Closed water type composite brick and preparation method thereof

A composite brick, closed water technology, applied in the direction of adhesive types, adhesive additives, asphalt material adhesives, etc., can solve the problems of peeling, freeze-thaw damage, denudation, etc., to prevent delamination, prolong service life, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

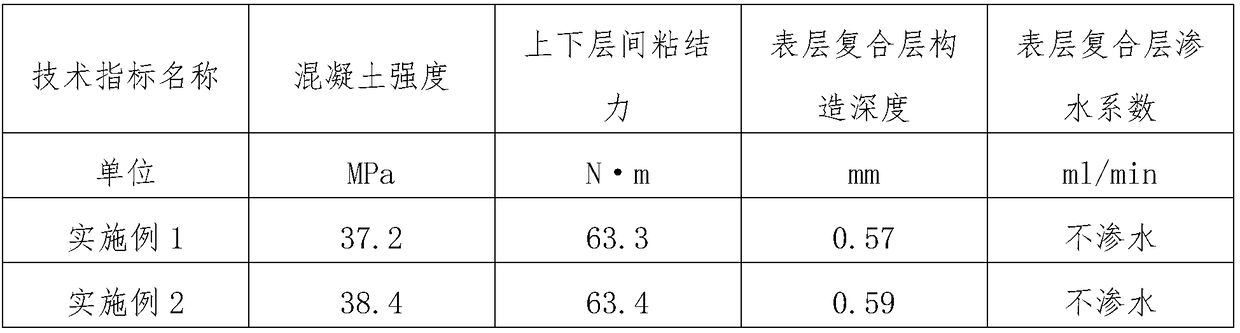

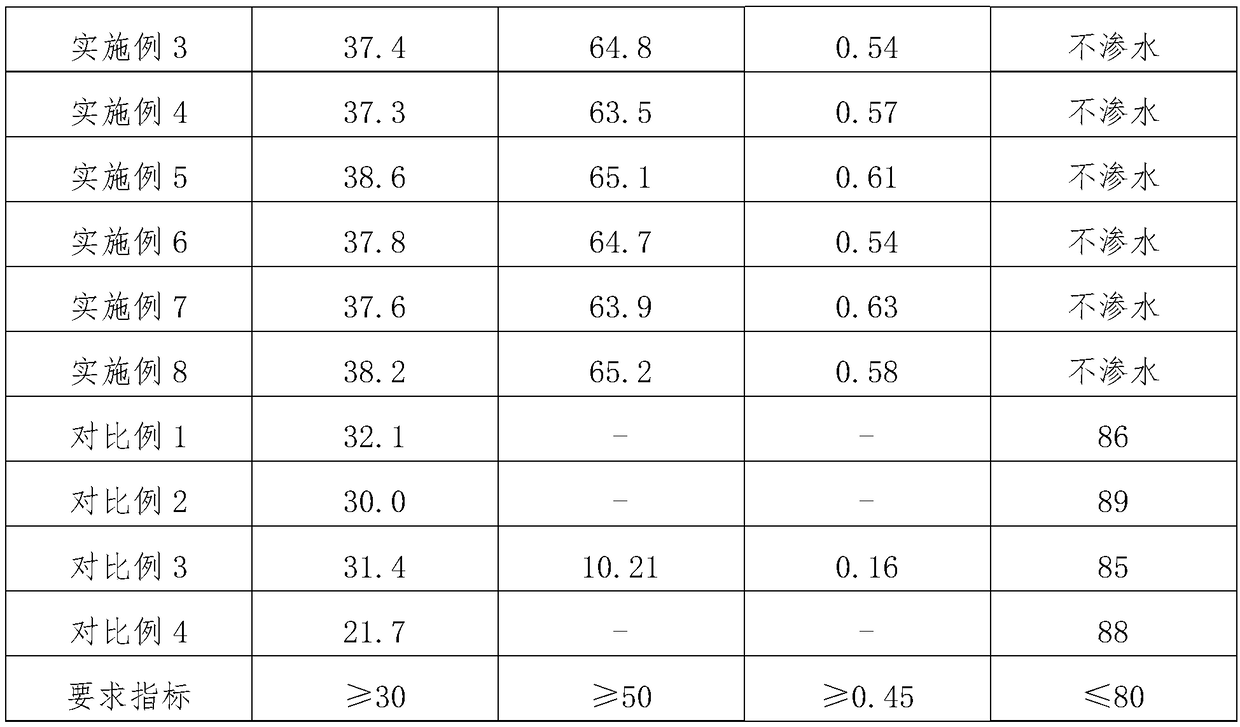

Examples

preparation example Construction

[0034] The embodiment of the present invention also provides a method for preparing a closed-water type composite brick, comprising the following steps:

[0035] S1, preparing a rigid concrete layer;

[0036] The concrete mixture formed by mixing cement, fly ash, water, aggregate, and water reducer, and the evenly mixed mixture is stamped into a mold at a certain height. The rigid concrete layer with good mechanical strength is prepared by using the above-mentioned materials, and then the closed-water type composite brick is guaranteed to have good mechanical strength.

[0037] S2, preparing light-colored adhesive;

[0038] The aromatic oil, modifier and tree are heated and ground at 130-160°C, and sheared to form a light-colored binder.

[0039] S3, preparing the emulsion bonding layer;

[0040] S3.1 prepare emulsion;

[0041] The asphalt, water, emulsifier, penetrant, latex and stabilizer are heated, ground and sheared in an environment of 130-160°C to form a high-conten...

Embodiment 1

[0052] This embodiment provides a water-blocking composite brick, which includes a rigid concrete layer, an emulsion bonding layer and a flexible composite layer connected in sequence.

[0053] The rigid concrete layer is made of rigid concrete. Rigid concrete includes 4Kg of cement, 3Kg of fly ash, 5Kg of water, 80Kg of aggregate and 0.5Kg of water reducer. The aggregates are gravel and crushed stone.

[0054] Emulsion tie coats are tie coats made from asphalt emulsions. The asphalt emulsion includes 50Kg of grade A road petroleum asphalt, 28Kg of water, 2Kg of emulsifier, 0.5Kg of fatty alcohol polyoxyethylene ether, 2Kg of SBR styrene-butadiene rubber latex and 0.1Kg of stabilizer.

[0055] The flexible composite layer is a composite layer made by mixing 10Kg of the asphalt emulsion with 77Kg of gravel and 3Kg of cement. The cement substance is a mixture of cement and mineral powder.

[0056] This embodiment also provides a method for preparing a closed-water type compo...

Embodiment 2-4

[0069] The water-closing type composite brick provided in this example has roughly the same composition as the water-closing type composite brick provided in Example 1, the difference is that the ratio of each raw material is different, and the preparation method of the water-closing type composite brick provided in this example is the same as The operation of the preparation method of the shut-off type composite brick provided in Example 1 is basically the same, the difference is that the operating conditions are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com