Synchronous cutting-off and unroofing repair method for coke side oven head of large-scale coke oven machine

A technology of mechanical coke and coke oven, which is applied in the field of coke oven maintenance, which can solve the problems of frequent furnace repairs, short service life of the furnace body, and high temperature in the repair area, so as to avoid high-temperature burn accidents, save energy and reduce consumption in coke oven production, and improve The effect on labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Our company adopts the method of synchronous cutting and topping maintenance during the maintenance process of No. 78-81 carbonization chamber machine and coke side burner head 1-4 of No. 5 large coke oven. The steps are as follows:

[0058] 1. To cool down the repair area, this stage mainly completes the following work:

[0059] 1.1. Reinforcement treatment of the furnace column: the machine side and the coke side are respectively connected with steel structural parts to repair the furnace number, the braising furnace number, and the buffer furnace number furnace column, and connect them into one body. The front of the ramp is supported by a spring device, and the furnace hook, Reinforce the furnace door frame protection plate;

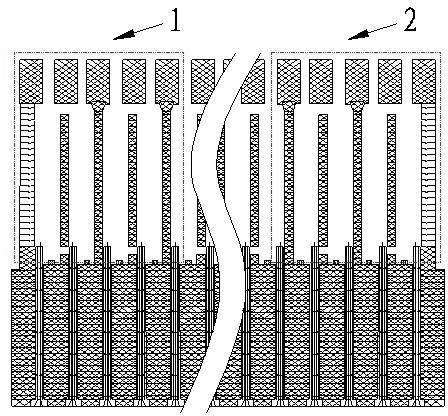

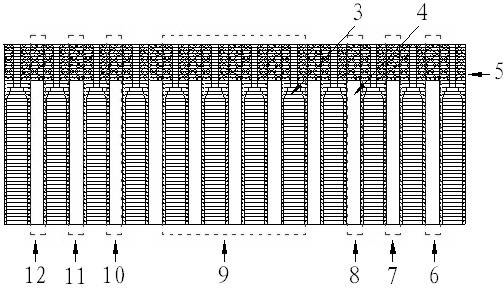

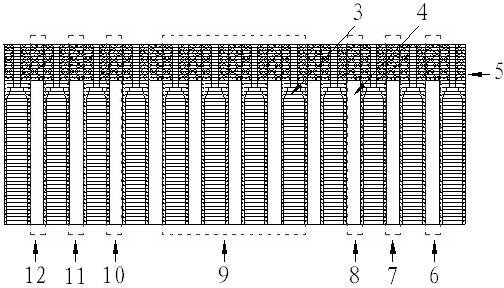

[0060] 1.2. Setting of stewing furnace number, buffer furnace number and repair number: by figure 1 It can be seen that the carbonization chambers on both sides adjacent to repair number 9 are set as furnace numbers 8 and 10, and the carboniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com