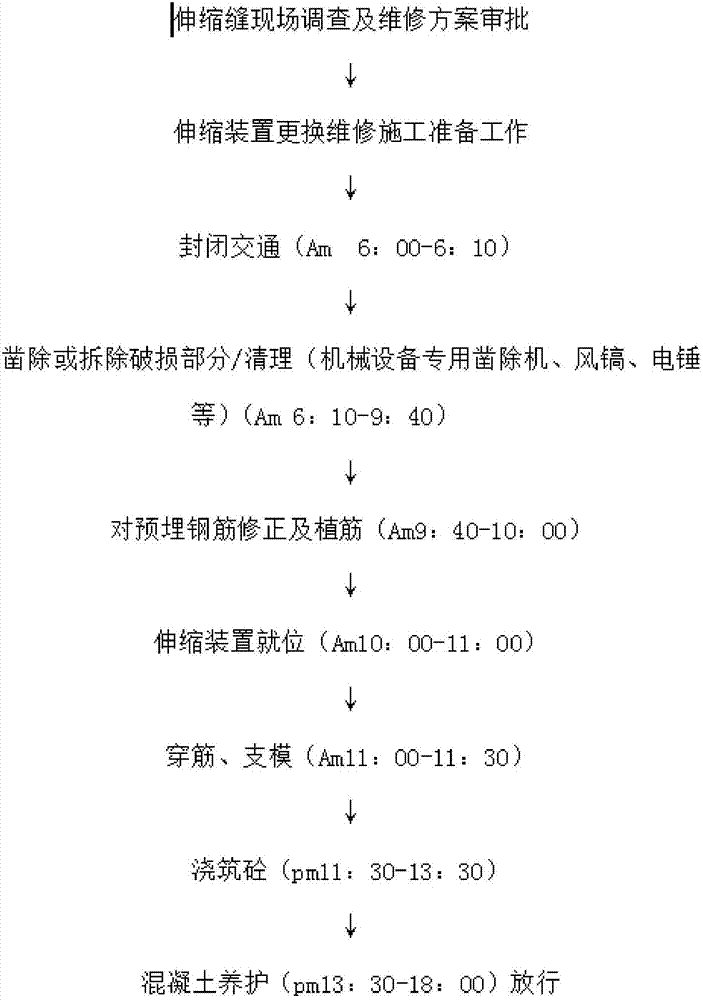

[0017] like figure 1 As shown, a construction method for rapid maintenance and replacement of modular expansion joints includes the following steps:

[0018] 1) Construction preparation: prepare all required mechanical equipment, and implement traffic closure at the construction site where expansion joints will be replaced;

[0019] 2) Concrete removal: first use professional mechanical equipment to chisel off the original loose surface concrete at the construction site, and use special powerful cleaning equipment to remove debris when chiseling to the hard layer of concrete; On the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com